installation of wiring loom and captivating spindle bases

Sommaire

- 1 Introduction

- 2 Étape 1 -

- 3 Étape 2 - Quality Check

- 4 Étape 3 - Start Wiring loom installation

- 5 Étape 4 - Quality check power routing

- 6 Étape 5 - Spindle 6 to 5 connections

- 7 Étape 6 - Spindle 5 to 4 connections

- 8 Étape 7 - Spindle 4 to 3 connections

- 9 Étape 8 - Spindle 3 to 2 connections

- 10 Étape 9 - Spindle 2 to 1 Connections

- 11 Étape 10 - Spindle 1 to 8 connections

- 12 Étape 11 - Spindle 8 to 7 connections

- 13 Étape 12 - Fit datum stop pin assembly to spindle plate

- 14 Étape 13 - Fit assembled R axis stop R0000713E

- 15 Étape 14 - Dowel D0000291 plates in position

- 16 Étape 15 - Add fixings

- 17 Étape 16 - Finalize dowel holes

- 18 Étape 17 - Add Spindle infill plates

- 19 Commentaires

Introduction

Tools Required

Standard hex key set

Ball pein hammer

6mm drift/punch

Drill driver

6mm hex drill attachment

Small g clamp 50-100m

Suport block

Stubby 4mm hex key

Parts Required

D00000291 spindle plate x 8

M0000025 Ident numbers

D0007703 r stop pin

D0007990 cylinder anchor

D0007611 infill plate x 4

D0001176 Infill plate x 4

Étape 1 -

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All bolts to be pen marked once adhesive applied and correct tension added

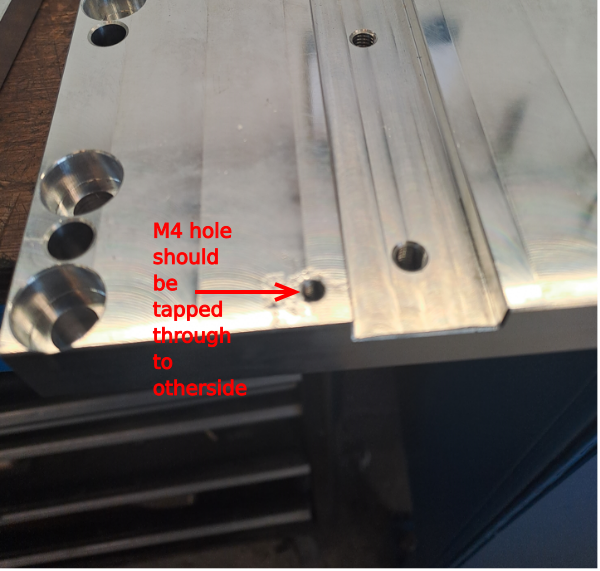

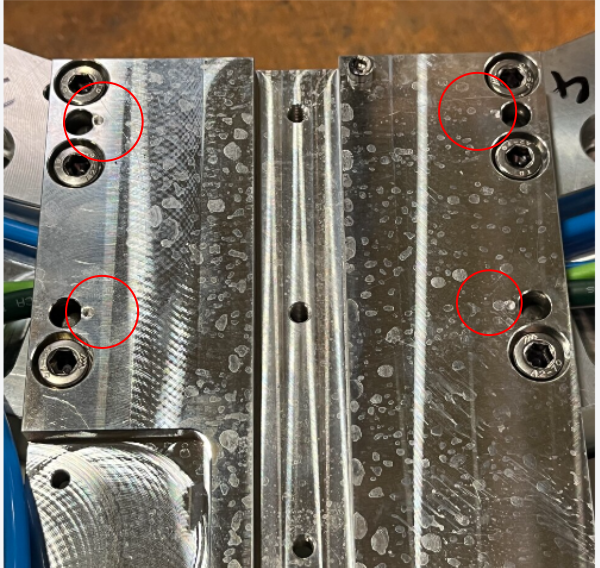

Étape 2 - Quality Check

Check D0000291 spindle base has M4 hole tapped all the way through the plate. Rework if not

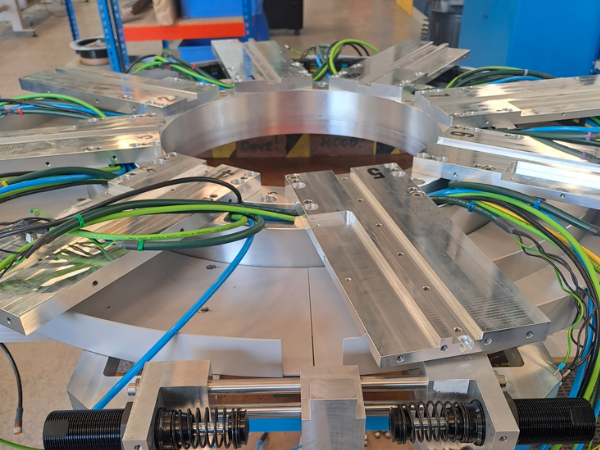

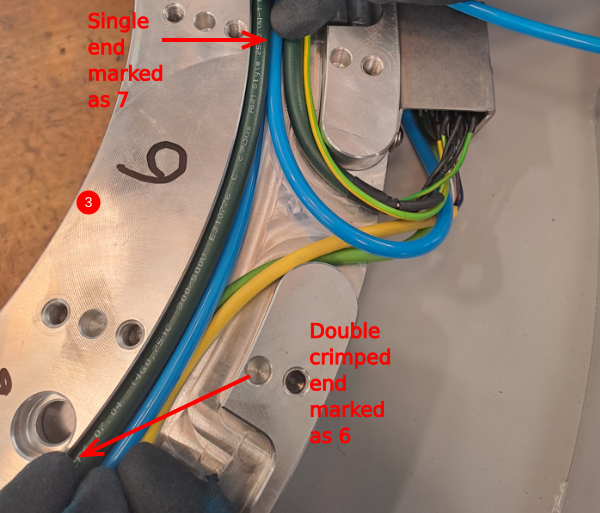

Étape 3 - Start Wiring loom installation

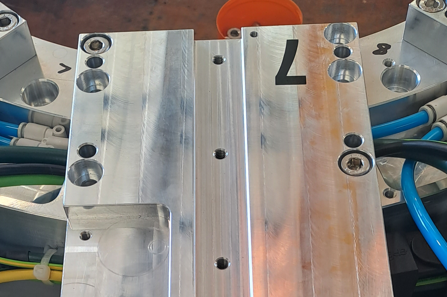

Wiring loom is started at position 6 as indicated by picture

1 Green and yellow Ethercat system cables route left to connection box 6

2 300 hz power cable and earth cable route to the right to connection box 7

3 Pre made 300 hz wiring loom . Identify Single end of loom marked as 7 connected to double crimped end marked as 6. Run between 7 and 6 as shown in image

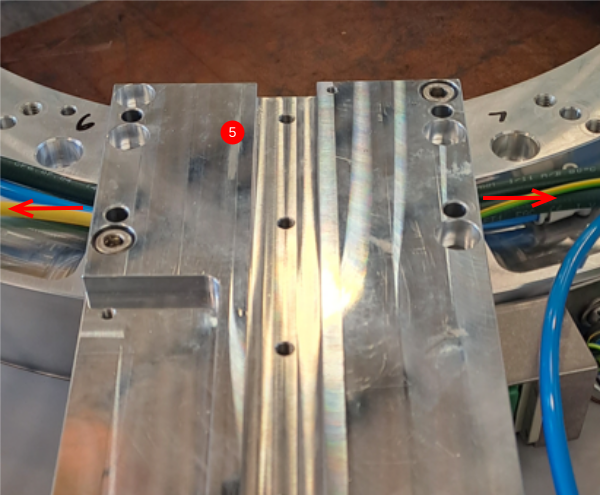

4 Fit plate D0000291 using 2 off m8 x 25 socket caps. Only apply light tension to the m8 socket caps with no adhesive .

5 Once plate is fitted, ensure cables under are not trapped by checking movement is possible in the direction shown

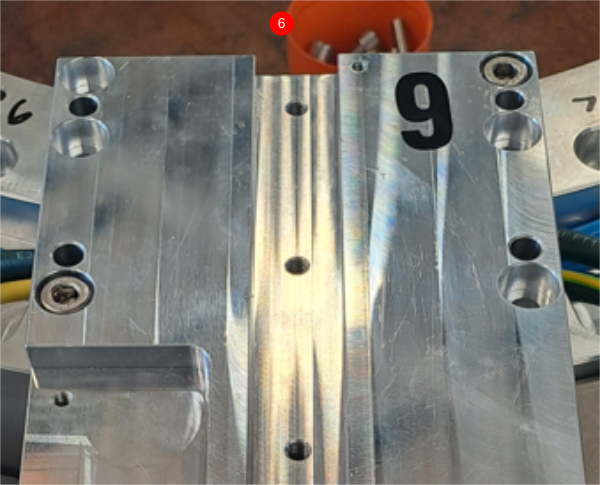

6 Fit M0000025 number ident

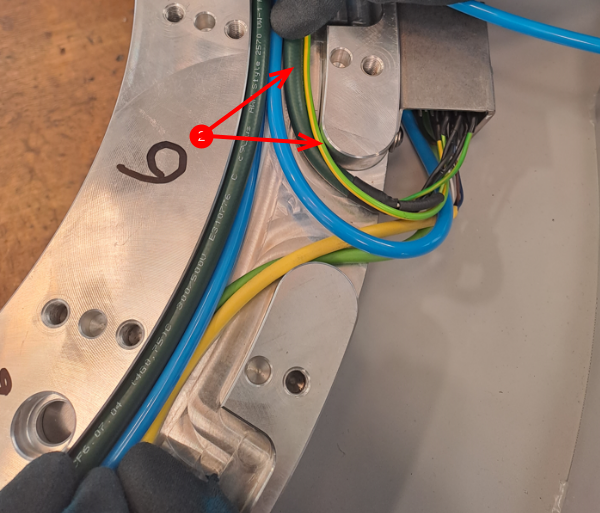

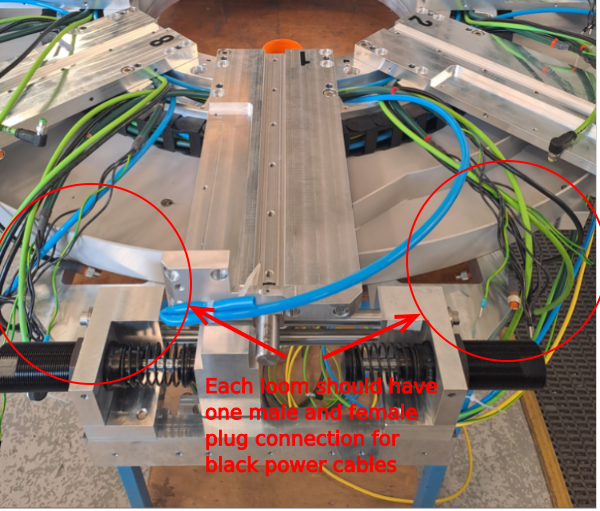

Étape 4 - Quality check power routing

Pre made power cables (ethercat power ) should be double checked for correct routing and orientation

Each spindle loom should contain one female and one male plug .

Check this is the case once loom is installed

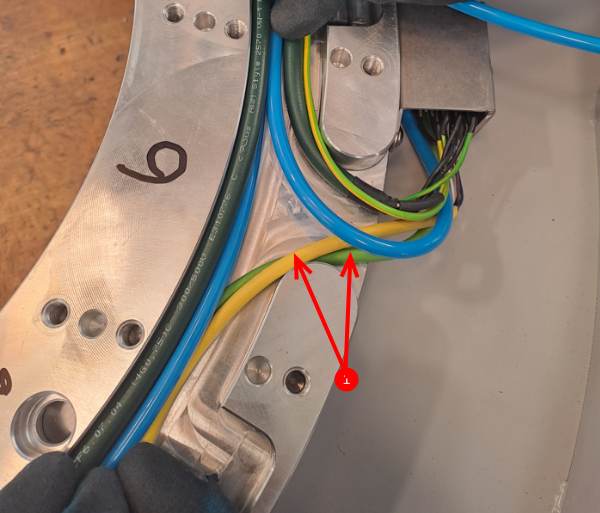

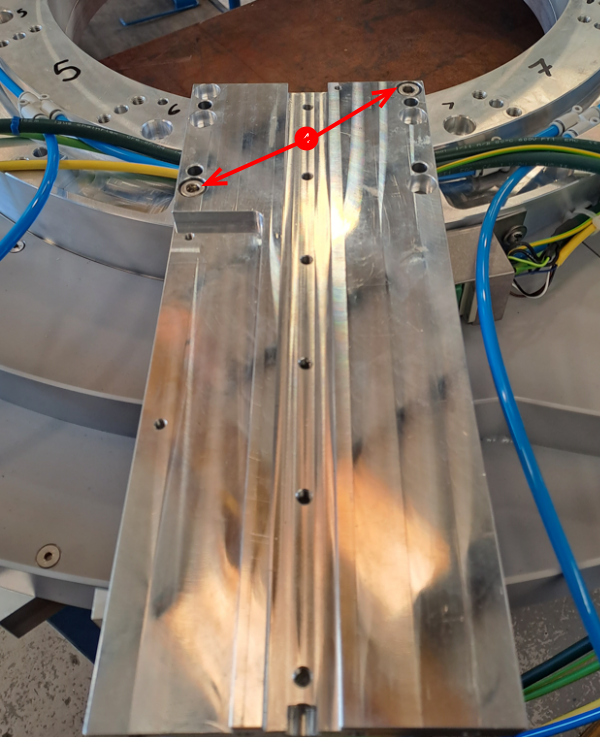

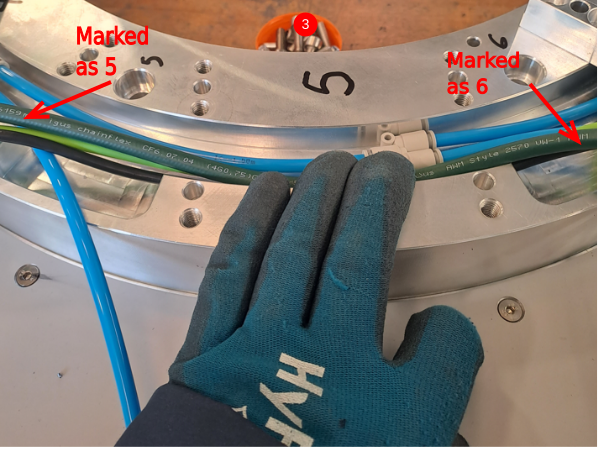

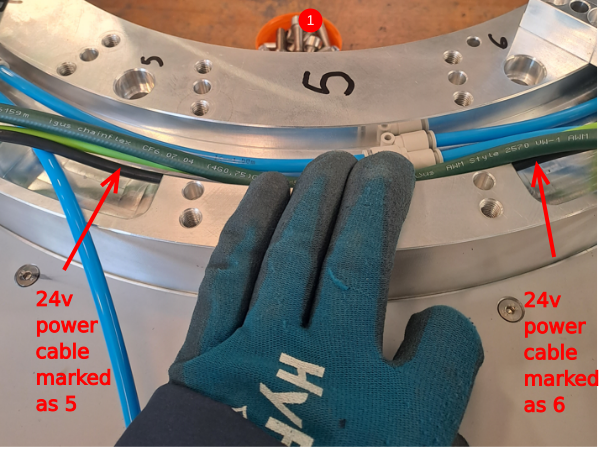

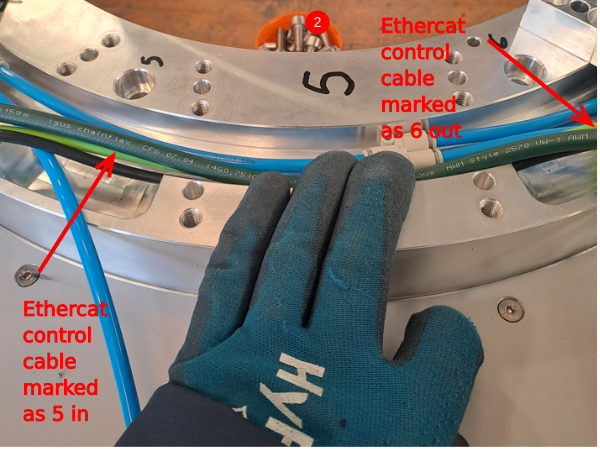

Étape 5 - Spindle 6 to 5 connections

From pre made cables, identify the following

24v power cable marked as 6 and 5

Green ethercat cable marked as 6 out - 5 in

1 Install 24v power cable as shown

2 Install green ethercat cable as shown

3 Install 300 hz power cable as shown

4 Attach next D0000291 plate as step 3

5 Fit M0000025 number ident

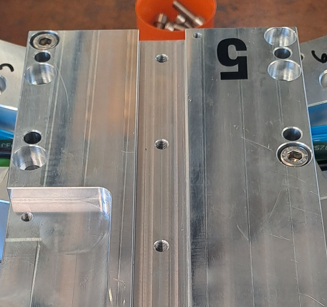

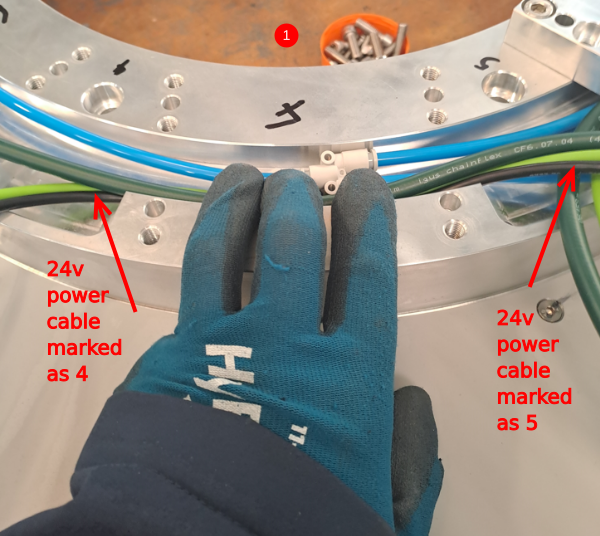

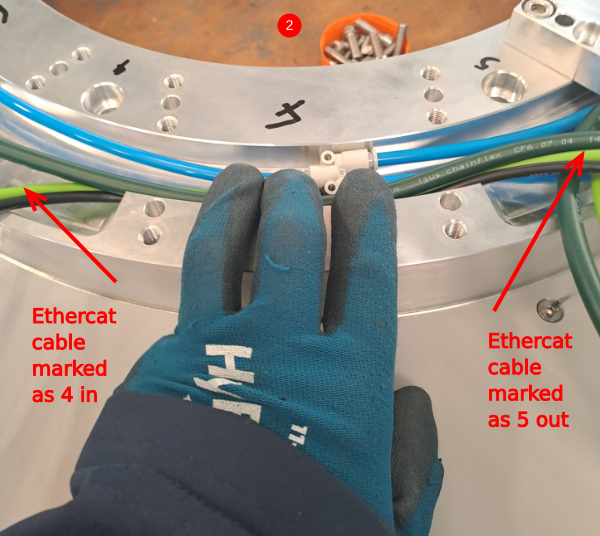

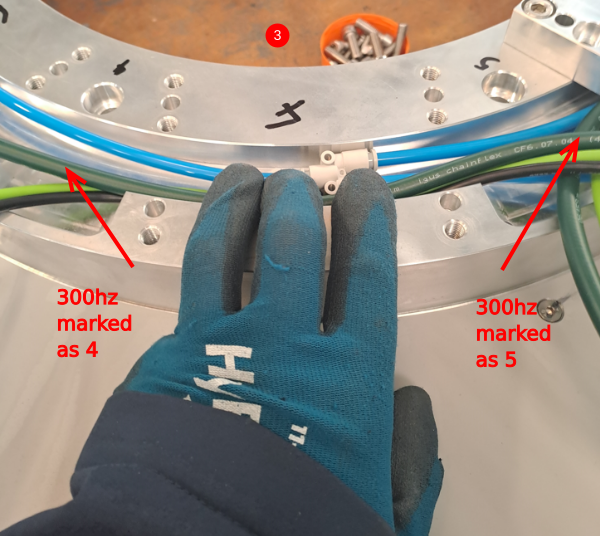

Étape 6 - Spindle 5 to 4 connections

24v power cable marked as 5 and 4

Green ethercat cable marked as 5 out - 4 in

1 Install 24v power cable as shown

2 Install green ethercat cable as shown

3 Install 300 hz power cable as shown

4 Attach next D0000291 plate as step 3

5 Fit M0000025 number ident

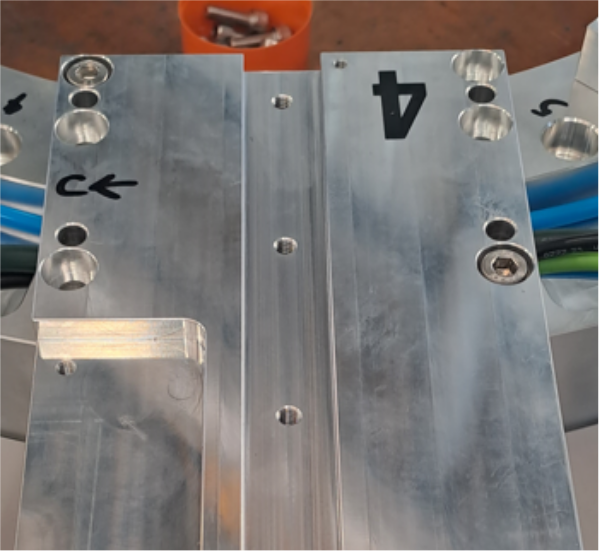

Étape 7 - Spindle 4 to 3 connections

24v power cable marked as 4 and 3

Green ethercat cable marked as 4 out - 3 in

1 Install 24v power cable as shown

2 Install green ethercat cable as shown

3 Install 300 hz power cable as shown

4 Attach next D0000291 plate as step 3

5 5 Fit M0000025 number ident

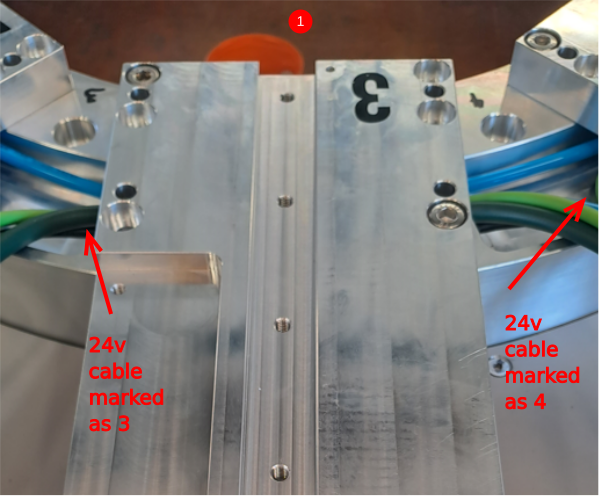

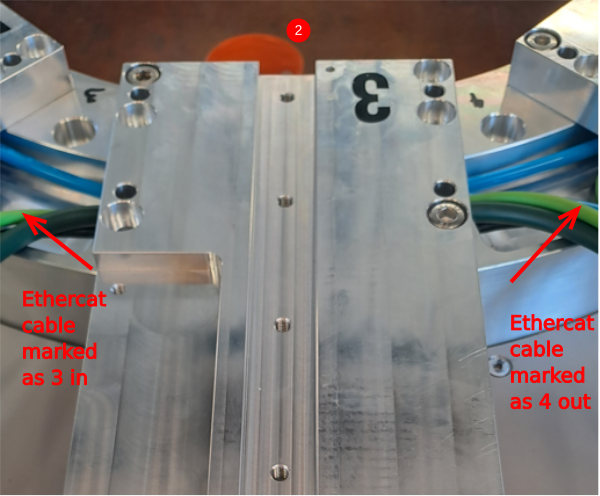

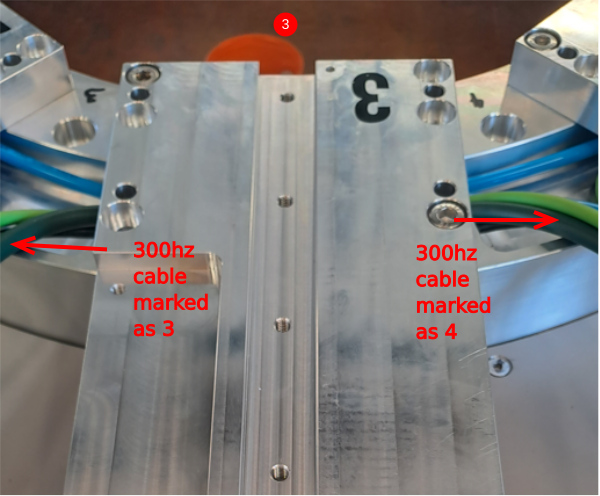

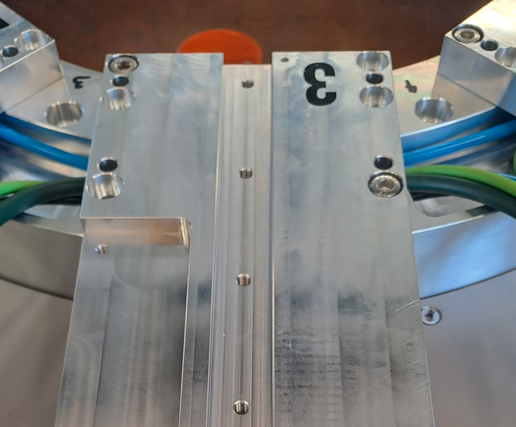

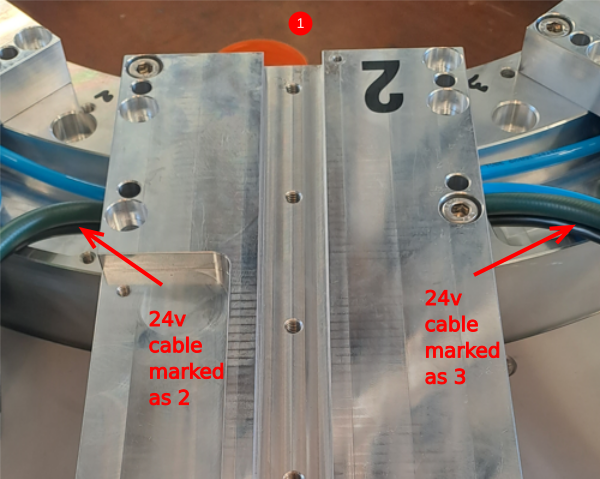

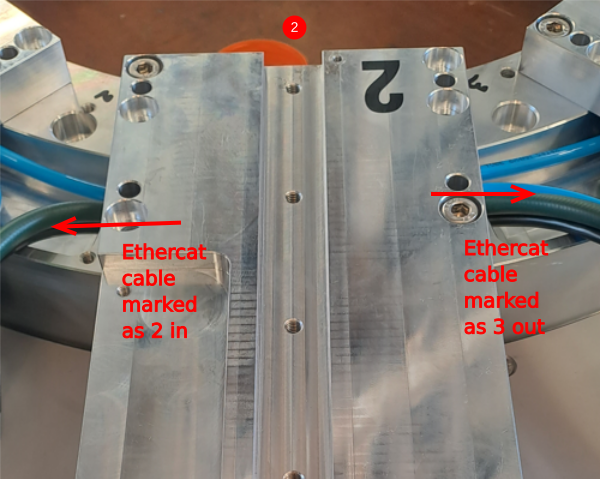

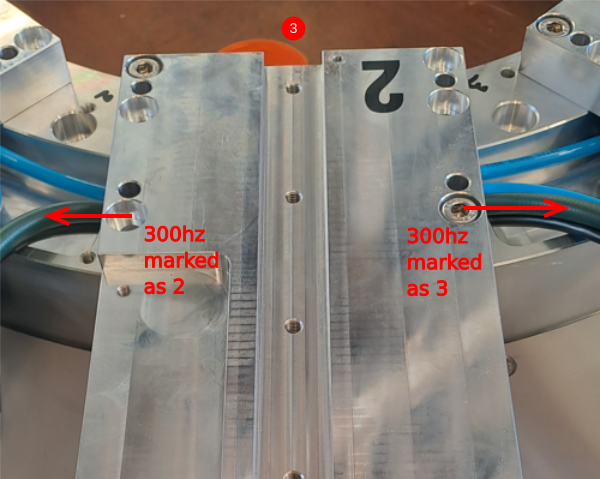

Étape 8 - Spindle 3 to 2 connections

24v power cable marked as 3 and 2

Green ethercat cable marked as 3 out - 2 in

1 Install 24v power cable as shown

2 Install green ethercat cable as shown

3 Install 300 hz power cable as shown

4 Attach next D0000291 plate as step 3

5 5 Fit M0000025 number ident

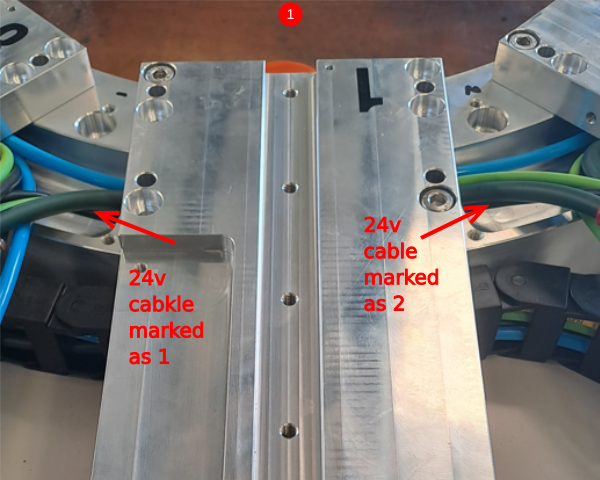

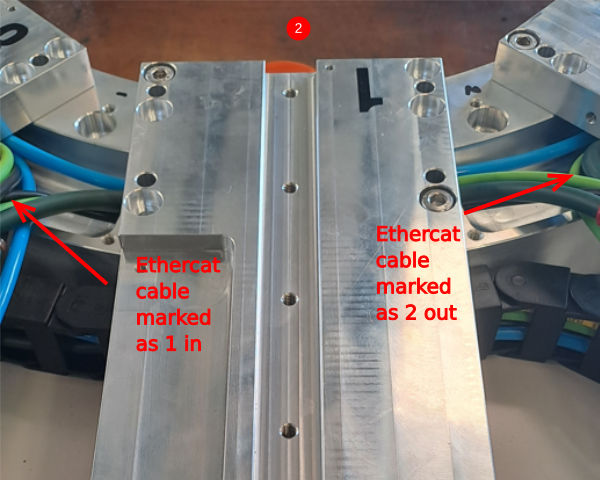

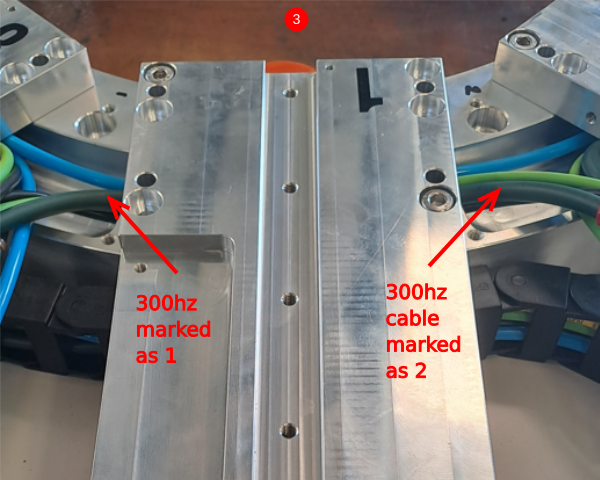

Étape 9 - Spindle 2 to 1 Connections

24v power cable marked as 2 and 1

Green ethercat cable marked as 2 out - 1 in

1 Install 24v power cable as shown

2 Install green ethercat cable as shown

3 Install 300 hz power cable as shown

4 Attach next D0000291 plate as step 3

5 5 Fit M0000025 number ident

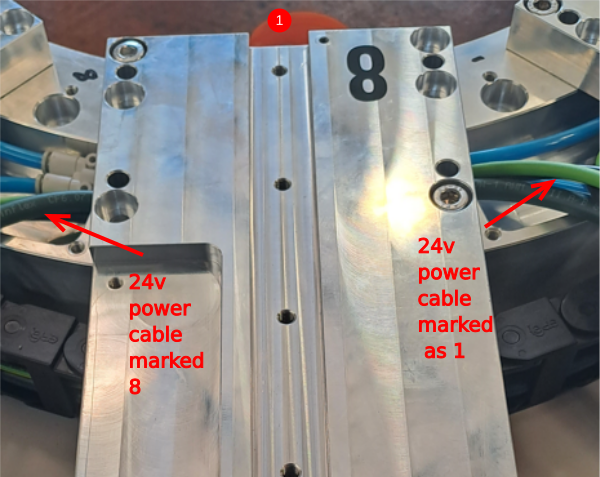

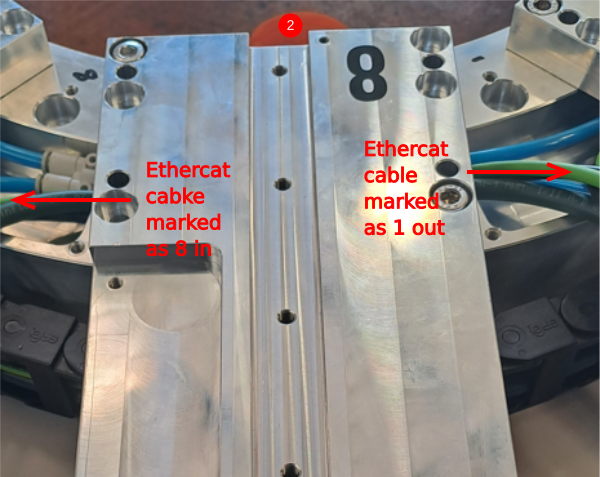

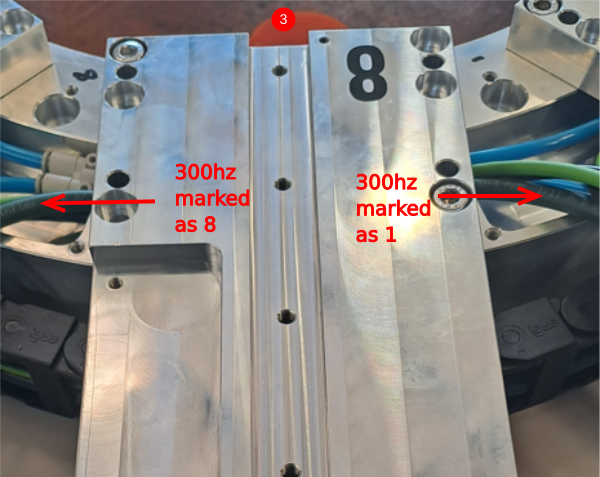

Étape 10 - Spindle 1 to 8 connections

24v power cable marked as 1 and 8

Green ethercat cable marked as 1 out - 8 in

1 Install 24v power cable as shown

2 Install green ethercat cable as shown

3 Install 300 hz power cable as shown

4 Attach next D0000291 plate as step 3

5 5 Fit M0000025 number ident

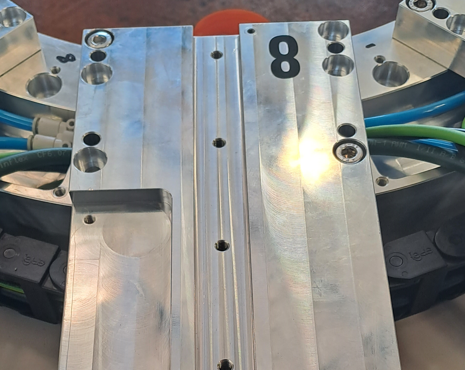

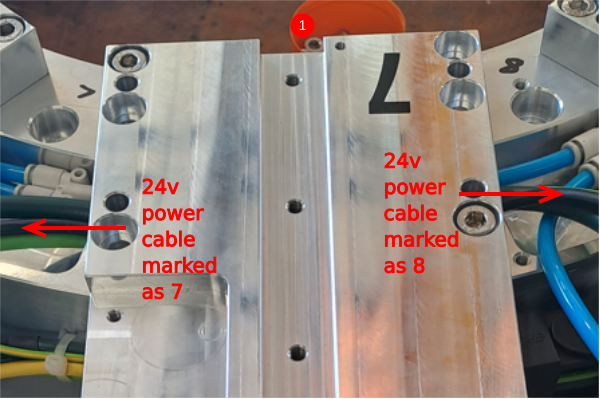

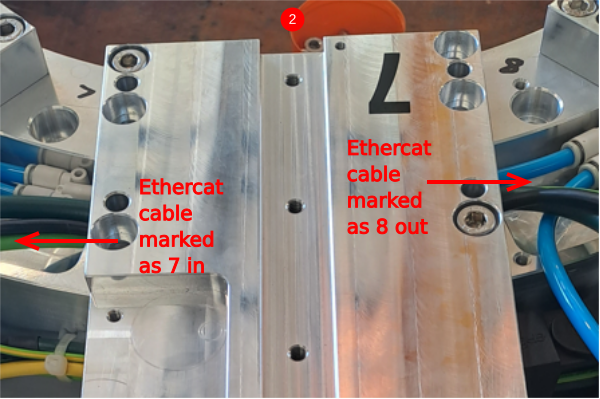

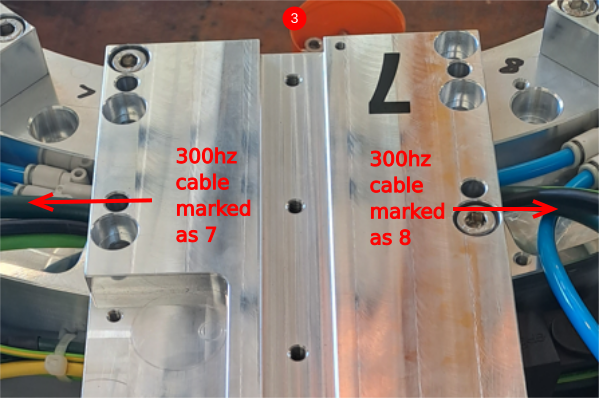

Étape 11 - Spindle 8 to 7 connections

24v power cable marked as 8 and 7

Green ethercat cable marked as 8 out - 7 in

1 Install 24v power cable as shown

2 Install green ethercat cable as shown

3 Install 300 hz power cable as shown

4 Attach next D0000291 plate as step 3

5 5 Fit M0000025 number ident

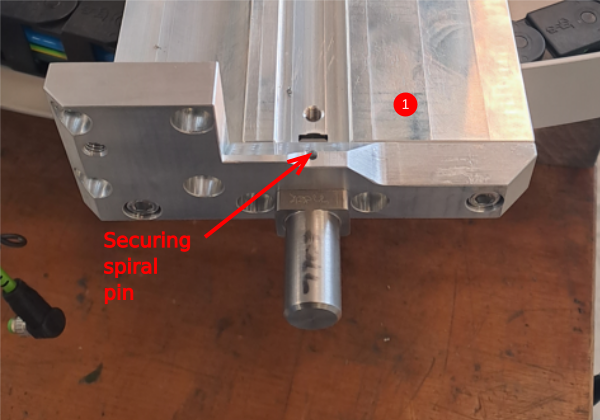

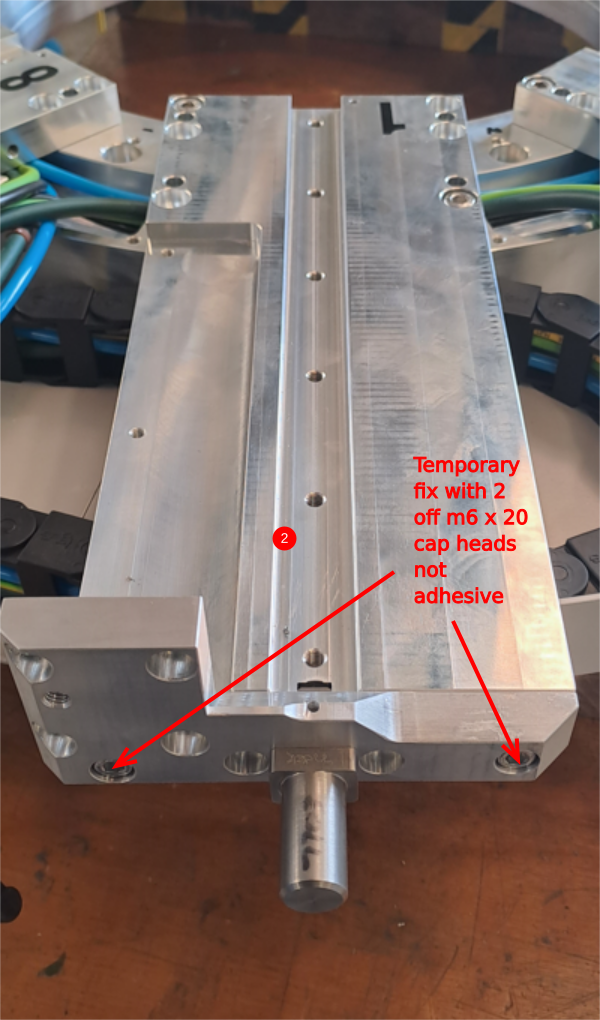

Étape 12 - Fit datum stop pin assembly to spindle plate

1 Assemble D0007990 cylinder anchor and D0007703 datum pin. Use

3mm x 26mm roll pin to secure together

2 Temporary fix to spindle plate with m6 x 20 socket caps

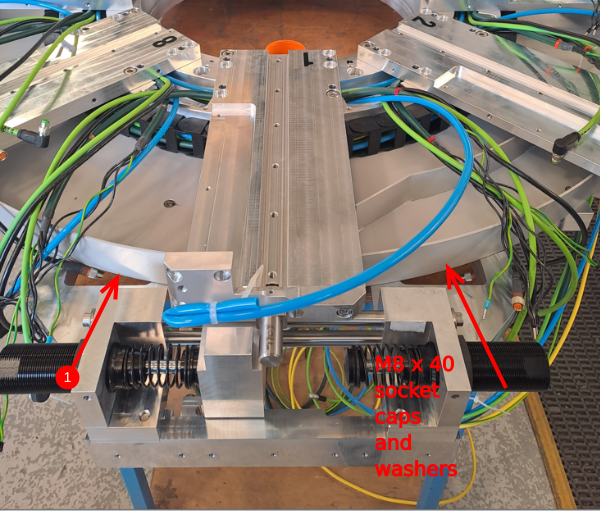

Étape 13 - Fit assembled R axis stop R0000713E

1 Fit r axis limit stop to main assembly . Use 6 off m8 x 40 socket caps with A form washers

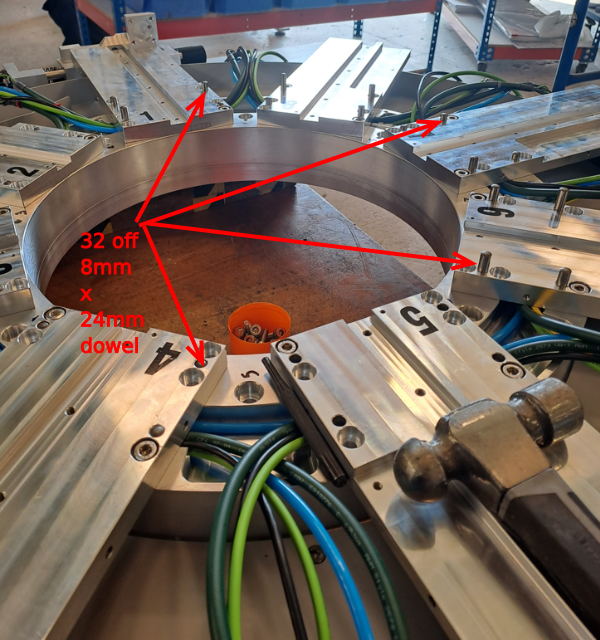

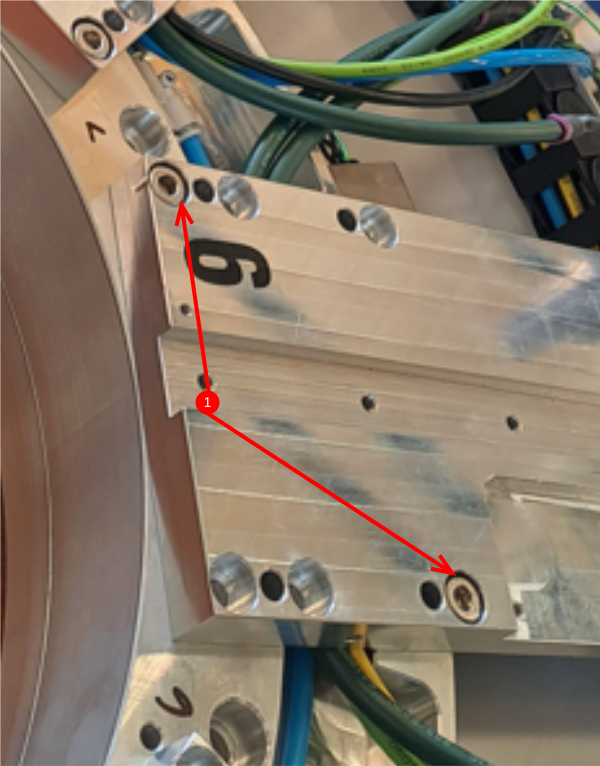

Étape 14 - Dowel D0000291 plates in position

Add 4 off 8mm x 24mm dowels to each spindle by hand to start . Use and hammer and drift to drive down dowel until it bottoms out in blind hole

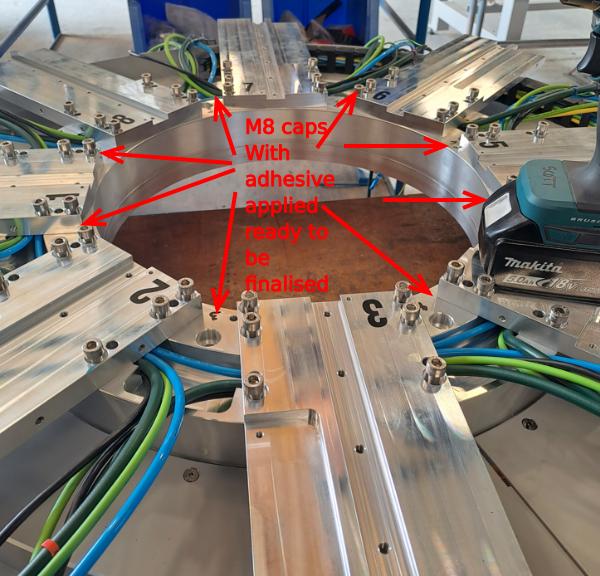

Étape 15 - Add fixings

1 Remove 2 off m8 x 25mm cap heads from each spindle plate

2 Apply adhesive and lay M8 x 25 cap heads in ALL spindle holes ready for fixing

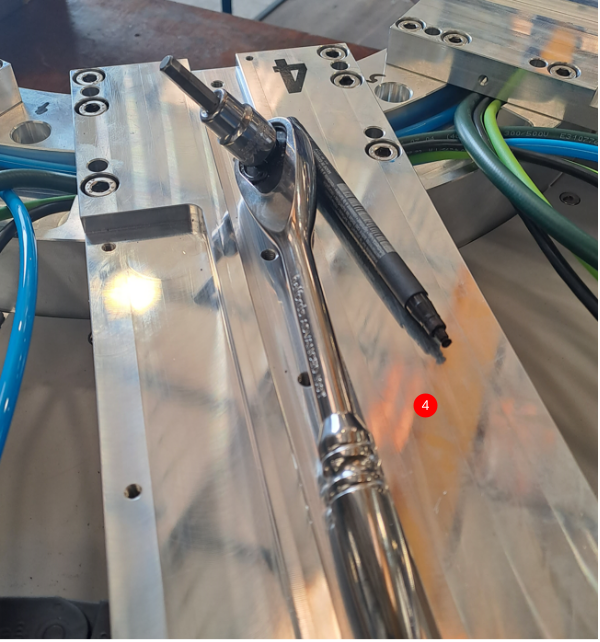

3 Use drill driver with 6mm hex bit to drive all cap heads in. Set clutch to 14

4 Methodically apply final tension to bolt by hand and mark as complete

Étape 16 - Finalize dowel holes

Once spindles are final fixed, preventative prep must be added to dowel holes to stop slip of dowel from hole.

Add 1 off centre dot to each dowel position to slightly swage over top of hole

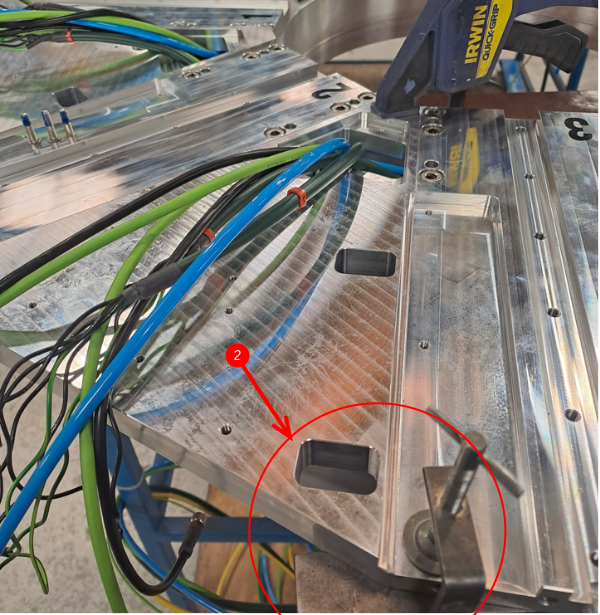

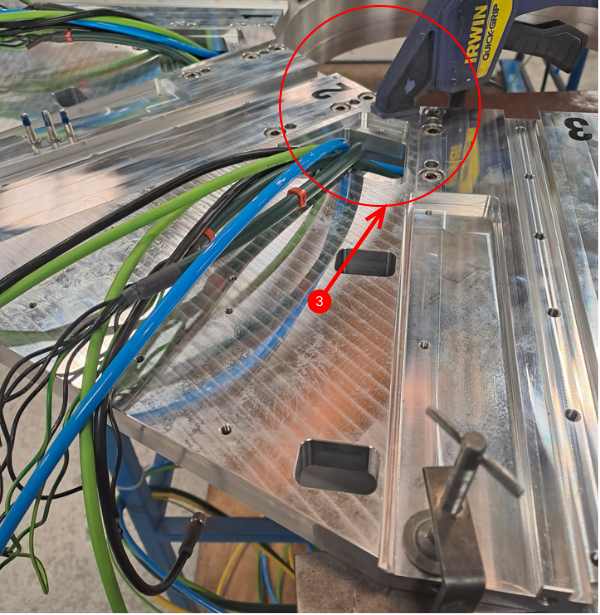

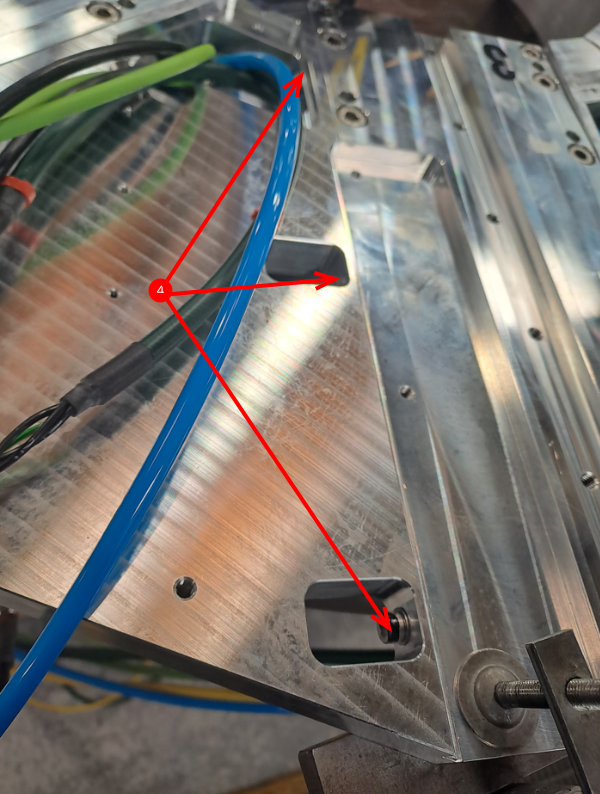

Étape 17 - Add Spindle infill plates

Add D0007611 infill plates to spindle plates 1,3,5 and 7

Add D0001176 infill plates to spindles 2,4,6 and 8

1 Place spindle infill plate in position threading through exiting cables

2 Place support block and small g clamp at position shown

3 Fit quick clamp to pin infill plate to ring base

4 Fit 3 off M5 x 20 socket caps With M5 A form washers to attach plate . Use a reduced length 4mm key for this

Repeat for all eight spindle plates

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português