|

|

| Ligne 5 : |

Ligne 5 : |

| | This process is also useful on an Autoflow where the SY axis distance is limited by the backfence / top clamp interference</translate> | | This process is also useful on an Autoflow where the SY axis distance is limited by the backfence / top clamp interference</translate> |

| | |Categories=Software | | |Categories=Software |

| | + | |Tags=Confluence |

| | }} | | }} |

| − | <translate>Similar problem is apparent on Autoflows see [[Minimum Residual on Autoflow Machines]]<br /> | + | <translate>Moved To Confluence 12/12/2025 |

| − | {| class="wikitable" border="1" cellspacing="0" cellpadding="0" width="673"

| |

| − | | width="118" valign="top" |'''TB Number:'''

| |

| − | | width="555" valign="top" |0434

| |

| − | |-

| |

| − | | width="118" valign="top" |'''Originator:'''

| |

| − | | width="555" valign="top" |Gareth Green

| |

| − | |-

| |

| − | | width="118" valign="top" |'''Machine:'''

| |

| − | | width="555" valign="top" |ZX

| |

| − | |-

| |

| − | | width="118" valign="top" |'''Date:'''

| |

| − | | width="555" valign="top" |04/04/19

| |

| − | |-

| |

| − | | width="118" valign="top" |'''Circulate to:'''

| |

| − | | width="555" valign="top" |Service;

| |

| − | |-

| |

| − | | width="118" valign="top" |'''Title:'''

| |

| − | | width="555" valign="top" |Setting Up “Deep” Y notches on ZX5

| |

| − | |}

| |

| | | | |

| − | ==Problem==

| |

| − | The saw “Y drive” on a ZX5 is limited in its depth range to +/- 20mm from the centreline of the profile, and 20mm from the backfence. This is fine for most normal Y notching, but there are combinations when a particularly deep Y notch is required.

| |

| | | | |

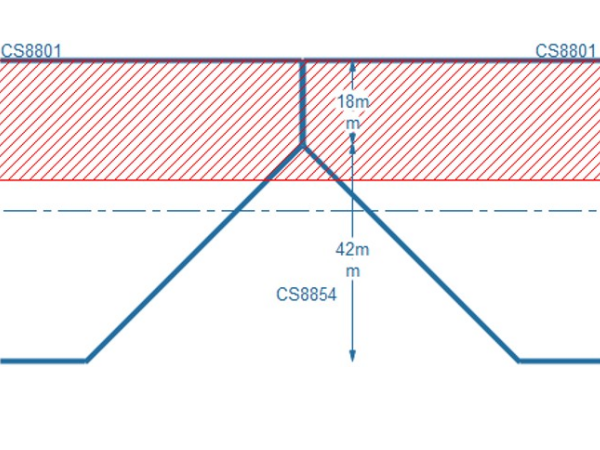

| − | For example: Reversible windows - have a wide transom (84mm) and narrow outer frame (60mm){{#annotatedImageLight:Fichier:TB0434 Setting Up Deep Y notches on ZX5 434-1.jpg|0=649px|hash=|jsondata=|mediaClass=Image|type=frameless|align=center|src=https://stuga.dokit.app/images/8/89/TB0434_Setting_Up_Deep_Y_notches_on_ZX5_434-1.jpg|href=./Fichier:TB0434 Setting Up Deep Y notches on ZX5 434-1.jpg|resource=./Fichier:TB0434 Setting Up Deep Y notches on ZX5 434-1.jpg|caption=|size=649px}}

| + | [https://stuga-ltd.atlassian.net/wiki/spaces/~5570585b7bb5d1bc31430e886883cbc774c182/pages/84541603/TB0434+-+Setting+Up+Deep+Y+notches+on+ZX5 Deep Y notches]</translate> |

| − | | |

| − | | |

| − | | |

| − | This gives a Y notch depth of 42mm in a 60mm wide profile, leaving 18mm “residual” square cut on the end. This is outside the minimum threshold of 20mm from the backfence and the saw centraliser would bottom out.

| |

| − | | |

| − | {{Info|...On an Autoflow Mk4, the minimum residual should be set to 26mm}}<br />

| |

| − | | |

| − | ==Solution==

| |

| − | To solve this problem, the machine has an automatic feature to allow the use of a SQCUT to create the Y notch – this operation uses the 10mm datum tool to make a square slot on the machining centre side, and then the saw side cuts a mitre to finish it off.

| |

| − | | |

| − | The software has to increase the length of the part to allow for this, using the following calculations:

| |

| − | | |

| − | These calculations are done automatically from the dimensions of profile width and Y notch depth. The Y notch depth is taken from the tool code (YFL475 will give a 47.5mm depth), plus the globalYDepthAdjustment parameter.{{#annotatedImageLight:Fichier:TB0434 Setting Up Deep Y notches on ZX5 434-2.png|0=559px|hash=|jsondata=|mediaClass=Image|type=frameless|align=center|src=https://stuga.dokit.app/images/3/38/TB0434_Setting_Up_Deep_Y_notches_on_ZX5_434-2.png|href=./Fichier:TB0434 Setting Up Deep Y notches on ZX5 434-2.png|resource=./Fichier:TB0434 Setting Up Deep Y notches on ZX5 434-2.png|caption=|size=559px}}<br />

| |

| − | | |

| − | ==Application==

| |

| − | To enable this feature carry out these steps:

| |

| − | {| class="wikitable" border="1" cellspacing="0" cellpadding="0"

| |

| − | | width="75" valign="top" |'''Step'''

| |

| − | | width="583" valign="top" |'''Instruction'''

| |

| − | |-

| |

| − | | width="75" valign="top" |'''1'''

| |

| − | | width="583" valign="top" |Ensure Front End version 6.3.4.0 or later is installed

| |

| − | |-

| |

| − | |'''2'''

| |

| − | |Set the minYNotchResidual parameter correctly

| |

| − | ZX5 - 21mm

| |

| − | | |

| − | Autoflow Mk4 -26mm

| |

| − | |-

| |

| − | | width="75" valign="top" |'''3'''

| |

| − | | width="583" valign="top" |Identify the profiles and tool codes that will give you a residual of < minYNotchResidual

| |

| − | |-

| |

| − | | width="75" valign="top" |'''4'''

| |

| − | | width="583" valign="top" |Create a new specific operation entry for these Y notch depths on the profiles affected.

| |

| − | | |

| − | | |

| − | Use the SQCUT operation that uses the datum spindle [SQC2DS] for these instead of the normal YFL / YFR std op code.

| |

| − | | |

| − | | |

| − | Ensure the offset (if it is a variable) is set to zero – the offset will be calculated and added automatically.

| |

| − | | |

| − | | |

| − | Set the start height and speeds as per other SQCUT operations for the profile

| |

| − | |}

| |

| − | | |

| − | =Max Centreline Offset on Wider Profiles=

| |

| − | The issue also applies to the maximum range that the SY axis can travel from its centreline (+/-20mm)

| |

| − | | |

| − | The following examples show how the profile width can affect what sizes of Y notches are possible

| |

| − | {| class="wikitable"

| |

| − | |30mm Deep Y notch in the "Red" zone beyond +/-20mm from centreline

| |

| − | |{{#annotatedImageLight:Fichier:TB0434 Setting Up Deep Y notches on ZX5 120 vs 30.png|0=400px|hash=|jsondata=|mediaClass=Image|type=frameless|align=center|src=https://stuga.dokit.app/images/e/ec/TB0434_Setting_Up_Deep_Y_notches_on_ZX5_120_vs_30.png|href=./Fichier:TB0434 Setting Up Deep Y notches on ZX5 120 vs 30.png|resource=./Fichier:TB0434 Setting Up Deep Y notches on ZX5 120 vs 30.png|caption=|size=400px}}

| |

| − | |Not Possible

| |

| − | |-

| |

| − | |40mm Deep Y notch in the "Green" zone within +/-20mm from centreline

| |

| − | |{{#annotatedImageLight:Fichier:TB0434 Setting Up Deep Y notches on ZX5 Image.png|0=400px|hash=|jsondata=|mediaClass=Image|type=frameless|align=center|src=https://stuga.dokit.app/images/3/31/TB0434_Setting_Up_Deep_Y_notches_on_ZX5_Image.png|href=./Fichier:TB0434 Setting Up Deep Y notches on ZX5 Image.png|resource=./Fichier:TB0434 Setting Up Deep Y notches on ZX5 Image.png|caption=|size=400px}}

| |

| − | |Possible

| |

| − | |}

| |

| − | | |

| − | = Error Messages and Parameters Used =

| |

| − | There are 2 distinct errors on batch loading to filter our impossible Y notches

| |

| − | {| class="wikitable"

| |

| − | !Parameter

| |

| − | !Autoflow Mk1-3

| |

| − | !Autoflow Mk4

| |

| − | !ZX5 / Flowline Default

| |

| − | !Error Message Displayed

| |

| − | |-

| |

| − | |minYNotchResidual

| |

| − | |26mm

| |

| − | |26mm

| |

| − | |20mm

| |

| − | |This leaves a residual of... which is less than minimum [minYNotchResidual]. This operation will be skipped

| |

| − | |-

| |

| − | |maxOffsetFromCentreline

| |

| − | |55

| |

| − | |55

| |

| − | |20mm

| |

| − | |This exceeds the maximum centreline offset of ... which is greater than maximum [maxOffsetFromCentreline]. This operation will be skipped

| |

| − | |}

| |

| − | </translate>

| |

| | {{PageLang | | {{PageLang |

| | |Language=en | | |Language=en |

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português