| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 89 : | Ligne 89 : | ||

Check sensor position has not moved</translate> | Check sensor position has not moved</translate> | ||

|Step_Picture_00=R0015085_Mount_SR_Datum_Sensor_and_Flag_Screenshot_2023-11-16_160935.png | |Step_Picture_00=R0015085_Mount_SR_Datum_Sensor_and_Flag_Screenshot_2023-11-16_160935.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Check sensor</translate> | ||

| + | |Step_Content=<translate>once finalised, double check correct operation of sensor. | ||

| + | |||

| + | |||

| + | Sensor should be within -1mm at all points of travel onto SR axis datum flag. Sensor should NEVER be in contact with flag at any point of movement</translate> | ||

| + | |Step_Picture_00=R0008013_Clacker_assembly_quality.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version du 4 décembre 2023 à 15:47

Mounting details for SR axis flag and sensor

Introduction

Tools Required

Standard Hex key set

Standard spanner set

Parts required

D0015489 Saw Turntable Sensor Bar x 1

E0000336 Sensor: M8; 2mm, PNP N/O, M8 conn x 1

M0001165 U bolt 3nb M12 BZP x 1

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

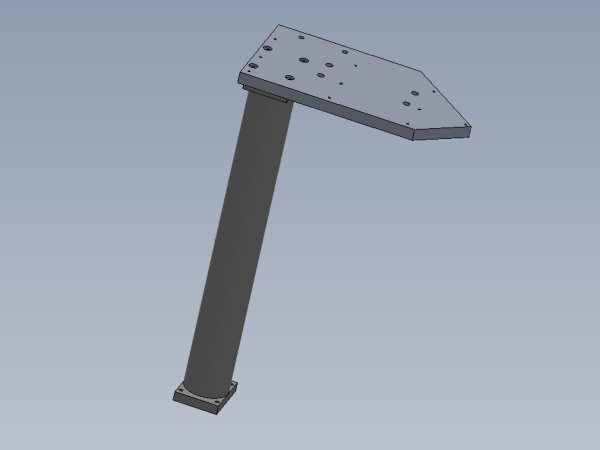

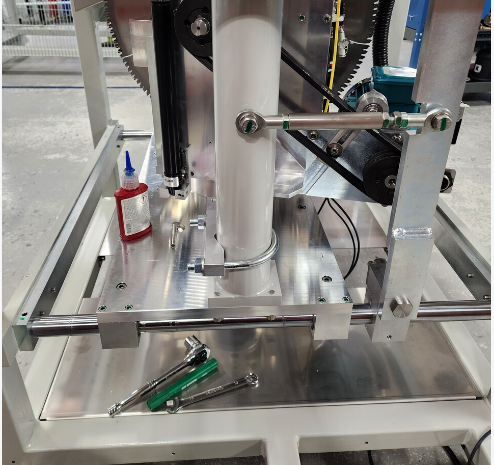

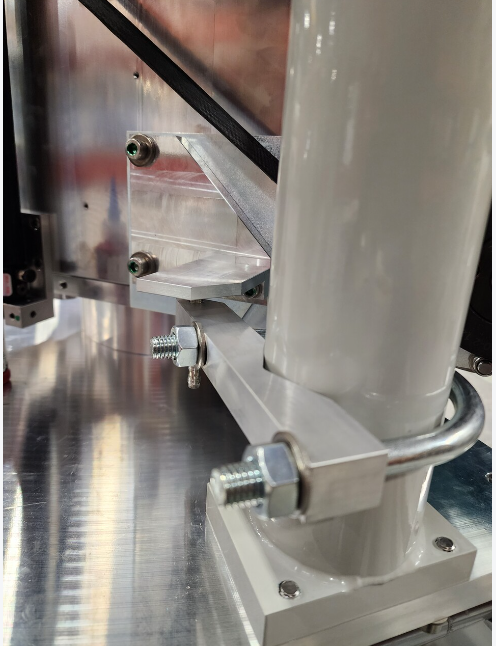

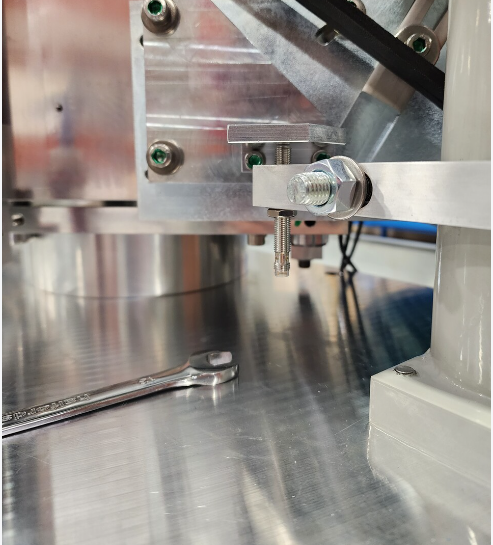

Étape 2 - Attach sensor bracket

Attach u bolt and sensor bracket on infeed mounting pillar

Fix with M12 nuts and M12 A form washers

Ensure bracket is mounted square to pillar base, only apply light tension to M12 nuts

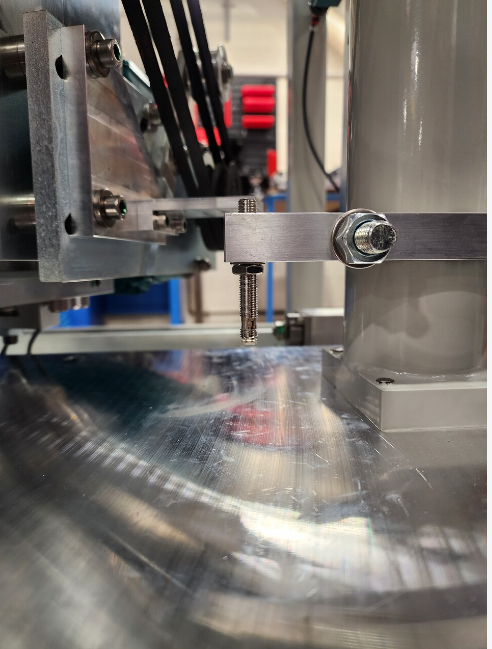

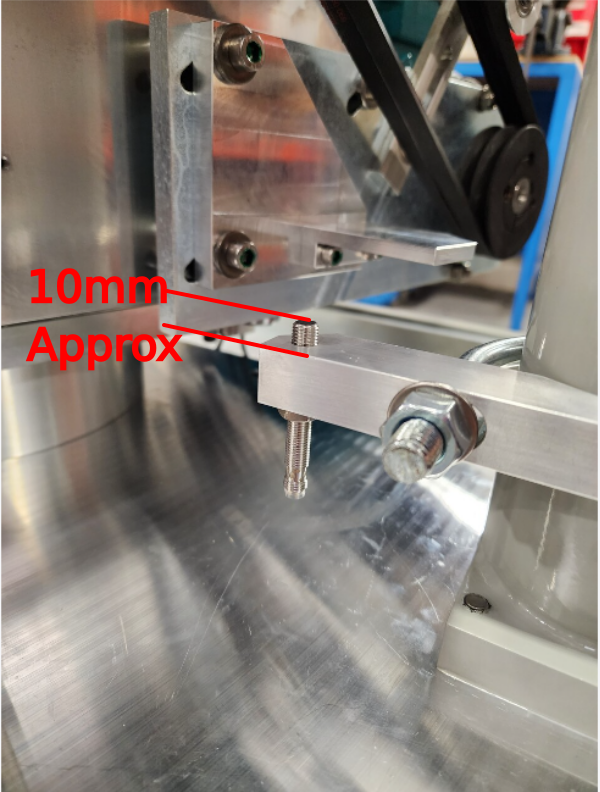

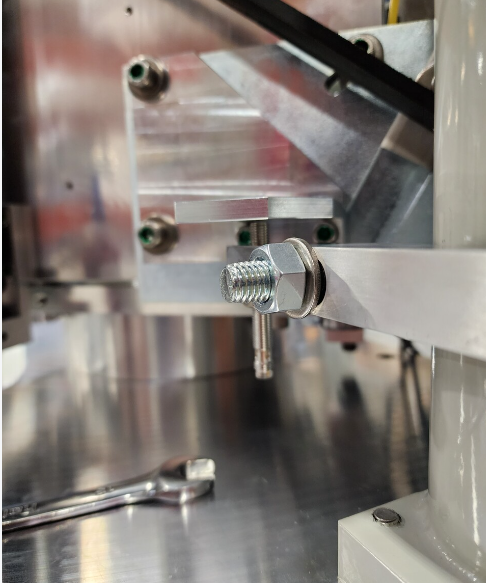

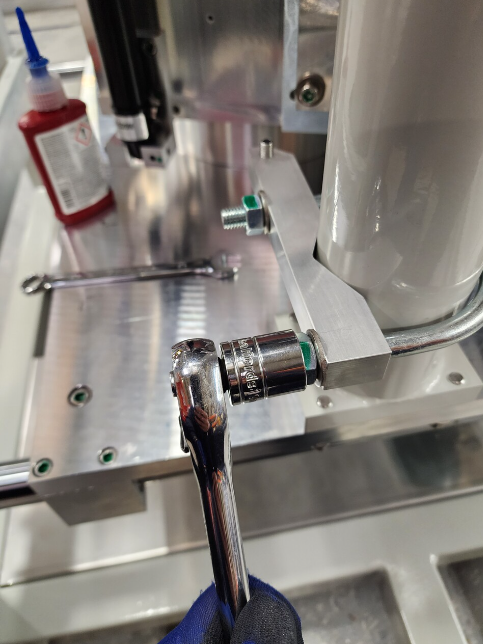

Étape 3 - Fit sensor

Fit E0000336 sensor to assembly

Leave 10mm protrusion from top of bracket as shown

Ensure shakeproof washer is fitted under sensor nut

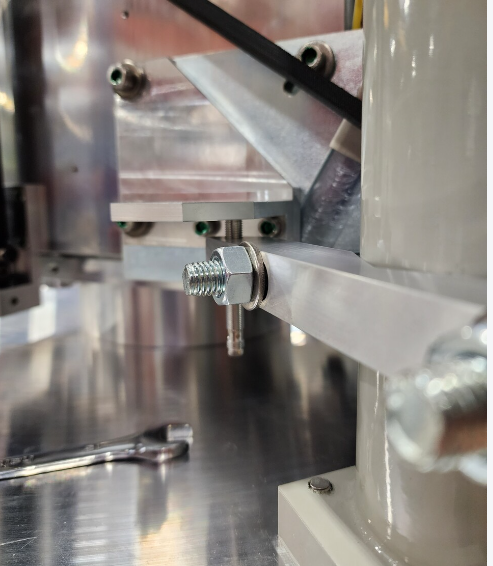

Étape 4 - Set height

Set Height of U bolt bracket assembly in relation to flag on saw motor plate, to set sensor withing +- 2mm of flag

Étape 5 - Set sensor height

Set sensor height to minimal clearance (-1mm )

Check gap is consistent on full travel over sensor flag when head is rotated

Étape 6 - Finalise

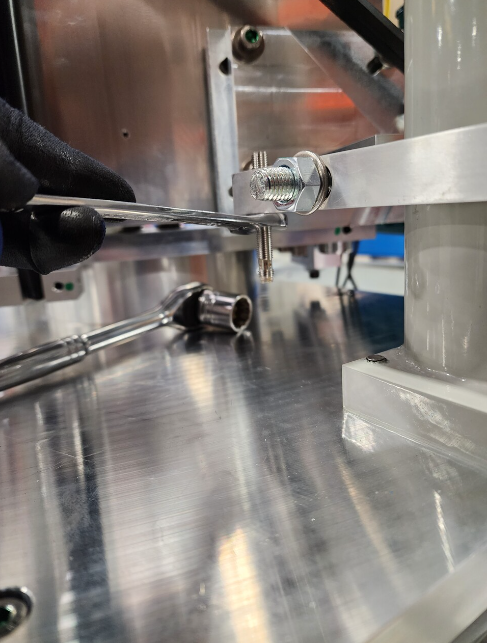

Finalise M12 nuts and ensure U bolt assembly is mounted true as to not impact on side sheet guarding panel when fitted later

Check sensor position has not moved

Étape 7 - Check sensor

once finalised, double check correct operation of sensor.

Sensor should be within -1mm at all points of travel onto SR axis datum flag. Sensor should NEVER be in contact with flag at any point of movement

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português