| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 347 : | Ligne 347 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Aligning Saw to saw infeed</translate> | |Step_Title=<translate>Aligning Saw to saw infeed</translate> | ||

| − | |Step_Content=<translate># Y axis alignment | + | |Step_Content=<translate>#Y axis alignment |

Saw back fence and saw infeed back fence are used for y axis alignment . Saw back fence should be slightly in front of saw infeed back fence. Around 1mm | Saw back fence and saw infeed back fence are used for y axis alignment . Saw back fence should be slightly in front of saw infeed back fence. Around 1mm | ||

Version du 6 décembre 2023 à 16:30

Key Steps for mechanical installation of ZX5

Sommaire

- 1 Introduction

- 2 Étape 1 - Information links

- 3 Étape 2 - Module Positioning

- 4 Étape 3 - Module order of positioning and levelling

- 5 Étape 4 - Identify correct factory location and set position

- 6 Étape 5 - Support post installation

- 7 Étape 6 - Levelling of multi outfeed or saw infeed Y axis

- 8 Étape 7 - Check reference points

- 9 Étape 8 - Levelling of multi outfeed or saw infeed X axis

- 10 Étape 9 - Position 2nd frame Saw infeed or Multi head outfeed

- 11 Étape 10 - Adjust height of 2nd levelled frame to match first

- 12 Étape 11 - Add 2 Transfer beams and Parallel set between hepco Rails

- 13 Étape 12 - Check and Set squareness of transfer table

- 14 Étape 13 - Add remaining transfer beams

- 15 Étape 14 - Check flatness of transfer beam top faces

- 16 Étape 15 - Check roller alignment

- 17 Étape 16 - Multi head levelling points

- 18 Étape 17 - Alignment of Machining center to outfeed table

- 19 Étape 18 - Machining centre Infeed levelling

- 20 Étape 19 - Saw Machining centre Leveling

- 21 Étape 20 - Aligning Saw to saw infeed

- 22 Étape 21 - Saw outfeed table levelling points

- 23 Étape 22 -

- 24 Étape 23 -

- 25 Étape 24 - Module B Machining centre installation

- 26 Commentaires

Introduction

Key data for installation of ZX5

Dokit to generate consistency of installation

Quality checks for installation

Étape 1 - Information links

In each step if applicable, Manufacturing links have been included to aid the installation progress for correct understanding of assembly process to achieve desired results

Please use the links if any adjustments have to be made on site, as critical measurements and setting details will be provided within the build data

Please ensure any quality/ discrepancies are correctly reported if encountered

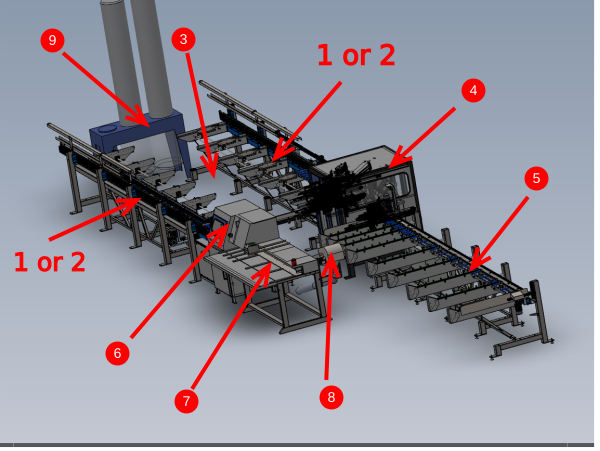

Étape 2 - Module Positioning

Identify if either saw infeed or multi head outfeed is the logical frame to place first .

Consider access to machine when installing 1st frame

Consider handing of machine

Étape 3 - Module order of positioning and levelling

- Saw infeed or Multi head outfeed

- multihead outfeed or saw infeed

- transfer table

- Machining centre

- Machining centre infeed

- Saw module

- Saw outfeed table

- Conveyor

- Extraction

- Guarding

Étape 4 - Identify correct factory location and set position

Position first frame identified to be first and set parallel to installation area

Take into consideration walkways, access one machine is installed and service connections

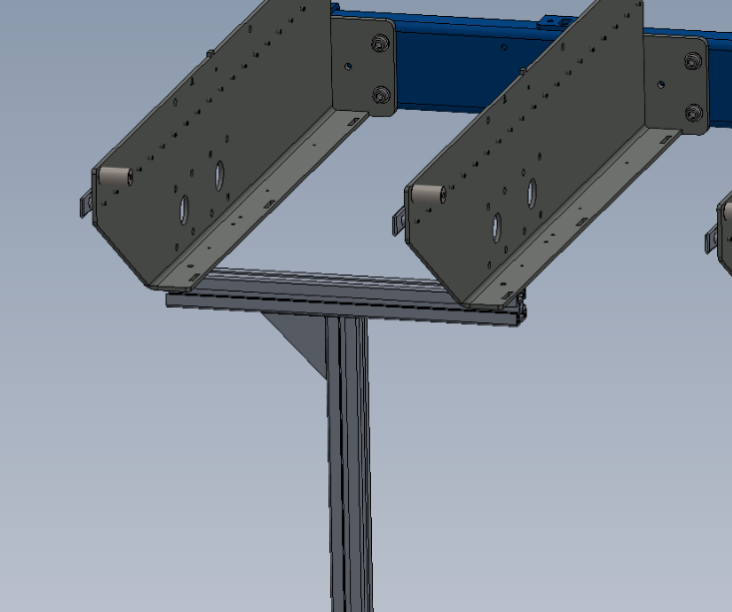

Étape 5 - Support post installation

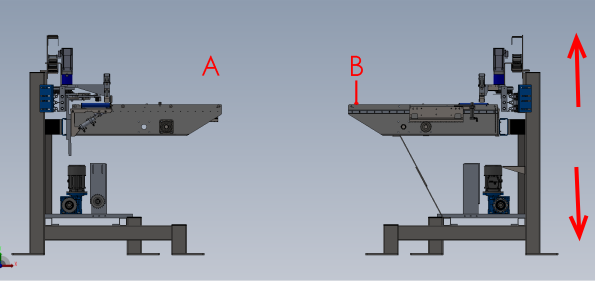

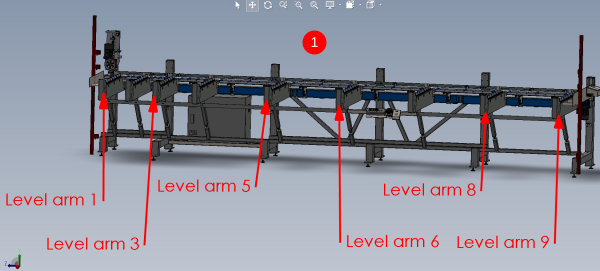

It is vital the support arm is utilized at this point to allow correct adjustment of position 1 and 2 support arms

Use the adjustment in the foot to correctly level arms 1 and 2

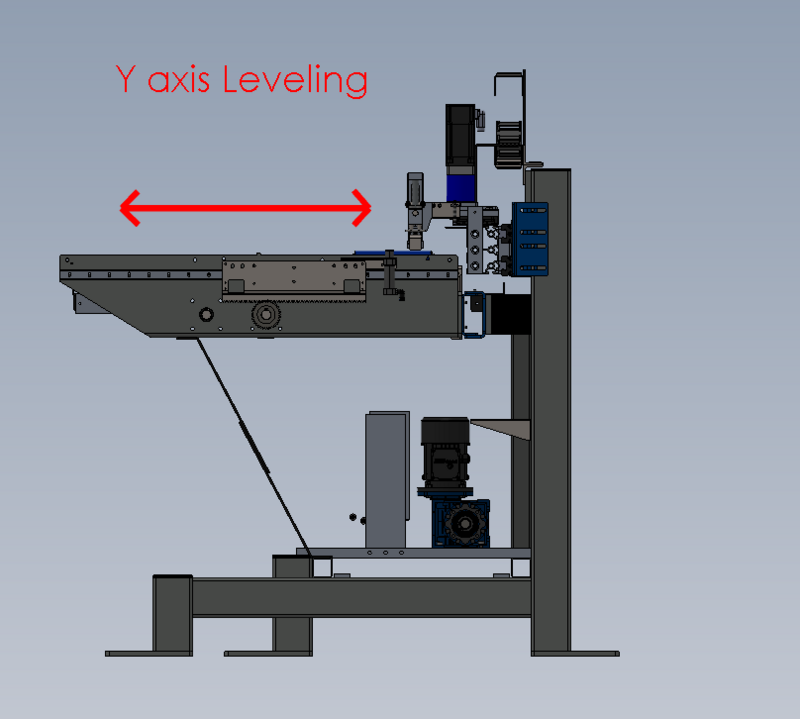

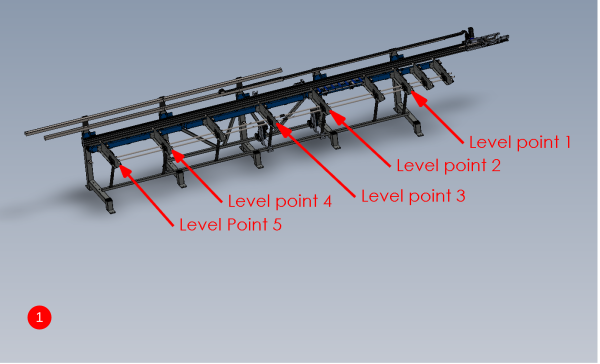

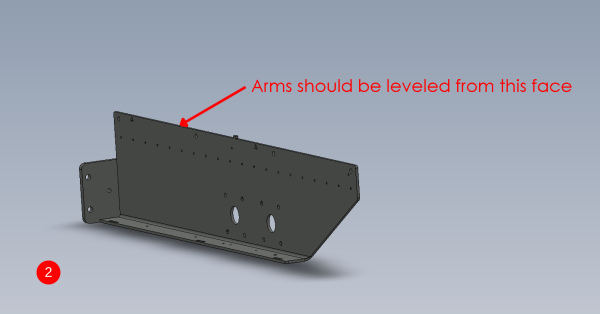

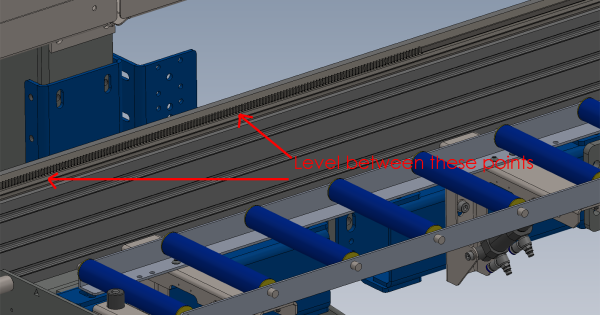

Étape 6 - Levelling of multi outfeed or saw infeed Y axis

Both frames will be initially levelled in the same way, and then fine tuned once multi head or saw is installed

Y axis levelling

- Only level the arms at the positions indicated, as these are the only arms that sit directly above adjustment feet

- Level support arms from the indicated face

Étape 7 - Check reference points

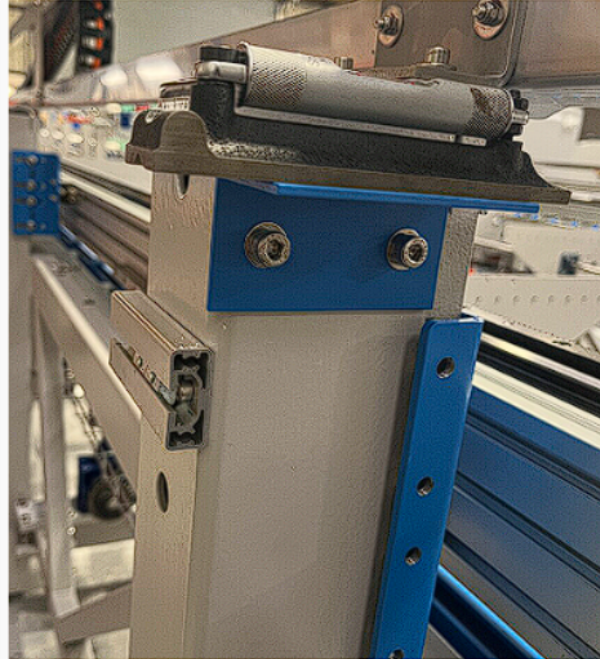

Once the previous step has been performed, reference brackets should be checked to confirm factory setting has been achieved

The levelling brackets indicated should match the level of the support arms

Discrepancy should be immediately reported

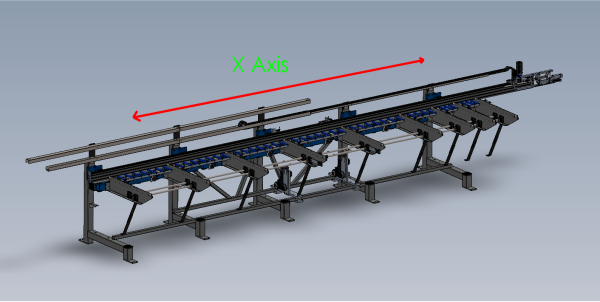

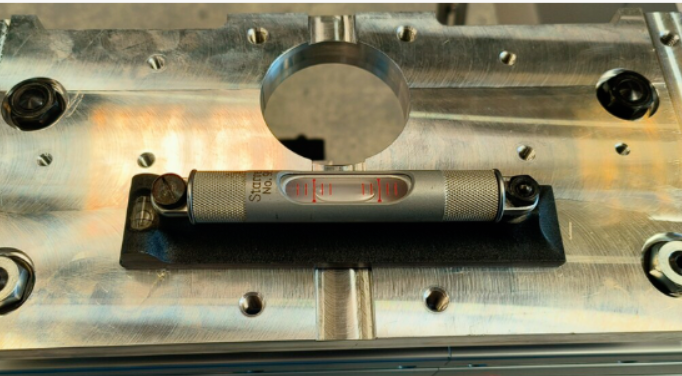

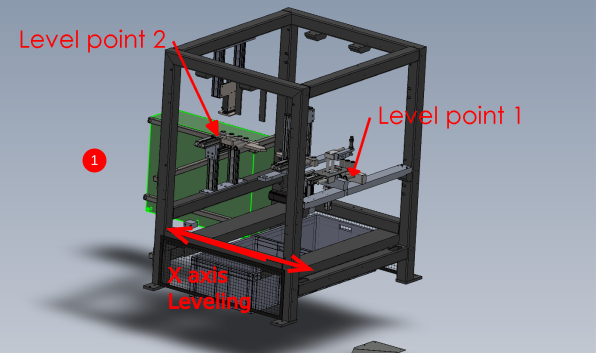

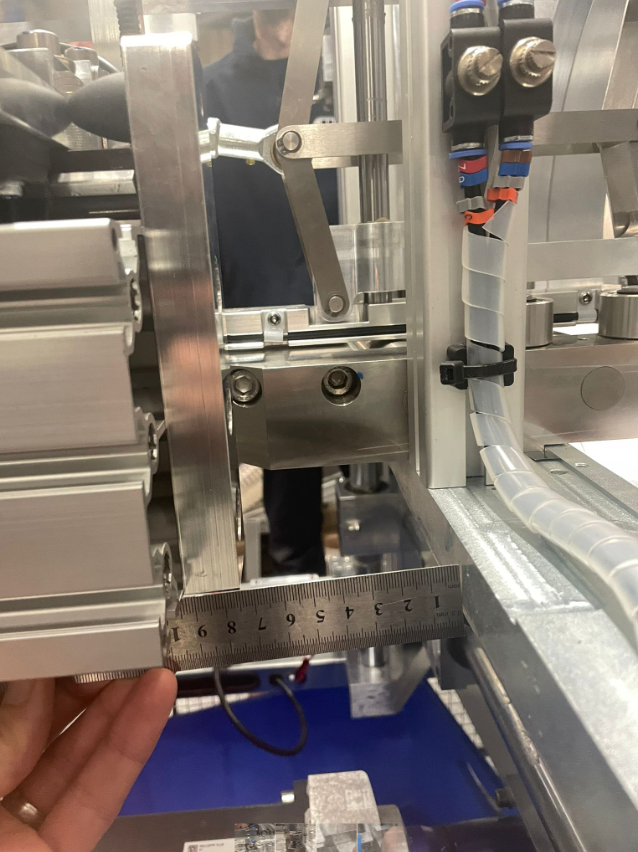

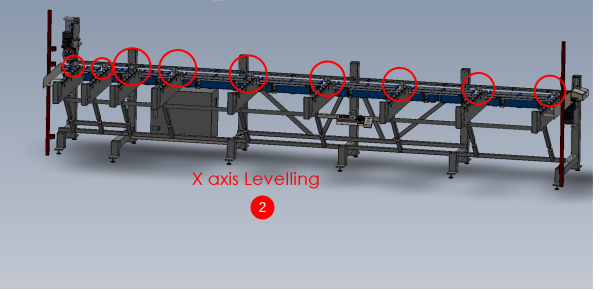

Étape 8 - Levelling of multi outfeed or saw infeed X axis

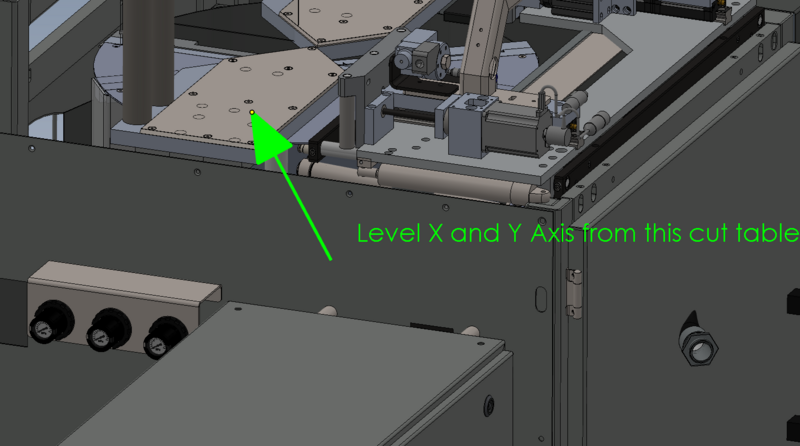

X axis is initially set up using the carriage plate as a register. Once additional units are installed and levelled , this x axis setting will be re checked and adjusted if required

Please note photo of level is taken from production stage. It is to give reference of the part to be used to to set X axis level. Position level at available point on assembled carriage plate

R0015028D ZX5 Hepco Beam Alignment Module C

R0015028D ZX5 Hepco Beam Alignment Module C part 2

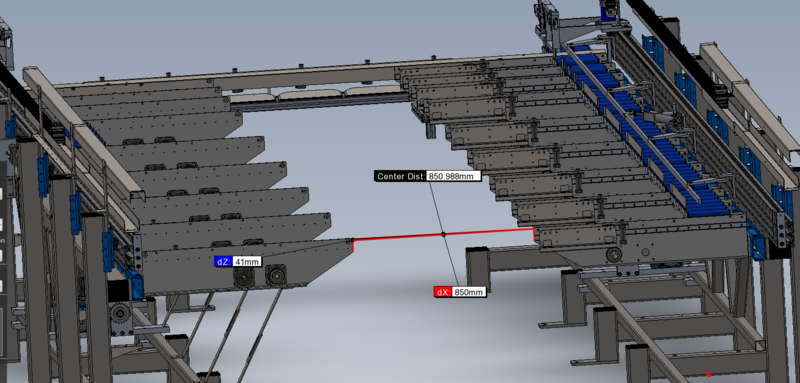

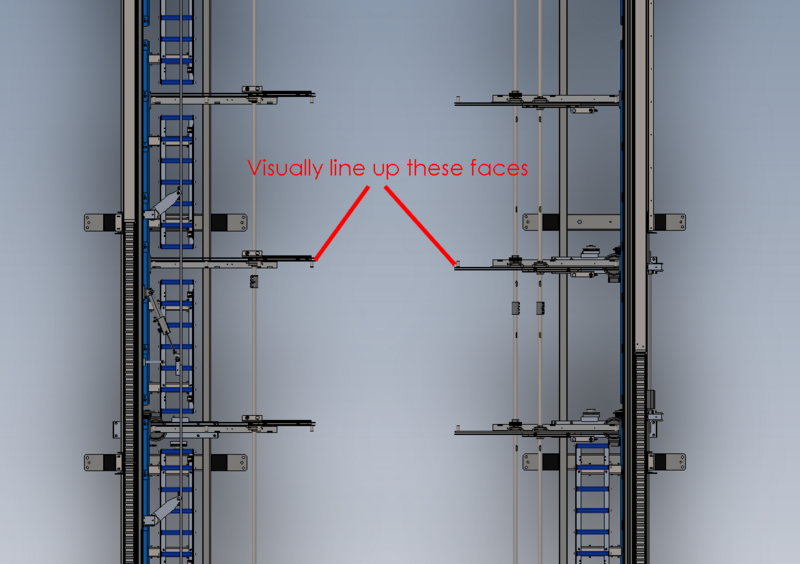

Étape 9 - Position 2nd frame Saw infeed or Multi head outfeed

- Position second frame opposing first one which has been levelled

- Use measurement shown to set the frames roughly the correct distance apart

- Move the frame on the x axis to visually line up the support arms on both frame

- Level second frame using steps for levelling first frame above

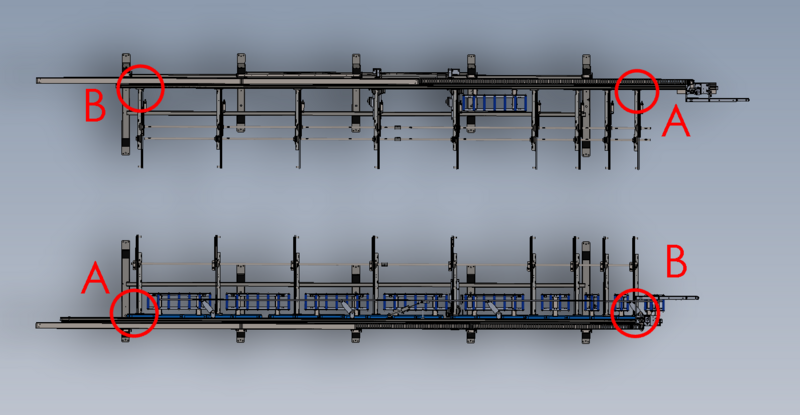

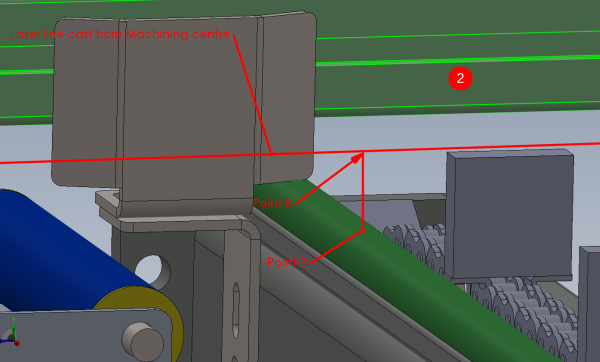

Étape 10 - Adjust height of 2nd levelled frame to match first

Points A and B should be level with each other.

Adjust 2nd frame up or down on all frame bolts to achieve this

Take care not to effect previous level settings when adjusting height

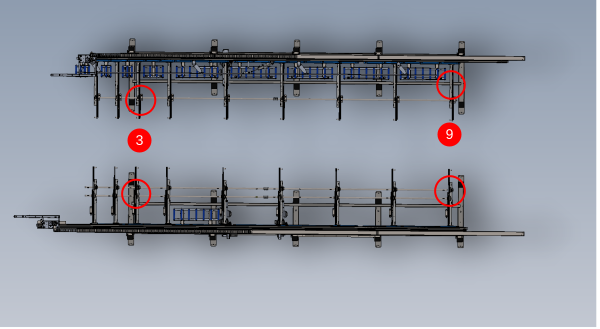

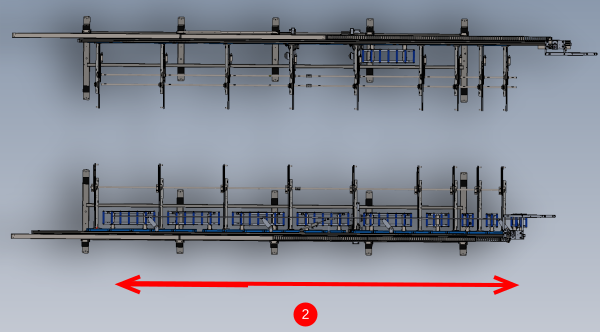

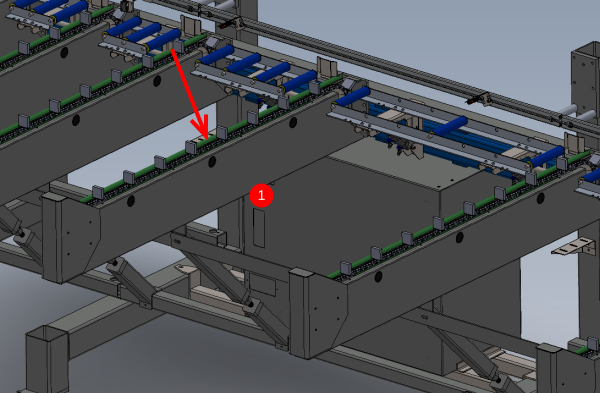

Étape 11 - Add 2 Transfer beams and Parallel set between hepco Rails

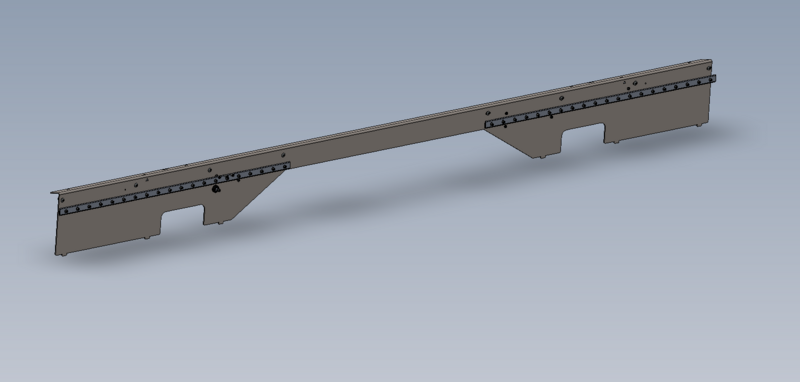

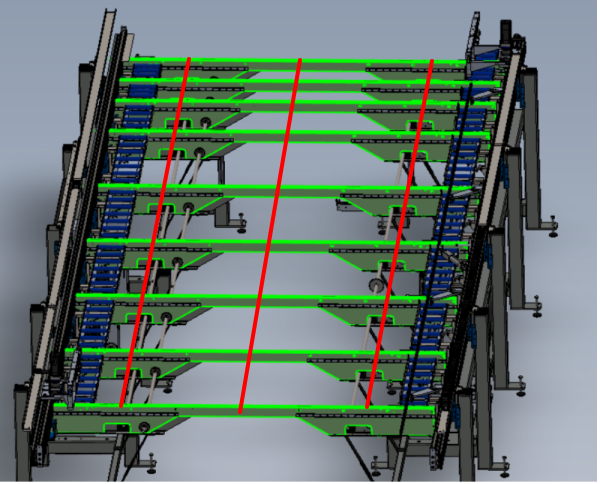

- Attach transfer beams 3 and 9 in there locations

- Add fasteners to beams to secure but leave loose enough for adjustment

- Measure the distance between the 2 hepco rails at the points shown on diagram 2 . Both indicated measurements should be the same . If not the slot in the transfer beam can be used to allow adjustment of this measurement to correct . Tolerance -+ 1mm

- Tighten transfer beam fixings to hold frames in correct position

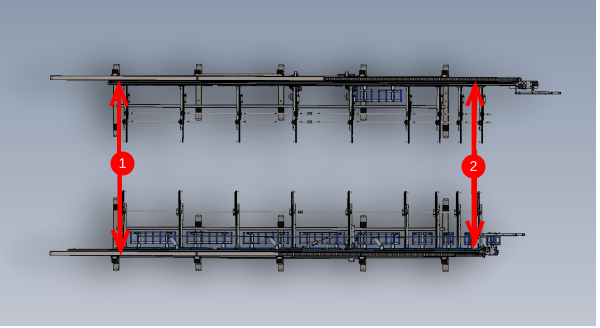

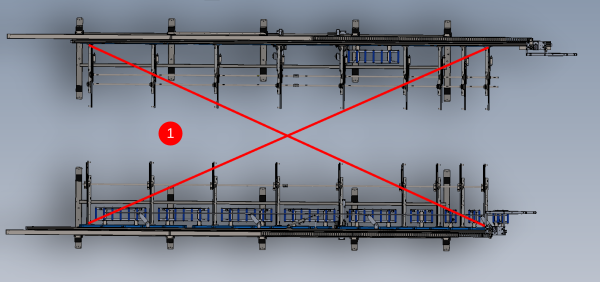

Étape 12 - Check and Set squareness of transfer table

It is crucial to set the squareness of the transfer table by adjusting the infeed/ outfeed tables.

1 The squareness can be checked by using a tape rule to make corner measurements at the points indicated

2 Second frame can be moved in the directions shown to adjust the corner measurements to make them both the same

Tolerance -+ 3mm

R0015291 Install Transfer Beams To Module C and E

Étape 13 - Add remaining transfer beams

Add remaining 7 transfer beams to two installed frames and fix in position on support arms

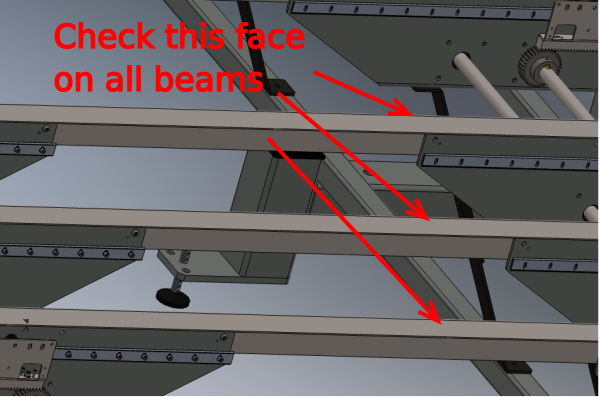

Étape 14 - Check flatness of transfer beam top faces

Once all transfer beams are installed, it is vital to check that the top faces or the transfer beams are all aligned to each other and provide a flat table for correct profile transfer

Use 2 meter straight edge to inspect top faces in relation to each other

Étape 15 - Check roller alignment

Check X axis alignment of horiczontal and vertical rollers using 2 meter straight edge and feeler gauges

Any discrepancy must be reported and rectified if present

Tolerance 0.002" / 0.05mm

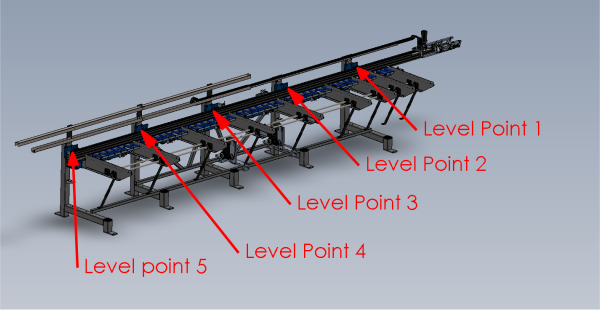

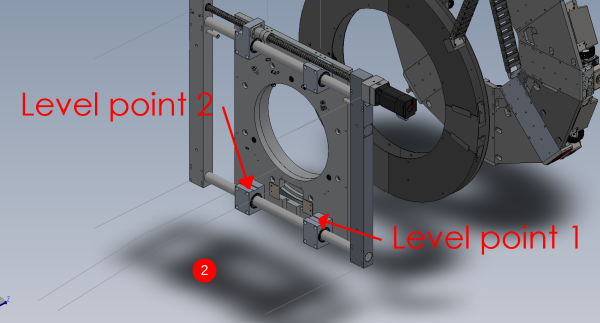

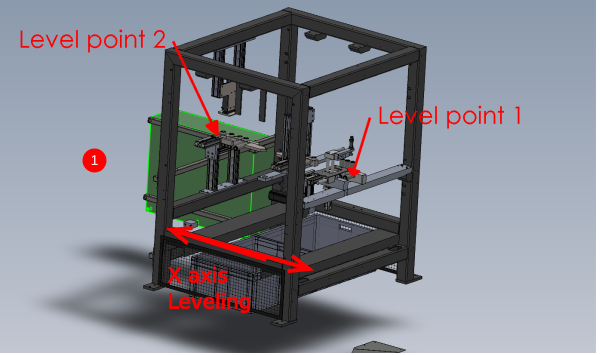

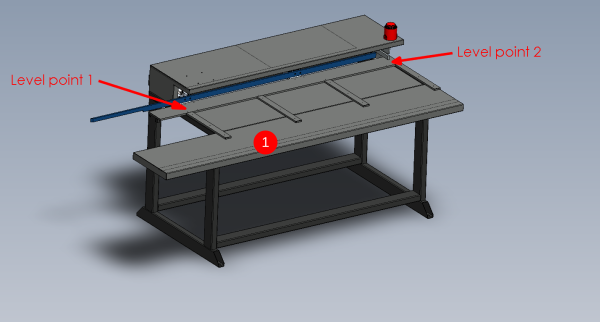

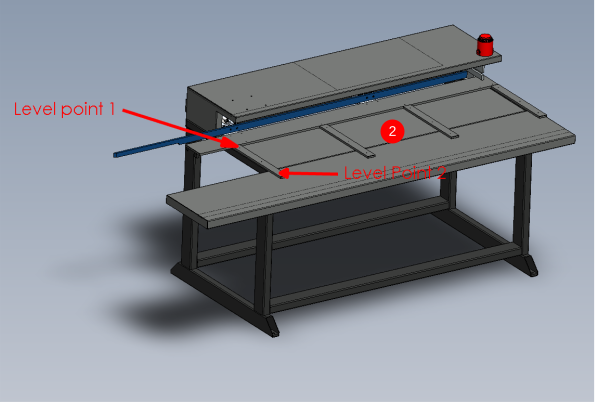

Étape 16 - Multi head levelling points

- x axis machine levelling. use a 2 meter straight edge between the indicated points and an engineers level on top to level this axis

- Y axis levelling. Use an engineers level to straddle the 2 indicated points to level the y axis of the machine

R0015311 Install and Align Datum rollers

R0002913E Install and Align Rotary head Subframe

Étape 17 - Alignment of Machining center to outfeed table

Machining center is aligned to the outfeed using the following

Grip pin setting jig

Laser level

2 meter straight edge

X axis position is determined by hepco rail travel at full extent and center clamp bar within machining center. The gap here should be approximately 75mm.

Y axis position is determined by the grip pin jig and the machining center backfence rollers. The grip pin jig must be used at 2 points for correct alignment . Infeed datum rollers and v notch datum rollers.

Ensure gripper pins fall freely and centrally into alignment jig when setting.

Only move Machining centre to adjust this position

Height is determined by the datum horizontal rollers in the machining center and the blue rollers on the outfeed table. Out feed rollers and platform should be less than 1mm below the Machining centre rollers

- position machining center roughly in place on the end of the outfeed table

- level using previous step

- once the module has been levelled, final levelling of the outfeed x axis can be done , as it uses the machining center as a datum to hold the laser level

Place laser level in the rear datum roller section of the machining center

Position gripper carriage as close to the laser level as possible

Mark a horizontal line of the carriage plate as a height datum

Move the carriage to above the next section of frame feet and adjust the pair of jacking bolts to adjust line to be on laser level mark

Repeat this step above every pair of frame legs where jacking bolts are

These steps will ensure the outfeed is now set on a dead flat plain

4. Use the pin jig to adjust the position of the machining center to allow the gripper pins to align with the jig at all points along the back fence rollers. hepco beam should also be moved from in to the out position also to double check this jig setting

5. Use laser against machining center rollers to cast a laser line along the outfeed. Pull the gripper as close as possible to the laser, and mark a vertical line on the gripper where the laser dot falls.

Move the gripper to the end of the hepco rail and check if the laser stop still aligns on the vertical line previously marked . If it doesn't , grip pin alignment will need re checking as it is crucial that both of these areas are correct

6 final height adjustment is set by using a 2 meter straight edge through the machining center rollers to the first set of rollers on the outfeed table. Machining center can be adjusted up or down to bring these rollers all onto the same height plain (-1mm maximum)

Étape 18 - Machining centre Infeed levelling

- Levelling Y axis of machining centre infeed . This is done on the indicated face of the arms using a level . Only level the indicated arms as these are the only ones controllable by the jacking feet positions

- Use a laser level placed on the levelled machining centre infeed rollers, and cast a laser line along the length of the infeed table. Ensure the beam is positioned so a reading can be taken from each circled point on the frame. Take a measurement from the first circled point with a steel rule of the indicated area. Replicate this measurement at all points indicated along the frame by Adjusting the legs in pairs to raise or lower the appropriate arm

- When height setting to the machining centre, the whole frame can simply be jacked up or down to achieve the correct height in relationship to the machining centre

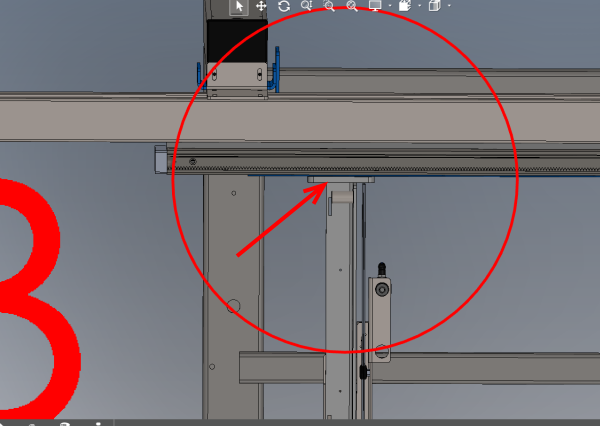

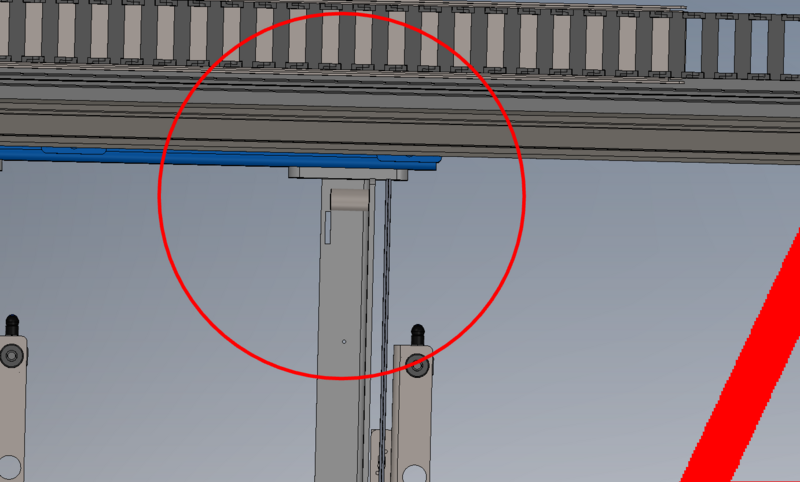

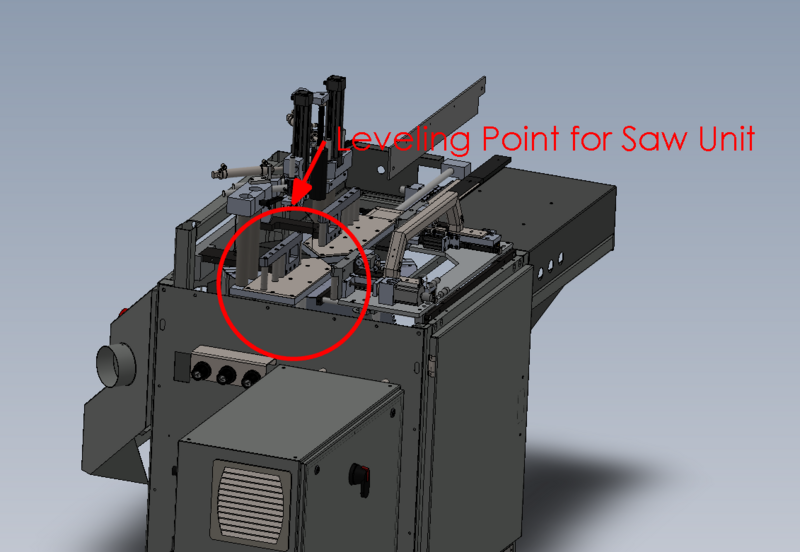

Étape 20 - Aligning Saw to saw infeed

- Y axis alignment

Saw back fence and saw infeed back fence are used for y axis alignment . Saw back fence should be slightly in front of saw infeed back fence. Around 1mm

2. X axis alignment

Frames should be marked to show measurement between frames to set this position . if not the defining factor is the gripper must not hit eject clamps when at full travel on x axis

Étape 21 - Saw outfeed table levelling points

- X axis of module is levelled from the two indicated points . Use a 2 meter straight edge between these points and an engineers level on top

- y axis is levelled from these two indicated points . an engineers level rested on this face is sufficient for levelling

Étape 22 -

Étape 23 -

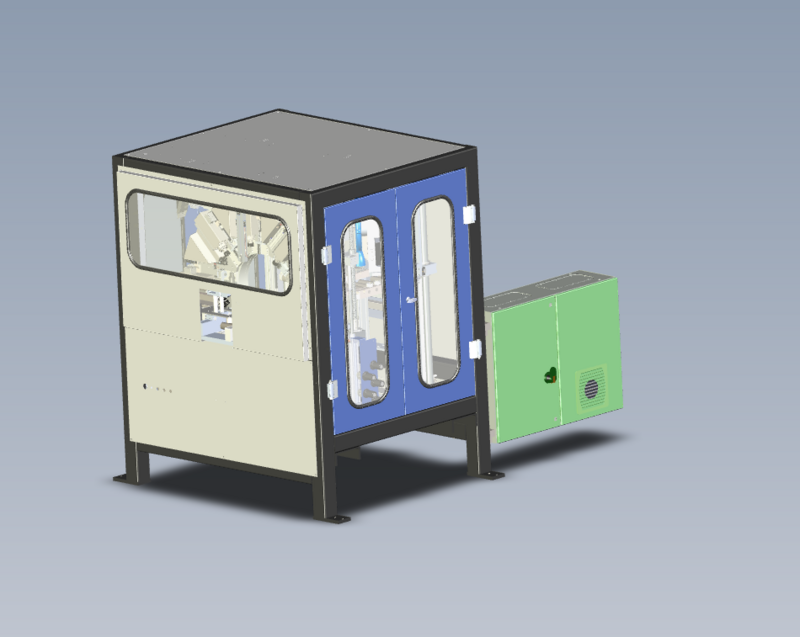

Étape 24 - Module B Machining centre installation

Position module B in front of Module C

Ensure electrical cabinet is hinged out from the transport position

Align datum rollers within Machining centre with gripper as starting reference point

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português