| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 5 : | Ligne 5 : | ||

|Categories=Production | |Categories=Production | ||

|Difficulty=Medium | |Difficulty=Medium | ||

| − | |Duration=1 | + | |Duration=1.5 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

Version actuelle datée du 3 avril 2024 à 12:39

quality checks and frame levelling

Introduction

Tools Required

2 meter straight edge

1 meter steel rule

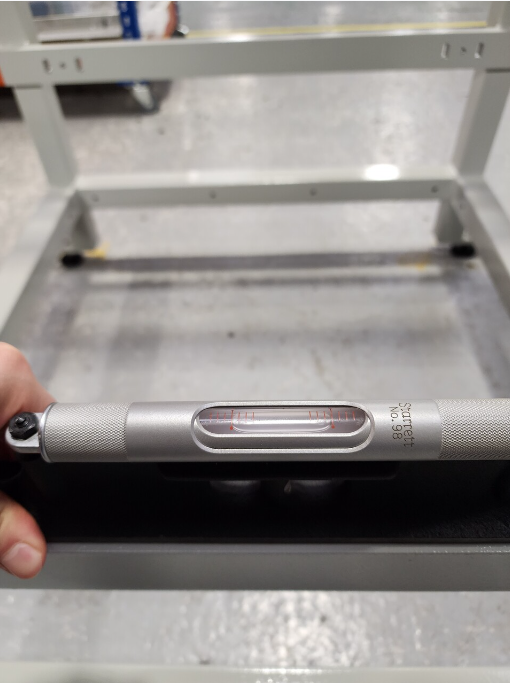

300mm engineers level

Standard spanner set

Copper grease

Standard tap set

Tape Measure

Standard ratchet/socket set

Parts Required

Workshop consumable floor pads

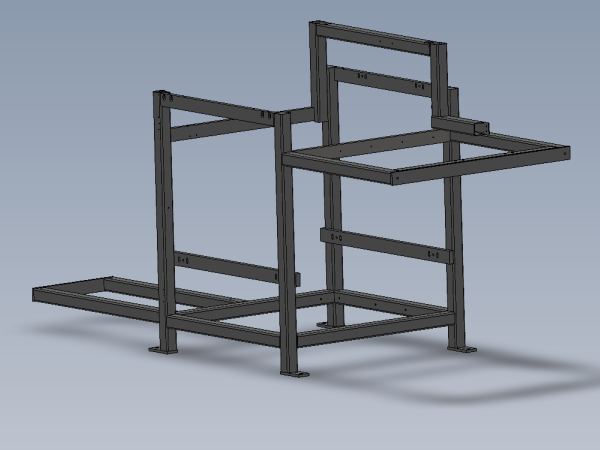

D0004576e frame x 1

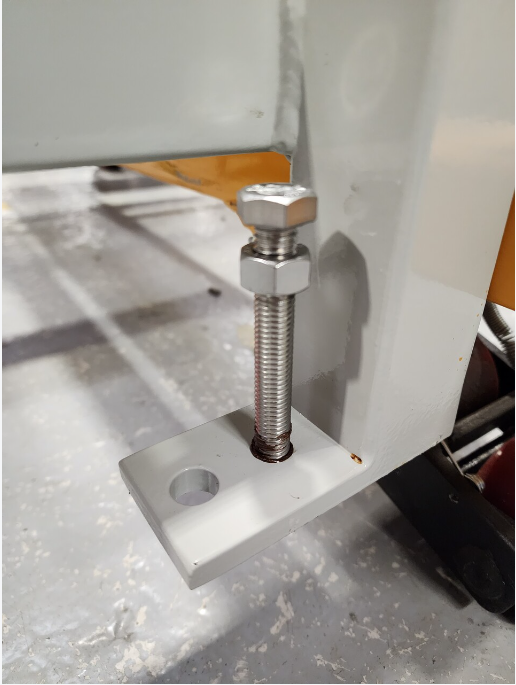

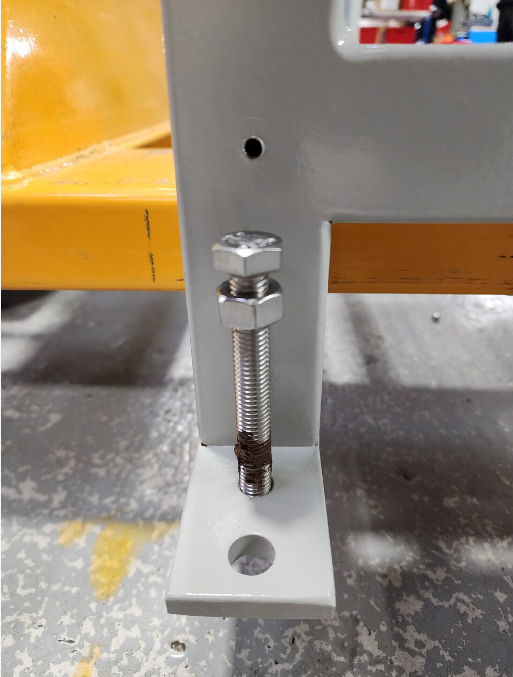

M12 x 100 set bolts x 4

M12 Standard nut x 4Étape 2 - Add levelling bolts

Fit 4 off M12 set bolts with M12 nut and copper slip to frame for levelling

Position black levelling pads beneath each bolt

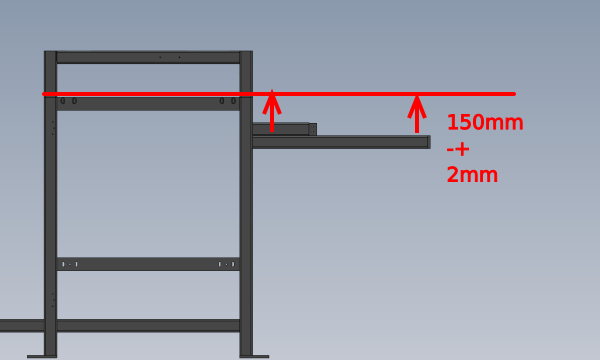

Étape 3 - Check projection

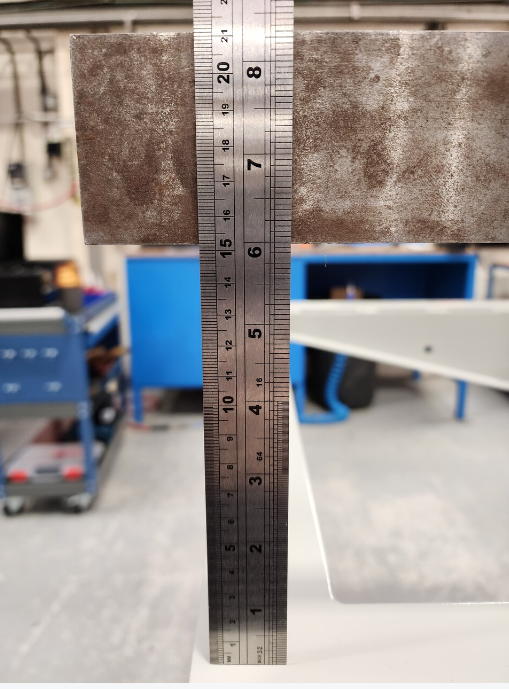

check indicated projection using 2 meter straight edge

check all 4 points

150mm -+ 2mm

Étape 4 - Check parallel

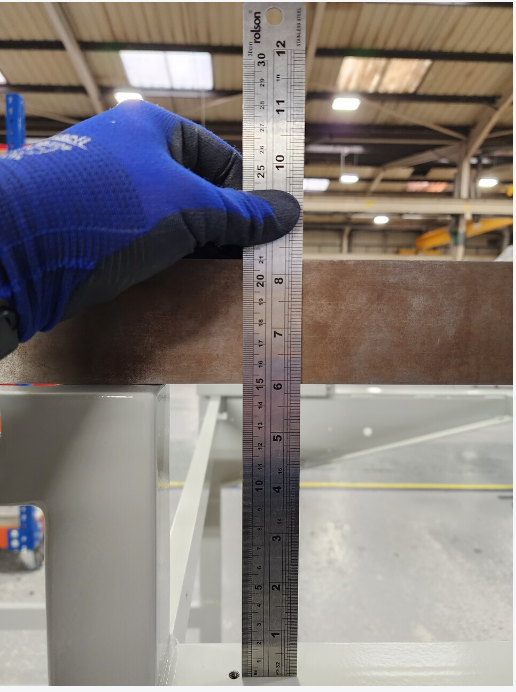

Use 1 meter steel rule or tape measure to check parallel of faces indicated

Report any deviation to supervisor

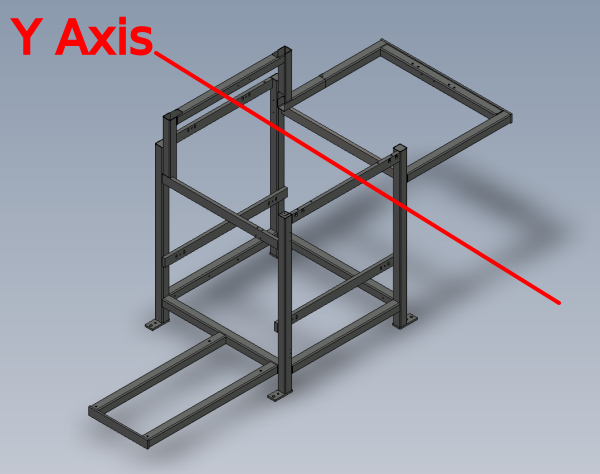

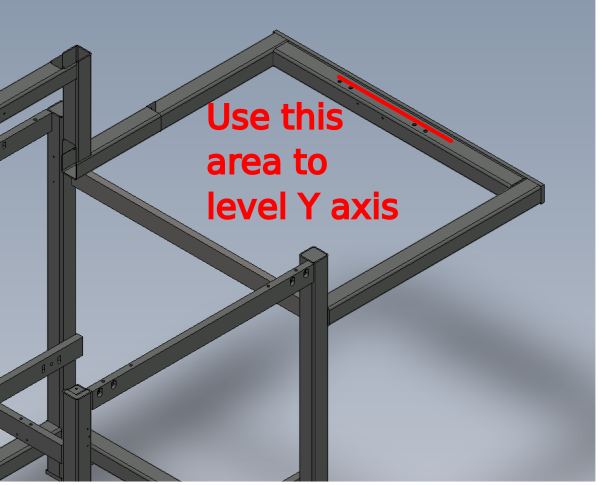

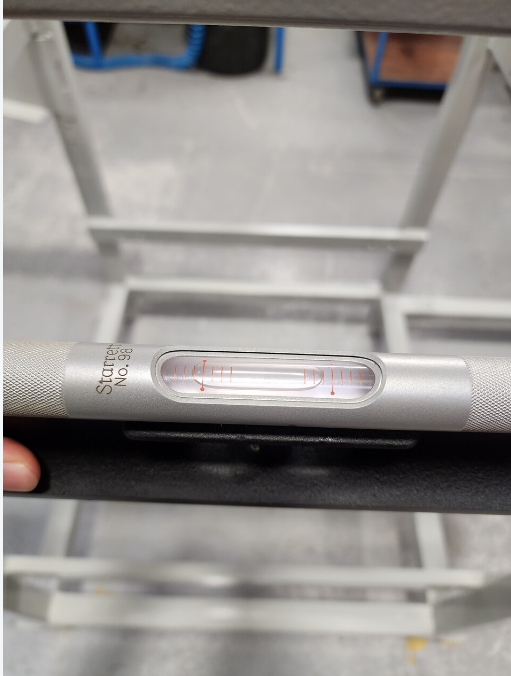

Étape 5 - Level Y axis

Use M12 bolts to level frame on the Y axis . Use indicated area to set level of frame

Ensure levelling face is flat

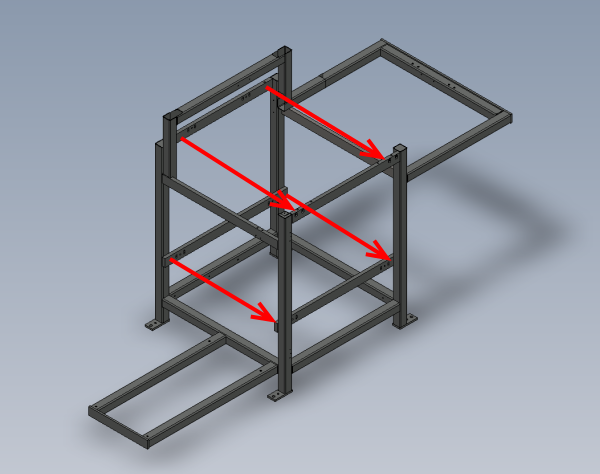

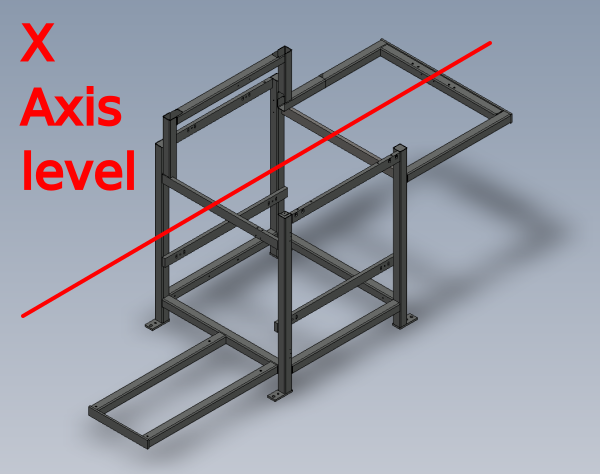

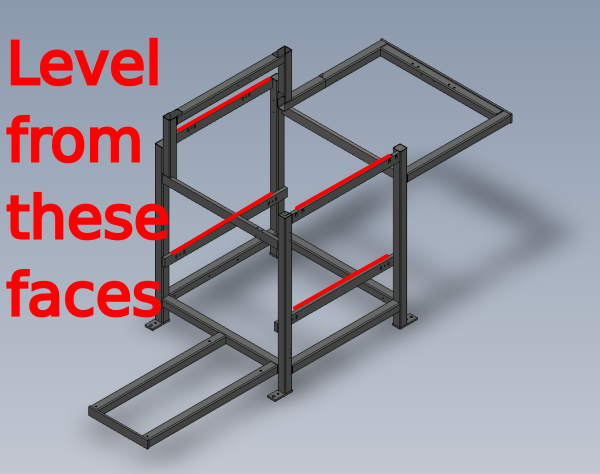

Étape 6 - Level X axis

Level X axis using indicated faces

Ensure Y axis level is maintained when adjusting X axis

Take an average over the 4 indicated points to set x axis level

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português