How to correctly set mesh between racks/pinions, V rail and delrin rollers

Sommaire

Introduction

Étape 1 - Misadjusted

Evidence of incorrect adjustment will be evidenced by components in the assemblies prematurely wearing and coming away from their fixings.

Étape 2 - Access V rails and adjust.

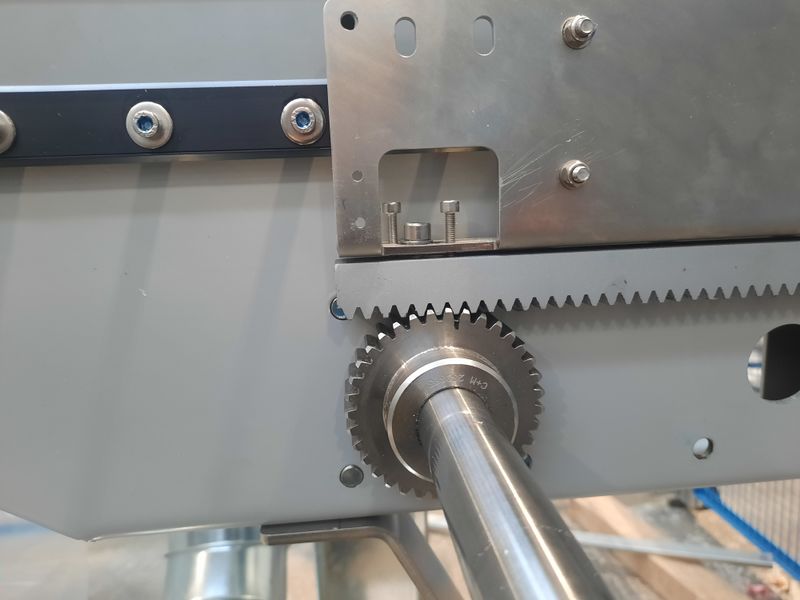

Remove pinion gear by slackening off grubscrews and sliding away. Good idea to mark up original position.

Disconnect airpipe feeding popup cylinder and slide off rack mounting plate.

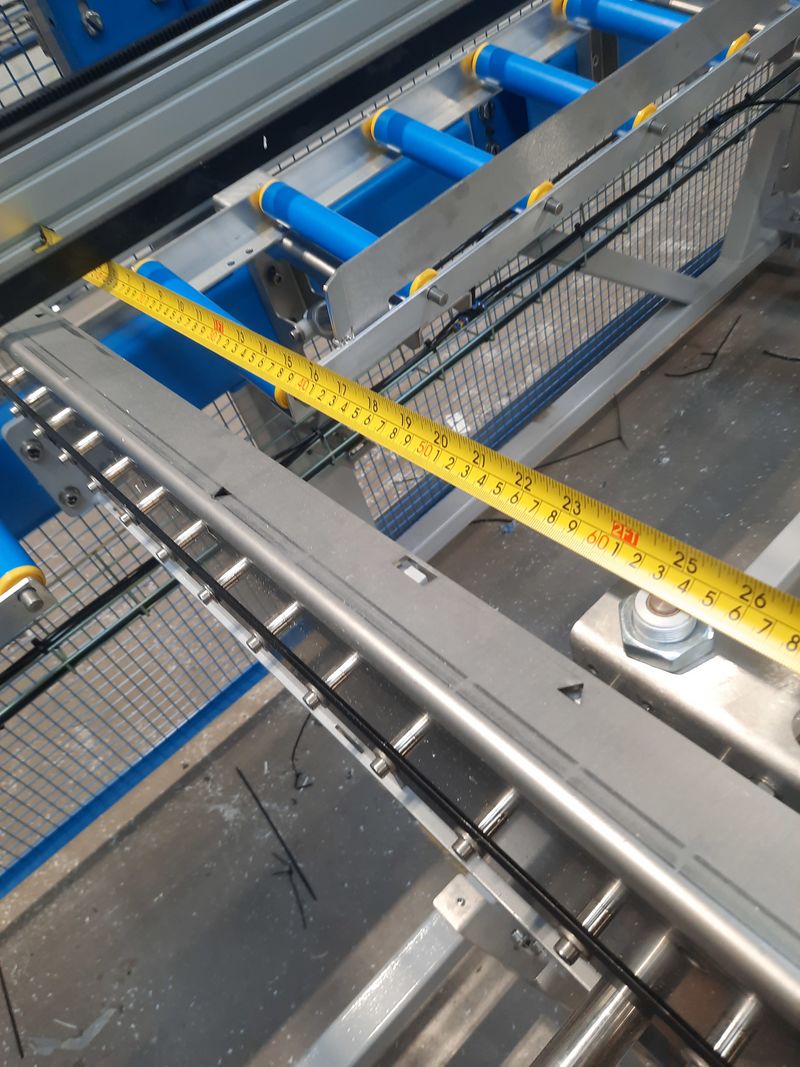

Slacken all 20 caphead screws, they only need a half to full turn. Move the rails up as far as they will go and then tighten just the screws on each end, finger tight is enough. These rails come in two parts, ensure they are fully mated together or they will cause tight spots later on. Using the joiners square in the picture set to 47mm, use it to set height of the V rails when the bubble shows it is level. Check at each end and in the middle. Once level, tighten all screws and recheck level.

Étape 3 - Check and adjust Delrin rollers

The rollers on top are mounted on eccentric bushes. We only need these just tight enough to not allow any slop or vertical play. Slacken the cams off completelely, you will need an 8mm spanner with the faces ground down to fit in the space.

Slide the plate onto the rail and tighten the eccentric bushes until any vertical play is removed. Lightly try to move the assembly on the X axis, if there is any slop then it needs to be a little tighter but probably no more than an 1/8th of a turn. Once set you should still be able to spin the rollers by hand, but still feel a fair bit of resistance. Once set slide the assembly over the full length of the V rails to check fo any tight spots. If there are then you need to check that the two halves of the fail are fully mated!!!

Étape 4 - Adjust Rack to Pinion

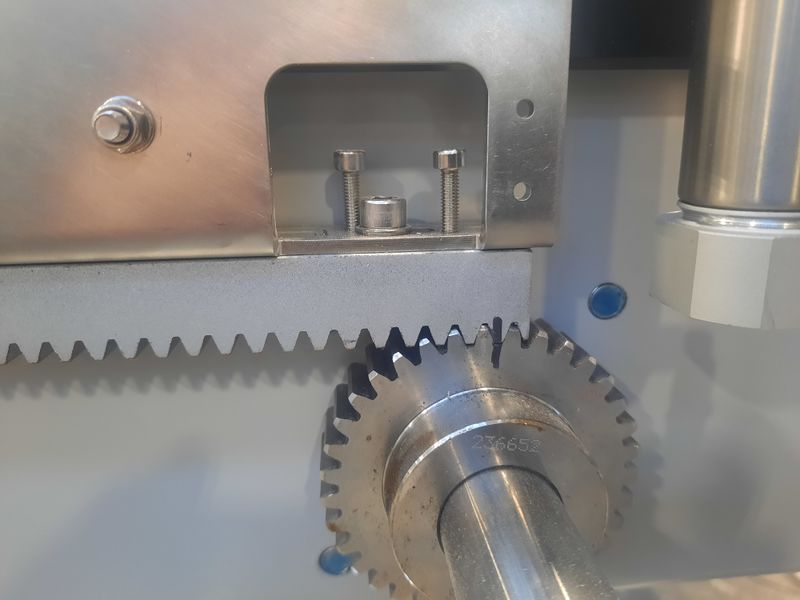

If there is no adjustment between the mounting plate and the rack as shown in the first picture, then we need to introduce some. This is the most important step as it ensures all the parts are running parallel to eachother and not causing excessive force!!!

Get your sharpies oot and mark where the rack and pinion mate!!! Slacken off the larger screws, one at either end of the rack until you have a 3mm gap at each end. This is easy when removed, but once refitted you will need a cut down allen key to fit in the gap to adjust. Back off the set screws if not already. Slide the assembly back on and mesh the pinion to the rack at one of the ends, it does not matter which, lightly tighten a grubscrew on pinion to ensure there is no backlash felt between the key and keyway. Using a combination of the set screws and adjustment screw, adjust until there is no play between rack and pinion. Then turn each of the small set screws back an 1/8th to 1/4 turn and fully tighten the adjustment screw. This introduces a very small amount of play that should hardly be felt, but is just enough to stop premature wear between the two. Remove the pinion, slide the rack to the other end and repeat the process. Recheck the first end in case it has moved slightly while doing the second. Set distance from beam to popup cylinder using measurements from another assembly, or if you were clever enough you took these before taking everything apart? I wasn't! If it needs adjusted then slacken off the two setting bolts, they give around 10mm on the mounting slots. 1mm either way is good enough and will not cause problems. Reconnect air pipes, make sure everything is locked off and tight, job done.

Étape 5 - End Stop

Mechanical end stops should only ever be used as a fail safe in cases of sensors failing. These should be set so that the gears can never come off the racks.

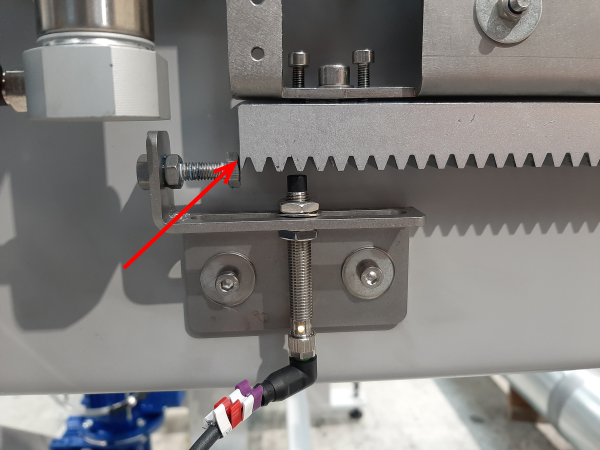

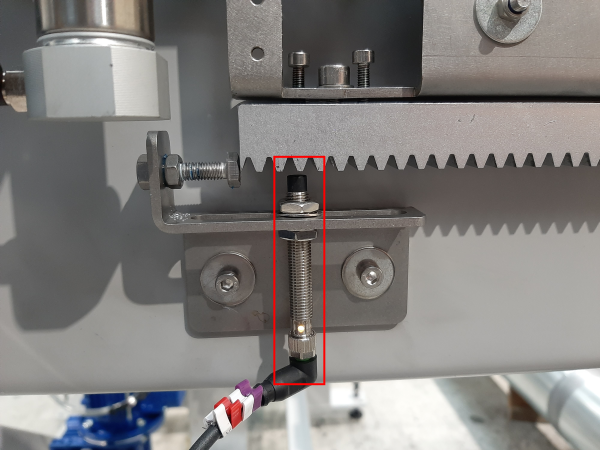

Étape 6 - Sensor Position

Using a pair of 13mm spanners, nip the proximity sensors in place so that they are roughly in the middle of the slot.

Do this for all 6 sensors (2 on each assembly - 1 'home' and 1 'out')

Étape 7 - Clutch Tension

Ensure the 3 clutches are tensioned correctly.

The goal is to ensure that if a sensor fails, the motion of the rack is stopped safely.

Too Tight:

The clutch tension does not allow slippage causing the end stop to bend

Too Loose:

The clutch slips with a full table of profile

Étape 8 - Other Checks

It is also worthwhile slackening off all the screws that hold the air pipe harness, let it find its own position and then tighten back up. If not done this can introduce pull on the brackets that carry the Delrin rollers.

Étape 9 - Testing

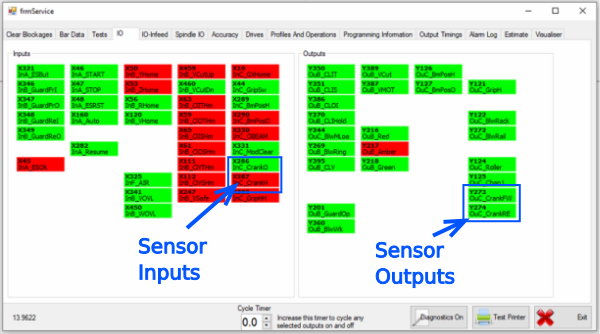

The cranks can be run from the IO testing screen. The system will automatically stop the crank motor when the associated input is active, or after an adjustable timeout delay in the parameters.

Machining centre side:

Crank C - Machining centre offload

Sawing Side:

Crank D - Transfer Table

Crank E - Saw Preload

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português