|

|

| (5 révisions intermédiaires par le même utilisateur non affichées) |

| Ligne 9 : |

Ligne 9 : |

| | }} | | }} |

| | {{Introduction | | {{Introduction |

| − | |Introduction=<translate>'''<u>Tools Required</u>''' | + | |Introduction=<translate>10/09/2025 |

| | | | |

| | | | |

| − | standard hex key set

| + | Moved to Confluance |

| | | | |

| − | Standard spanner set

| |

| | | | |

| − | Standard HSS drill set

| + | Click [https://stuga-ltd.atlassian.net/wiki/external/YzI4OWNiOWM2ZWMwNDU0YWFiNzY5ZDJhODg4YTFhZDg Here]</translate> |

| − | | |

| − | Standard tap set

| |

| − | | |

| − | Utility knife

| |

| − | | |

| − | | |

| − | '''<u>Parts Required</u>'''

| |

| − | | |

| − | | |

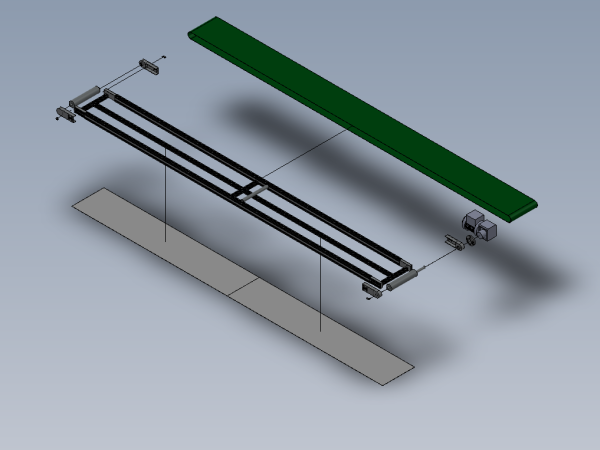

| − | B0000441 Conveyor 3580mm x 300mm x 1

| |

| − | | |

| − | B0001013 Conveyor Motor SEW - WA 10 x 1

| |

| − | | |

| − | B0001177 Pair conveyor side cheeks and bearings slave x 2

| |

| − | | |

| − | M0000133 Conveyor Belt XL-AS 7350 x 300 B x 1

| |

| − | | |

| − | P0000200 Elbow Adaptor 6mm - M5 x 3

| |

| − | | |

| − | | |

| − | | |

| − | <br /></translate>

| |

| | }} | | }} |

| | {{Materials}} | | {{Materials}} |

| | {{EPI}} | | {{EPI}} |

| | {{Tuto Step | | {{Tuto Step |

| − | |Step_Title=<translate>Unless otherwise stated</translate> | + | |Step_Title=<translate></translate> |

| − | |Step_Content=<translate>Use Loctite 243 on all fasteners | + | |Step_Content=<translate></translate> |

| − | | |

| − | Use Loctite 572 on all threaded pneumatic connection

| |

| − | | |

| − | Pen mark all fasteners to show finalised</translate>

| |

| − | |Step_Picture_00=R0015086_Assemble_Pneumatics_on_to_electrical_cabinet_loctite_243.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Drill blower points on rollers</translate>

| |

| − | |Step_Content=<translate>indicated 3 roller housings will require blower holes adding

| |

| − | | |

| − | | |

| − | Mark Blowers as shown . <u>'''Please provide dimensions for these holes'''</u>

| |

| − | | |

| − | Drill through with 2.5mm drill

| |

| − | | |

| − | Then drill half way from outside face with 4.2mm drill

| |

| − | | |

| − | Then tap outside face shown M5</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_123909.png

| |

| − | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":1165,"height":802,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.52,"scaleY":0.52,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/1/18/R0015358_Conveyor_chassis_Screenshot_2023-10-31_123909.png","filters":[]},{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":385.7,"top":284.7,"width":51.99,"height":51.99,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":25.992534366440456,"ry":25.992534366440456},{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":154.46,"top":50.46,"width":55.45,"height":55.45,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":27.72574265396749,"ry":27.72574265396749},{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":69.2,"top":103.2,"width":52.98,"height":52.98,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":26.48771182253443,"ry":26.48771182253443}],"height":413,"width":600}

| |

| − | |Step_Picture_01=R0015358_Conveyor_chassis_Screenshot_2023-11-16_141728.png

| |

| − | |Step_Picture_02=R0015358_Conveyor_chassis_Screenshot_2023-11-16_141738.png

| |

| − | |Step_Picture_03=R0015358_Conveyor_chassis_Screenshot_2023-11-16_141743.png

| |

| − | |Step_Picture_04=R0015358_Conveyor_chassis_Screenshot_2023-11-16_141806.png

| |

| − | |Step_Picture_05=R0015358_Conveyor_chassis_Screenshot_2023-11-16_141753.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Assemble mounts</translate>

| |

| − | |Step_Content=<translate>Assemble 4 off mounts

| |

| − | | |

| − | | |

| − | Ensure maytec fittings are orientated correctly

| |

| − | | |

| − | Ensure spring clip is fitted to D nut

| |

| − | | |

| − | '''<u>Please capture picture of maytec fittings added to this block and correct orientation</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_124234.png

| |

| − | |Step_Picture_01=R0015358_Conveyor_chassis_Screenshot_2023-11-16_142104.png

| |

| − | |Step_Picture_02=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>insert M4 plate nuts</translate>

| |

| − | |Step_Content=<translate>insert 8 off supplied m4 plate nuts into correct face of long frame sections

| |

| − | | |

| − | | |

| − | 4 off per side</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_125250.png

| |

| − | |Step_Picture_01=R0015358_Conveyor_chassis_Screenshot_2023-11-16_142233.png

| |

| − | |Step_Picture_02=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Assemble main frame</translate>

| |

| − | |Step_Content=<translate>{{Warning|...Ensure maytec barrel fittings are positioned on inside face}}

| |

| − | | |

| − | Assemble main maytec frame

| |

| − | | |

| − | | |

| − | Ensure all sections are set in a parallel position

| |

| − | | |

| − | '''<u>Please capture pictures for this please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_124445.png

| |

| − | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":800,"height":501,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.75,"scaleY":0.75,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/thumb/0/06/R0015358_Conveyor_chassis_Screenshot_2023-10-31_124445.png/800px-R0015358_Conveyor_chassis_Screenshot_2023-10-31_124445.png","filters":[]},{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":512.4,"top":269.4,"width":36.08,"height":36.08,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":18.042478565249787,"ry":18.042478565249787}],"height":376,"width":600}

| |

| − | |Step_Picture_01=R0015358_Conveyor_chassis_Screenshot_2023-10-31_124539.png

| |

| − | |Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":1476,"height":848,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.41,"scaleY":0.41,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/8/81/R0015358_Conveyor_chassis_Screenshot_2023-10-31_124539.png","filters":[]},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":140.6,"top":42.98,"width":47.8,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.03,"scaleY":3.03,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"=","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} },{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":323.28,"top":137.8,"width":47.8,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.1,"scaleY":3.1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"=","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} },{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":585.73,"top":271.02,"width":47.8,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.2,"scaleY":3.2,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"=","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} },{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":406.85,"top":171.13,"width":47.8,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.62,"scaleY":3.62,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"=","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} }],"height":345,"width":600}

| |

| − | |Step_Picture_02=R0015358_Conveyor_chassis_Screenshot_2023-10-31_134920.png

| |

| − | |Step_Picture_02_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":1161,"height":850,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.52,"scaleY":0.52,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/3/31/R0015358_Conveyor_chassis_Screenshot_2023-10-31_134920.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":354.5,"top":118,"width":41,"height":72,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":20.5,"x2":-20.5,"y1":-36,"y2":36,"x2a":-3.6513484949614616,"y2a":22.579011122060994,"x2b":-17.555106756998995,"y2b":14.661593222845175},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":375,"top":82,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":334,"top":154,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":485.58,"top":72.61,"width":118.44,"height":75.03,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.52,"scaleY":1.52,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"Barrel fittings on inside face ","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} }],"height":439,"width":600}

| |

| − | |Step_Picture_03=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Finalise all fasteners</translate>

| |

| − | |Step_Content=<translate>Ensure all fasteners are finalised on frame</translate>

| |

| − | |Step_Picture_00=R0000711_Rotary_Base_Assembly_quality-assurance-testing.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Fit Slave roller (non driven)</translate>

| |

| − | |Step_Content=<translate>Fit slave roller assembly as shown

| |

| − | | |

| − | Ensure spacer washers are fitted

| |

| − | | |

| − | | |

| − | Ensure blower points are orientated correctly to suit belt rotation direction

| |

| − | | |

| − | '''<u>Better photos required please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_124815.png

| |

| − | |Step_Picture_01=R0015358_Conveyor_chassis_Screenshot_2023-11-16_142440.png

| |

| − | |Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":480,"height":599,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.25,"scaleY":1.25,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/9/96/R0015358_Conveyor_chassis_Screenshot_2023-11-16_142440.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":274.5,"top":418,"width":107,"height":158,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-53.5,"x2":53.5,"y1":79,"y2":-79,"x2a":48.90933210410229,"y2a":-57.95419832200317,"x2b":35.661377262972806,"y2b":-66.92591457517314},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":221,"top":497,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":328,"top":339,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":235.52,"top":574.96,"width":64.47,"height":48.82,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":2.6,"scaleY":2.6,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"Spacer washer","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} }],"height":749,"width":600}

| |

| − | |Step_Picture_02=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Fit drive roller</translate>

| |

| − | |Step_Content=<translate>Fit drive roller assembly as shown

| |

| − | | |

| − | | |

| − | Ensure spacer washers are fitted

| |

| − | | |

| − | | |

| − | Ensure blower point is orientated correctly to suit belt rotation direction

| |

| − | | |

| − | '''<u>Photos in correct sequence required please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_125023.png

| |

| − | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Attach adhesive tape</translate>

| |

| − | |Step_Content=<translate>Fit supplied adhesive tape to top face of frame at shown points

| |

| − | | |

| − | | |

| − | '''<u>Photos required in correct sequence please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_125153.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Quality Check</translate>

| |

| − | |Step_Content=<translate>Check issued stainless plates 2 off have been countersunk correctly

| |

| − | | |

| − | | |

| − | M4 countersunk should sit flush, not above top of stainless sheet</translate>

| |

| − | |Step_Picture_00=R0008013_Clacker_assembly_quality.png

| |

| − | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Fit stainless top plates</translate>

| |

| − | |Step_Content=<translate>Use stainless plates as a guide to align M4 plate nuts before removing adhesive tape backing

| |

| − | | |

| − | <br />{{Warning|...Ensure stainless plates are aligned correctly. They should be parallel to maytec main frame}}

| |

| − | | |

| − | | |

| − | | |

| − | Once aligned , remove adhesive tape backing and secure stainless plates into position

| |

| − | | |

| − | | |

| − | Fit 8 off supplied m4 countersunk hex sockets to finalise stainless plate fitting

| |

| − | | |

| − | '''<u>Photos required in correct sequence please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_125404.png

| |

| − | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Fit belt</translate>

| |

| − | |Step_Content=<translate>Fit belt to assembly

| |

| − | | |

| − | | |

| − | '''<u>Photos required in correct sequence please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133247.png

| |

| − | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Fit mid rollers</translate>

| |

| − | |Step_Content=<translate>Fit mid rollers</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133333.png

| |

| − | |Step_Picture_01=R0015358_Conveyor_chassis_Screenshot_2023-11-16_142811.png

| |

| − | |Step_Picture_02=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Tension drive roller</translate>

| |

| − | |Step_Content=<translate>Set lower roller tension (motor end)

| |

| − | | |

| − | | |

| − | Measure and set gap to 15mm either side

| |

| − | | |

| − | '''<u>Photos required in correct sequence please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133447.png

| |

| − | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":661,"height":536,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.91,"scaleY":0.91,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/4/44/R0015358_Conveyor_chassis_Screenshot_2023-10-31_133447.png","filters":[]},{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":370.01,"top":263.01,"width":101.36,"height":101.36,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":50.68230839379009,"ry":50.68230839379009}],"height":487,"width":600}

| |

| − | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Tension slave roller</translate>

| |

| − | |Step_Content=<translate>Tension drive roller to 22mm gap at both sides of roller

| |

| − | | |

| − | | |

| − | Ensure both sides are set tot he same measurement

| |

| − | | |

| − | '''<u>Photos required in correct sequence please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133536.png

| |

| − | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | |Step_Picture_02=R0015358_Conveyor_chassis_Screenshot_2024-01-29_134913.png

| |

| − | |Step_Picture_02_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":943,"height":596,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.64,"scaleY":0.64,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/3/3b/R0015358_Conveyor_chassis_Screenshot_2024-01-29_134913.png","filters":[]},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":262,"top":46,"width":55.57,"height":48.82,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"22mm ","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} },{"type":"wfline","version":"2.4.6","originX":"center","originY":"center","left":214.5,"top":108,"width":1,"height":164,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-0.5,"x2":0.5,"y1":82,"y2":-82},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":214,"top":190,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":215,"top":26,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfline","version":"2.4.6","originX":"center","originY":"center","left":304.5,"top":108,"width":1,"height":144,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":0.5,"x2":-0.5,"y1":-72,"y2":72},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":305,"top":36,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":304,"top":180,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":379,"width":600}

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Check all fasteners</translate>

| |

| − | |Step_Content=<translate>Quality check all fasteners

| |

| − | | |

| − | | |

| − | ensure all fasteners have adhesive applied, are correctly tensioned and are pen marked to indicate finalised</translate>

| |

| − | |Step_Picture_00=R0000711_Rotary_Base_Assembly_quality-assurance-testing.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Fit drive motor and flange</translate>

| |

| − | |Step_Content=<translate>Fit drive flange to bearing cheek ensuring correct orientation to allow correct fitment of motor

| |

| − | | |

| − | | |

| − | Fit motor to bearing flange, do not apply final tension or adhesive to locating grubscrew as motor will need to be removed later on

| |

| − | | |

| − | It is important to test fit at this stage to identify correct fitment

| |

| − | | |

| − | '''<u>Photos required in correct sequence please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133901.png

| |

| − | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| − | }}

| |

| − | {{Tuto Step

| |

| − | |Step_Title=<translate>Fit blower fittings</translate>

| |

| − | |Step_Content=<translate>Fit 3 off blower fittings to mounting points on bearing cheeks

| |

| − | | |

| − | | |

| − | '''<u>Photos required in correct sequence please</u>'''</translate>

| |

| − | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_134014.png

| |

| − | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png

| |

| | }} | | }} |

| | {{Notes}} | | {{Notes}} |

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português