| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Description=<translate>Instructions for correct assembly and setting of stroke assembly gearboxes</translate> |Difficulty=Very hard |Duration=5 |Duration-t... ») |

|||

| (7 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 1 : | Ligne 1 : | ||

{{Tuto Details | {{Tuto Details | ||

| − | |Description=<translate>Instructions for correct assembly and setting of stroke assembly gearboxes</translate> | + | |Main_Picture=R0000299_Stroke_assembly_rebuild_Screenshot_2024-07-04_153226.png |

| + | |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":26,"top":-170,"width":650,"height":778,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.85,"scaleY":0.85,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/e/ea/R0000299_Stroke_assembly_rebuild_Screenshot_2024-07-04_153226.png","filters":[]}],"height":450,"width":600} | ||

| + | |Description=<translate>Instructions for correct assembly and setting of stroke assembly gearboxes | ||

| + | Original part numbers R0000728 and R0000729</translate> | ||

| + | |Categories=Production | ||

|Difficulty=Very hard | |Difficulty=Very hard | ||

| − | |Duration= | + | |Duration=4 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

{{Introduction | {{Introduction | ||

| − | |Introduction=<translate></translate> | + | |Introduction=<translate> The following instructions should be followed to ensure that correct assembly and setting are performed |

| + | |||

| + | |||

| + | <u>'''Tools / consumables Required'''</u> | ||

| + | |||

| + | |||

| + | Standard hex key set | ||

| + | |||

| + | Standard spanner set | ||

| + | |||

| + | Large adjustable spanner | ||

| + | |||

| + | Drifts and punches | ||

| + | |||

| + | Ballpein hammer | ||

| + | |||

| + | Soft hammer | ||

| + | |||

| + | FE10 Solvent | ||

| + | |||

| + | Hylomar Gasket | ||

| + | |||

| + | |||

| + | <u>'''Parts Required'''</u> | ||

| + | |||

| + | |||

| + | Kit R0000299 containing | ||

| + | |||

| + | |||

| + | B0000043 Double Angular bearing 15 I?D 35 O?D 15.9 long rubber seal 3 x 2 | ||

| + | |||

| + | B0000105 Double Angular Bearing 15 I/D 35 O/D 15.9 Long x 1 | ||

| + | |||

| + | B0000335 3ph Brake motor 2 pole 3000rpm x 1 | ||

| + | |||

| + | B0000380 Double Angular Bearing 25 I/D 52 O/D 20.6 Long + rubber seal x 2 | ||

| + | |||

| + | D0000059 Damper Bridge x 1 | ||

| + | |||

| + | D0000062 Damper Bridge Boss x 2 | ||

| + | |||

| + | D0007730 ZX4 V Notch Mk1 Spindle Shaft x1 | ||

| + | |||

| + | D0007867 Bevel Gear (Left) x 1 | ||

| + | |||

| + | D0007868 Bevel Gear (Right ) x 1 | ||

| + | |||

| + | D0007873 Motor Gear x 1 | ||

| + | |||

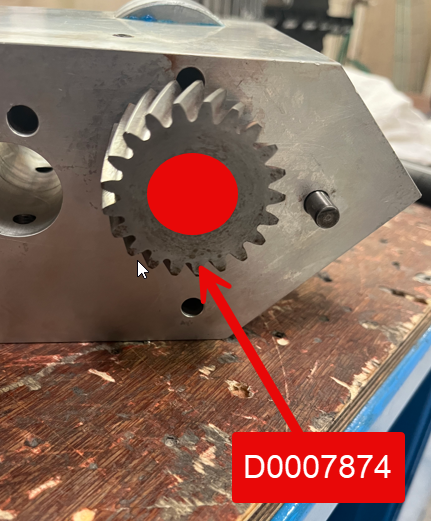

| + | D0007874 Pinion Gear x 1 | ||

| + | |||

| + | D0007875 Pinion Shaft x 1 | ||

| + | |||

| + | P0000165 damper x 1</translate> | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Handing clarification</translate> |

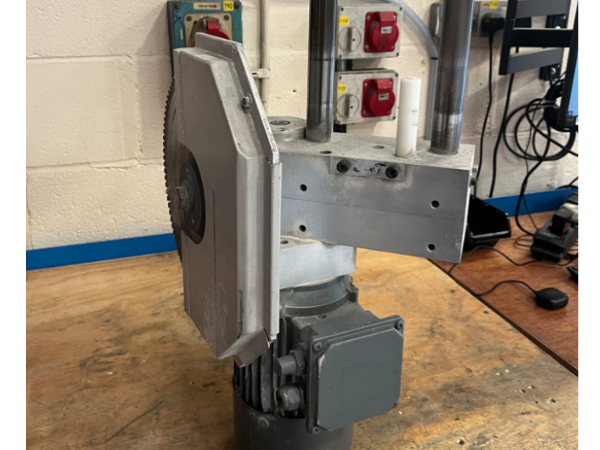

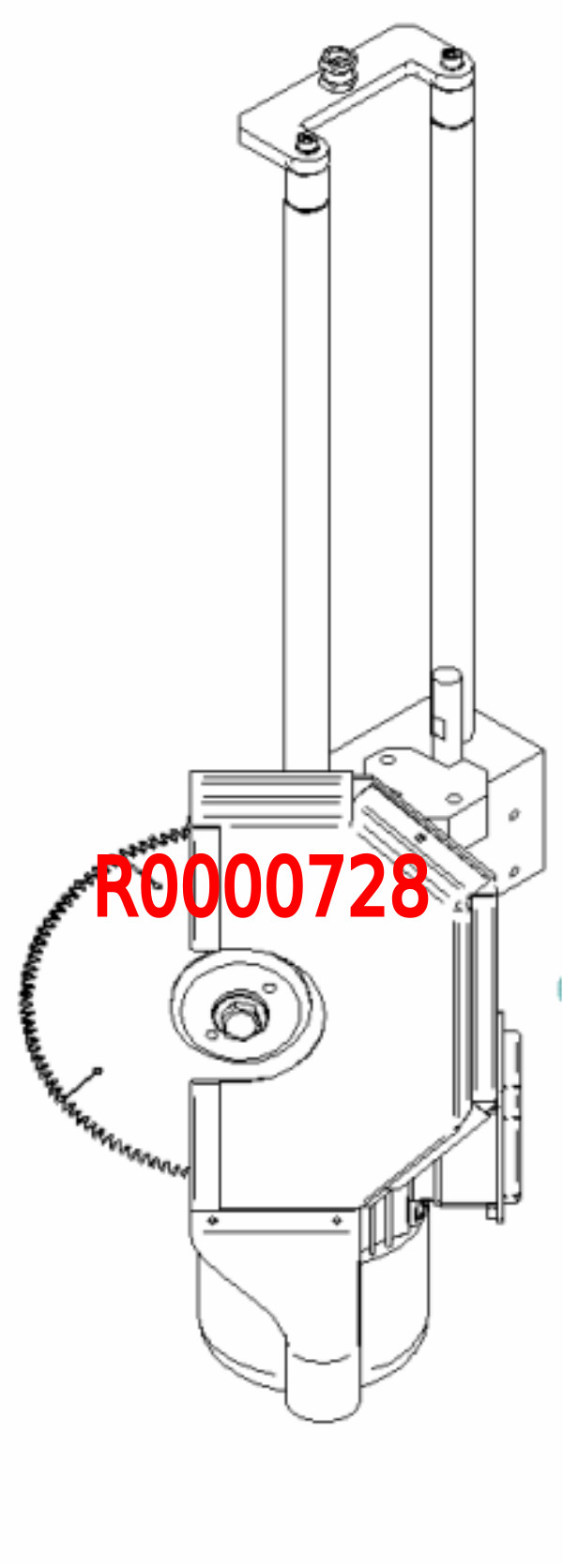

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>R0000728 and R0000729 are mirror images to each other |

| + | |||

| + | |||

| + | Please inspect pictures to clarify and confirm correct hand to be built | ||

| + | |||

| + | |||

| + | (Supplied unit to be refurbished will always be rebuilt as the same hand )</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_Screenshot_2024-06-04_075738.png | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":221,"height":616,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":2.71,"scaleY":2.71,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/b/bd/R0000299_Stroke_assembly_rebuild_Screenshot_2024-06-04_075738.png","filters":[]},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":300.14,"top":948.6,"width":115.11,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.5,"scaleY":4.27,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"R0000728","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} }],"height":1672,"width":600} | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_Screenshot_2024-06-04_075806.png | ||

| + | |Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":240,"height":497,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":2.5,"scaleY":2.5,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/1/19/R0000299_Stroke_assembly_rebuild_Screenshot_2024-06-04_075806.png","filters":[]},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":297.91,"top":706.36,"width":92.3,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.83,"scaleY":3.83,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"R0000729","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} }],"height":1243,"width":600} | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Unless otherwise stated</translate> | ||

| + | |Step_Content=<translate>Always use Loctite 243 on all fasteners fitted unless stated different | ||

| + | |||

| + | |||

| + | All bearings should be an acceptable fit, with Loctite 641 and FE10 solvent used if required | ||

| + | |||

| + | |||

| + | All fasteners should be marked once finalised</translate> | ||

| + | |Step_Picture_00=R0008013_Clacker_assembly_quality.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

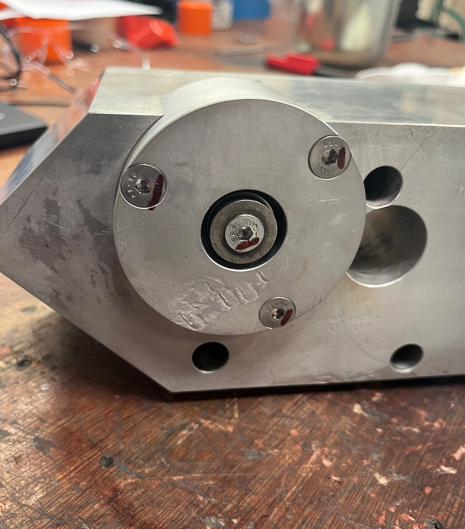

| + | |Step_Title=<translate>Motor Drive pinion</translate> | ||

| + | |Step_Content=<translate>1 Check fit of Motor drive gear D0007873 onto B0000335 motor. Ensure fit is smooth and pinion can be fitted by hand. | ||

| + | |||

| + | |||

| + | 2 If gear does not fit onto spindle by hand, remove key from motor shaft and | ||

| + | |||

| + | * Check motor gear fits on shaft with no key present. If not rework bore of motor gear to ensure correct fitment | ||

| + | * Check key passes through motor gear keyway . If not rework keyway until key passes through by hand | ||

| + | * Re fit key and check motor gear now fits by hand onto motor shaft | ||

| + | |||

| + | 3 Set motor pinion flush to top of shaft and secure with 2 off M6 x 10 KCP grubscrews and Loctite 243. Ensure these are fully tightened</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-04_16-10-27.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-04_16-11-52.png | ||

| + | |Step_Picture_02=R0000299_Stroke_assembly_rebuild_2024-07-04_16-13-37.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

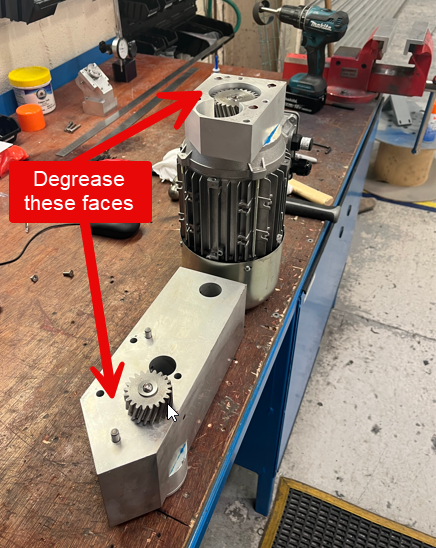

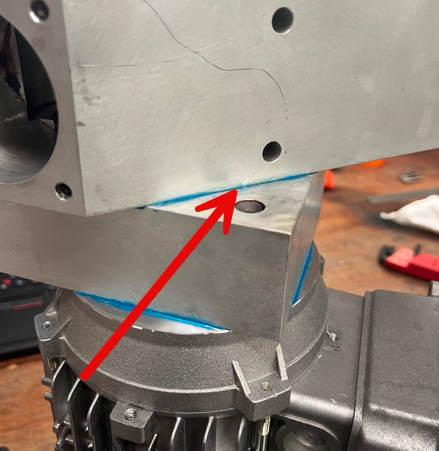

| + | |Step_Title=<translate>Fit Motor Drive gear Housing</translate> | ||

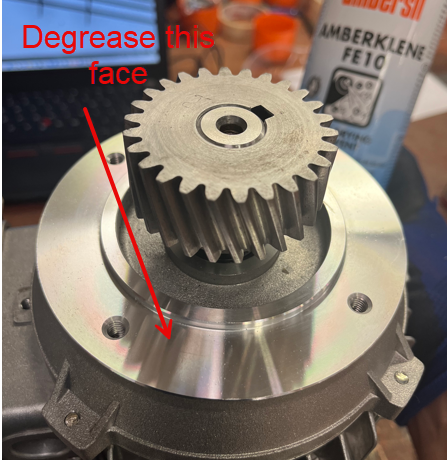

| + | |Step_Content=<translate>1 Degrease mounting faces indicated with FE10 solvent | ||

| + | |||

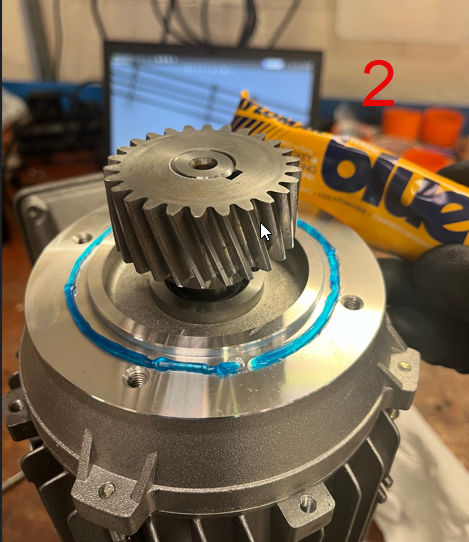

| + | 2 Apply bead of Hylomar as shown to drive pinion housing | ||

| + | |||

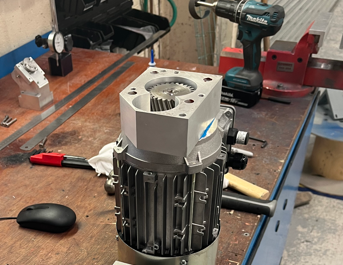

| + | 3 Fit housing to motor, paying attention to orientation and fix with 4 off M6 x 50 socket caps</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-04_16-26-35.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-04_16-25-28.png | ||

| + | |Step_Picture_02=R0000299_Stroke_assembly_rebuild_2024-07-04_16-32-08.png | ||

| + | }} | ||

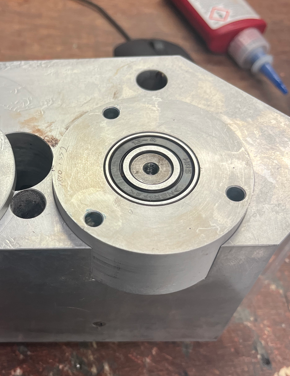

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit B0000043 Bearings</translate> | ||

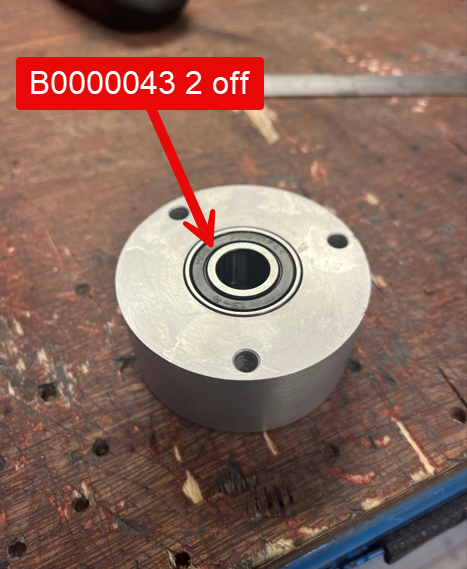

| + | |Step_Content=<translate>Fit 2 off B0000043 bearings to housing D0007870 | ||

| + | |||

| + | |||

| + | Ensure correct bearing fitment is achieved. Use loctite 641 and thoroughly degrease with FE10 is bearing are loose in bore</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_07-41-56.png | ||

| + | }} | ||

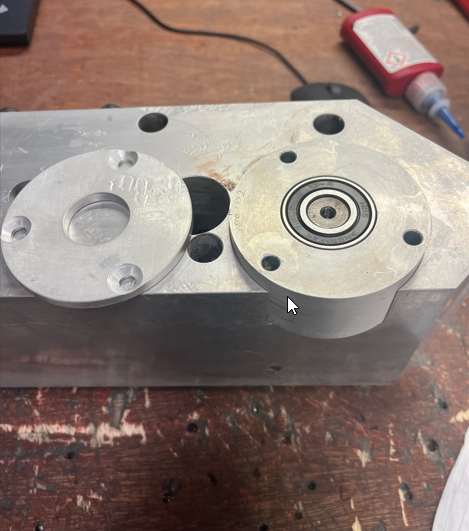

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit B0000105 bearing</translate> | ||

| + | |Step_Content=<translate>Fit B0000105 bearing to shaft D0007875 , ensuring correct orientation | ||

| + | |||

| + | |||

| + | Use loctite 641 and FE10 if bearing fit is loose</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_07-45-31.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Bevel gear identification</translate> | ||

| + | |Step_Content=<translate>Ensure bevel gears are identified correctly | ||

| + | |||

| + | |||

| + | D0007868 has an additional raised face on the rear of the gear</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_07-49-26.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit Gear to shaft</translate> | ||

| + | |Step_Content=<translate>Fit Key B0000383 to Shaft , and fit bevel gear D0007868 , ensuring correctly orientated</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_07-54-36.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_07-55-50.png | ||

| + | |Step_Picture_02=R0000299_Stroke_assembly_rebuild_2024-07-08_07-56-39.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit shaft assembly to housing</translate> | ||

| + | |Step_Content=<translate>Fit assembled shaft to bearing housing as shown | ||

| + | |||

| + | |||

| + | Again, observe fit of bearings and if required, use Loctite 641 bearing fit and FE10 solvent to correct if bearings are loose</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_07-57-47.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_07-58-07.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

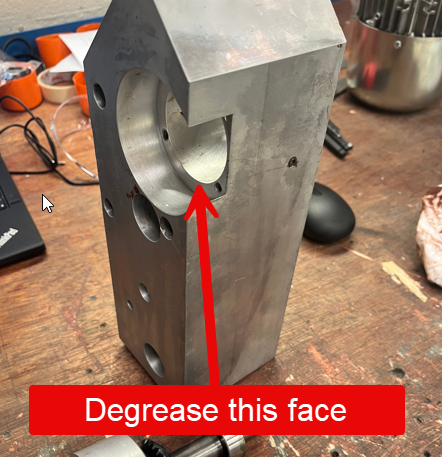

| + | |Step_Title=<translate>Degrease faces</translate> | ||

| + | |Step_Content=<translate>Degrease indicated faces with FE10 solvent</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_08-01-34.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_08-02-24.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

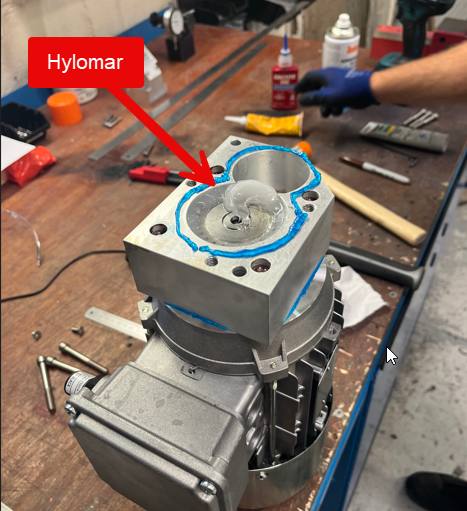

| + | |Step_Title=<translate>Fit and seal shaft assembly</translate> | ||

| + | |Step_Content=<translate>Apply Hylomar as shown | ||

| + | |||

| + | |||

| + | Apply Loctite 641 to bearing | ||

| + | |||

| + | |||

| + | Fit assembly to main housing | ||

| + | |||

| + | {{Warning|...Hole fixing PCD must be observed to allow correct alignment . If not aligned correctly, all 3 fixing M6 holes will not align. Check orientation before fitting assembly}}<br /></translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_08-04-53.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_08-08-46.png | ||

| + | |Step_Picture_02=R0000299_Stroke_assembly_rebuild_2024-07-08_08-09-11.png | ||

| + | |Step_Picture_03=R0000299_Stroke_assembly_rebuild_2024-07-08_08-09-33.png | ||

| + | }} | ||

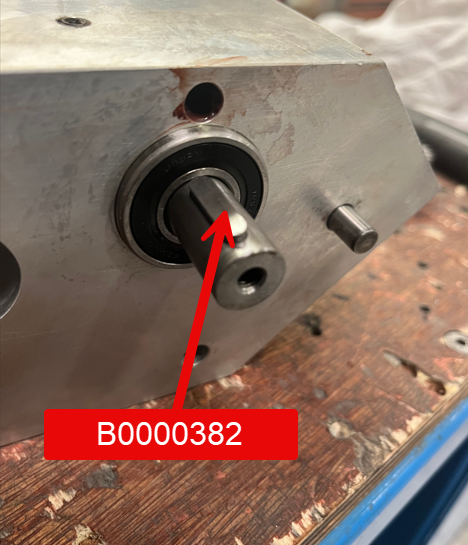

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit drive gear</translate> | ||

| + | |Step_Content=<translate>Fit B0000382 key to shaft | ||

| + | |||

| + | |||

| + | Fit D0007874 gear to shaft</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_08-12-35.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_08-14-13.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit fixings</translate> | ||

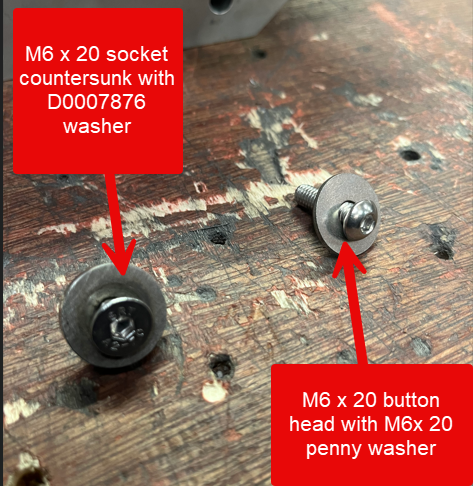

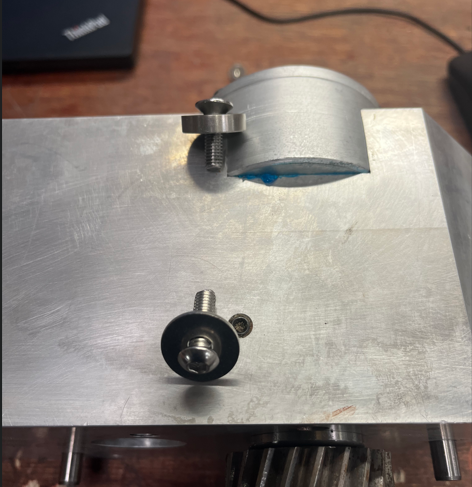

| + | |Step_Content=<translate>Use M6 x 20 socket countersunk with D0007876 washer | ||

| + | |||

| + | |||

| + | Use M6 x 20 button head with M6x 20 penny washer | ||

| + | |||

| + | |||

| + | Use Loctite 243 and ensure all threads and tapped holes are thoroughly degreased with FE10 solvent | ||

| + | |||

| + | |||

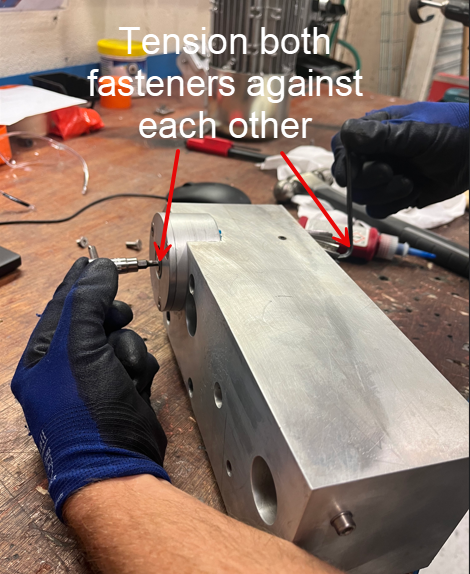

| + | Fit fasteners as shown and tighten both fasteners at the same time, using opposing threads to enable sufficient tensioning</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_08-19-06.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_08-20-23.png | ||

| + | |Step_Picture_02=R0000299_Stroke_assembly_rebuild_2024-07-08_08-20-44.png | ||

| + | |Step_Picture_03=R0000299_Stroke_assembly_rebuild_2024-07-08_08-22-55.png | ||

| + | |Step_Picture_04=R0000299_Stroke_assembly_rebuild_2024-07-08_08-23-13.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Degrease faces</translate> | ||

| + | |Step_Content=<translate>Degrease indicated faces with FE10 solvent | ||

| + | |||

| + | |||

| + | Apply 1/3 of tube of M0000603 grease as indicated | ||

| + | |||

| + | |||

| + | Apply Hylomar to face as indicated</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_08-24-57.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_08-29-14.png | ||

| + | |Step_Picture_02=R0000299_Stroke_assembly_rebuild_2024-07-08_08-29-55.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

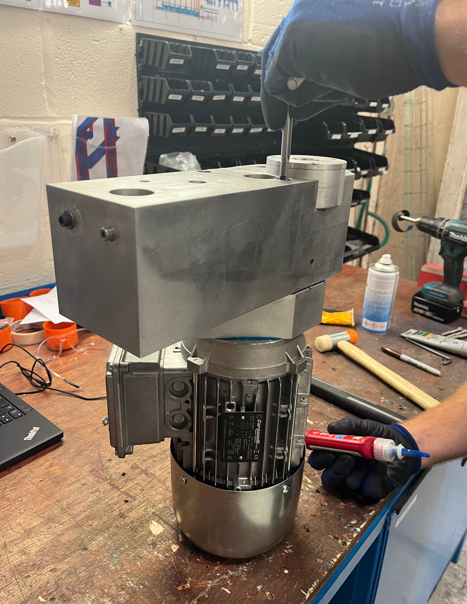

| + | |Step_Title=<translate>Attach to main housing</translate> | ||

| + | |Step_Content=<translate>Combine 2 assemblies as shown. | ||

| + | |||

| + | |||

| + | Use location dowels to position | ||

| + | |||

| + | |||

| + | Fix with 3 off M8 70 socket caps and Loctite 243 | ||

| + | |||

| + | |||

| + | Smooth excess Hylomar with clean rag once fasteners have been finalised</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_08-31-43.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_08-33-10.png | ||

| + | |Step_Picture_02=R0000299_Stroke_assembly_rebuild_2024-07-08_08-33-36.png | ||

| + | }} | ||

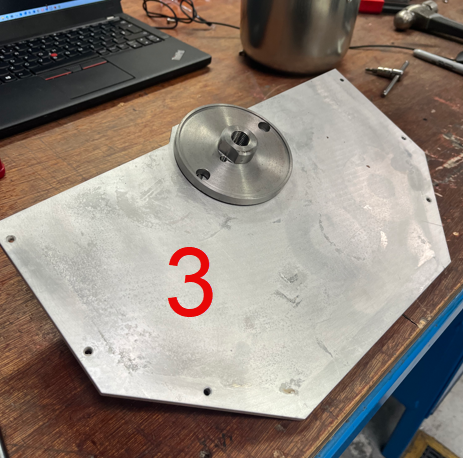

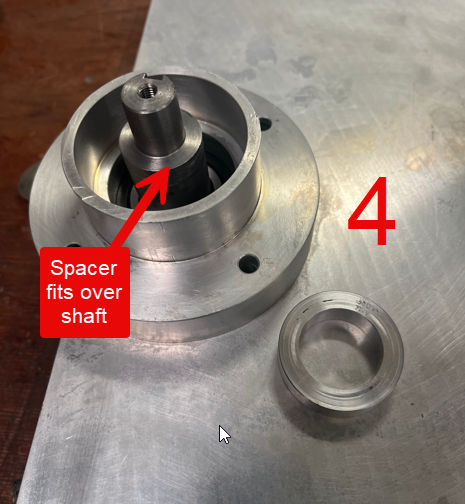

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit B0000380 bearing to housing</translate> | ||

| + | |Step_Content=<translate>1 Fit 1 off B0000380 bearing to D0007797 as shown. Ensure correct bearing fit is observed | ||

| + | |||

| + | |||

| + | 2 Fit to D0007750 backplate and secure with 4 off M6 x 16 socket countersunk | ||

| + | |||

| + | |||

| + | 3 Fit D0007730 spindle | ||

| + | |||

| + | |||

| + | 4 Fit D0007729 spacer | ||

| + | |||

| + | |||

| + | 5 Fit 2nd B0000380 bearing</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_2024-07-08_08-40-58.png | ||

| + | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_2024-07-08_08-41-29.png | ||

| + | |Step_Picture_02=R0000299_Stroke_assembly_rebuild_2024-07-08_08-41-51.png | ||

| + | |Step_Picture_03=R0000299_Stroke_assembly_rebuild_2024-07-08_08-42-17.png | ||

| + | |Step_Picture_04=R0000299_Stroke_assembly_rebuild_2024-07-08_08-43-35.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version actuelle datée du 8 juillet 2024 à 10:28

Instructions for correct assembly and setting of stroke assembly gearboxes Original part numbers R0000728 and R0000729

Sommaire

- 1 Introduction

- 2 Étape 1 - Handing clarification

- 3 Étape 2 - Unless otherwise stated

- 4 Étape 3 - Motor Drive pinion

- 5 Étape 4 - Fit Motor Drive gear Housing

- 6 Étape 5 - Fit B0000043 Bearings

- 7 Étape 6 - Fit B0000105 bearing

- 8 Étape 7 - Bevel gear identification

- 9 Étape 8 - Fit Gear to shaft

- 10 Étape 9 - Fit shaft assembly to housing

- 11 Étape 10 - Degrease faces

- 12 Étape 11 - Fit and seal shaft assembly

- 13 Étape 12 - Fit drive gear

- 14 Étape 13 - Fit fixings

- 15 Étape 14 - Degrease faces

- 16 Étape 15 - Attach to main housing

- 17 Étape 16 - Fit B0000380 bearing to housing

- 18 Commentaires

Introduction

The following instructions should be followed to ensure that correct assembly and setting are performed

Tools / consumables Required

Standard hex key set

Standard spanner set

Large adjustable spanner

Drifts and punches

Ballpein hammer

Soft hammer

FE10 Solvent

Hylomar Gasket

Parts Required

Kit R0000299 containing

B0000043 Double Angular bearing 15 I?D 35 O?D 15.9 long rubber seal 3 x 2

B0000105 Double Angular Bearing 15 I/D 35 O/D 15.9 Long x 1

B0000335 3ph Brake motor 2 pole 3000rpm x 1

B0000380 Double Angular Bearing 25 I/D 52 O/D 20.6 Long + rubber seal x 2

D0000059 Damper Bridge x 1

D0000062 Damper Bridge Boss x 2

D0007730 ZX4 V Notch Mk1 Spindle Shaft x1

D0007867 Bevel Gear (Left) x 1

D0007868 Bevel Gear (Right ) x 1

D0007873 Motor Gear x 1

D0007874 Pinion Gear x 1

D0007875 Pinion Shaft x 1

P0000165 damper x 1Étape 1 - Handing clarification

R0000728 and R0000729 are mirror images to each other

Please inspect pictures to clarify and confirm correct hand to be built

(Supplied unit to be refurbished will always be rebuilt as the same hand )

Étape 2 - Unless otherwise stated

Always use Loctite 243 on all fasteners fitted unless stated different

All bearings should be an acceptable fit, with Loctite 641 and FE10 solvent used if required

All fasteners should be marked once finalised

Étape 3 - Motor Drive pinion

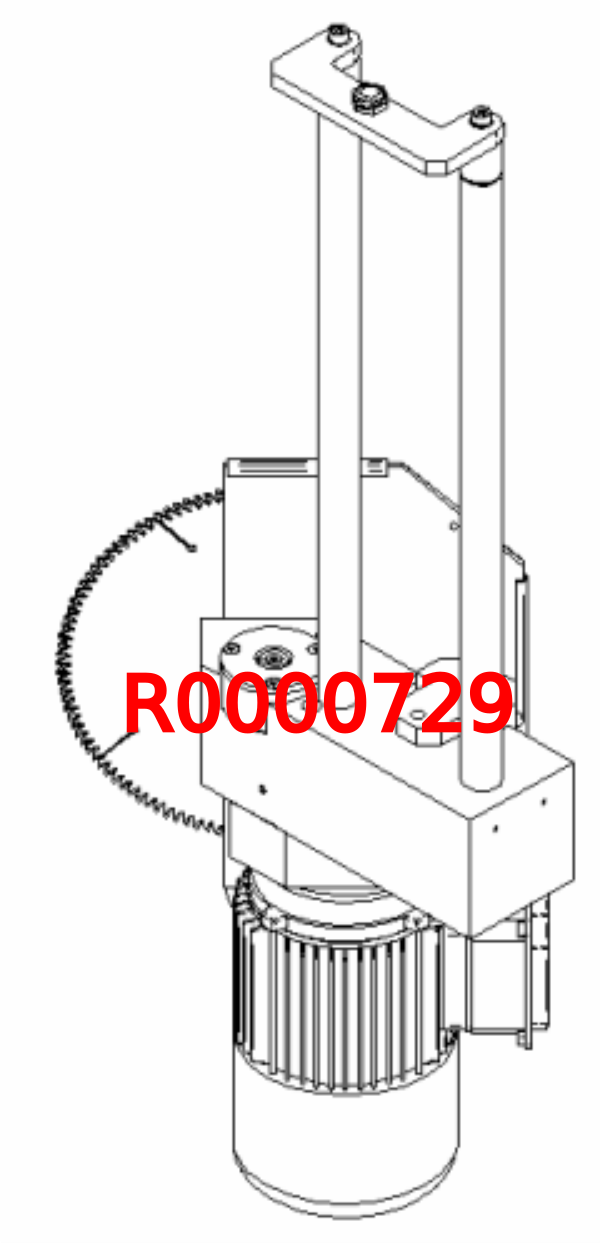

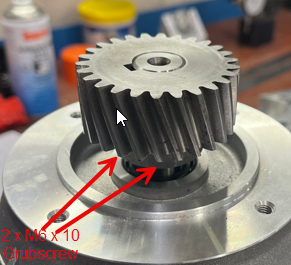

1 Check fit of Motor drive gear D0007873 onto B0000335 motor. Ensure fit is smooth and pinion can be fitted by hand.

2 If gear does not fit onto spindle by hand, remove key from motor shaft and

- Check motor gear fits on shaft with no key present. If not rework bore of motor gear to ensure correct fitment

- Check key passes through motor gear keyway . If not rework keyway until key passes through by hand

- Re fit key and check motor gear now fits by hand onto motor shaft

3 Set motor pinion flush to top of shaft and secure with 2 off M6 x 10 KCP grubscrews and Loctite 243. Ensure these are fully tightened

Étape 4 - Fit Motor Drive gear Housing

1 Degrease mounting faces indicated with FE10 solvent

2 Apply bead of Hylomar as shown to drive pinion housing

3 Fit housing to motor, paying attention to orientation and fix with 4 off M6 x 50 socket caps

Étape 5 - Fit B0000043 Bearings

Fit 2 off B0000043 bearings to housing D0007870

Ensure correct bearing fitment is achieved. Use loctite 641 and thoroughly degrease with FE10 is bearing are loose in bore

Étape 6 - Fit B0000105 bearing

Fit B0000105 bearing to shaft D0007875 , ensuring correct orientation

Use loctite 641 and FE10 if bearing fit is loose

Étape 7 - Bevel gear identification

Ensure bevel gears are identified correctly

D0007868 has an additional raised face on the rear of the gear

Étape 8 - Fit Gear to shaft

Fit Key B0000383 to Shaft , and fit bevel gear D0007868 , ensuring correctly orientated

Étape 9 - Fit shaft assembly to housing

Fit assembled shaft to bearing housing as shown

Again, observe fit of bearings and if required, use Loctite 641 bearing fit and FE10 solvent to correct if bearings are loose

Étape 11 - Fit and seal shaft assembly

Apply Hylomar as shown

Apply Loctite 641 to bearing

Fit assembly to main housing

Étape 13 - Fit fixings

Use M6 x 20 socket countersunk with D0007876 washer

Use M6 x 20 button head with M6x 20 penny washer

Use Loctite 243 and ensure all threads and tapped holes are thoroughly degreased with FE10 solvent

Fit fasteners as shown and tighten both fasteners at the same time, using opposing threads to enable sufficient tensioning

Étape 14 - Degrease faces

Degrease indicated faces with FE10 solvent

Apply 1/3 of tube of M0000603 grease as indicated

Apply Hylomar to face as indicated

Étape 15 - Attach to main housing

Combine 2 assemblies as shown.

Use location dowels to position

Fix with 3 off M8 70 socket caps and Loctite 243

Smooth excess Hylomar with clean rag once fasteners have been finalised

Étape 16 - Fit B0000380 bearing to housing

1 Fit 1 off B0000380 bearing to D0007797 as shown. Ensure correct bearing fit is observed

2 Fit to D0007750 backplate and secure with 4 off M6 x 16 socket countersunk

3 Fit D0007730 spindle

4 Fit D0007729 spacer

5 Fit 2nd B0000380 bearing

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português