| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=R0015314_Fit_Z_Axis_Drive_components_Screenshot_2023-10-25_093149.png |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","... ») |

|||

| Ligne 363 : | Ligne 363 : | ||

| − | Wind by hand to top travel by rotating leadscrew</translate> | + | Wind by hand to top travel by rotating leadscrew, then again to bottom |

| + | |||

| + | Movement should be smooth and consistent with no tight spots</translate> | ||

| + | |Step_Picture_00=R0000711_Rotary_Base_Assembly_quality-assurance-testing.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit servo mount block</translate> | ||

| + | |Step_Content=<translate>Fit servo mount block to driven side | ||

| + | |||

| + | |||

| + | Ensure access hole is facing rear | ||

| + | |||

| + | |||

| + | Dry fit fasteners</translate> | ||

| + | |Step_Picture_00=R0015314_Fit_Z_Axis_Drive_components_Screenshot_2023-10-25_102436.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Attach servo motor</translate> | ||

| + | |Step_Content=<translate>Attach servo motor | ||

| + | |||

| + | |||

| + | Ensure motor is orientated correctly , and servo plug is facing the correct way</translate> | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 25 octobre 2023 à 10:58

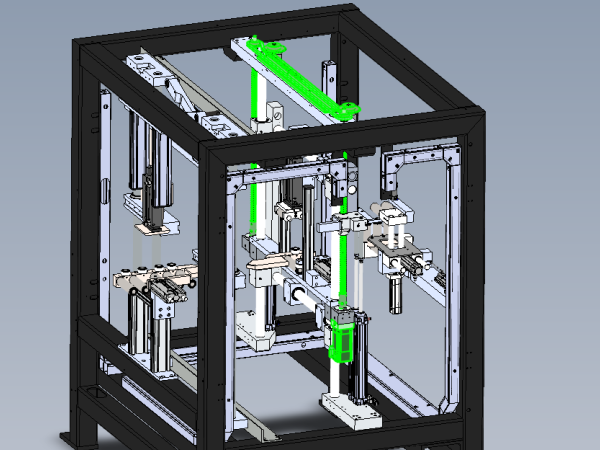

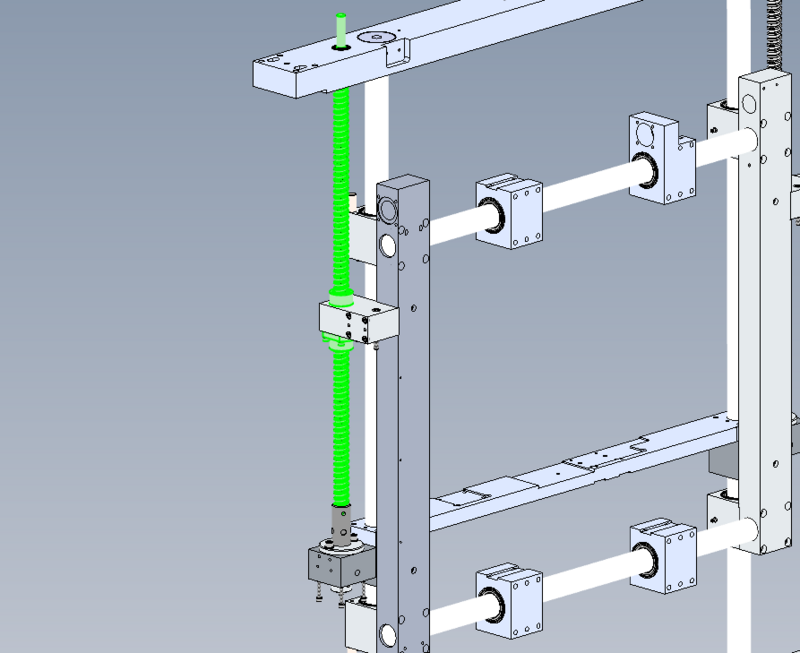

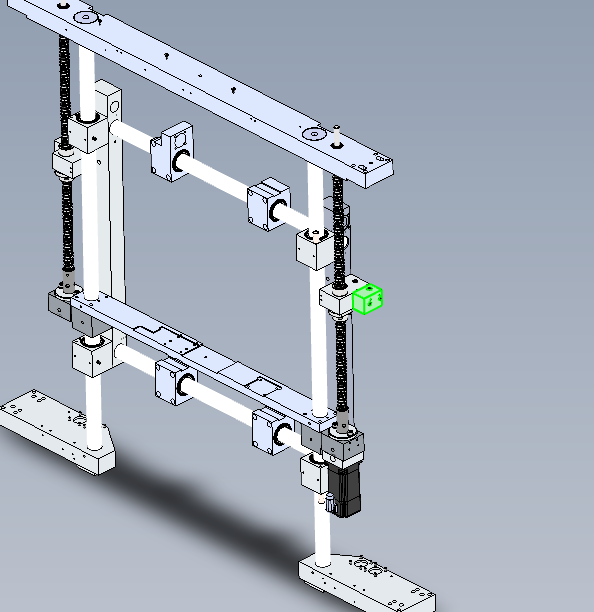

Assembly and setting details for final Z axis component installation

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Attach leadscrew sleeves

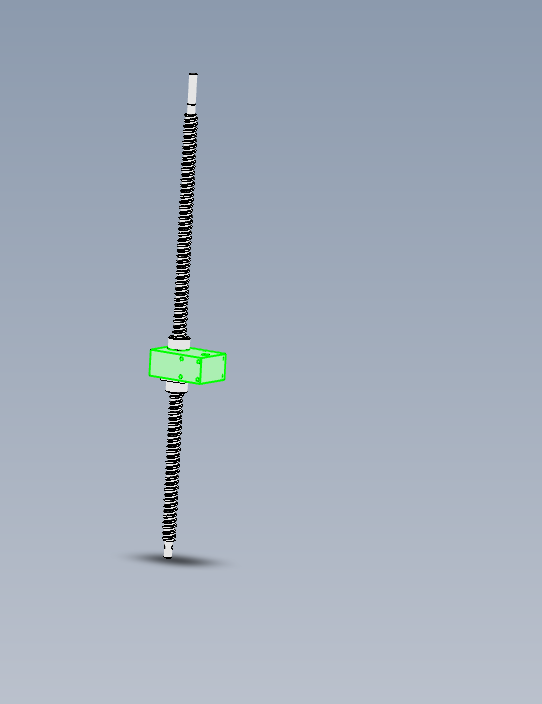

- 4 Étape 3 - Fit front leadscrew

- 5 Étape 4 - Fit rear leadscrew

- 6 Étape 5 - Fix Z axis sleeve to leadscrew

- 7 Étape 6 - Fit top bearings to leadscrews

- 8 Étape 7 - Fit double cylinder brackets

- 9 Étape 8 - Loose fit sprockets

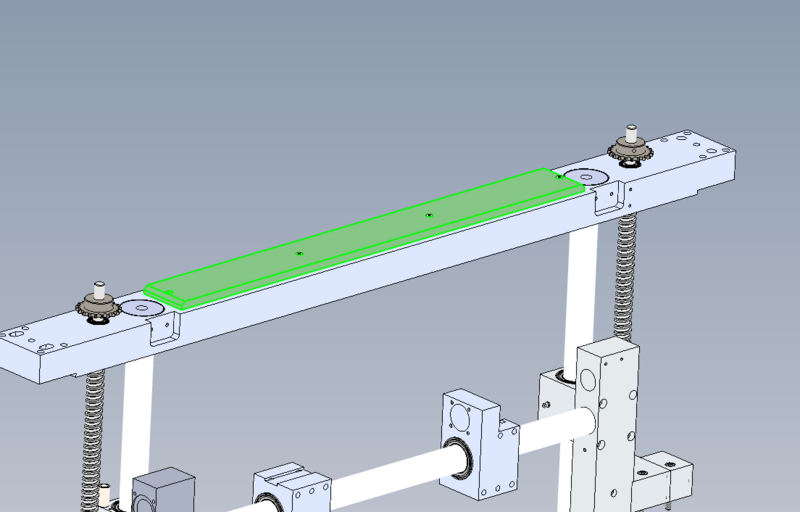

- 10 Étape 9 - Fit chain slide

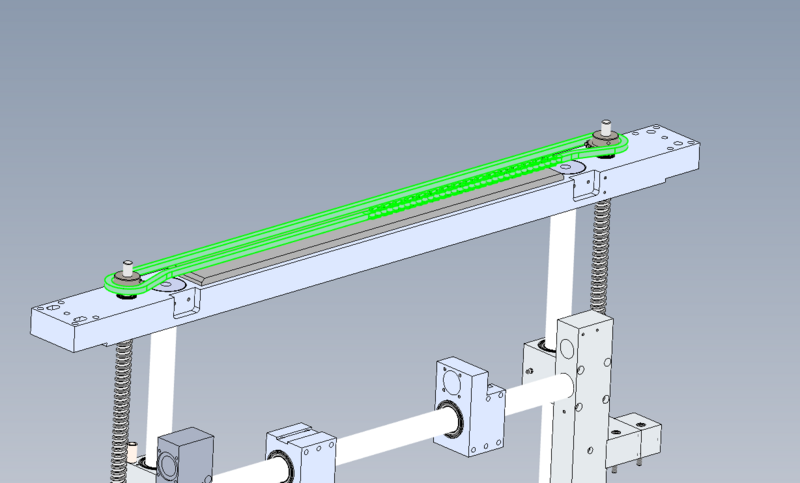

- 11 Étape 10 - Attach z axis chain

- 12 Étape 11 - Attach chain tensions

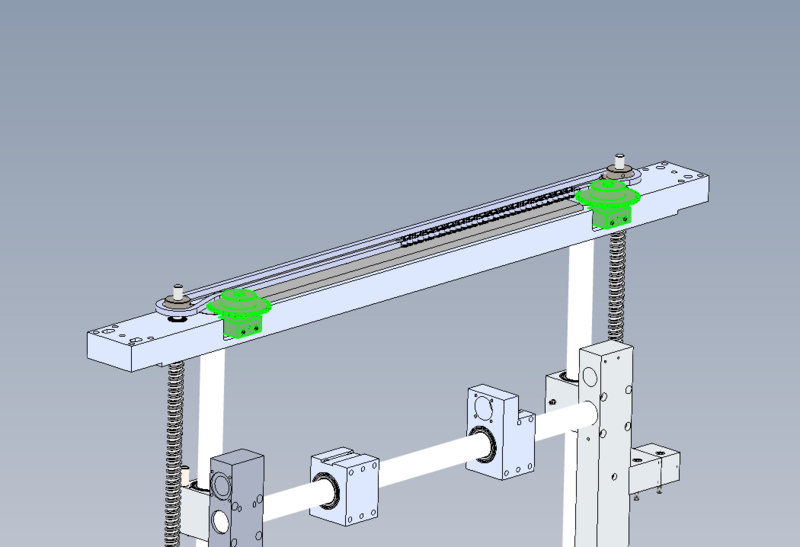

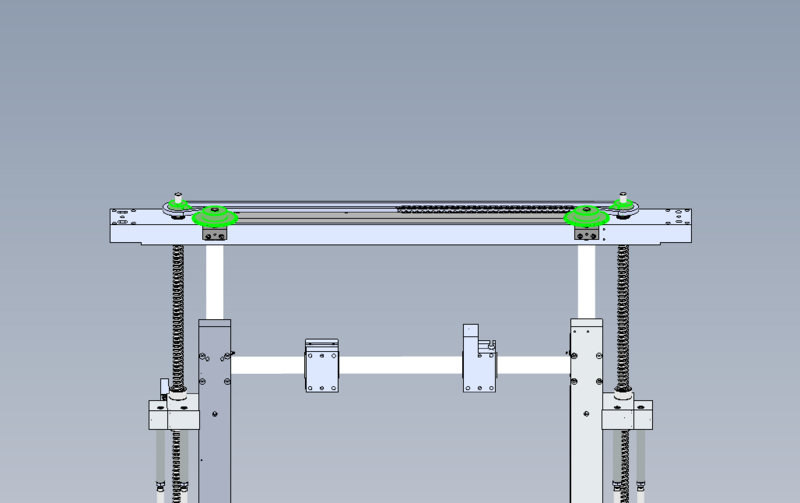

- 13 Étape 12 - Adjust sprocket height

- 14 Étape 13 - Tension chain

- 15 Étape 14 - Remove slave side support

- 16 Étape 15 - Fit level to y axis shaft

- 17 Étape 16 - Adjust slave side

- 18 Étape 17 - Tension sprocket

- 19 Étape 18 - Drill leadscrews

- 20 Étape 19 - Check Z axis movement

- 21 Étape 20 - Fit front leadscrew

- 22 Étape 21 - Fit rear leadscrew

- 23 Étape 22 - Fix Z axis sleeve to leadscrew

- 24 Étape 23 - Fit top bearings to leadscrews

- 25 Étape 24 - Fit double cylinder brackets

- 26 Étape 25 - Loose fit sprockets

- 27 Étape 26 - Fit chain slide

- 28 Étape 27 - Attach z axis chain

- 29 Étape 28 - Attach chain tensions

- 30 Étape 29 - Adjust sprocket height

- 31 Étape 30 - Tension chain

- 32 Étape 31 - Remove slave side support

- 33 Étape 32 - Fit level to y axis shaft

- 34 Étape 33 - Adjust slave side

- 35 Étape 34 - Tension sprocket

- 36 Étape 35 - Drill leadscrews

- 37 Étape 36 - Check Z axis movement

- 38 Étape 37 - Fit servo mount block

- 39 Étape 38 - Attach servo motor

- 40 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Engineers level 300mm

5mm Carbide drill

150m verniers

Parts Required

A0001069 Energy Chain Series B15.050 (48mm radius) Openable x 2

A0001070 Igus Mounting Br Set for A0001069 Non-Pivot x 2

B0000344 Circlip 15mm External x 2

B0000400 Circlip 17mm External x 2

D0001249 Z Axis Chain Offset Plate x 1

D0001271 Z Axis Chain Mounting Plate x 1

D0001927 Intermediate Housing (AM3032) x 1

D0006498 Z Housing Cap x 2

D0007453 Double Cylinder Bracket OH (D8106) x 1

D0007610 Chain Slide x 1

D0007795 Nut Housing x 1

D0007796 Nut Housing - Mirror x 1

D0007858 Kit: Z Axis Drive Chain ZX + Micro x 1

D0008106 Double Cylinder Bracket (D7453) x 1

H0007714 Z Spocket 20 teeth x 2

R0000963E Bench Assemble Z axis Components x 1

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

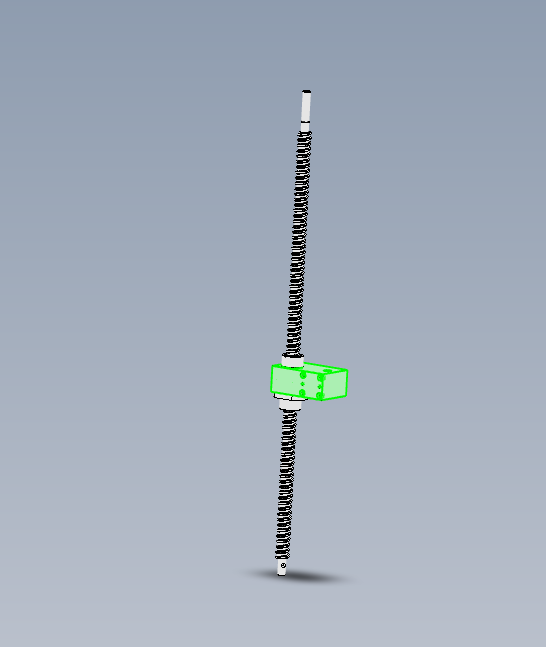

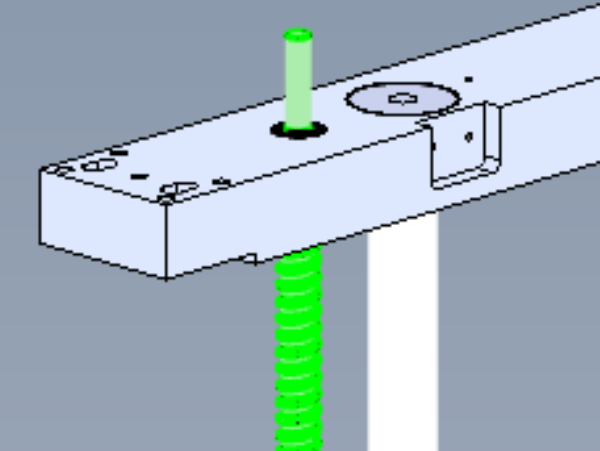

Étape 2 - Attach leadscrew sleeves

Fit pre assembled leadscrew sleeves to front and rear Z axis

Bearing fit and solvent if bearing fit is loose

Captivate with Z housing cap

Étape 3 - Fit front leadscrew

Slide onto leadscrew nut Z nut housing

Insert into frame leadscrew

Fit z nut housing to tie beam

Étape 4 - Fit rear leadscrew

Slide onto leadscrew nut Z nut housing

Insert into frame leadscrew

Fit z nut housing to tie beam

Étape 5 - Fix Z axis sleeve to leadscrew

Align dimples and fix with M8 x 12 kcp grubscrews

Repeat other side

Étape 6 - Fit top bearings to leadscrews

Fit 2 off bearings to top of each leadscrew. Use bearing and solvent if loose .

Captivate with circlip

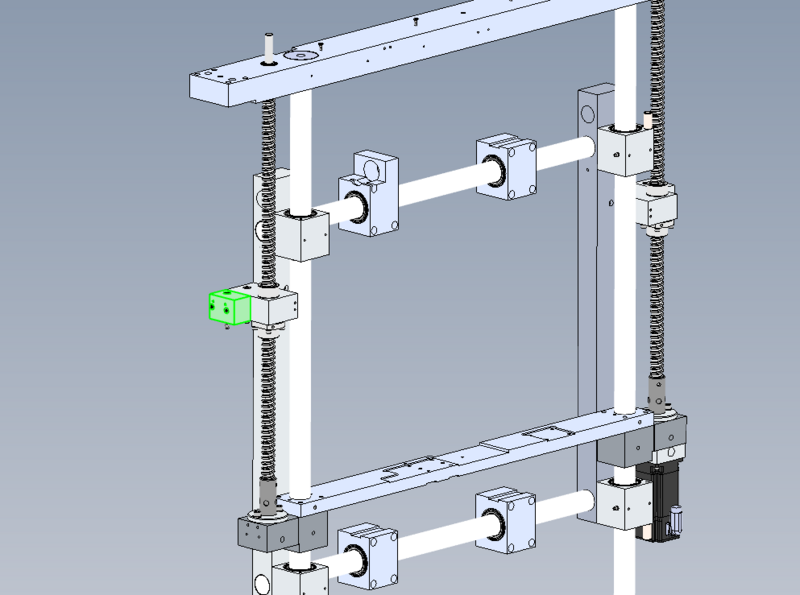

Étape 10 - Attach z axis chain

Attach Z axis chain around sprockets

Ensure chain join clips are facing upwards

Étape 11 - Attach chain tensions

Attach chain tensioners to top bar

Ensure mounting at highest point up (clearance in fixing holes )

Étape 12 - Adjust sprocket height

Measure height of tensioner sprockets from top bar and set drive sprockets to same measurement

Use verniers

Apply final tension to driven side (side with servo motor mounting point)

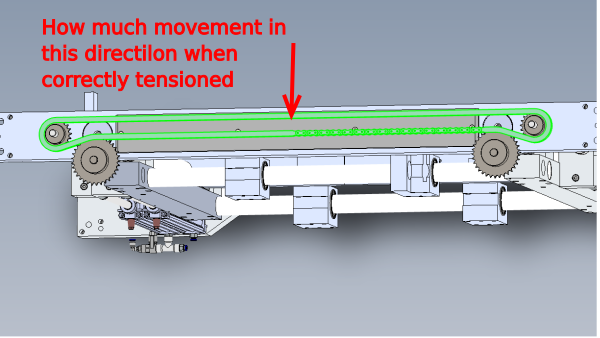

Étape 13 - Tension chain

Tension chain by using adjusting grubscrew on tensioners

Set chain tension to remove slack

Sam, Can you measure the amount of chain flex once set correctly please

Étape 16 - Adjust slave side

Adjust slave side relationship between sprocket and leadscrew by rotating leadscrew with sprocket fixings loose

Adjust to bring shaft level

Étape 17 - Tension sprocket

Check sprocket height is still correct then apply final tension to fixings in sprocket

Étape 18 - Drill leadscrews

individually remove fixing grubscrews, dimple leadscrew through sprocket with 5mm carbide drill, clean swarf, apply adhesive and refit grubscrew

Repeat for all 4 fixing grubscrews in sprockets

Étape 19 - Check Z axis movement

Remove 2nd axis support and allow Z axis to move to bottom of movement

Wind by hand to top travel by rotating leadscrew

Étape 20 - Fit front leadscrew

Slide onto leadscrew nut Z nut housing

Insert into frame leadscrew

Fit z nut housing to tie beam

Étape 21 - Fit rear leadscrew

Slide onto leadscrew nut Z nut housing

Insert into frame leadscrew

Fit z nut housing to tie beam

Étape 22 - Fix Z axis sleeve to leadscrew

Align dimples and fix with M8 x 12 kcp grubscrews

Repeat other side

Étape 23 - Fit top bearings to leadscrews

Fit 2 off bearings to top of each leadscrew. Use bearing and solvent if loose .

Captivate with circlip

Étape 27 - Attach z axis chain

Attach Z axis chain around sprockets

Ensure chain join clips are facing upwards

Étape 28 - Attach chain tensions

Attach chain tensioners to top bar

Ensure mounting at highest point up (clearance in fixing holes )

Étape 29 - Adjust sprocket height

Measure height of tensioner sprockets from top bar and set drive sprockets to same measurement

Use verniers

Apply final tension to driven side (side with servo motor mounting point)

Étape 30 - Tension chain

Tension chain by using adjusting grubscrew on tensioners

Set chain tension to remove slack

Sam, Can you measure the amount of chain flex once set correctly please

Étape 33 - Adjust slave side

Adjust slave side relationship between sprocket and leadscrew by rotating leadscrew with sprocket fixings loose

Adjust to bring shaft level

Étape 34 - Tension sprocket

Check sprocket height is still correct then apply final tension to fixings in sprocket

Étape 35 - Drill leadscrews

individually remove fixing grubscrews, dimple leadscrew through sprocket with 5mm carbide drill, clean swarf, apply adhesive and refit grubscrew

Repeat for all 4 fixing grubscrews in sprockets

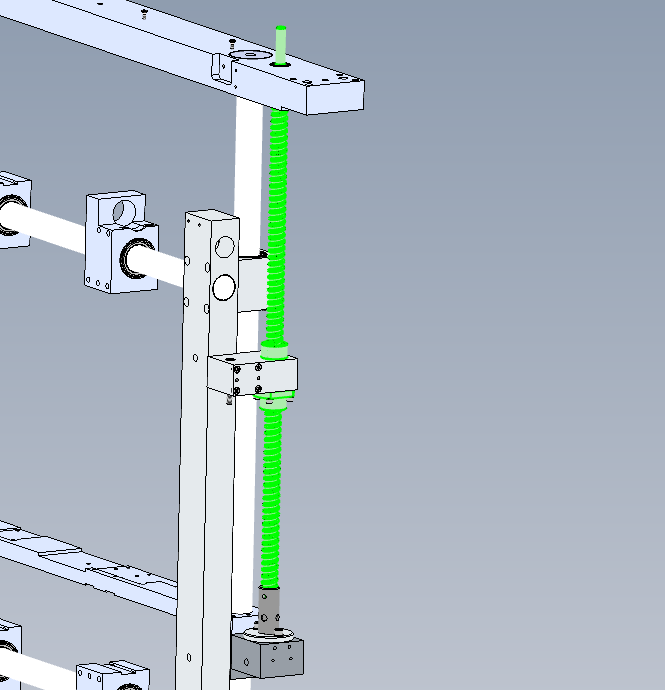

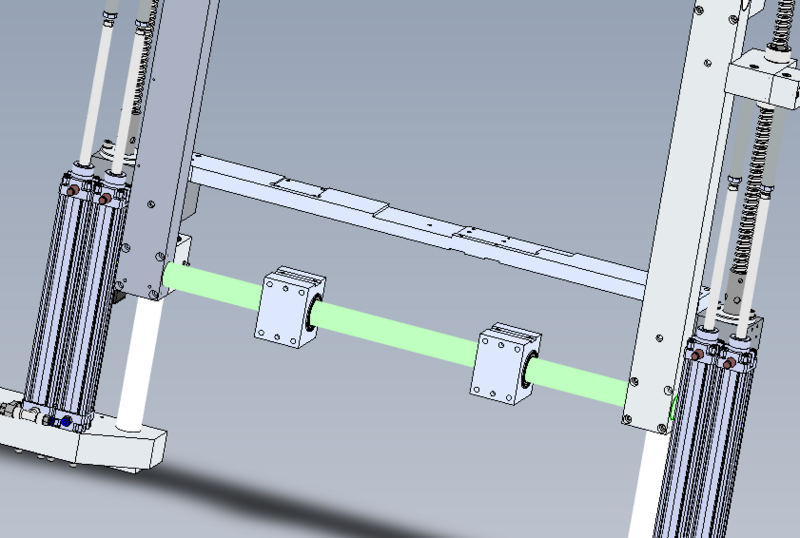

Étape 36 - Check Z axis movement

Remove 2nd axis support and allow Z axis to move to bottom of movement

Wind by hand to top travel by rotating leadscrew, then again to bottom

Movement should be smooth and consistent with no tight spots

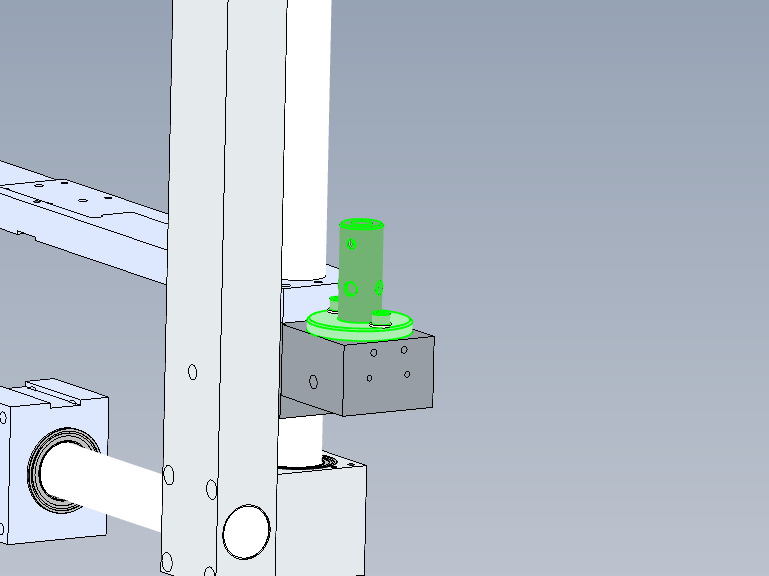

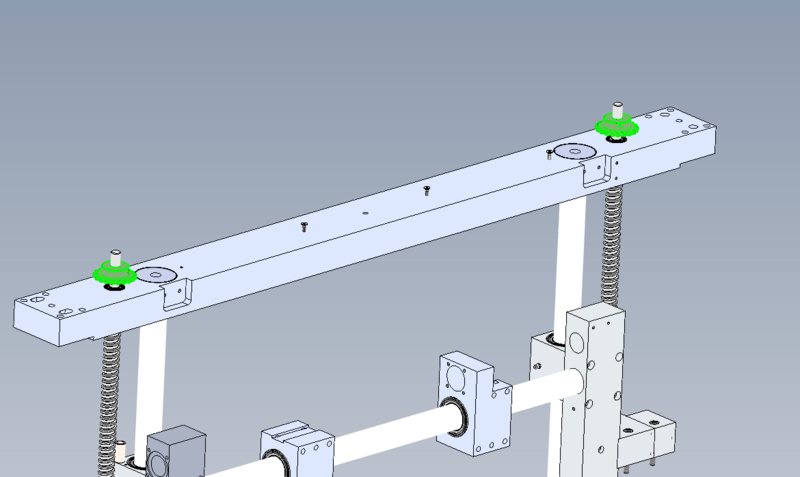

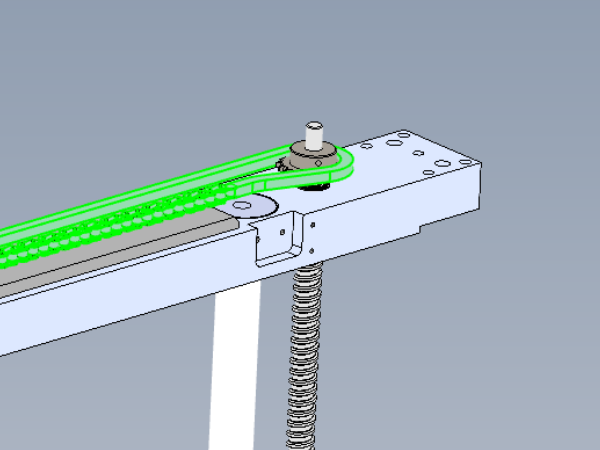

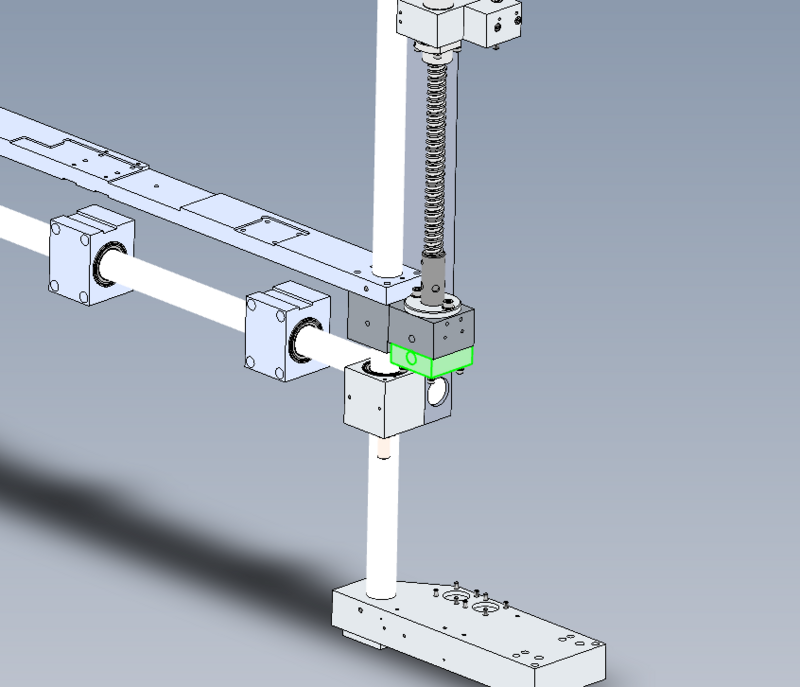

Étape 37 - Fit servo mount block

Fit servo mount block to driven side

Ensure access hole is facing rear

Dry fit fasteners

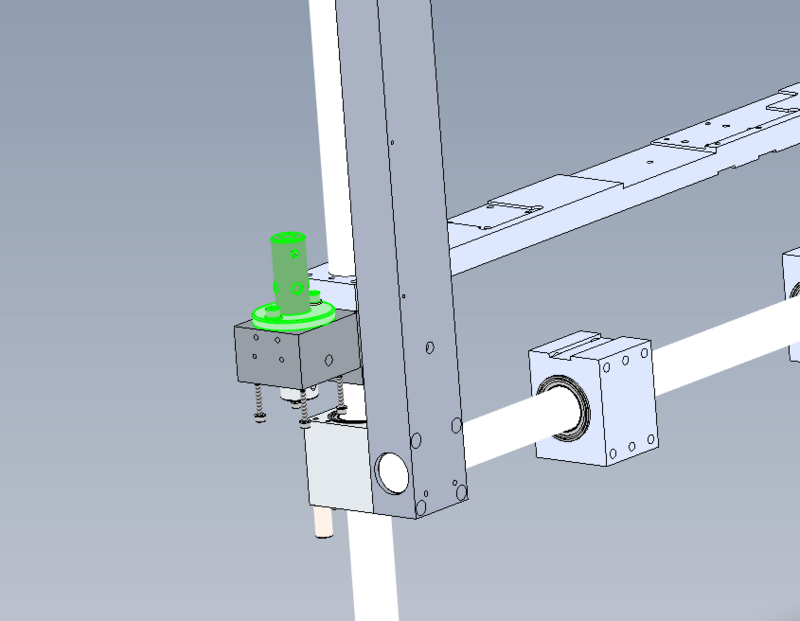

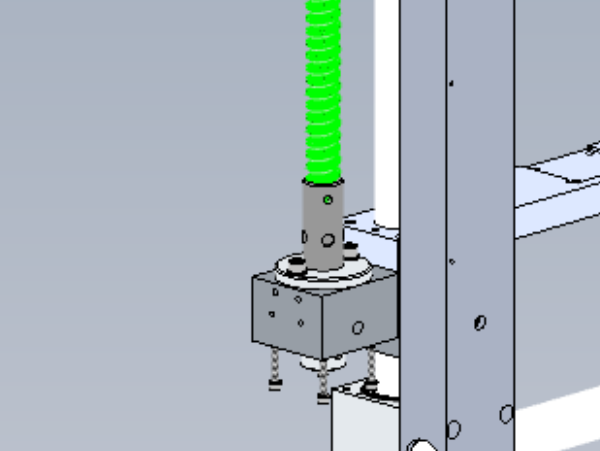

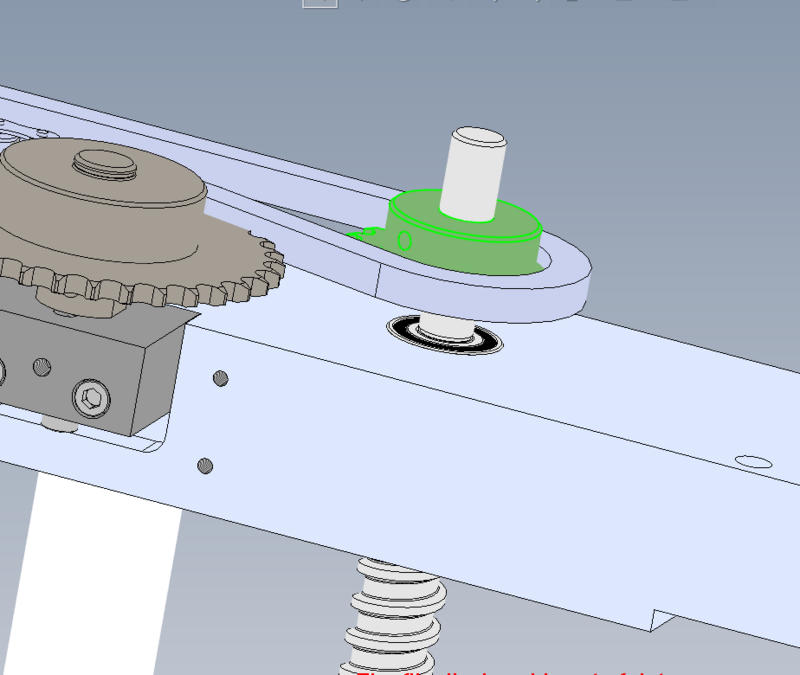

Étape 38 - Attach servo motor

Attach servo motor

Ensure motor is orientated correctly , and servo plug is facing the correct way

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português