| [version en cours de rédaction] | [version en cours de rédaction] |

| (2 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 2 : | Ligne 2 : | ||

|Main_Picture=SR_Axis_Torque_Adjustment_TorqueCrib.png | |Main_Picture=SR_Axis_Torque_Adjustment_TorqueCrib.png | ||

|Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":-27,"top":-456,"width":490,"height":862,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.46,"scaleY":1.46,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/d/db/SR_Axis_Torque_Adjustment_TorqueCrib.png","filters":[]}],"height":450,"width":600} | |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":-27,"top":-456,"width":490,"height":862,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.46,"scaleY":1.46,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/d/db/SR_Axis_Torque_Adjustment_TorqueCrib.png","filters":[]}],"height":450,"width":600} | ||

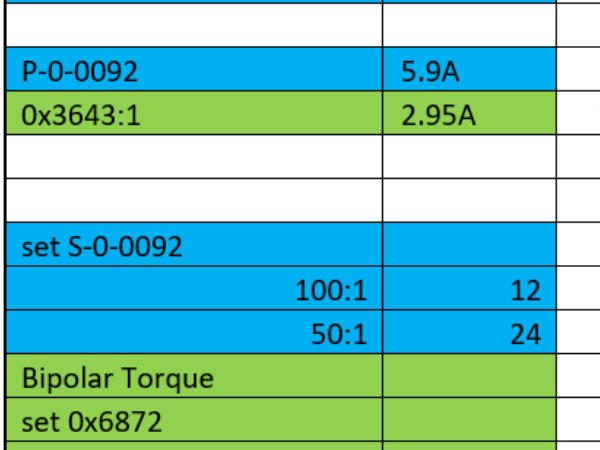

| − | |Description=<translate>For the | + | |Description=<translate>For the Sawing Modules that have a servo motor rather than a piston to rotate the Saw the Torque needs to be reduced significantly</translate> |

|Categories=Maintenance | |Categories=Maintenance | ||

|Difficulty=Medium | |Difficulty=Medium | ||

| Ligne 10 : | Ligne 10 : | ||

}} | }} | ||

{{Introduction | {{Introduction | ||

| − | |Introduction=<translate></translate> | + | |Introduction=<translate>14/08/25 Moved to Confluence |

| + | |||

| + | Click [https://stuga-ltd.atlassian.net/wiki/external/YzFiODc3ODY3NjVlNDZmZjg1ODJhOGJkZTQzZWU1MjA here]</translate> | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate> | + | |Step_Title=<translate></translate> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|Step_Content=<translate></translate> | |Step_Content=<translate></translate> | ||

| − | |||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version actuelle datée du 14 août 2025 à 15:53

For the Sawing Modules that have a servo motor rather than a piston to rotate the Saw the Torque needs to be reduced significantly

Difficulté

Moyen

Durée

20 minute(s)

Sommaire

Introduction

14/08/25 Moved to Confluence

Click hereÉtape 1 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português