| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Description=<translate>How to safely decommission and load a Stuga Autoflow Mk4.1 machine</translate> |Categories=Maintenance |Difficulty=Hard |Duration=1... ») |

|||

| (3 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 1 : | Ligne 1 : | ||

{{Tuto Details | {{Tuto Details | ||

| + | |Main_Picture=Safe_Moving_of_Top_Heavy_Machine_Modules_20250331_114322.jpg | ||

|Description=<translate>How to safely decommission and load a Stuga Autoflow Mk4.1 machine</translate> | |Description=<translate>How to safely decommission and load a Stuga Autoflow Mk4.1 machine</translate> | ||

|Categories=Maintenance | |Categories=Maintenance | ||

| Ligne 11 : | Ligne 12 : | ||

The '''infeed table''' gripper carriage and conveyor split into two sections | The '''infeed table''' gripper carriage and conveyor split into two sections | ||

| − | The '''machining head''' and '''saw''' split apart like a cam shell | + | The '''machining head''' and '''saw''' split apart like a cam shell. They are joined with a dowel system in joining blocks at the base |

The '''outfeed''' splits in to a rear bed and front tray | The '''outfeed''' splits in to a rear bed and front tray | ||

| − | <br /></translate> | + | <br />{{Warning|...Please follow the process carefully and ensure you understand how the machine is connected together}} |

| + | |||

| + | |||

| + | See Also | ||

| + | |||

| + | [[Safe Moving of Top Heavy Machine Modules]]<br /></translate> | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

| Ligne 21 : | Ligne 27 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Move axes to park positions</translate> | |Step_Title=<translate>Move axes to park positions</translate> | ||

| − | |Step_Content=<translate>* X axis to machining side of lifting points | + | |Step_Content=<translate>*X axis to machining side of lifting points |

| − | * GZ axis to minimum</translate> | + | *Z axis to bottom of travel |

| + | *GZ axis to minimum</translate> | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Power off</translate> | |Step_Title=<translate>Power off</translate> | ||

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>{{Warning|...Isolate power and air completely from the machine}}</translate> |

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| Ligne 46 : | Ligne 53 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Infeed Gripper Module - Stowing</translate> | |Step_Title=<translate>Infeed Gripper Module - Stowing</translate> | ||

| − | |Step_Content=<translate> | + | |Step_Content=<translate>Tie gripper carriage to prevent axis movement in transit</translate> |

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Infeed Gripper Module - Attach lifting Equipment</translate> | |Step_Title=<translate>Infeed Gripper Module - Attach lifting Equipment</translate> | ||

| − | |Step_Content=<translate>Attach safe moving equipment - see [[Spécial:AjouterDonnées/Tutorial/R0019264 Autoflow Mk 4,1 Infeed Safe moving equipment|R0019264 Autoflow Mk 4,1 Infeed Safe moving equipment]]</translate> | + | |Step_Content=<translate>Attach safe moving equipment - see [[Spécial:AjouterDonnées/Tutorial/R0019264 Autoflow Mk 4,1 Infeed Safe moving equipment|R0019264 Autoflow Mk 4,1 Infeed Safe moving equipment]] |

| + | |||

| + | {{Warning|...The gripper table is top - heavy and the moving equipment is vital to move, and particularly lift the table safely}}<br /></translate> | ||

| + | |Step_Picture_00=R0019264_Autoflow_Mk_4_1_Infeed_Safe_moving_equipment_Screenshot_2025-03-10_091059.png | ||

| + | |Step_Picture_01=R0019264_Autoflow_Mk_4_1_Infeed_Safe_moving_equipment_Screenshot_2025-03-10_120252.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| Ligne 59 : | Ligne 70 : | ||

|Step_Title=<translate>Machining Head and Saw - Disconnects</translate> | |Step_Title=<translate>Machining Head and Saw - Disconnects</translate> | ||

|Step_Content=<translate>Locate and unplug the electrical and pneumatic interconnections. | |Step_Content=<translate>Locate and unplug the electrical and pneumatic interconnections. | ||

| + | |||

| + | Ensure the plugs are labelled | ||

{{Warning|...The cables and plugs will need to be pulled through the frame holes during separation.}} | {{Warning|...The cables and plugs will need to be pulled through the frame holes during separation.}} | ||

| Ligne 66 : | Ligne 79 : | ||

'''Front Side''' | '''Front Side''' | ||

| − | # X2F and X3F ILME Connectors. Pull one through one way, one through other way | + | #X2F and X3F ILME Connectors. Pull one through one way, one through other way |

| − | # Grease Lines - 2 off | + | #Grease Lines - 2 off |

| − | # Air Lines Red and Blue | + | #Air Lines Red and Blue |

'''Rear''' | '''Rear''' | ||

| − | # ILME Connection | + | #ILME Connection |

| − | # Network Connection - 2 Off | + | #Network Connection - 2 Off |

| − | + | <br />{{Info|...The two front ILME plugged connections are located in different modules to ensure that cannot be plugged incorrectly. They physically cannot reach each other}} | |

<br /></translate> | <br /></translate> | ||

| Ligne 86 : | Ligne 99 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Unlink Upper Guards</translate> | |Step_Title=<translate>Unlink Upper Guards</translate> | ||

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>The guard shells are fastened with a plate internally. |

| + | |||

| + | Unbolt the Saw side front and rear, then bag and label the screws</translate> | ||

| + | |Step_Picture_00=Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-59-40.PNG | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Split Machining Head and Saw</translate> | |Step_Title=<translate>Split Machining Head and Saw</translate> | ||

| − | |Step_Content=<translate>Using a crowbar, spit the main modules apart</translate> | + | |Step_Content=<translate># Remove the M16 front and rear hex head joining bolts, access from saw module. These are the only 2 bolts that fasten the machine together. |

| + | |||

| + | <br />{{Warning|...Do not undo any cap head bolts}} | ||

| + | |||

| + | 2. Using a crowbar, spit the main modules apart by around 100mm | ||

| + | |||

| + | Walk the front and rear by 23-30mm a time until the dowels are clear | ||

| + | |||

| + | 3. You will see the location pin exposed in the joining blocks | ||

| + | |||

| + | {{Warning|...Double check to ensure all interconnection pipes and cables are clear of the through holes}}<br /></translate> | ||

| + | |Step_Picture_00=Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-15-43.PNG | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":1243,"height":947,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.48,"scaleY":0.48,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/f/f1/Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-15-43.PNG","filters":[]},{"type":"wfnumberedbullet","version":"2.4.6","originX":"left","originY":"top","left":142,"top":173,"width":25,"height":25,"fill":"rgb(0,0,0)","stroke":"#FF0000","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"objects":[{"type":"circle","version":"2.4.6","originX":"center","originY":"center","left":0,"top":0,"width":24,"height":24,"fill":"#FF0000","stroke":null,"strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":12,"startAngle":0,"endAngle":6.283185307179586},{"type":"text","version":"2.4.6","originX":"center","originY":"center","left":0,"top":0,"width":7.79,"height":15.82,"fill":"rgba(255,255,255,255)","stroke":null,"strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"1","fontSize":14,"fontWeight":"normal","fontFamily":"arial","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"styles":{} }],"number":1}],"height":457,"width":600} | ||

| + | |Step_Picture_01=Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-11-12.PNG | ||

| + | |Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":1219,"height":965,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.49,"scaleY":0.49,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/6/66/Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-11-12.PNG","filters":[]},{"type":"wfnumberedbullet","version":"2.4.6","originX":"left","originY":"top","left":449,"top":239,"width":25,"height":25,"fill":"rgb(0,0,0)","stroke":"#FF0000","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"objects":[{"type":"circle","version":"2.4.6","originX":"center","originY":"center","left":0,"top":0,"width":24,"height":24,"fill":"#FF0000","stroke":null,"strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":12,"startAngle":0,"endAngle":6.283185307179586},{"type":"text","version":"2.4.6","originX":"center","originY":"center","left":0,"top":0,"width":7.79,"height":15.82,"fill":"rgba(255,255,255,255)","stroke":null,"strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"2","fontSize":14,"fontWeight":"normal","fontFamily":"arial","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"styles":{} }],"number":2}],"height":475,"width":600} | ||

| + | |Step_Picture_02=Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-10-46.PNG | ||

| + | |Step_Picture_02_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":1471,"height":1113,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.41,"scaleY":0.41,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/d/d3/Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-10-46.PNG","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":199.5,"top":151.5,"width":299,"height":203,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-149.5,"x2":149.5,"y1":-101.5,"y2":101.5,"x2a":137.44687511628115,"y2a":83.64720804642933,"x2b":128.45960477139624,"y2b":96.88461609135835},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":50,"top":50,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":349,"top":253,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfnumberedbullet","version":"2.4.6","originX":"left","originY":"top","left":334,"top":209,"width":25,"height":25,"fill":"rgb(0,0,0)","stroke":"#FF0000","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"objects":[{"type":"circle","version":"2.4.6","originX":"center","originY":"center","left":0,"top":0,"width":24,"height":24,"fill":"#FF0000","stroke":null,"strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":12,"startAngle":0,"endAngle":6.283185307179586},{"type":"text","version":"2.4.6","originX":"center","originY":"center","left":0,"top":0,"width":7.79,"height":15.82,"fill":"rgba(255,255,255,255)","stroke":null,"strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"3","fontSize":14,"fontWeight":"normal","fontFamily":"arial","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"styles":{} }],"number":3}],"height":454,"width":600} | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Complete the split</translate> | ||

| + | |Step_Content=<translate>The modules can be moved with a pump trolley</translate> | ||

| + | |Step_Picture_00=Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-23-53.PNG | ||

| + | |Step_Picture_01=Decommissioning_-_Autoflow_Mk4_1_2025-03-28_13-24-22.PNG | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>See also</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>[[Safe Strop Positions - Autoflow Mk4 1]] |

| + | |||

| + | [[Safe Moving of Top Heavy Machine Modules]]</translate> | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version actuelle datée du 31 mars 2025 à 14:18

How to safely decommission and load a Stuga Autoflow Mk4.1 machine

Sommaire

- 1 Introduction

- 2 Étape 1 - Move axes to park positions

- 3 Étape 2 - Power off

- 4 Étape 3 - Infeed Conveyor Module - Disconnect

- 5 Étape 4 - Infeed Conveyor Module - Move

- 6 Étape 5 - Infeed Gripper Module - Disconnect

- 7 Étape 6 - Infeed Gripper Module - Stowing

- 8 Étape 7 - Infeed Gripper Module - Attach lifting Equipment

- 9 Étape 8 - Outfeed table disconnect

- 10 Étape 9 - Machining Head and Saw - Disconnects

- 11 Étape 10 - Unlink Upper Guards

- 12 Étape 11 - Split Machining Head and Saw

- 13 Étape 12 - Complete the split

- 14 Étape 13 - See also

- 15 Commentaires

Introduction

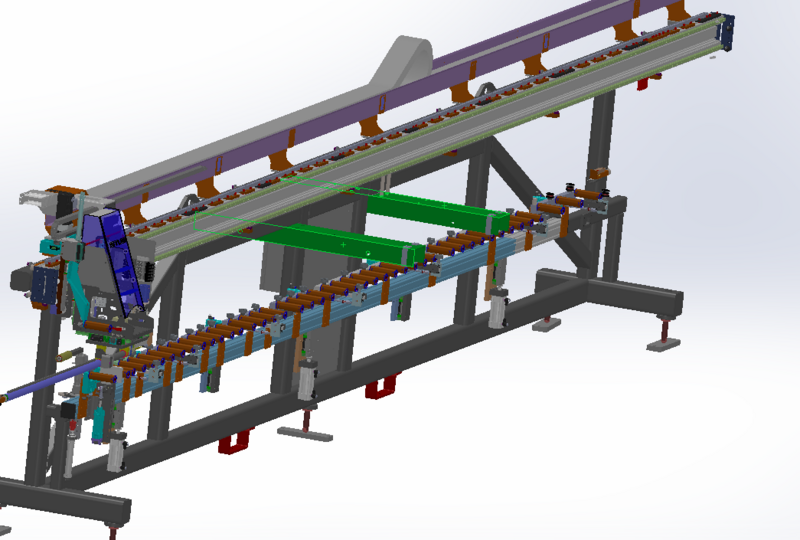

The Autoflow Mk4.1 machine has been designed to separate into modules for safe transport

The infeed table gripper carriage and conveyor split into two sections

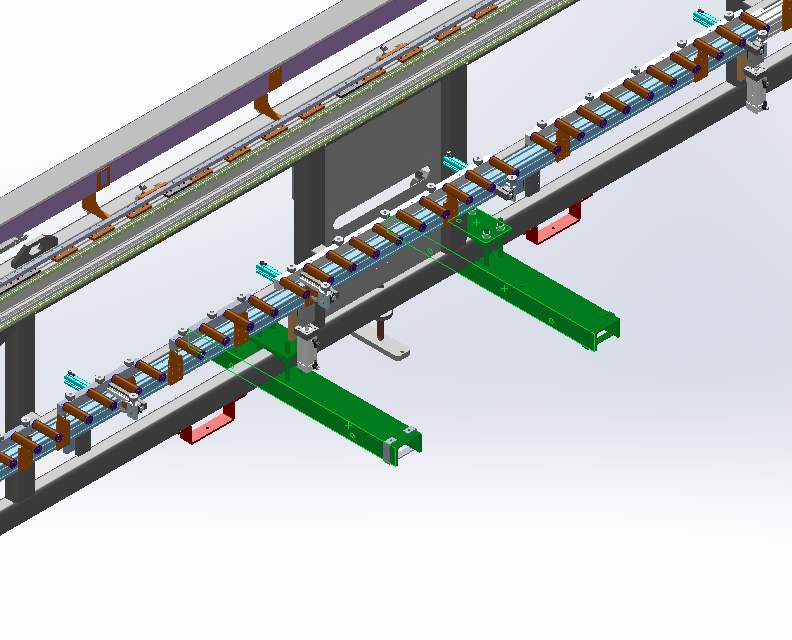

The machining head and saw split apart like a cam shell. They are joined with a dowel system in joining blocks at the base

The outfeed splits in to a rear bed and front tray

See Also

Étape 1 - Move axes to park positions

- X axis to machining side of lifting points

- Z axis to bottom of travel

- GZ axis to minimum

Étape 2 - Power off

Étape 3 - Infeed Conveyor Module - Disconnect

Ensure the plugs are labelled

Étape 4 - Infeed Conveyor Module - Move

Pull away from backfence towards front of machine

Étape 5 - Infeed Gripper Module - Disconnect

Ensure the plugs are labelled

Étape 6 - Infeed Gripper Module - Stowing

Tie gripper carriage to prevent axis movement in transit

Étape 7 - Infeed Gripper Module - Attach lifting Equipment

Attach safe moving equipment - see R0019264 Autoflow Mk 4,1 Infeed Safe moving equipment

Étape 8 - Outfeed table disconnect

Ensure the plugs are labelled

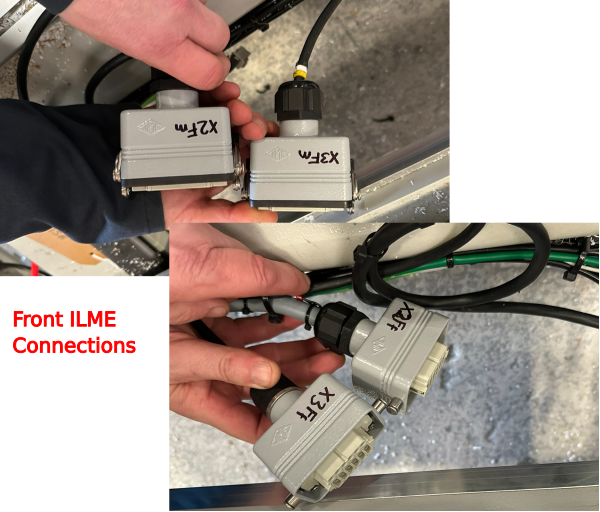

Étape 9 - Machining Head and Saw - Disconnects

Locate and unplug the electrical and pneumatic interconnections.

Ensure the plugs are labelled

Front Side

- X2F and X3F ILME Connectors. Pull one through one way, one through other way

- Grease Lines - 2 off

- Air Lines Red and Blue

Rear

- ILME Connection

- Network Connection - 2 Off

Étape 10 - Unlink Upper Guards

The guard shells are fastened with a plate internally.

Unbolt the Saw side front and rear, then bag and label the screws

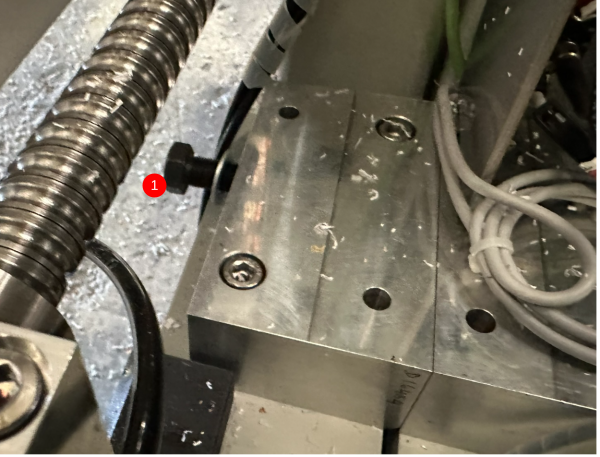

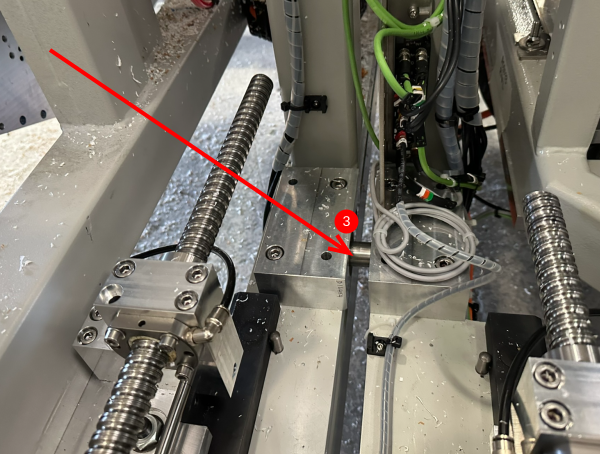

Étape 11 - Split Machining Head and Saw

- Remove the M16 front and rear hex head joining bolts, access from saw module. These are the only 2 bolts that fasten the machine together.

2. Using a crowbar, spit the main modules apart by around 100mm

Walk the front and rear by 23-30mm a time until the dowels are clear

3. You will see the location pin exposed in the joining blocks

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português