| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 58 : | Ligne 58 : | ||

Bolts must be pen marked when finalised</translate> | Bolts must be pen marked when finalised</translate> | ||

|Step_Picture_00=R0000712E_Rotary_Trunking_Screenshot_2023-05-31_084239.png | |Step_Picture_00=R0000712E_Rotary_Trunking_Screenshot_2023-05-31_084239.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>All Air fittings must have sealant applied</translate> | ||

| + | |Step_Content=<translate>All threaded pneumatic fittings MUST have adequate Loctite572 applied | ||

| + | |||

| + | |||

| + | The ring has an anti drop system for tooling on emergency stop, and presence of any air leaks will affect this feature</translate> | ||

| + | |Step_Picture_00=R0008013_Clacker_assembly_quality.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version du 11 décembre 2023 à 15:17

Pre Assembly of drive cylinders with sensors

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - All Air fittings must have sealant applied

- 4 Étape 3 - Mount single plunge home sensor

- 5 Étape 4 - Attach air fittings to single plunge cylinders

- 6 Étape 5 - Attach sensor bracket to Single plunge cylider

- 7 Étape 6 - Fit single out sensor

- 8 Étape 7 - Attach air fittings to double plunge cylinders

- 9 Étape 8 - Mount double plunge cylinder sensors

- 10 Étape 9 - Mount magnet to cylinder anchor

- 11 Commentaires

Introduction

Tools Required

Standard spanner set

Small screwdriver set

Reed switch test box

Araldite 2 part adhesive

Parts Required

D0015540 sensor bracket x 8

P0000488 Sensor x 8

P0001098 elbow adapter x 12

P0000238 6mm elbow x 8

P0001198 6mm flow elbow x 8

P0000459 4mm elbow x 4

P0001202 4mm flow elbow x 4

P0001200 cylinder x 8

P0001201 cylinder x 4

P0001047 reed switch x 16

D0007630 cylinder anchor x 8

M0001170 magnet x 8

Étape 1 - Unless otherwise stated

Loctite 243 must be used on all bolts

Bolts must be pen marked when finalised

Étape 2 - All Air fittings must have sealant applied

All threaded pneumatic fittings MUST have adequate Loctite572 applied

The ring has an anti drop system for tooling on emergency stop, and presence of any air leaks will affect this feature

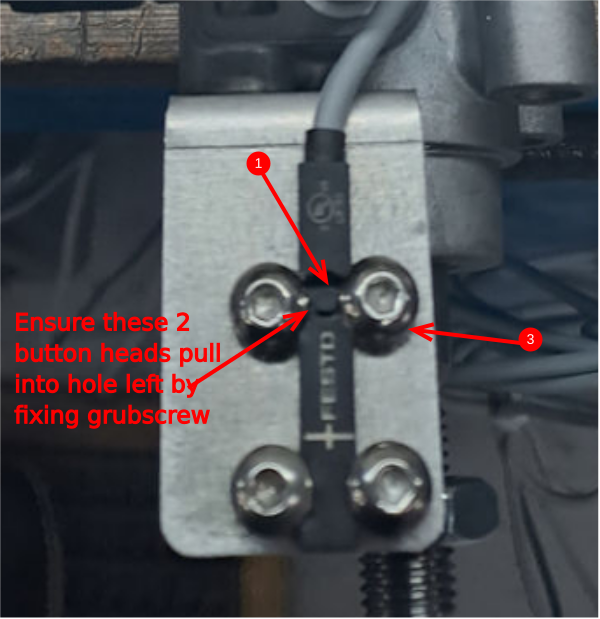

Étape 3 - Mount single plunge home sensor

8 off

1 Remove OEM sensor locking nut from sensors P0000488

2 Label sensors at trailing end SH

3 Use m4 x 6 button heads and attach sensor to D0015540 as shown

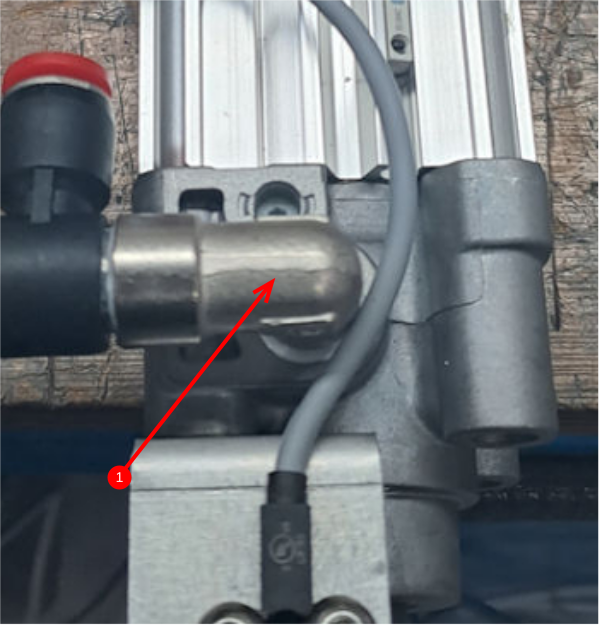

Étape 4 - Attach air fittings to single plunge cylinders

8 off P0001200 cylinder

Use Loctite 572 on all air fittings

1 Attach P0001098 elbow as shown

2 Attach P0001198 elbow

3 Attach P0000238 elbow

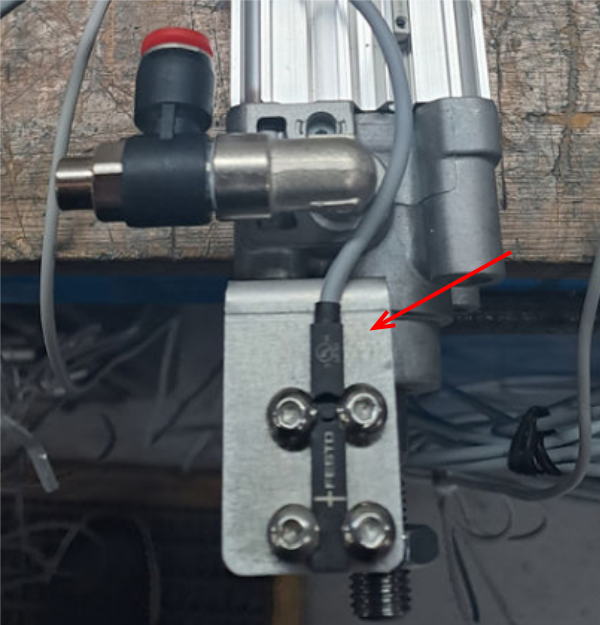

Étape 5 - Attach sensor bracket to Single plunge cylider

8 off

Use 2 off m6 x 16 socket caps to attach sensor bracket to cylinder

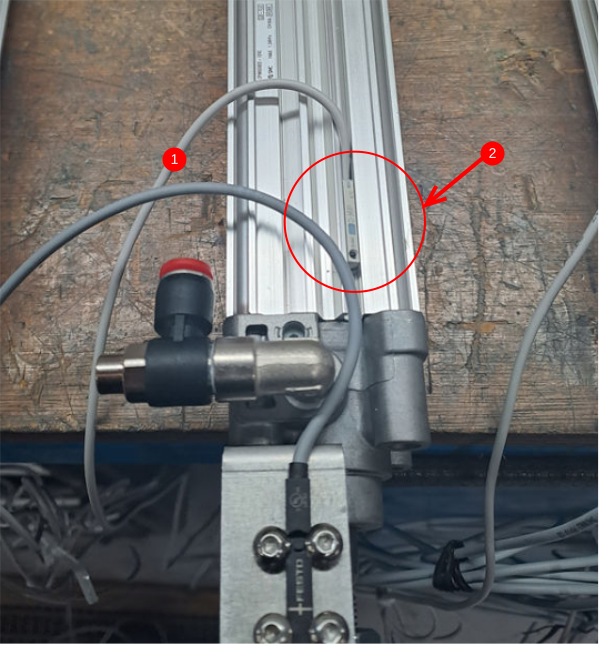

Étape 6 - Fit single out sensor

8 off

1 label 8 off P0001047 sensor SO at connection end

2 Use test box and connect sensor and set position on cylinder with piston extended out of cylinder

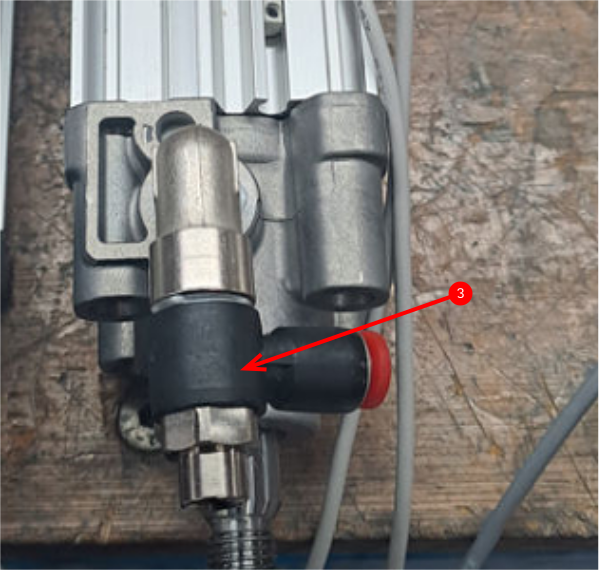

Étape 7 - Attach air fittings to double plunge cylinders

Use Loctite 572 on all air fittings

4 off Cylinder P0001201

1 Attach P0000459 4mm elbow

2 Attach P0001098 elbow

3 Attach P0001202 flow regulator elbow

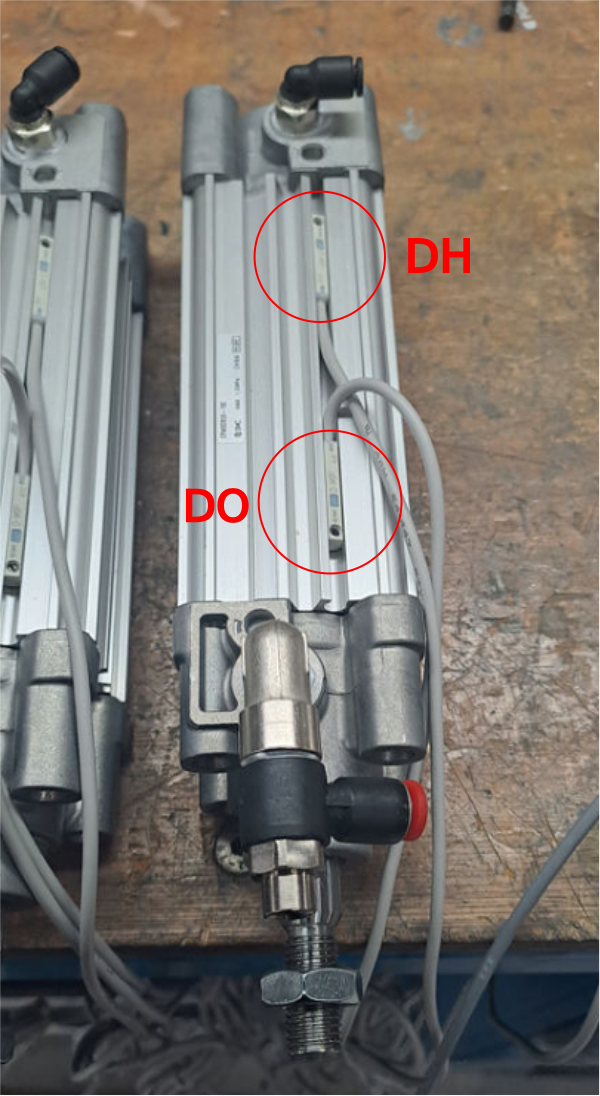

Étape 8 - Mount double plunge cylinder sensors

Mark 4 off sensors P0001047 at connection end DO

Mark 4 off sensors P0001047 at connection end DH

Use test box and set reed switches in position on cylinders orientated as shown in picture

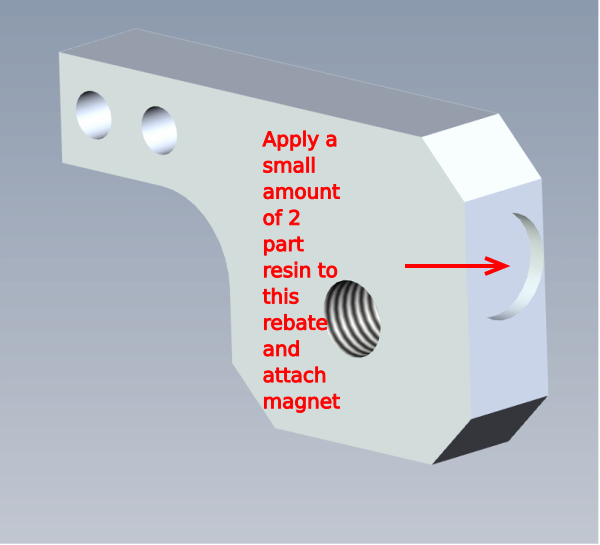

Étape 9 - Mount magnet to cylinder anchor

M0001170 magnet must have additional adhesive applied to be adequately attached to D0007630 cylinder anchor

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português