Fitting and setting details for back fences

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Attach backfence support

- 4 Étape 3 - Attach roller fences

- 5 Étape 4 - Set squareness

- 6 Étape 5 - Set alignment between roller fences

- 7 Étape 6 - Set height

- 8 Étape 7 - Recheck all settings

- 9 Étape 8 - Remove all sharp edges

- 10 Commentaires

Introduction

Tools Required

Standard hex key set

1 Meter straight edge

Feeler gauges

engineers square

Shim pack

Parts Required

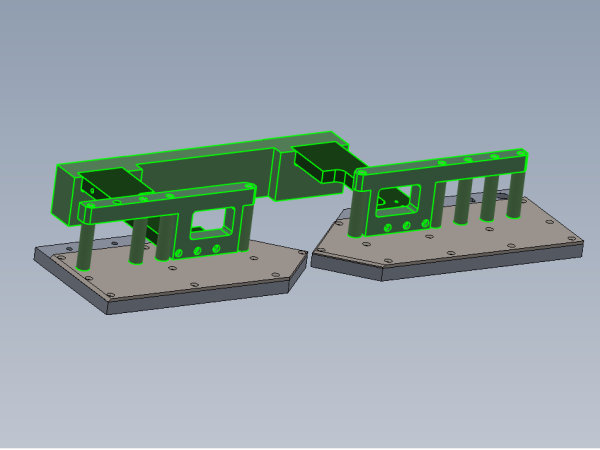

R0000559 Bench assemble machined parts

R0015326 Bench Assemble Roller Backfences

Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

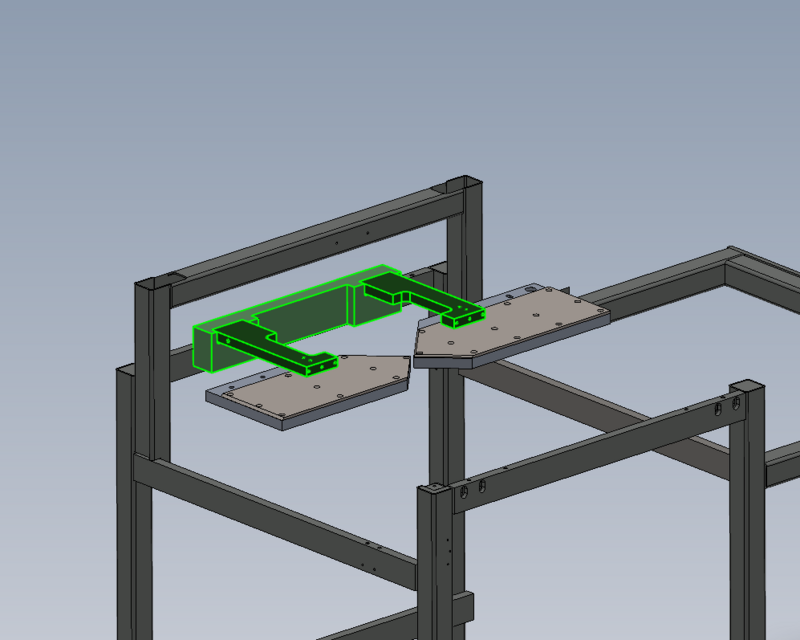

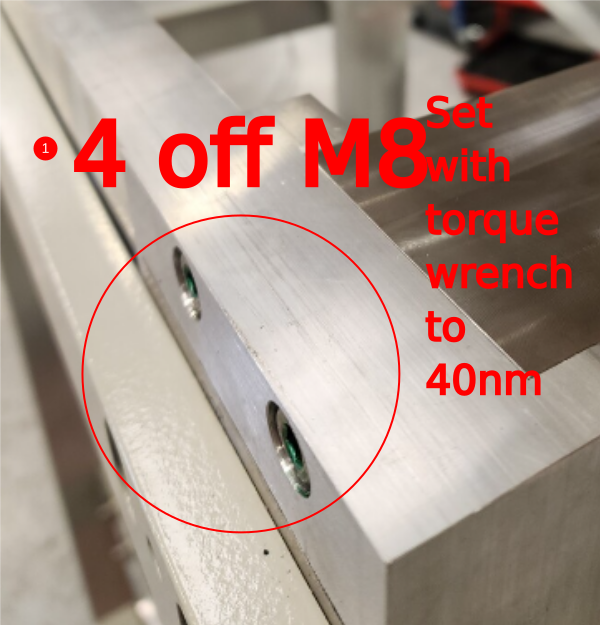

Étape 2 - Attach backfence support

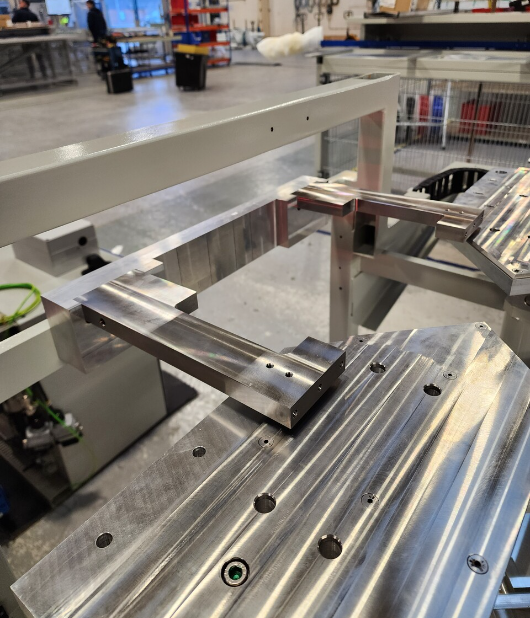

Attach pre machined back fence support to main frame

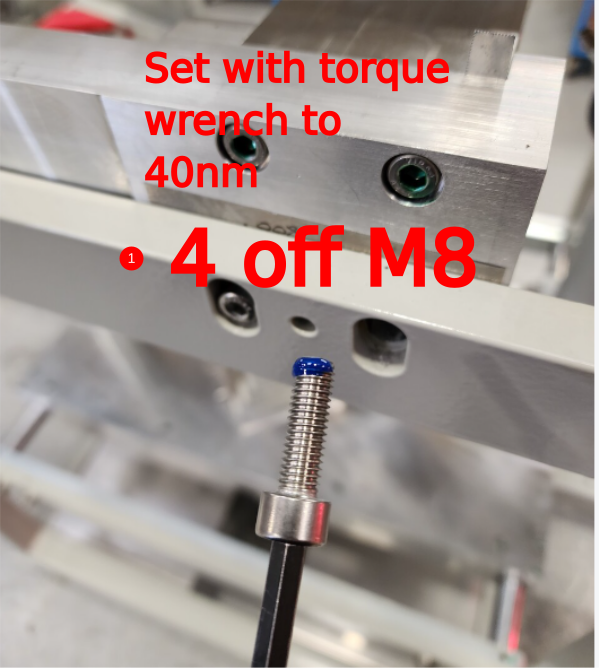

Use 4 off M8 x 25 socket caps , do not apply adhesive

Set assembly to maximum height position in fixing slots

Étape 3 - Attach roller fences

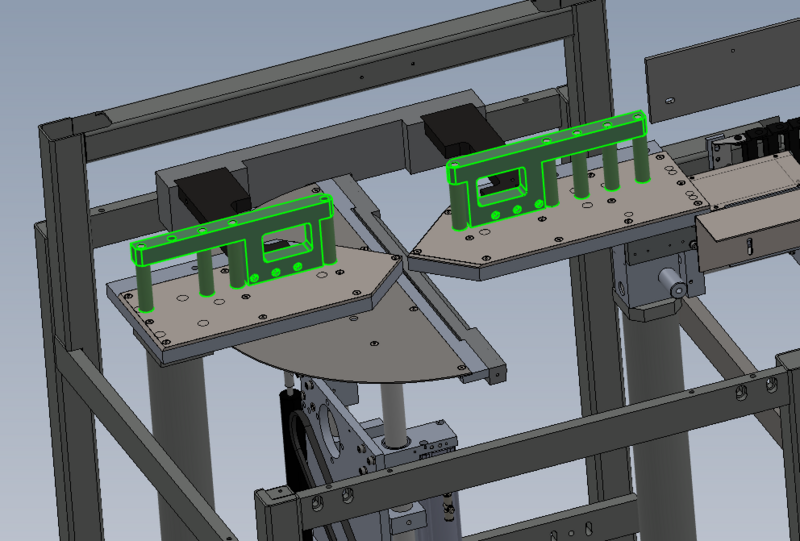

Attach pre build roller fences to backfence support bar using M6 x 35 socket caps . Do not apply adhesive

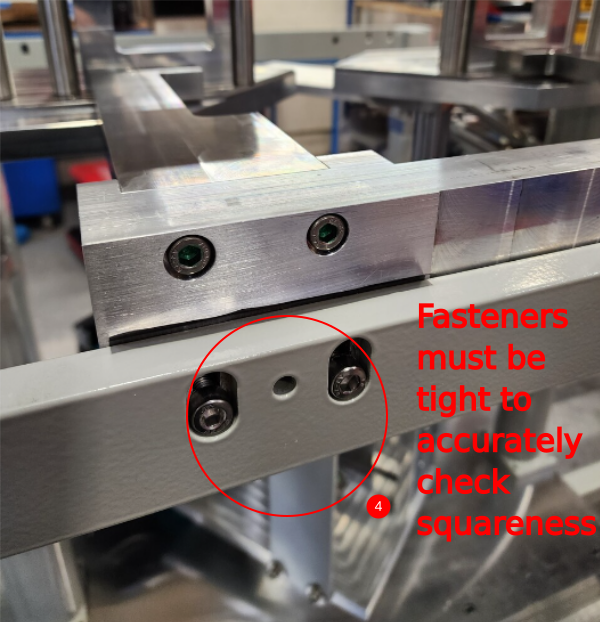

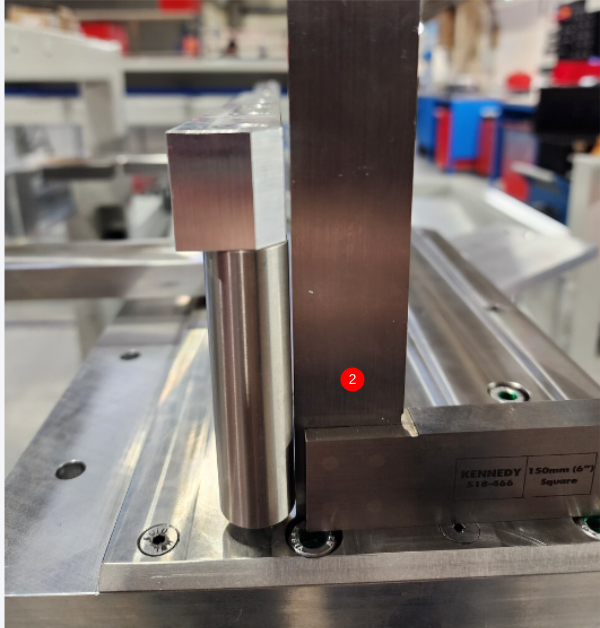

Étape 4 - Set squareness

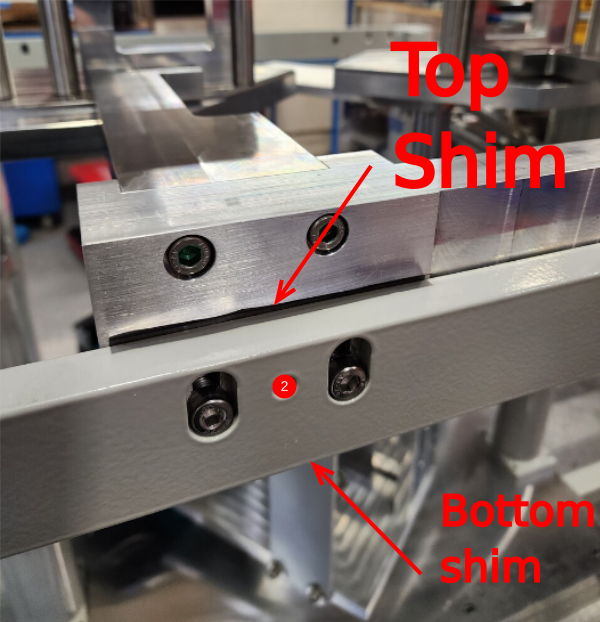

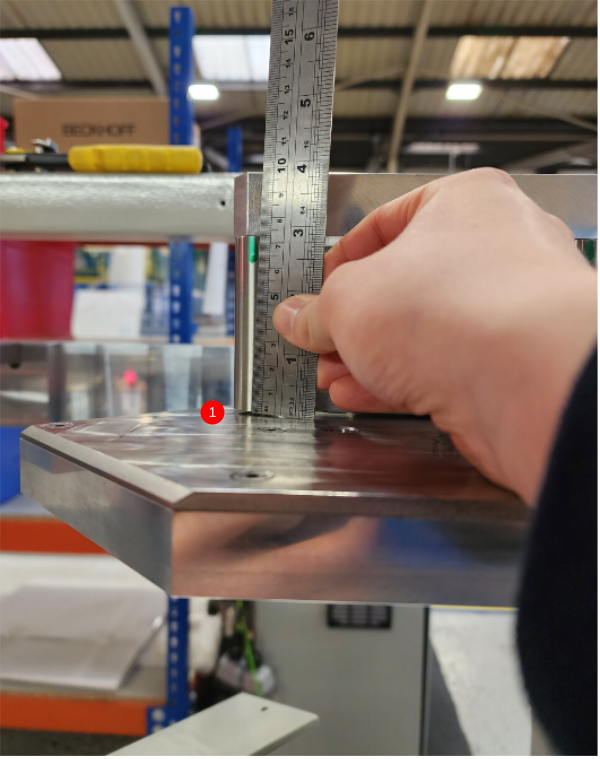

1 Use engineers square to check squareness of roller fences to cut tables. Check at multiple points

2 Identify movement required to adjust square.

Gap between square and roller:

Top = add shim to top of bar

Bottom = Add shim to bottom of bar

3 Cut and add shim ensuring shim bottoms out on M8 fastener, as this will act as a datum

4 Adjust until rollers are square with full tension on M8 fixings

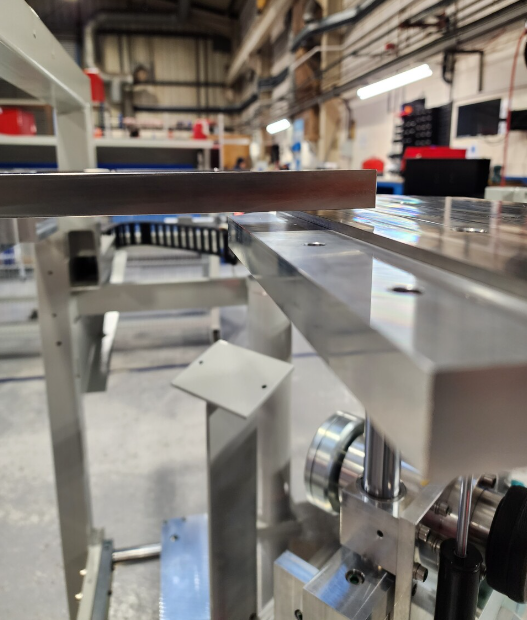

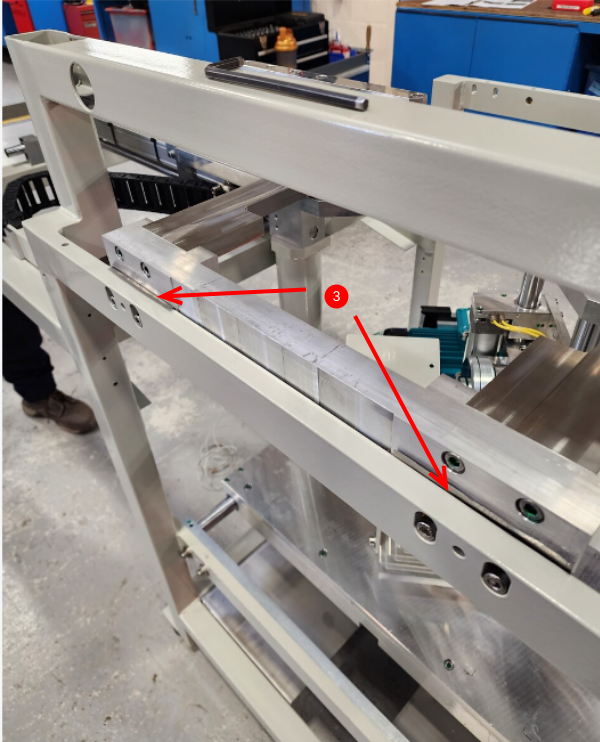

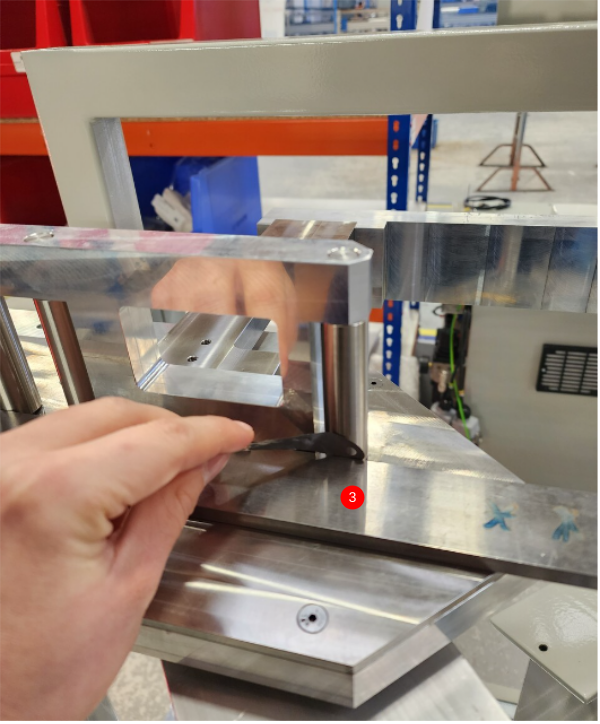

Étape 5 - Set alignment between roller fences

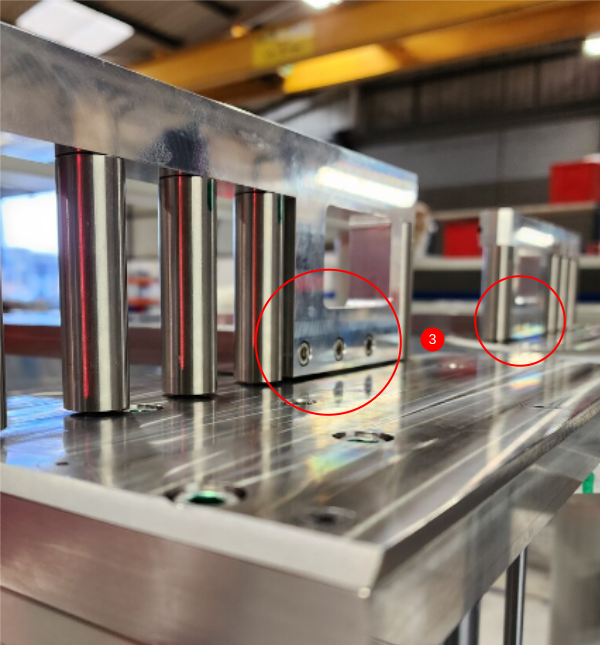

1 Use 1 meter straight edge to check alignment of rollers. Identify which direction movement is required to achieve alignment of all rollers.

Tolerance 0.002"/0.05mm

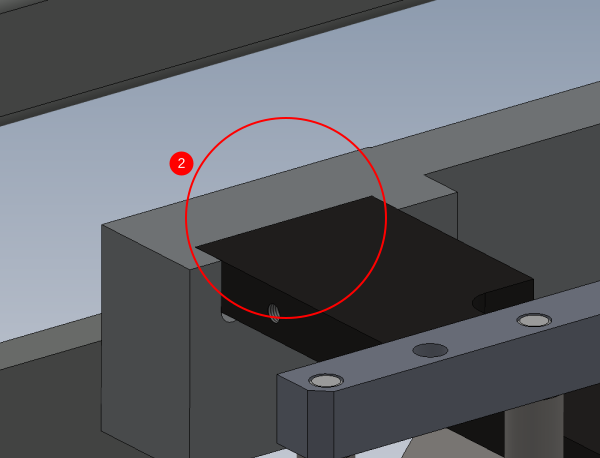

2 Adjust using shim at indicated point on either / both arms

3 Adjust until all roller are within tolerance to straight edge

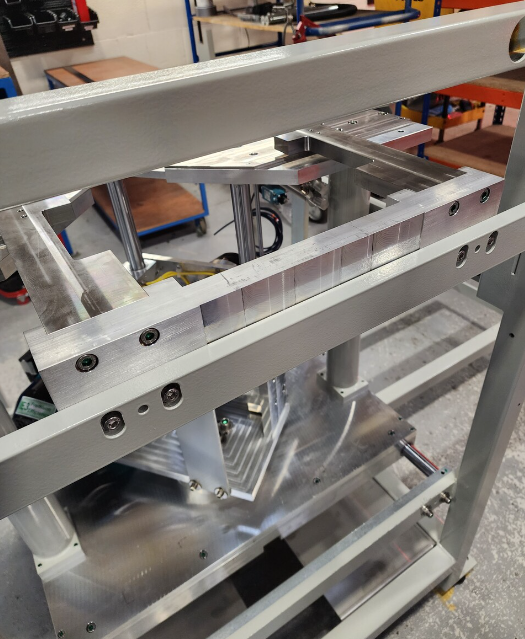

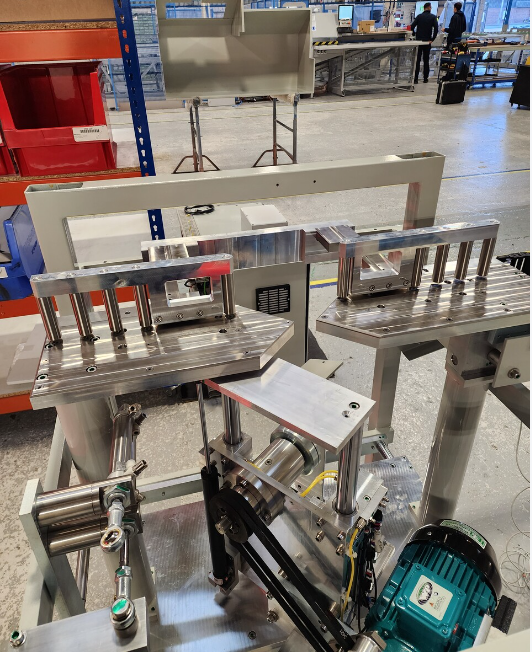

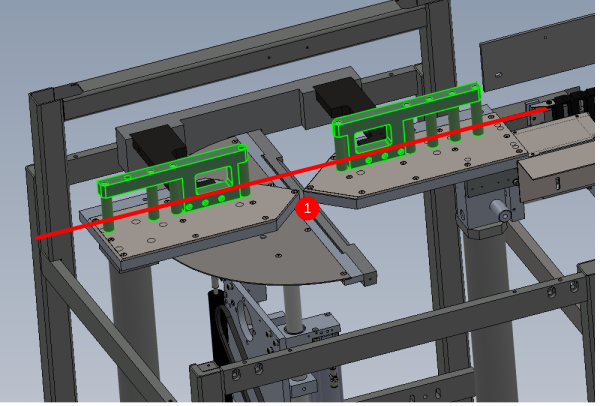

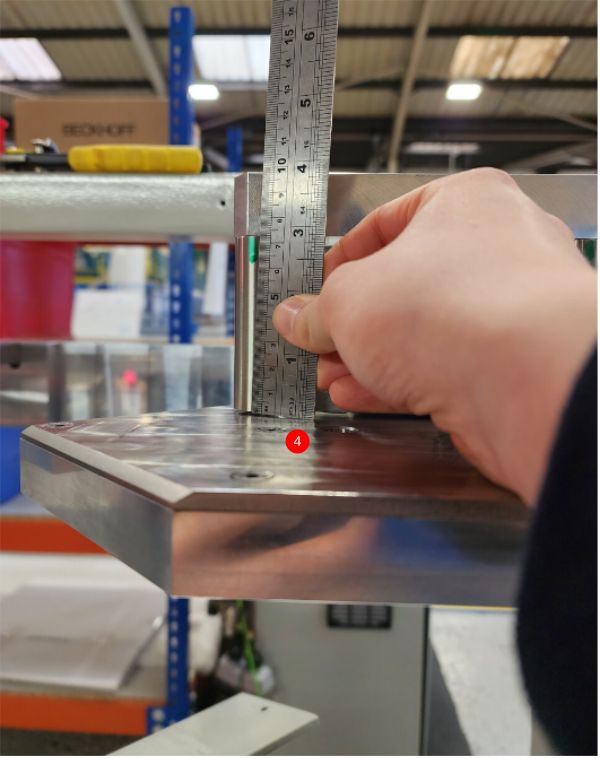

Étape 6 - Set height

1 Set heights of all rollers to cut tables to a gap of 1.5 mm . tolerance -+0.5mm

2 Use slots shown for main adjustment

3 Use counterbores shown for fine adjustment

4 Check all measurements on all rollers are correct

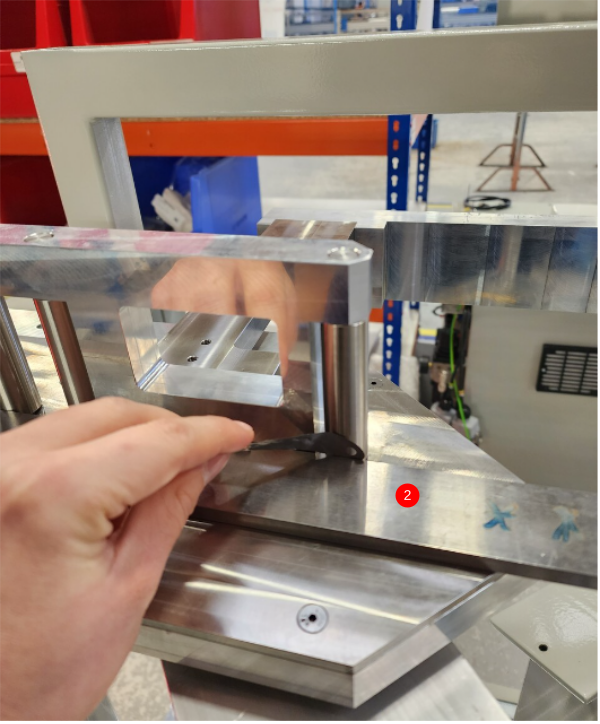

Étape 7 - Recheck all settings

1 Finalise all fasteners shown. 8 off M8 indicated should be set to 40 nm toque setting

Once final adjustment has been done, recheck all settings as movement is possible when adjusting

2 Table /roller squareness

3 Roller alignment

4 Roller height

Étape 8 - Remove all sharp edges

Once all fasteners are finalised and settings checked, shim over hangs must be removed.

Ensure no cut points are left from exposed shims

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português