| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 248 : | Ligne 248 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Drill additional tie base</translate> | |Step_Title=<translate>Drill additional tie base</translate> | ||

| − | |Step_Content=<translate>Drill and tap additional M5 at point indicated | + | |Step_Content=<translate>Drill and tap additional M5 at point indicated, drill through |

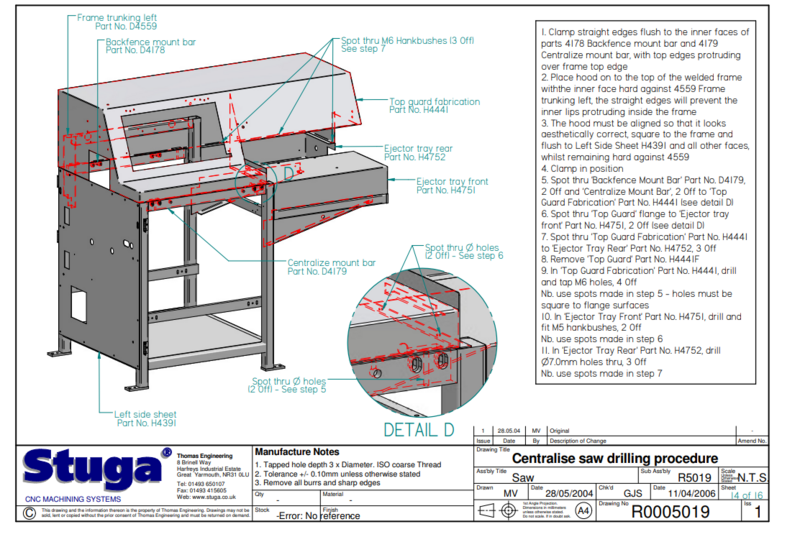

Version actuelle datée du 18 décembre 2023 à 15:07

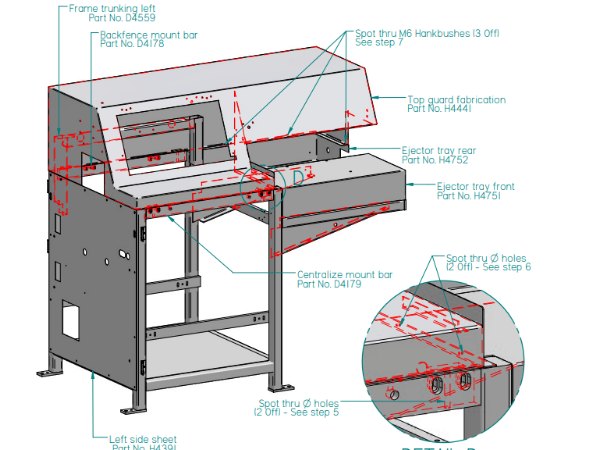

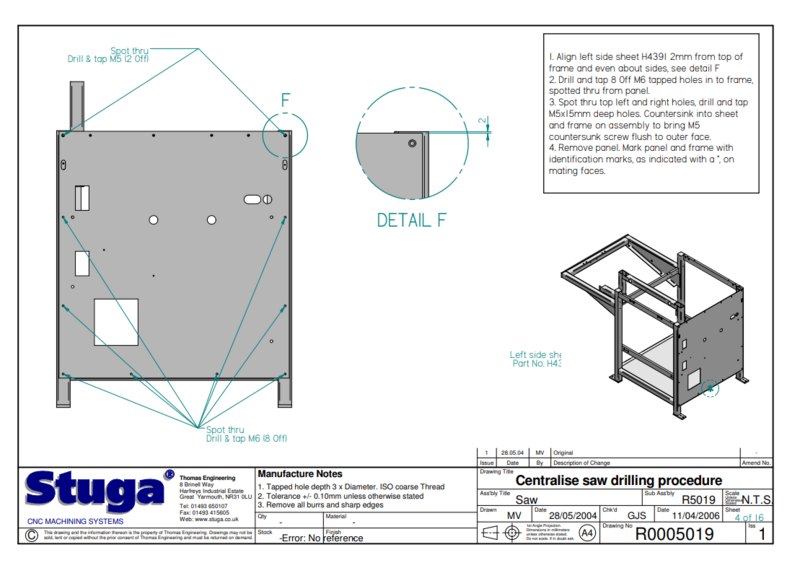

Details to drill to suit guard panels

Sommaire

- 1 Introduction

- 2 Étape 1 - Drill hinge panel

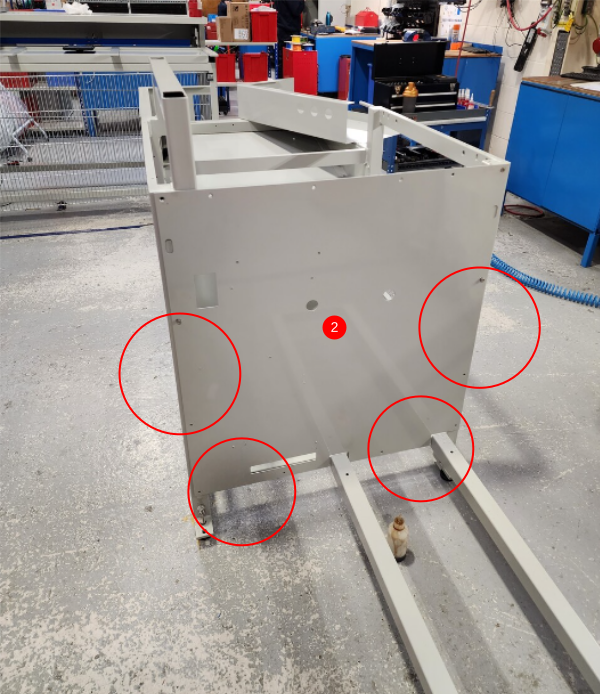

- 3 Étape 2 - Drill Side sheet

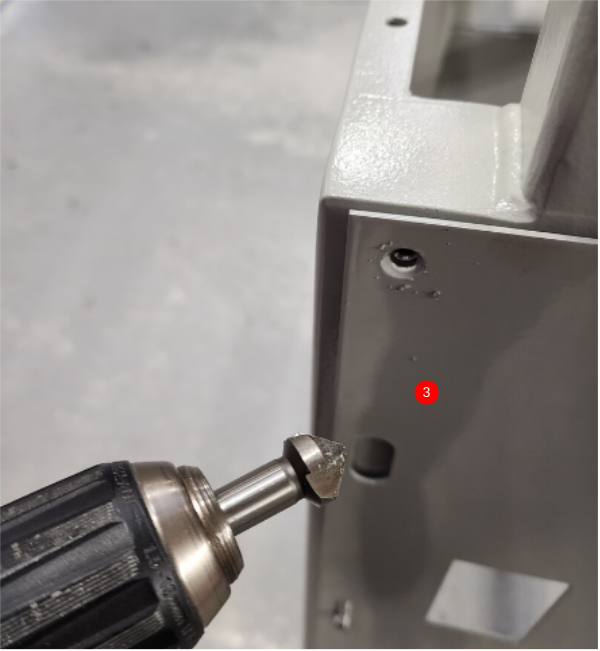

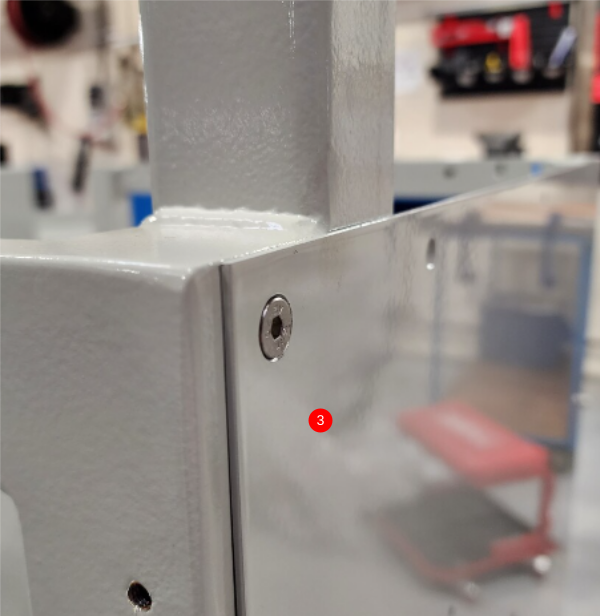

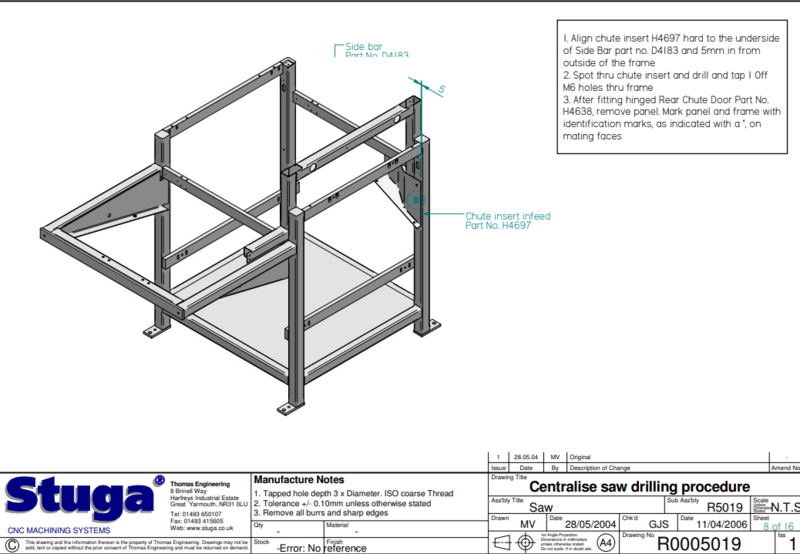

- 4 Étape 3 - Drill rear chute and inserts

- 5 Étape 4 - Drill rear door

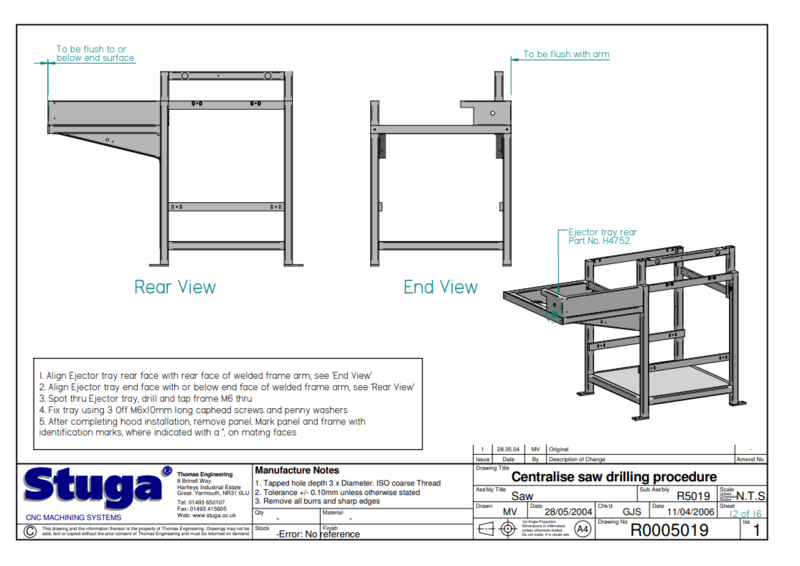

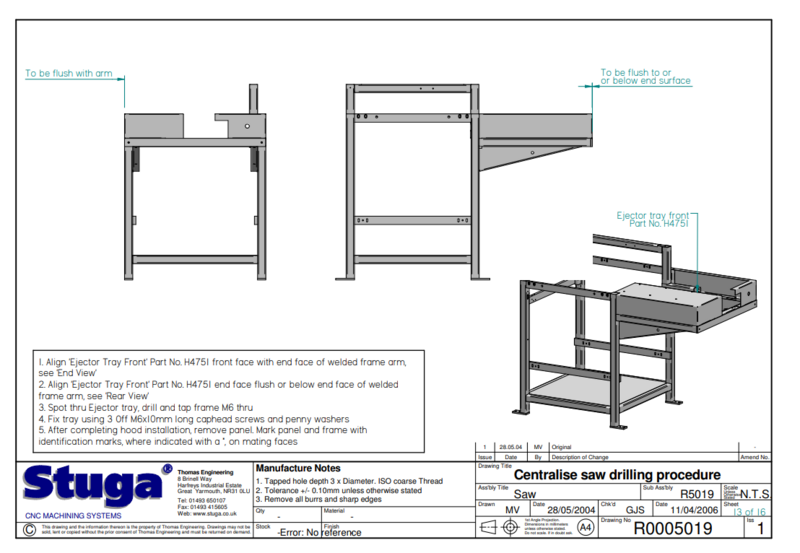

- 6 Étape 5 - Drill rear tray

- 7 Étape 6 - Drill front tray

- 8 Étape 7 - Fit top hood and position

- 9 Étape 8 - Mark Fixing points

- 10 Étape 9 - Drill hood and rear tray

- 11 Étape 10 - Drill and add rivnut Front tray

- 12 Étape 11 - Remove all fitted panels

- 13 Étape 12 - Drill additional tie base

- 14 Étape 13 - Fit stainless undertrays

- 15 Commentaires

Introduction

Tools Required

Standard hex key set

Standard Hss drill set

Standard Tap set

Material clamps

Clamping blocks

Drill

Cutting fluid

Marker pen

Hide hammer

Parts Required

D0000330 Rear Chute Panel (500mm) x 1

D0004391E LF Side Sheet Mk5 (5395E) x 1

D0004576E Saw Centre Frame Mk5 (5343E) Standard Hand x 1

D0010967 Saw Mk5 Undertray x 2

D0015238 Saw Top Hood ZX5 x 1

H0004649 Chute Insert Outfeed (5321) x 1

H0004697 Chute Insert Infeed (5322) x 1

H0004751 Ejector Tray Front (5323) x 1

H0004752 Ejector Tray Rear (5324) x 1

H0004846 Right Side Hinged Panel x 1

D0001878 Rear saw door x 1

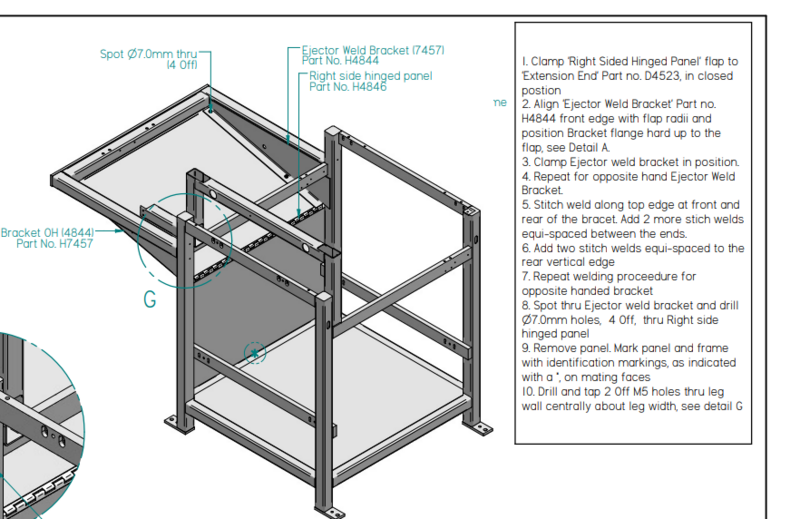

Étape 1 - Drill hinge panel

Drill hinge panel as detailed

1 Clamp panel in position equalising edges to frame

2 Drill vertical face holes onto frame M6 tapped

3 Mark 4 off holes with M6 pointed grubscrew

4 Drill 4 off to 7.5 mm

5 Check correct drilling by fixing panel with M6 socket caps

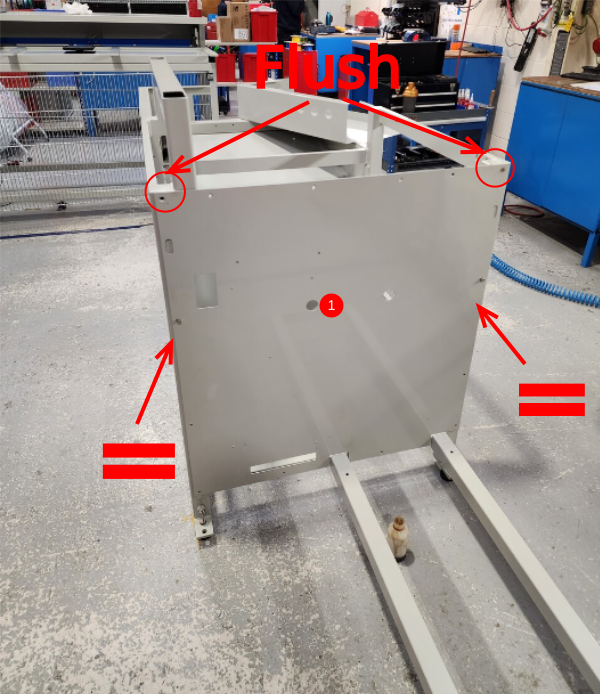

Étape 2 - Drill Side sheet

1 Clamp panel in place. Set equal position side ways and flush to top face

2 Drill 8 off M6 tapped holes as shown

3 Drill and tap M5 , then countersink to allow flush fitment of M5 countersunk bolt

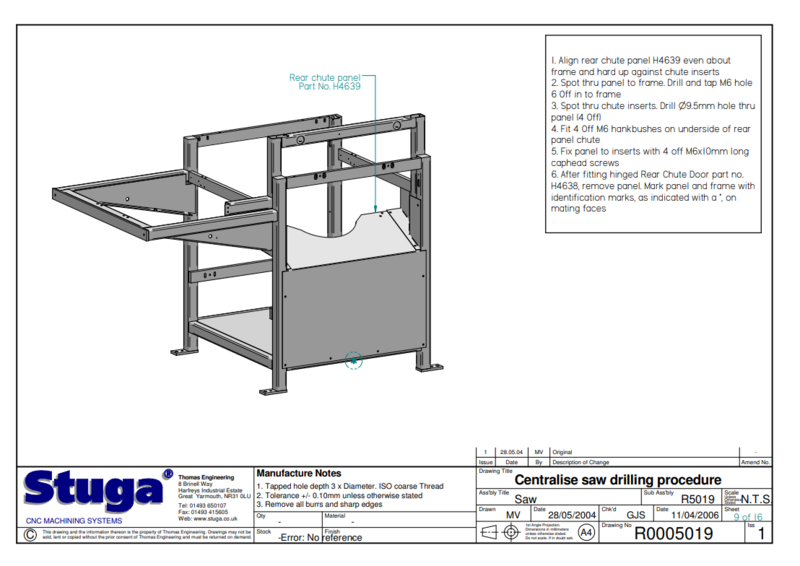

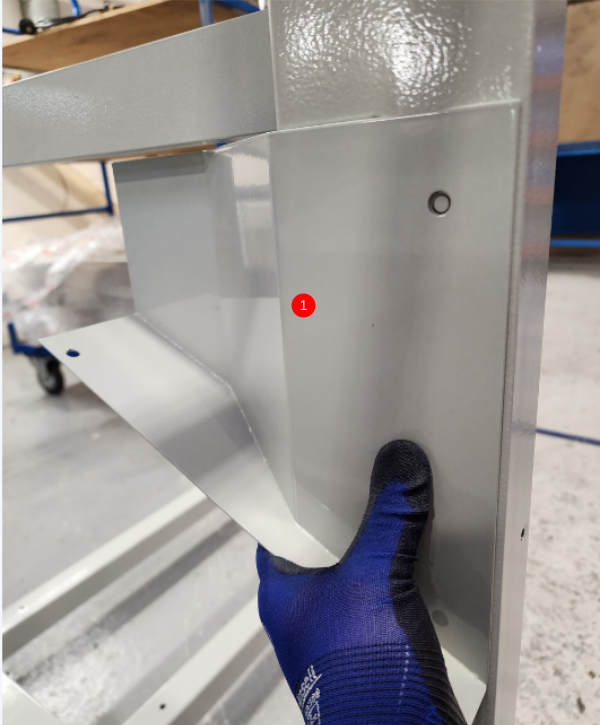

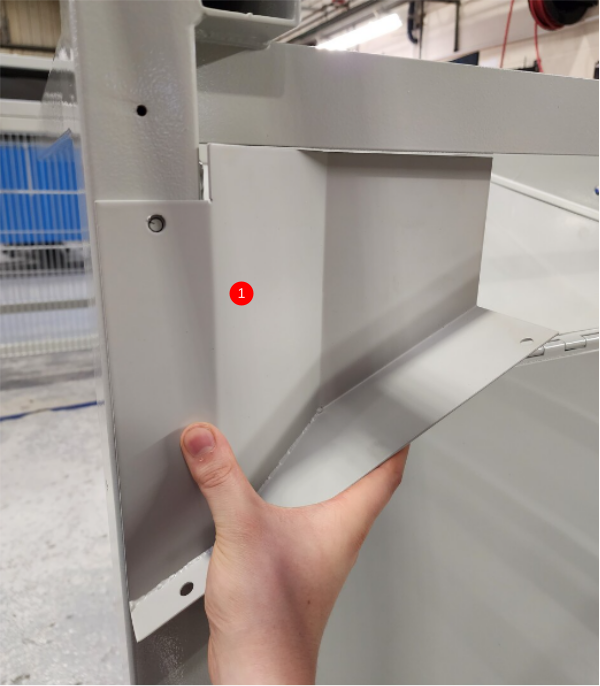

Étape 3 - Drill rear chute and inserts

1 Drill infeed and outfeed chute inserts 1 off M6 tapped per insert

Align as shown

Pictures required please

2 Drill and fit main rear chute as detailed

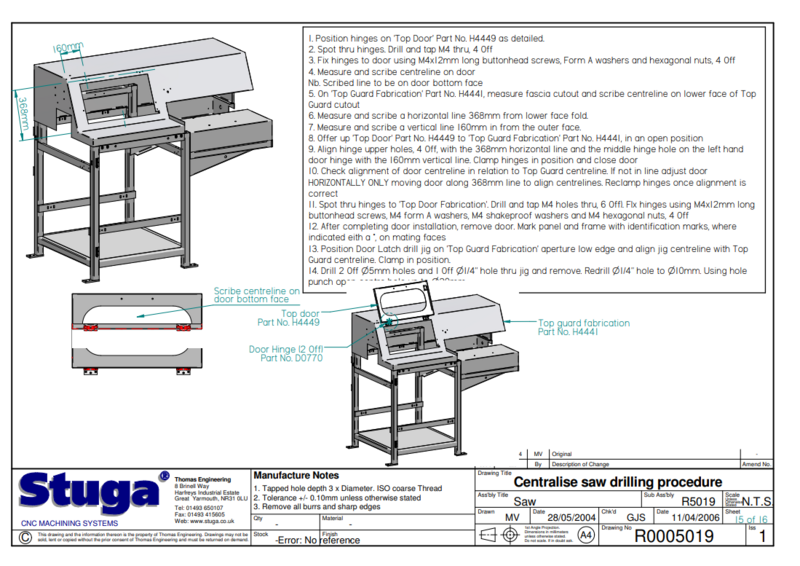

Étape 4 - Drill rear door

1 Position door above rear chute panel

Pictures of below required please

2 Align height so inner door lip is below chute panel lip

3 check to of door is above frame top crossmember

4 Drill 4 off M6 tapped holes for fixing to frame

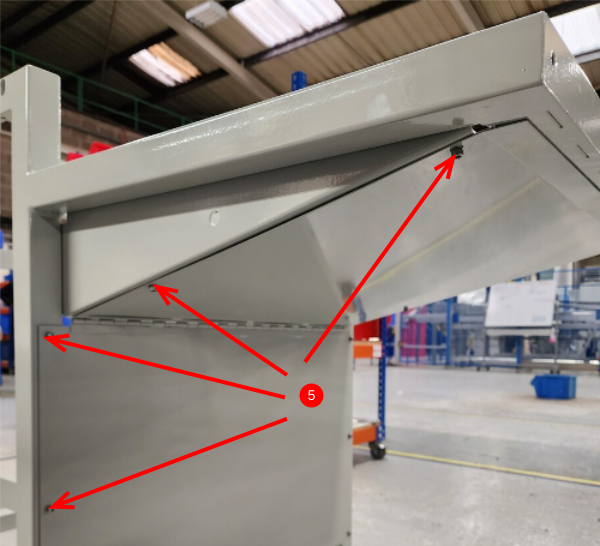

Étape 6 - Drill front tray

Set front tray flush with all edges shown

Mark and drill Panel M6 tapped,

Ecr raised to amend panel 10/11/23

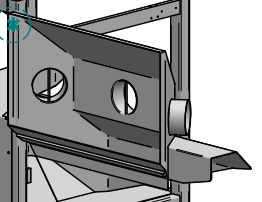

Étape 7 - Fit top hood and position

1 Lift hood onto frame

2 Clamp hood into position , ensuring all faces are set flush with frame

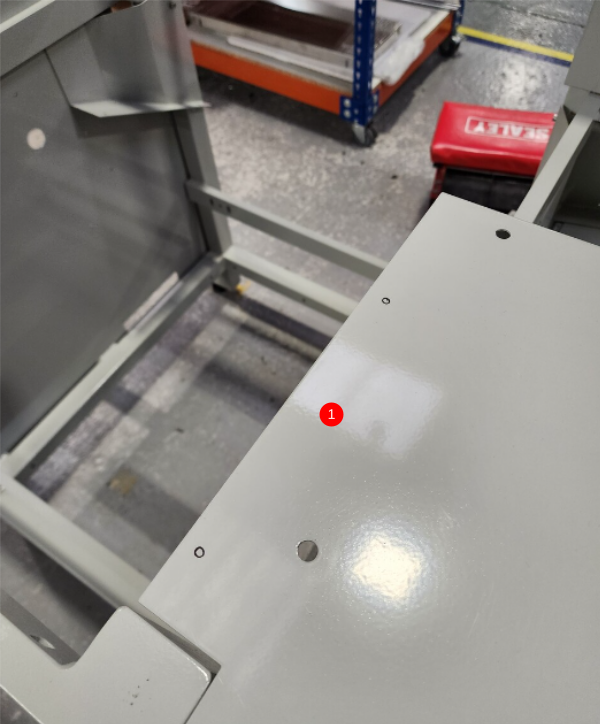

Étape 8 - Mark Fixing points

1 Mark 4 off fixing points with 7.5mm drill

2 Mark 3 off rear hood points by using M6 x 10 pointed grubscrews , winding into lower panel and impacting with hammer

3 Set top hood position even to front tray

4 Remove hood from frame

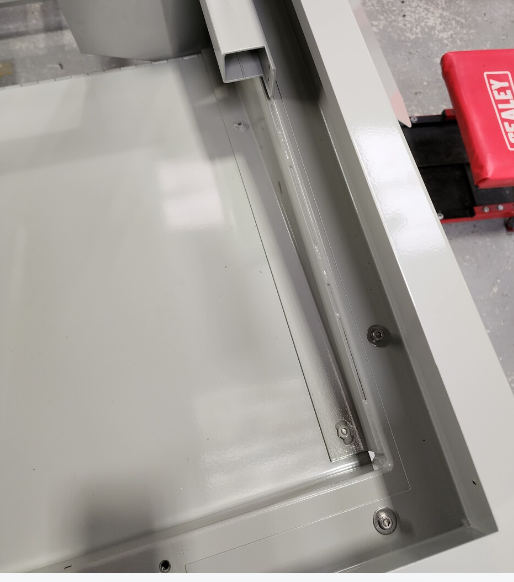

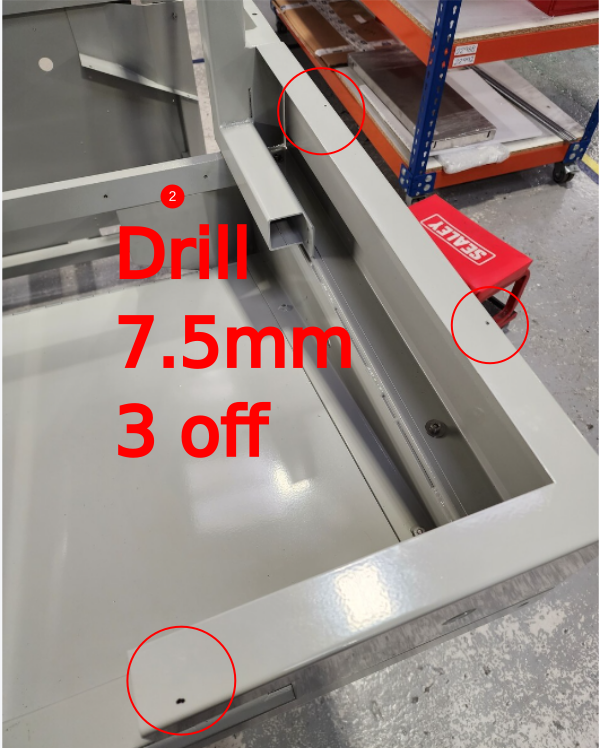

Étape 9 - Drill hood and rear tray

1 Drill 4 off marked holes on hood to M6 tapped , add small countersink to face indicated to aid fitment to frame

2 Drill rear tray to 7.5mm at points indicted by grubscrews

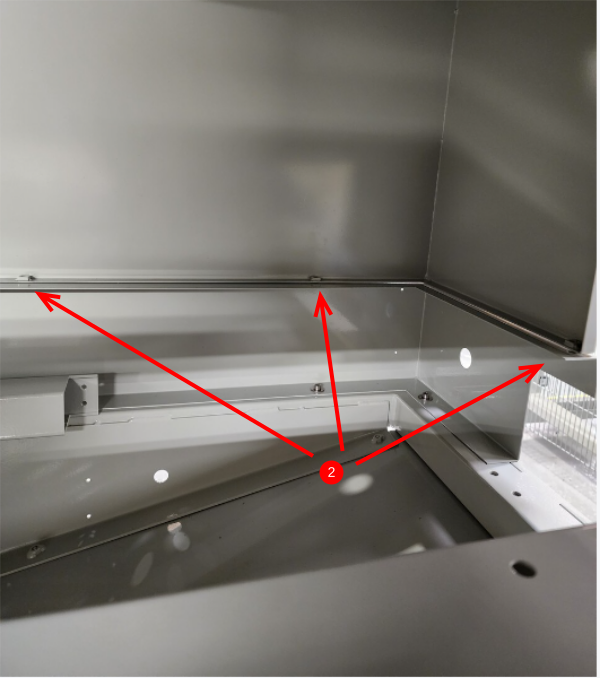

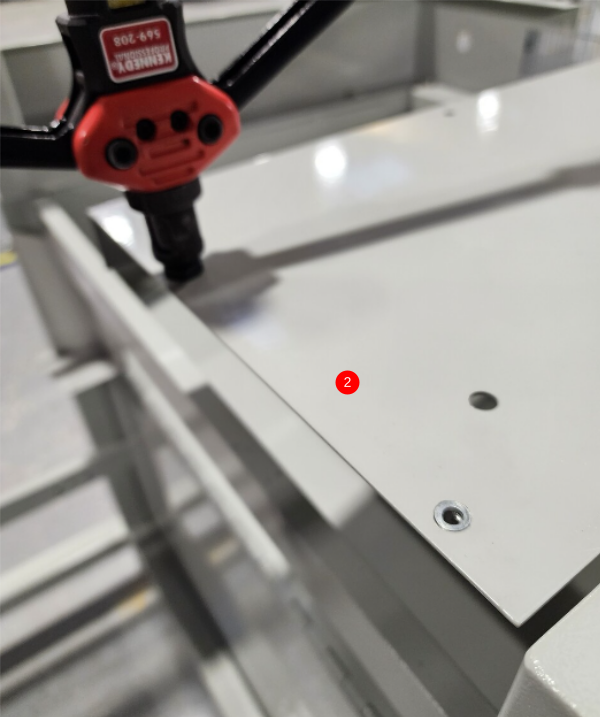

Étape 10 - Drill and add rivnut Front tray

1 Drill marked positions to correct core size (please provide size) for M5 rivnut. Add small countersink to hole to allow flush fitment

2 Use rivnut applicator to insert and fix 2 off M5 rivnuts

Étape 11 - Remove all fitted panels

Remove all panels

Clean all swarf from frame and clean paintwork

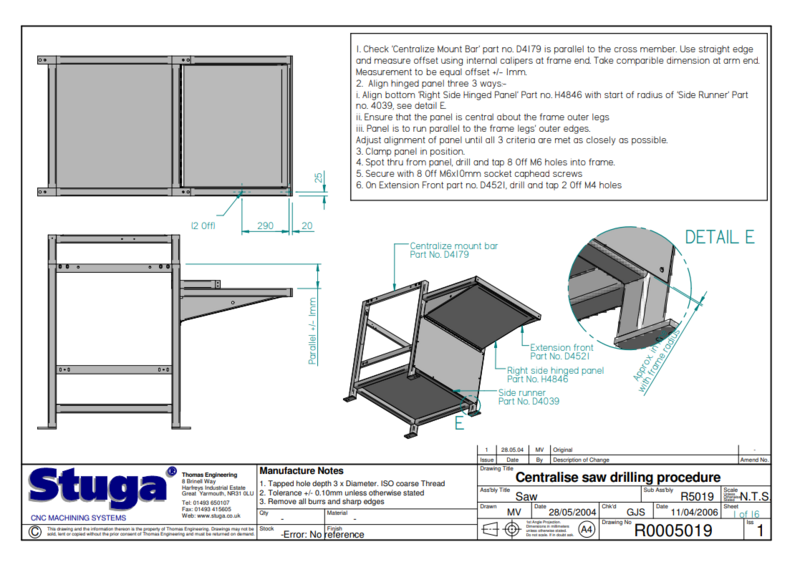

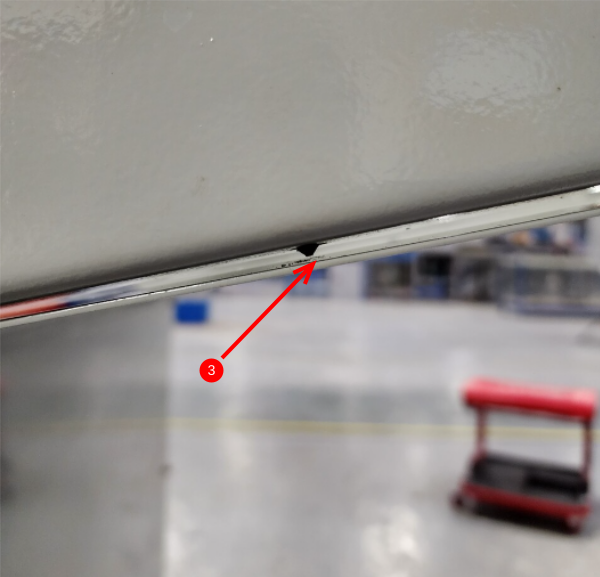

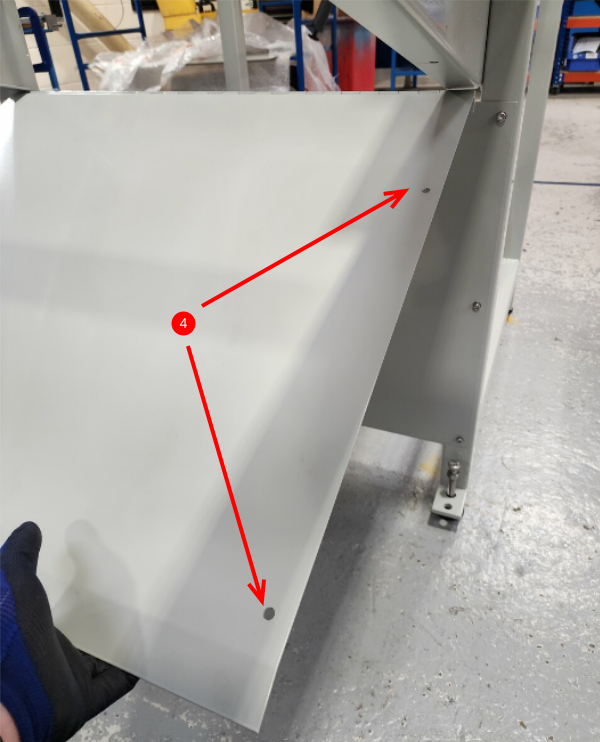

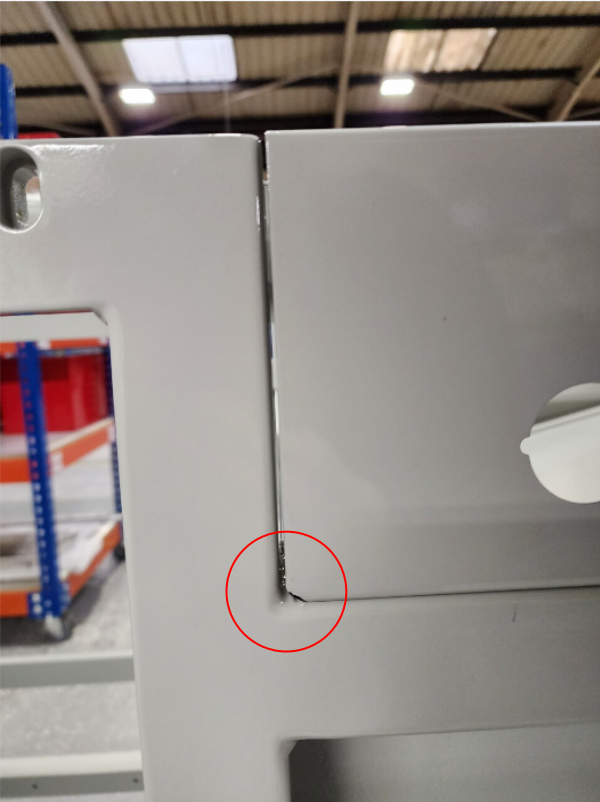

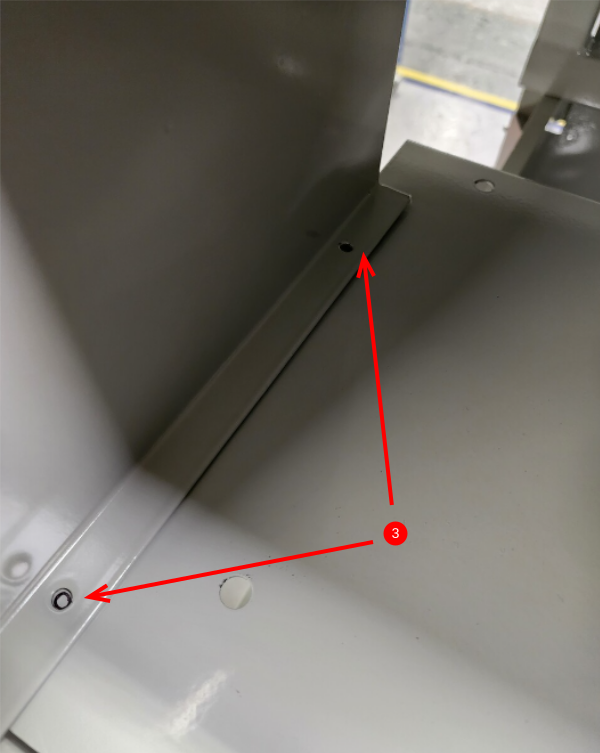

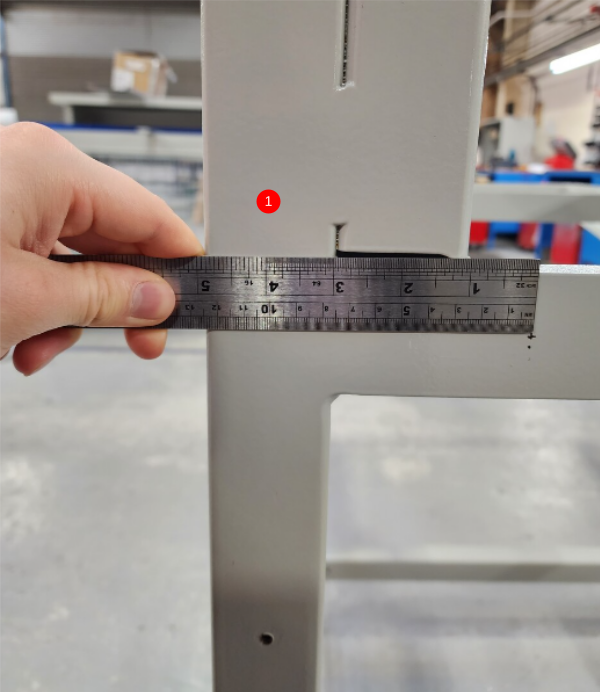

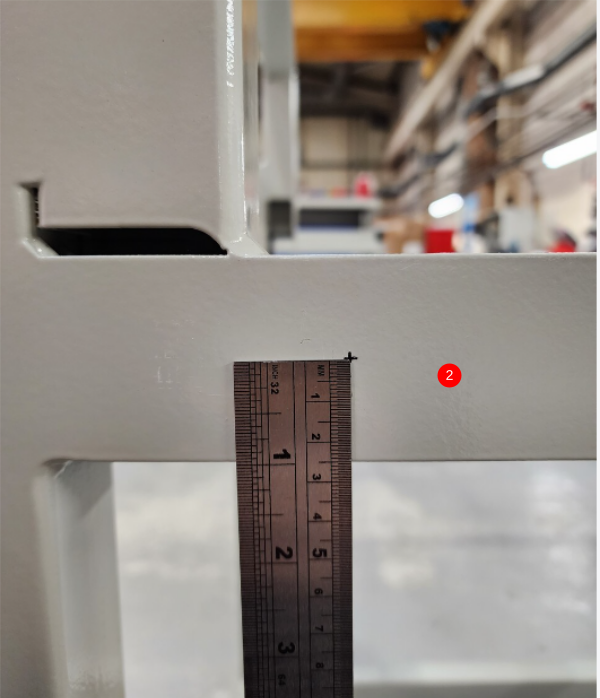

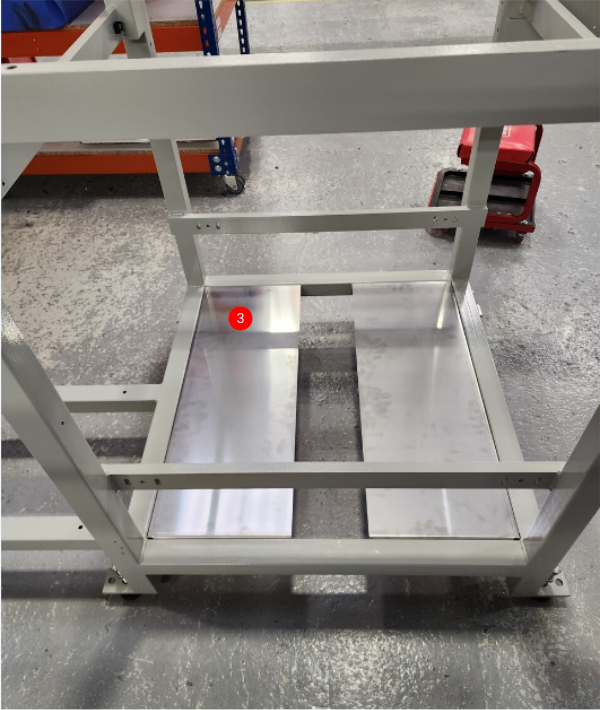

Étape 12 - Drill additional tie base

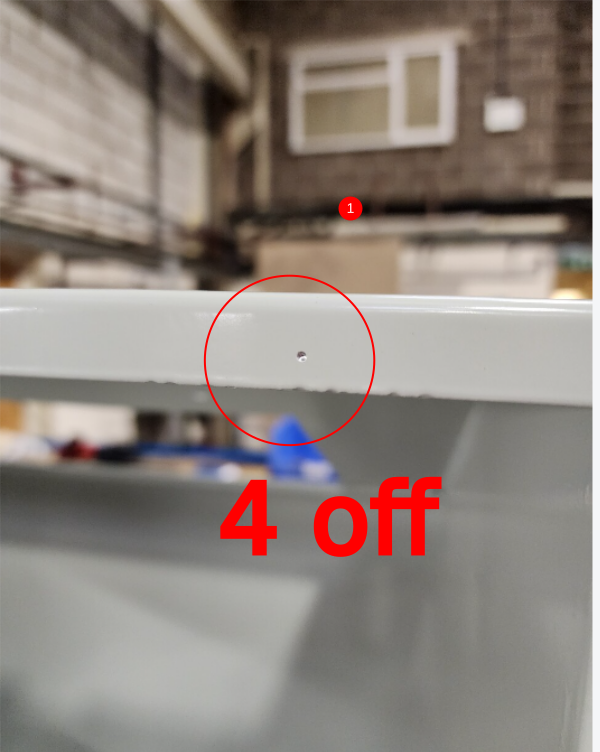

Drill and tap additional M5 at point indicated, drill through

1 position 125mm

2 position 25mm

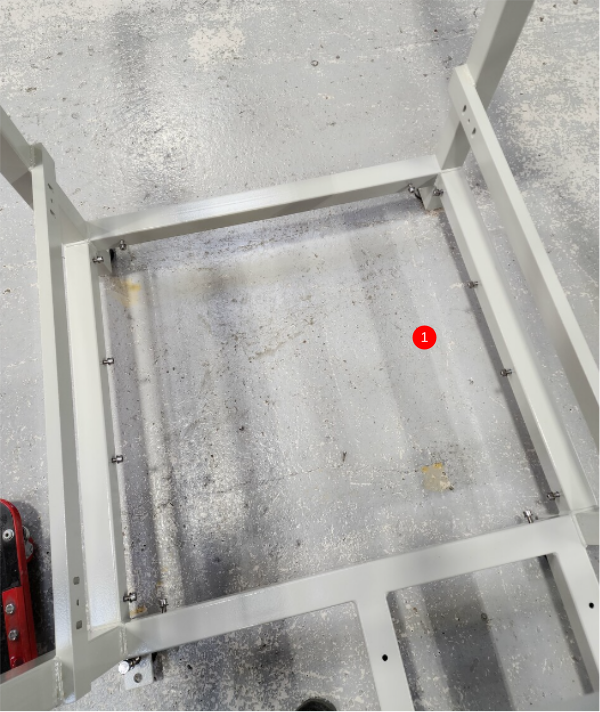

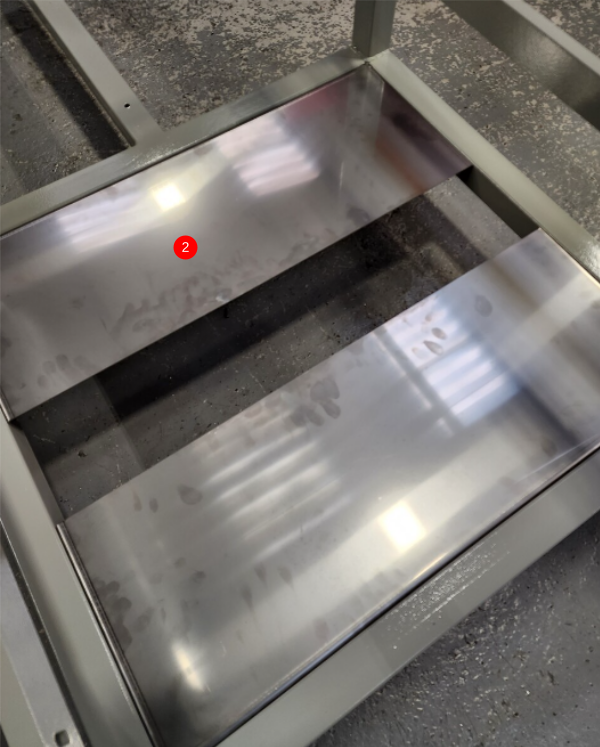

Étape 13 - Fit stainless undertrays

1 Fit 16 off M8 x 16 socket caps with M8 A form washers at the points indicated. Add loctite 243 as fitting bolts

Leave enough clearance for trays to slot over

2 Position stainless trays as shown

3 Adjust height of trays to fit flush with top of frame and finalise bolts to secure

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português