| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 6 : | Ligne 6 : | ||

|Tags=TB0420, Flowline, Spindle, Motor | |Tags=TB0420, Flowline, Spindle, Motor | ||

}} | }} | ||

| − | <translate>= Parts Affected = | + | <translate>=Parts Affected= |

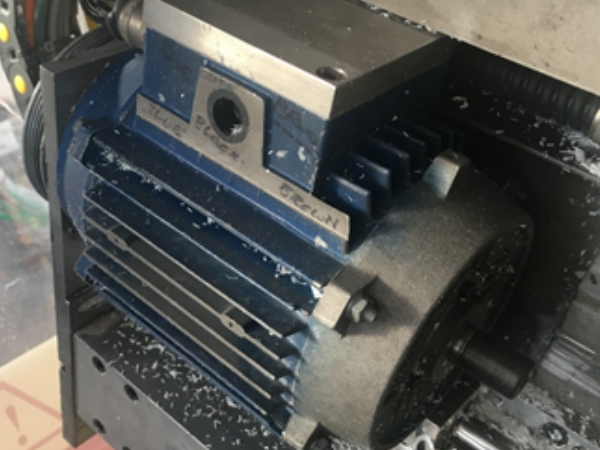

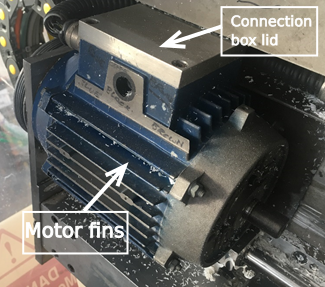

| − | {{#annotatedImageLight:Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image.png|0=138px|hash=|jsondata=|mediaClass=Image|type=frameless|align=right|src=https://stuga.dokit.app/images/4/40/TB0420_Obsolescence_Note_-_Flowline_Spindle_Motors_Image.png|href=./Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image.png|resource=./Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image.png|caption=|size=138px}}The original motor is no longer available, and a replacement has proved impossible to find due to the physical size of the motor | + | {{#annotatedImageLight:Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image.png|0=138px|hash=|jsondata=|mediaClass=Image|type=frameless|align=right|src=https://stuga.dokit.app/images/4/40/TB0420_Obsolescence_Note_-_Flowline_Spindle_Motors_Image.png|href=./Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image.png|resource=./Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image.png|caption=|size=138px}}The original motor is no longer available, and a replacement has proved impossible to find due to the physical size of the motor, '''and in particular, the size and shape of the connection box''' |

The design constrains the frame size, and requires two modifications | The design constrains the frame size, and requires two modifications | ||

| Ligne 15 : | Ligne 15 : | ||

| − | 2. The motor electrical connection box needs to sit in the correct orientation and be physically low enough to pass underneath the spindle connection | + | 2. The motor electrical connection box needs to sit in the correct orientation and be physically low enough to pass underneath the spindle connection box. A modified lid was fitted to allow this to happen |

| − | |||

| − | box. A modified lid was fitted to allow this to happen | ||

| Ligne 24 : | Ligne 22 : | ||

Stuga have a limited stock of second-hand motors. The recommendation is to get the motors rewound locally to the customer site | Stuga have a limited stock of second-hand motors. The recommendation is to get the motors rewound locally to the customer site | ||

| − | |||

{{#annotatedImageLight:Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image1.png|0=146px|hash=|jsondata=|mediaClass=Image|type=frameless|align=right|src=https://stuga.dokit.app/images/2/2b/TB0420_Obsolescence_Note_-_Flowline_Spindle_Motors_Image1.png|href=./Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image1.png|resource=./Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image1.png|caption=|size=146px}}<br /> | {{#annotatedImageLight:Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image1.png|0=146px|hash=|jsondata=|mediaClass=Image|type=frameless|align=right|src=https://stuga.dokit.app/images/2/2b/TB0420_Obsolescence_Note_-_Flowline_Spindle_Motors_Image1.png|href=./Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image1.png|resource=./Fichier:TB0420 Obsolescence Note - Flowline Spindle Motors Image1.png|caption=|size=146px}}<br /> | ||

| Ligne 57 : | Ligne 54 : | ||

<br /> | <br /> | ||

| − | = Refurbishment Process = | + | =Refurbishment Process= |

Stuga offer a refurbishment process on old motors which involves three processes | Stuga offer a refurbishment process on old motors which involves three processes | ||

{| class="wikitable" | {| class="wikitable" | ||

| Ligne 68 : | Ligne 65 : | ||

|1 | |1 | ||

|L0009001 | |L0009001 | ||

| − | |Flowline Spindle motor repair | + | |Flowline Spindle motor repair |

|Overhaul, bearings and seals only | |Overhaul, bearings and seals only | ||

|Swift Rewinds | |Swift Rewinds | ||

| Ligne 75 : | Ligne 72 : | ||

|L0009002 | |L0009002 | ||

|Flowline Spindle motor rewind | |Flowline Spindle motor rewind | ||

| − | |Rewind flowline spindle motor | + | |Rewind flowline spindle motor |

|Swift Rewinds | |Swift Rewinds | ||

|- | |- | ||

| Ligne 84 : | Ligne 81 : | ||

|Machine Shop | |Machine Shop | ||

|} | |} | ||

| − | {{Warning|...This process absolutely depends on customer returning older motors for refurbishment. The item MUST NOT be sold without this understanding in place}} | + | {{Warning|...This process absolutely depends on customer returning older motors for refurbishment. The item MUST NOT be sold without this understanding in place}}</translate> |

| − | </translate> | ||

{{PageLang | {{PageLang | ||

|Language=en | |Language=en | ||

Version actuelle datée du 13 mars 2025 à 15:02

The original motor is no longer available, and a replacement has proved impossible to find due to the physical size of the motor

Parts Affected

The original motor is no longer available, and a replacement has proved impossible to find due to the physical size of the motor, and in particular, the size and shape of the connection box

The design constrains the frame size, and requires two modifications

1. Fins on the motor need to be machined off to prevent the motor casing hitting the infeed clamps

2. The motor electrical connection box needs to sit in the correct orientation and be physically low enough to pass underneath the spindle connection box. A modified lid was fitted to allow this to happen

All replacements considered cannot meet these physical constraints, particularly the connection box issue.

Stuga have a limited stock of second-hand motors. The recommendation is to get the motors rewound locally to the customer site

| Part Nos | Description |

| D0008252 | Std Hand |

| D0007342 | Opp Hand |

| E0000219 | Original Motor 71/B14 2 Pole 0.75kW |

Refurbishment Process

Stuga offer a refurbishment process on old motors which involves three processes

| No | Order Code | Description | Notes | Supplier |

|---|---|---|---|---|

| 1 | L0009001 | Flowline Spindle motor repair | Overhaul, bearings and seals only | Swift Rewinds |

| 2 | L0009002 | Flowline Spindle motor rewind | Rewind flowline spindle motor | Swift Rewinds |

| 3 | D0008252UH | Unhanding Flowline Spindle Motor | Physical machining of the motor to ensure it works on either hand | Machine Shop |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português