| [version en cours de rédaction] | [version en cours de rédaction] |

| (Une révision intermédiaire par le même utilisateur non affichée) | |||

| Ligne 16 : | Ligne 16 : | ||

Crank D is also mounted on the Machining Centre Outfeed and controls the pop ups on the Transfer Table. | Crank D is also mounted on the Machining Centre Outfeed and controls the pop ups on the Transfer Table. | ||

| − | Crank E is the crank on the Saw Infeed and controls the single pop up that moves the profile in to the channel.</translate> | + | Crank E is the crank on the Saw Infeed and controls the single pop up that moves the profile in to the channel. |

| + | |||

| + | <br /> | ||

| + | |||

| + | ===UPDATE 2024=== | ||

| + | The default clutch spring setup has been found to be incorrect. The clutch spring contains 3 components, which is the wrong range for this application. | ||

| + | |||

| + | The correct spring setup is just one spring</translate> | ||

}} | }} | ||

{{Materials | {{Materials | ||

| Ligne 22 : | Ligne 29 : | ||

}} | }} | ||

{{EPI}} | {{EPI}} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Check the system friction and tension</translate> | ||

| + | |Step_Content=<translate>There is no point in setting up the clutch torque if the transfer table friction points are not set correctly. | ||

| + | |||

| + | Common points where friction is encountered due to misalignment and misunderstanding : | ||

| + | |||

| + | # Delrin wheel tightness (should turn between thumb and forefinger) | ||

| + | # Over meshing of drive pinions to racks</translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Check Crank spring count</translate> | ||

| + | |Step_Content=<translate>The default clutch spring setup has been found to be incorrect. The clutch spring contains 3 components, which is the wrong range for this application. | ||

| + | |||

| + | The correct spring setup is just one spring</translate> | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Programme Eaton Drives.</translate> | |Step_Title=<translate>Programme Eaton Drives.</translate> | ||

Version actuelle datée du 8 août 2024 à 11:14

How to set up the cranks mechanically so the correct overlaps and limits are achieved.

Sommaire

- 1 Introduction

- 2 Pièces et outils

- 3 Étape 1 - Check the system friction and tension

- 4 Étape 2 - Check Crank spring count

- 5 Étape 3 - Programme Eaton Drives.

- 6 Étape 4 - Set idler and tighten clutches

- 7 Étape 5 - Set mechanical end stops

- 8 Étape 6 - Roughly set sensor positions

- 9 Étape 7 - Check crank directions

- 10 Étape 8 - Set minimum and maximum positions

- 11 Étape 9 - Check overlaps between the different racks

- 12 Étape 10 - Lock off sensors and mechanical end stops

- 13 Commentaires

Introduction

This tutorial will show you how to mechanically set up the cranks and sensors so that the correct overlaps between the different cranks are achieved.

Crank C is the crank on the Machining Centre Outfeed that controls the single pop up.

Crank D is also mounted on the Machining Centre Outfeed and controls the pop ups on the Transfer Table.

Crank E is the crank on the Saw Infeed and controls the single pop up that moves the profile in to the channel.

UPDATE 2024

The default clutch spring setup has been found to be incorrect. The clutch spring contains 3 components, which is the wrong range for this application.

The correct spring setup is just one spring- Pièces et outils

Pièces et outils

Étape 1 - Check the system friction and tension

There is no point in setting up the clutch torque if the transfer table friction points are not set correctly.

Common points where friction is encountered due to misalignment and misunderstanding :

- Delrin wheel tightness (should turn between thumb and forefinger)

- Over meshing of drive pinions to racks

Étape 2 - Check Crank spring count

The default clutch spring setup has been found to be incorrect. The clutch spring contains 3 components, which is the wrong range for this application.

The correct spring setup is just one spring

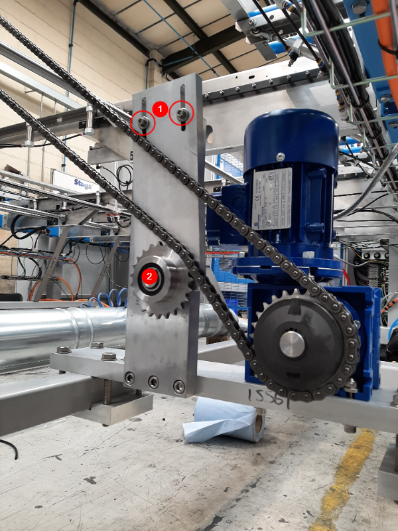

Étape 4 - Set idler and tighten clutches

- Loosen the two bolts holding the idler

- Adjust until the idler sprocket is applying some pressure to the chain

- Use a C spanner or a hammer and drift to tighten the clutch.

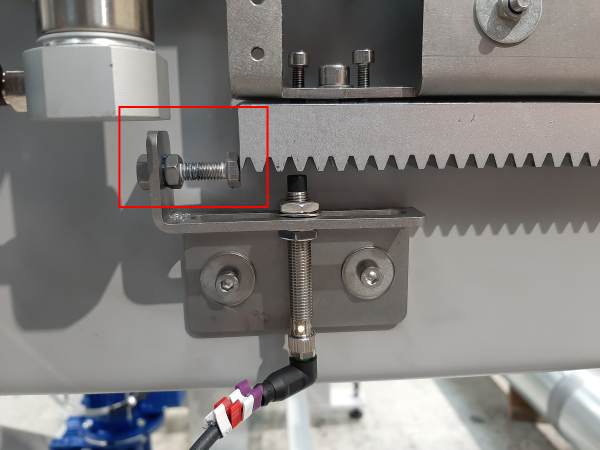

Étape 5 - Set mechanical end stops

These mechanical end stops should only ever be used as a fail safe in cases of sensors failing. These should be set so that the gears can never come off the racks.

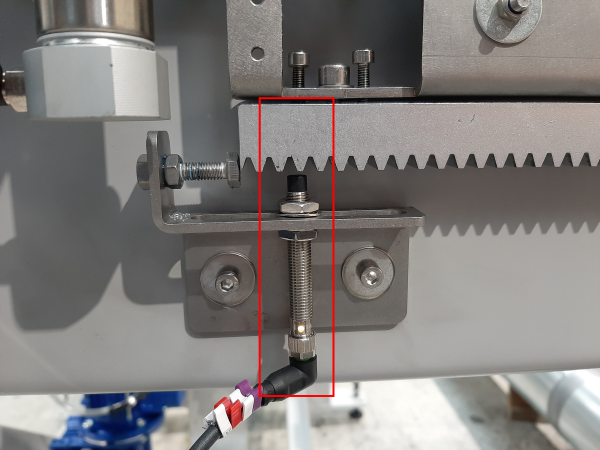

Étape 6 - Roughly set sensor positions

Using a pair of 13mm spanners, nip the proximity sensors in place so that they are roughly in the middle of the slot.

Do this for all 6 sensors (2 on each assembly - 1 'home' and 1 'out')

Étape 7 - Check crank directions

- Using the outputs (1) run the crank in forward and reversing movements

Étape 8 - Set minimum and maximum positions

Moving the sensor left and right on the slot will change the distance the crank travels. The aim here is to stop the rack before it hits the mechanical end stops.

You may have to run the cranks backwards and forwards a few times to get these right.

The aim is for the gap between the end stop and the rack to be between 3mm and 8mm each time. IT MUST NOT BOTTOM OUT

Étape 9 - Check overlaps between the different racks

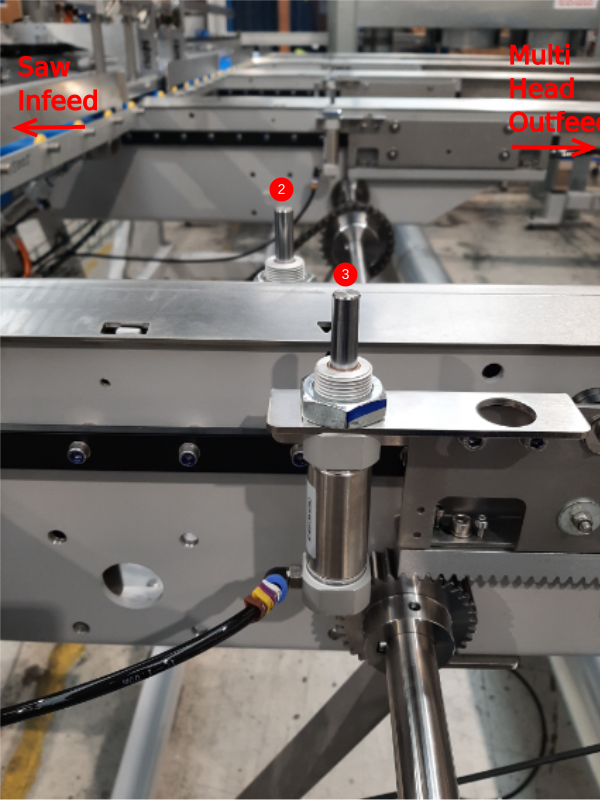

It is important to get the overlaps between the cranks correct so that the profile is transferred smoothly from one module to the next and to also avoid collisions between the grippers and the pop ups.

- Crank C 'Home' position (1) needs to be behind the backfence

- Crank C 'Out' position needs to overlap Crank D 'Home' position

- Crank D 'Out' (2) position needs to overlap Crank E 'Home' (3) position

- Crank E 'Out' position (4) needs to sit in front of the Saw Infeed backfences but not so far forward that it will be hit by the gripper (5)

Étape 10 - Lock off sensors and mechanical end stops

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português