| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 51 : | Ligne 51 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Quality check</translate> | |Step_Title=<translate>Quality check</translate> | ||

| − | |Step_Content=<translate>It is vital to confirm Cut tables are in the correct position once levelled, and that movement | + | |Step_Content=<translate>It is vital to confirm Cut tables are in the correct position once levelled, and that movement hasn't occurred during transport |

To do this the base of the saw turn table must be checked for level. These readings must read exactly the same as the levelled cut table in the previous step | To do this the base of the saw turn table must be checked for level. These readings must read exactly the same as the levelled cut table in the previous step | ||

| Ligne 58 : | Ligne 58 : | ||

|Step_Picture_00=ZX5_Production_R0015040_Module_F_to_R0015001B_Module_E_alignment_Screenshot_2023-12-20_132804.png | |Step_Picture_00=ZX5_Production_R0015040_Module_F_to_R0015001B_Module_E_alignment_Screenshot_2023-12-20_132804.png | ||

|Step_Picture_01=ZX5_Production_R0015040_Module_F_to_R0015001B_Module_E_alignment_Screenshot_2023-12-20_132815.png | |Step_Picture_01=ZX5_Production_R0015040_Module_F_to_R0015001B_Module_E_alignment_Screenshot_2023-12-20_132815.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Cut Table flatness</translate> | ||

| + | |Step_Content=<translate>Once above step has been completed, both cut tables should be inspected for flatness | ||

| + | |||

| + | |||

| + | Use 1 meter straight edge on top face of cut tables and use 0.02" feeler gauge to inspect flatness of tables</translate> | ||

| + | |Step_Picture_00=R0008013_Clacker_assembly_quality.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version actuelle datée du 5 mars 2024 à 09:52

Details for correct alignment and process steps

Sommaire

- 1 Introduction

- 2 Étape 1 - Connect Air to Module F rollers

- 3 Étape 2 - Module F Saw Alignment points

- 4 Étape 3 - Position Module F

- 5 Étape 4 - Level Module F X and Y Axis

- 6 Étape 5 - Quality check

- 7 Étape 6 - Cut Table flatness

- 8 Étape 7 - Roller level quality check

- 9 Étape 8 - Z axis Saw Height Adjustment

- 10 Étape 9 - Caution

- 11 Étape 10 - Laser alignment of Saw to Saw infeed height

- 12 Étape 11 - Adjust alignment Saw module

- 13 Étape 12 - Check laser alignment

- 14 Étape 13 - Quality Check

- 15 Étape 14 - Set deflector plate

- 16 Étape 15 - Pneumatic connections

- 17 Commentaires

Introduction

Étape 1 - Connect Air to Module F rollers

Connect permanent air feed to lift module E rollers to the lifted position

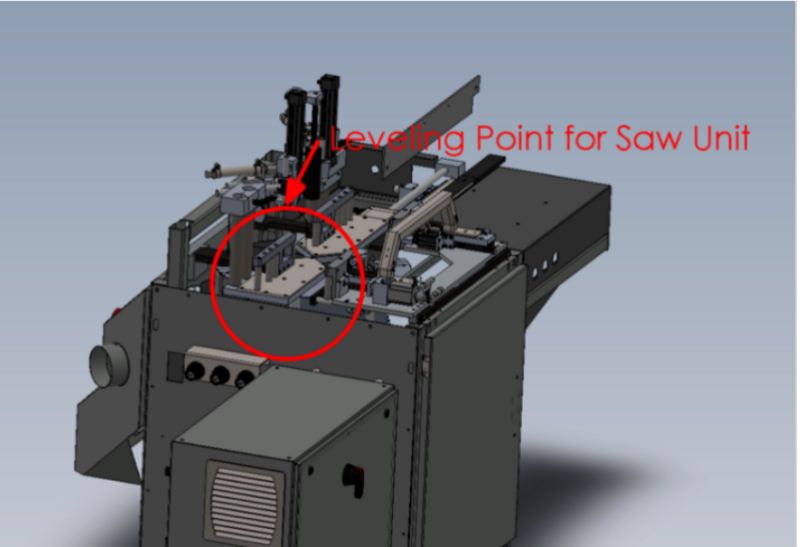

Étape 2 - Module F Saw Alignment points

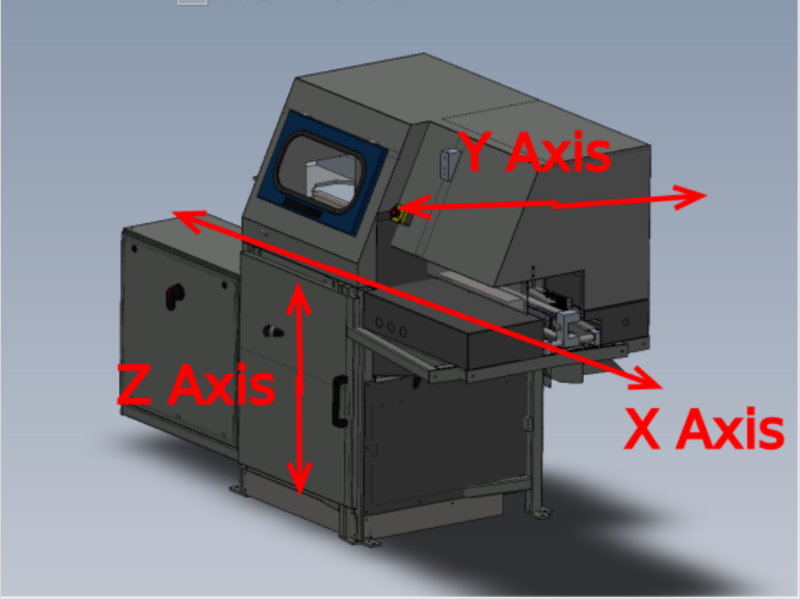

X axis position is determined by gripper travel

Y axis position is determined back fences

Z axis is determined by cut table to infeed roller height

Étape 3 - Position Module F

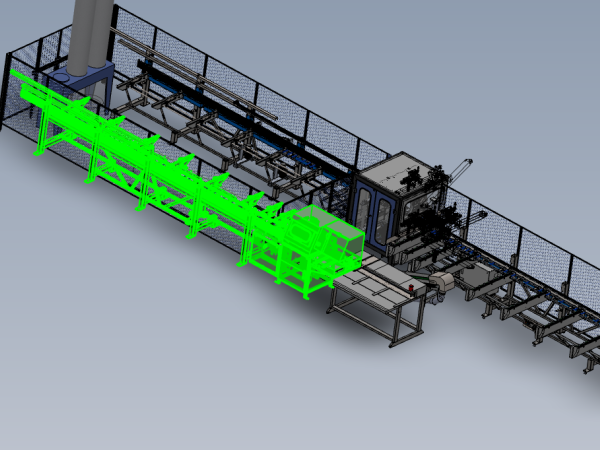

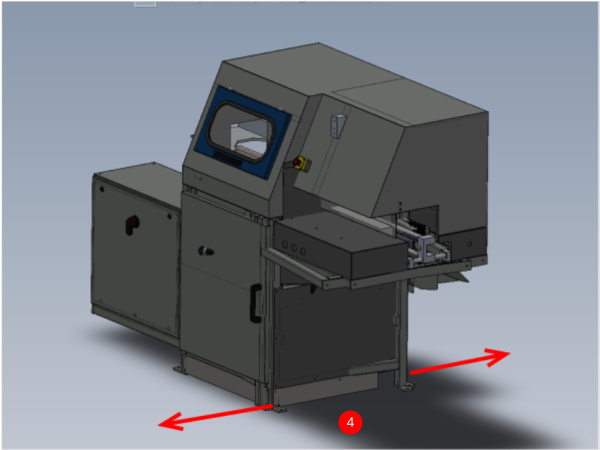

Position module F at end of Module E infeed frame

Approximately Align Saw roller back fences to Saw infeed back fences

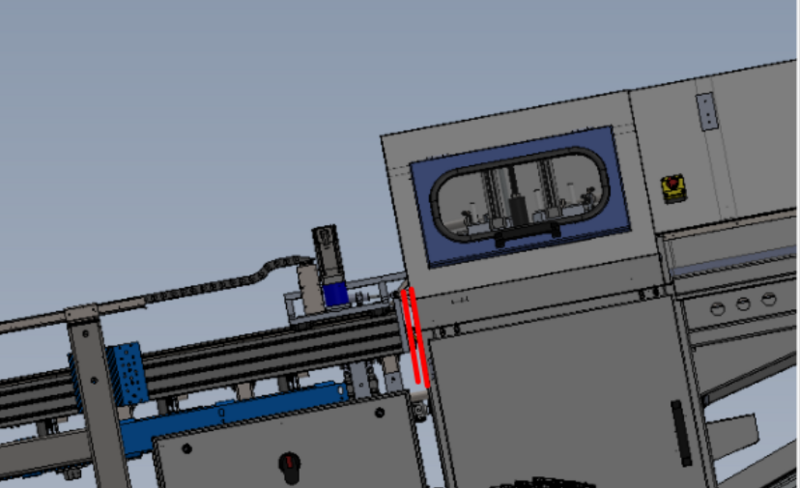

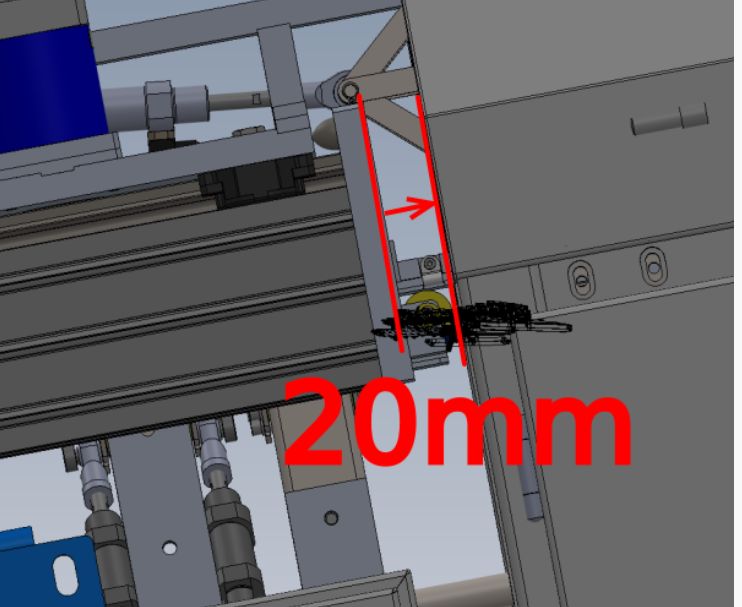

Approximately align X axis position by setting the to frames spaced at the distance shown of 20mm

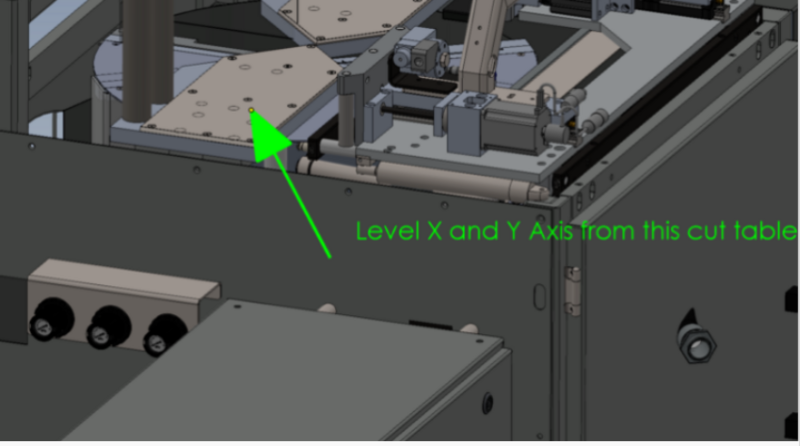

Étape 4 - Level Module F X and Y Axis

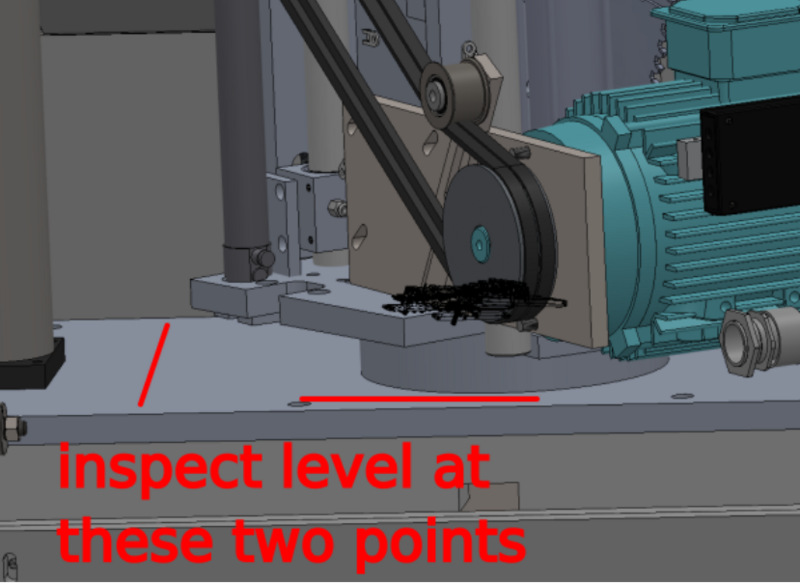

Use the indicated points to level the frame.

Use cut table indicated as levelling point

Level Y and X Axis of saw

Étape 5 - Quality check

It is vital to confirm Cut tables are in the correct position once levelled, and that movement hasn't occurred during transport

To do this the base of the saw turn table must be checked for level. These readings must read exactly the same as the levelled cut table in the previous step

Any discrepancy should be reported

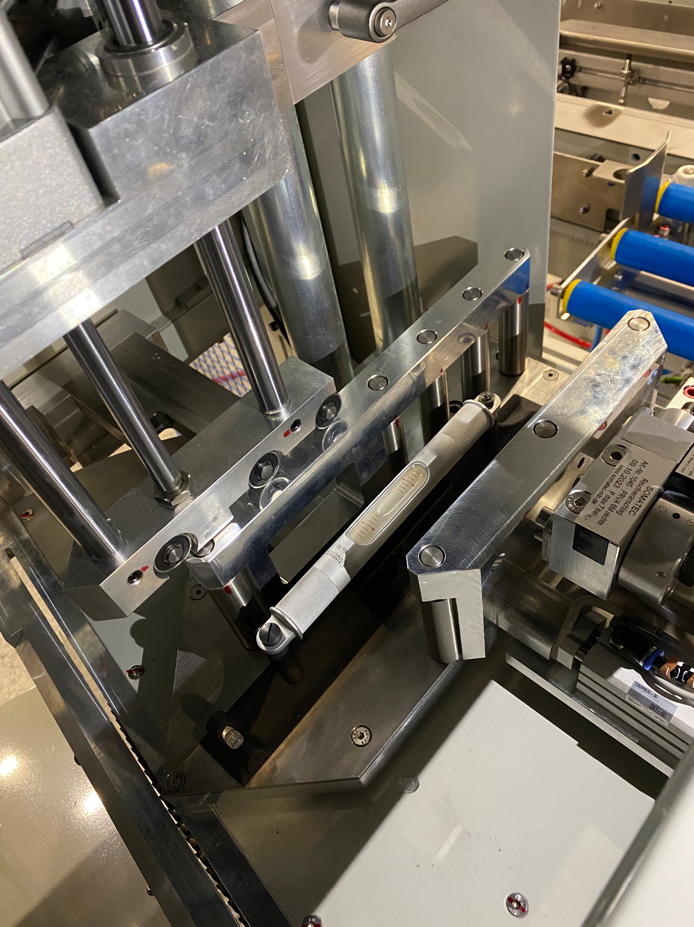

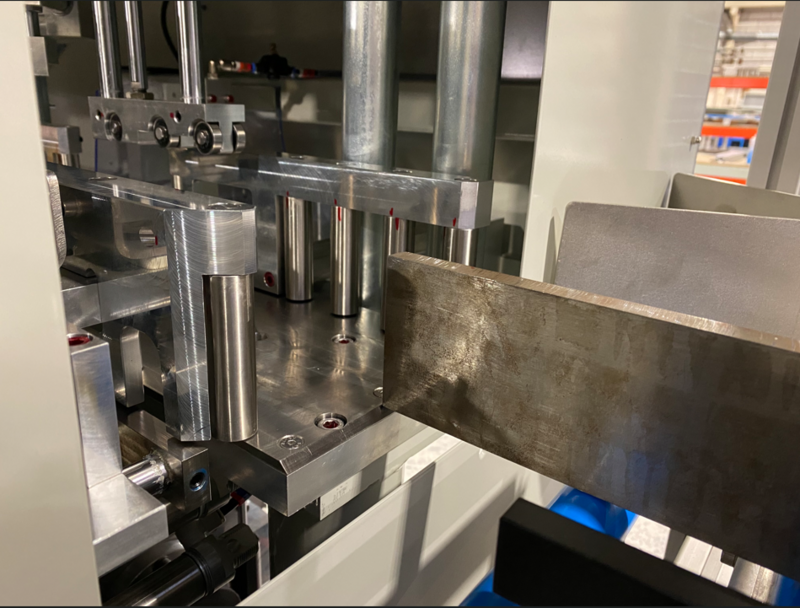

Étape 6 - Cut Table flatness

Once above step has been completed, both cut tables should be inspected for flatness

Use 1 meter straight edge on top face of cut tables and use 0.02" feeler gauge to inspect flatness of tables

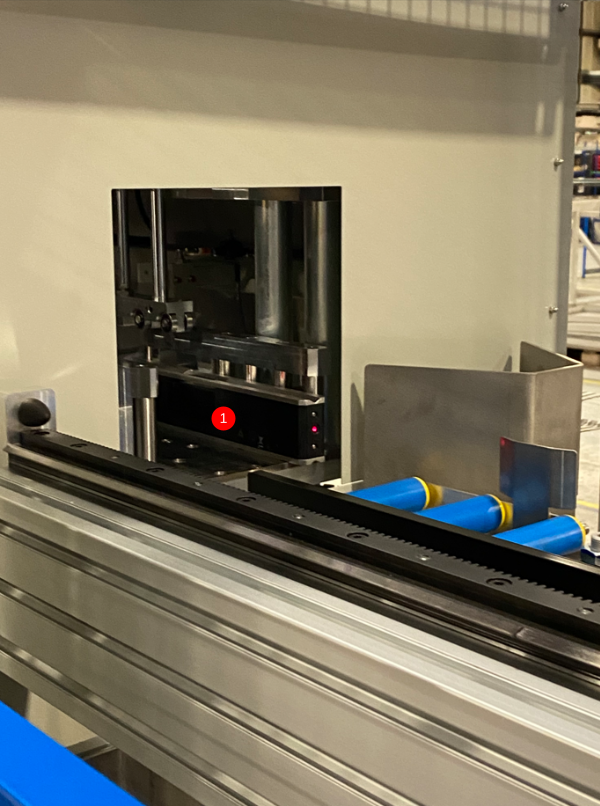

Étape 7 - Roller level quality check

Check with 2meter straight edge alignment of infeed rollers

All rollers should be level to each other, with no bumps onto adjacent rollers when straight edge is moved across. check this at front and rear section of roller beds to confirm roller bed levels are correct also

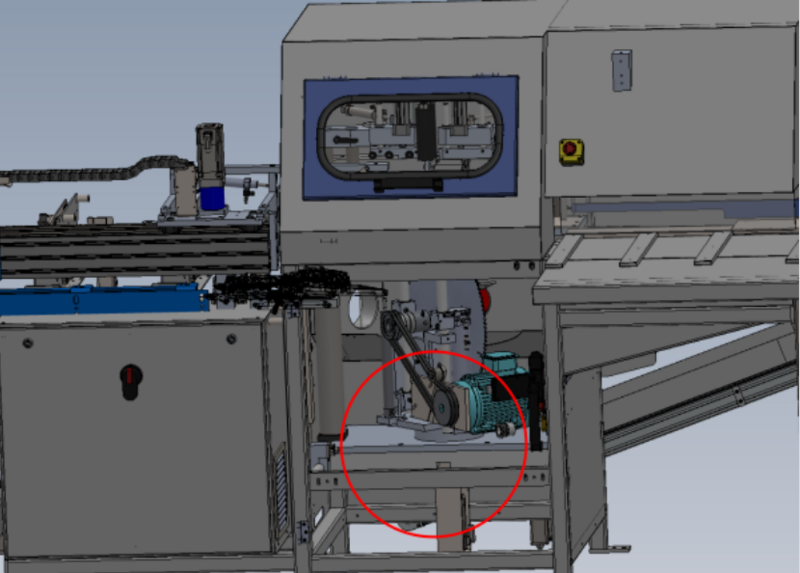

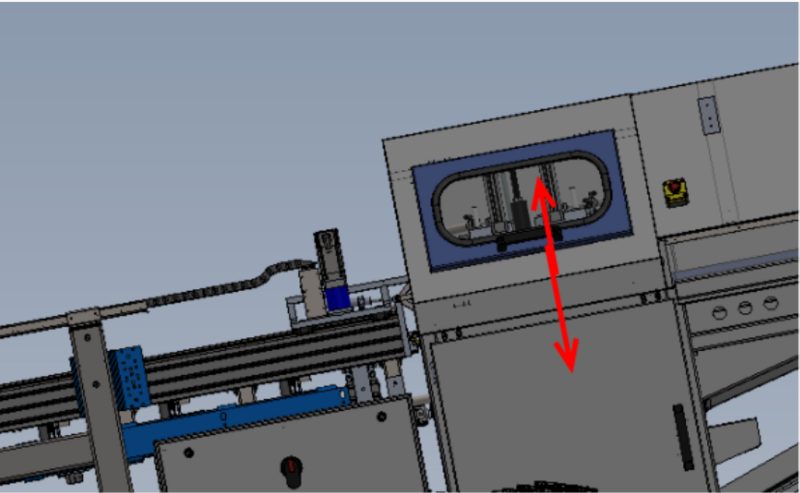

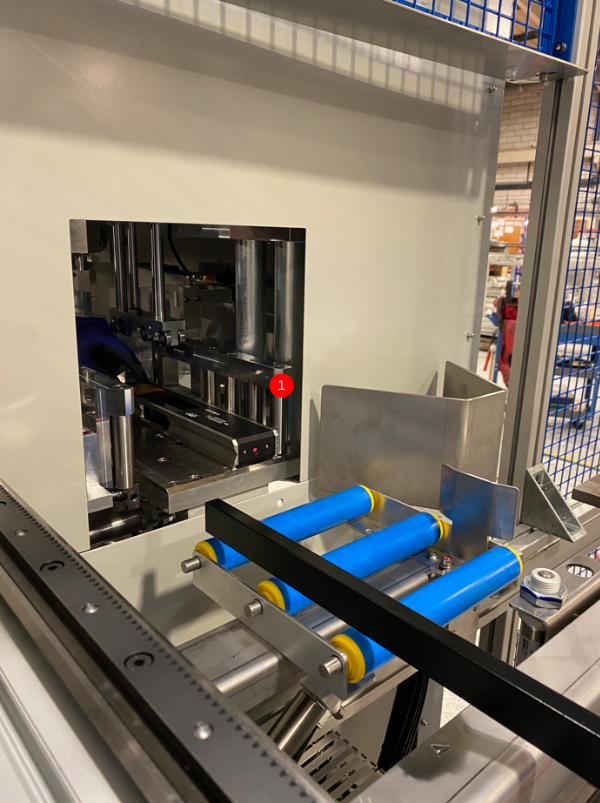

Étape 8 - Z axis Saw Height Adjustment

Saw module should be raised or lowered to align with blue load rollers on saw infeed table

Saw module should sit above blue rollers by no more than 1mm

Ensure levels previously set are not compromised when adjusting height

Double check levels are still correct once height has been adjusted

Étape 9 - Caution

It is vital before the next step is performed that cut tables are accurately levelled.

Double check that tables are level after height adjustment.

Tolerance -+ 1 division on engineers level

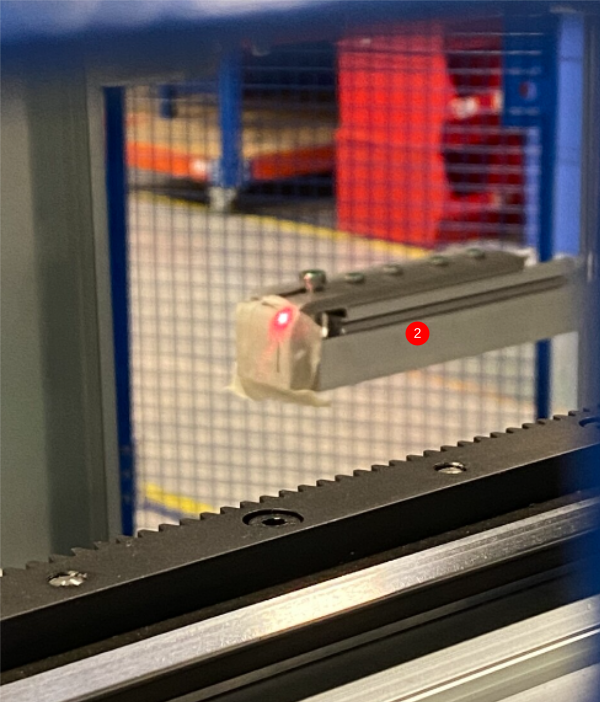

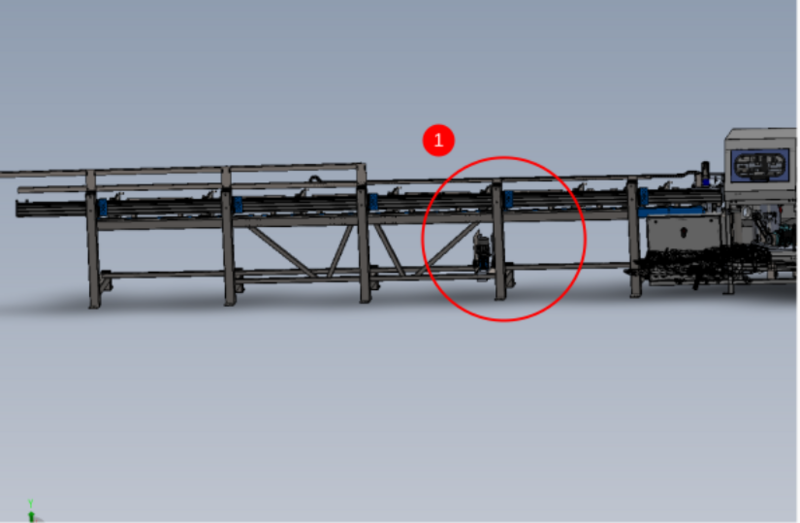

Étape 10 - Laser alignment of Saw to Saw infeed height

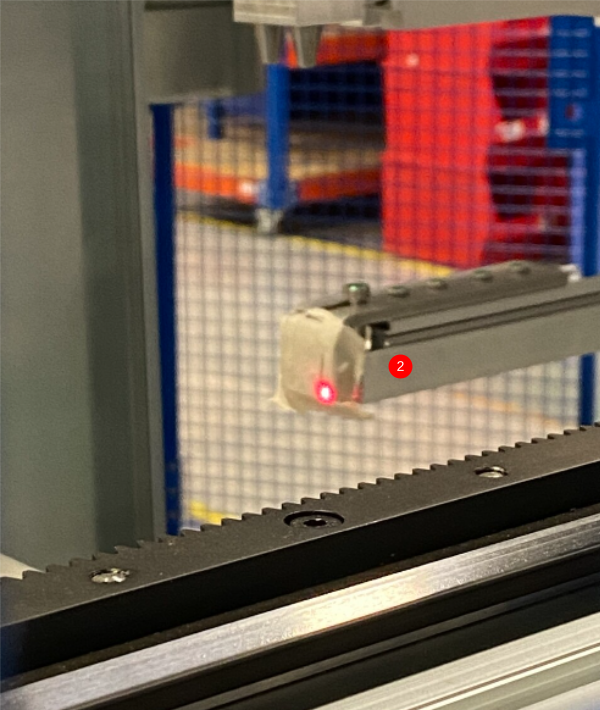

1 Position base of laser on cut table and cast beam towards gripper

2 Position Gripper directly Infront of laser and mark horizontal line on gripper to match laser dot

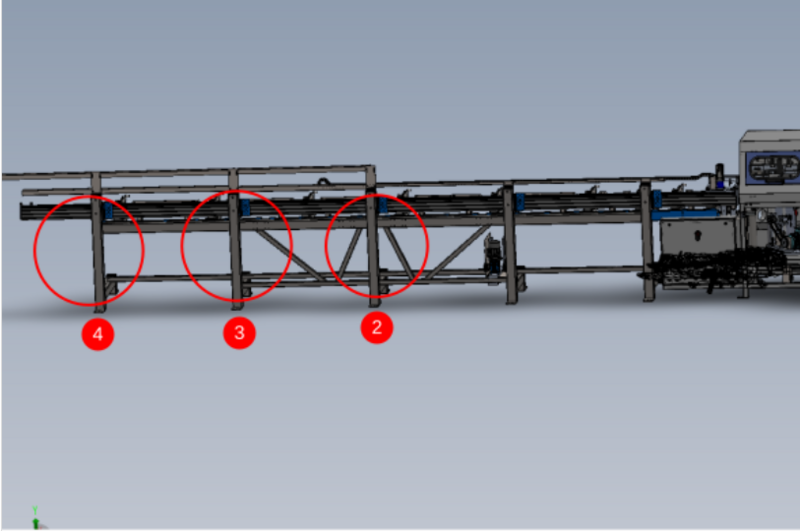

3 Move Gripper to point one indicated , and inspect horizontal line to laser dot . Any discrepancy can be adjusted by the 2 off adjusting floor bolts directly below

4 Repeat this step and indicated points 2,3 and 4

Étape 11 - Adjust alignment Saw module

1 Rotate the laser so the base is against the rear roller fence, and position the gripper at its closest point of travel to the saw .

2 Project the laser to the gripper, and mark a vertical line on the gripper Adjust Saw module in directions shown to align the laser to the vertical mark on gripper

3 Move gripper to end of infeed frame , and inspect laser mark

4 Adjust saw module as shown to correct laser mark onto gripper

Étape 12 - Check laser alignment

With the laser still casting along the infeed table, slowly return the gripper along the axis and inspect the laser dot in relation to lines added to gripper. Discrepancy should be less than 4mm on both axis

Étape 13 - Quality Check

All settings should be double checked once final adjustments have been made

Machine level

Laser alignment

Grip pin positions

Back fence alignments

Étape 14 - Set deflector plate

Set deflection plate to be 4mm behind backfences of Saw and Infeed table and finalise position

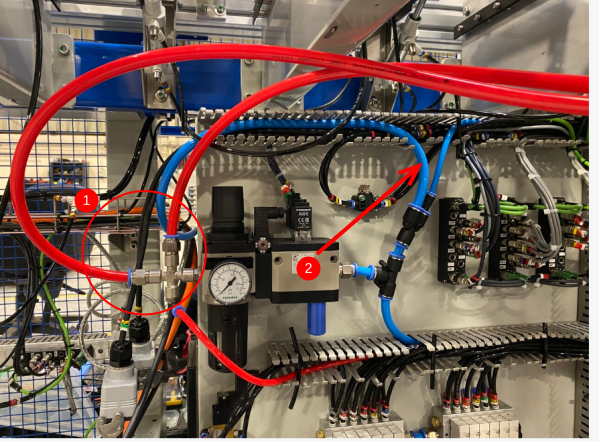

Étape 15 - Pneumatic connections

1 Connect 2 off 12mm red pipes from transfer basket to saw air service unit

Connect 1 off 12mm blue pipe from Module E saw infeed table

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português