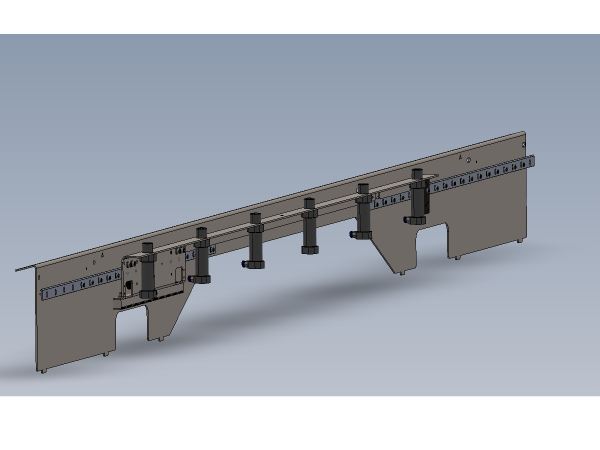

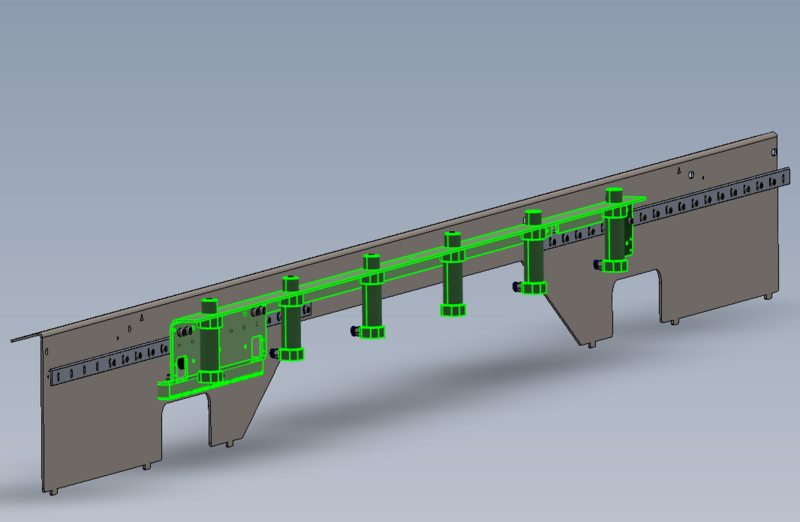

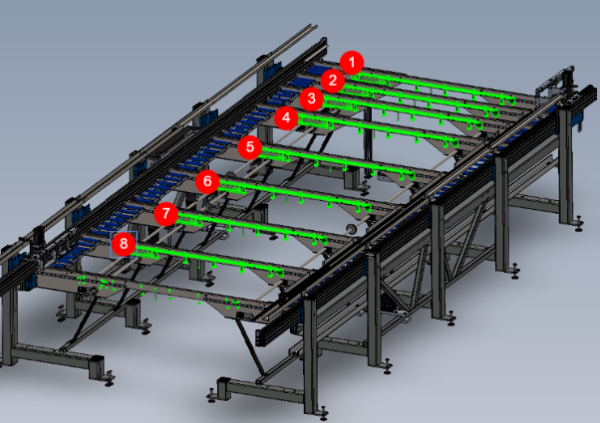

Details for mounting cylinder rails to transfer beams

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

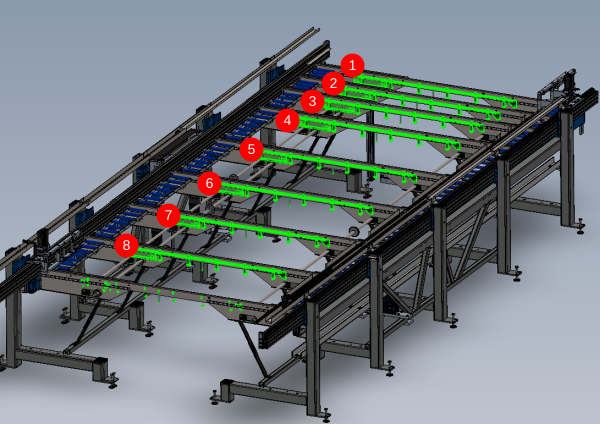

- 3 Étape 2 - Position pre built cylinder rails

- 4 Étape 3 - Adjust delrin wheels front

- 5 Étape 4 - Adjust Delrin wheels Rear

- 6 Étape 5 - Check all fasteners

- 7 Étape 6 - Check movement

- 8 Étape 7 - Cylinder heights checked on all areas

- 9 Étape 8 - Set rack meshing

- 10 Étape 9 - Check for clearance

- 11 Étape 10 - Caution

- 12 Étape 11 - Start setup on Cylinder rail 1

- 13 Étape 12 - Set rack mesh 1

- 14 Étape 13 - Set Rack mesh point 2

- 15 Étape 14 - Repeat steps 10 and 11

- 16 Étape 15 - Align Cylinders to Hepco

- 17 Étape 16 - Attach pneumatic jig

- 18 Étape 17 - Set wire line

- 19 Étape 18 - Adjust cylinder rails 2-7

- 20 Étape 19 - Quality check

- 21 Étape 20 - Finalise drive pinions

- 22 Étape 21 - Add Hard stops

- 23 Étape 22 - Delrin wheel Quality check

- 24 Étape 23 - Quality sign off

- 25 Étape 24 - Quality sign off

- 26 Étape 25 - Warning

- 27 Commentaires

Introduction

Tools Required

Standard spanner set

Standard hex key set

Tape measure

Wire line

Pneumatic cylinder setting jig

Parts Required

R0015288 Bench Assemble Transfer slid units and cylinder rails

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

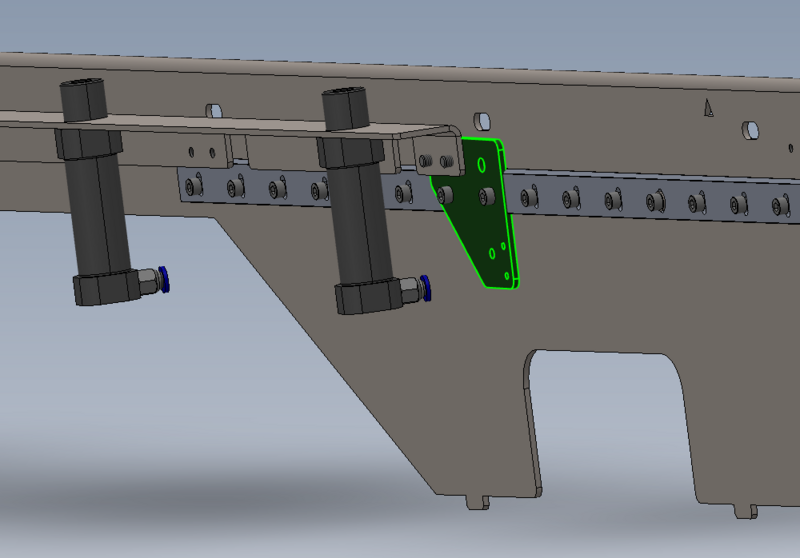

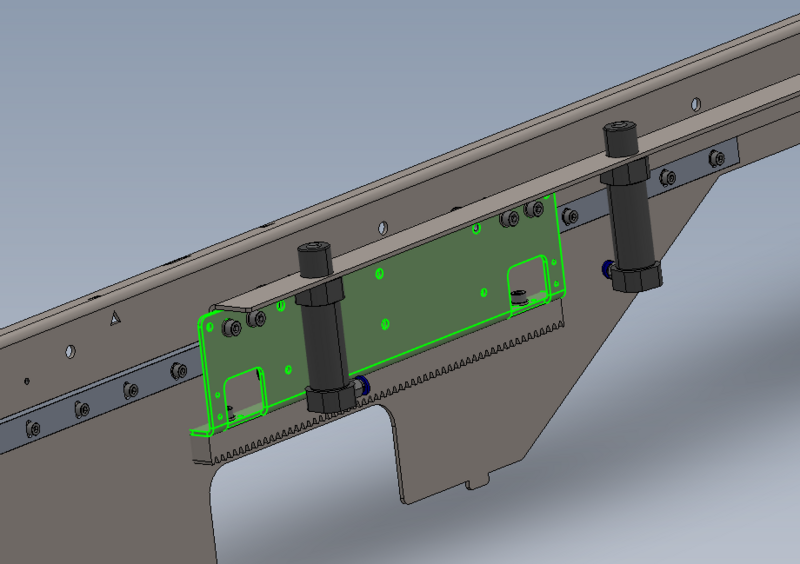

Étape 3 - Adjust delrin wheels front

Remove safety bolt stop from cylinder rails

Adjust delrin wheels on section shown

Ensure to use Setting Delrin Transfer Table Wheel Tension To set delrin wheels correctly

Étape 4 - Adjust Delrin wheels Rear

Adjust delrin wheels on section shown

Ensure to use Setting Delrin Transfer Table Wheel Tension To set delrin wheels correctly

Étape 5 - Check all fasteners

Check all fasteners are correctly tensioned

Ensure all delrin wheels are correctly set and all fasteners on delrin wheels are tensioned to final tension

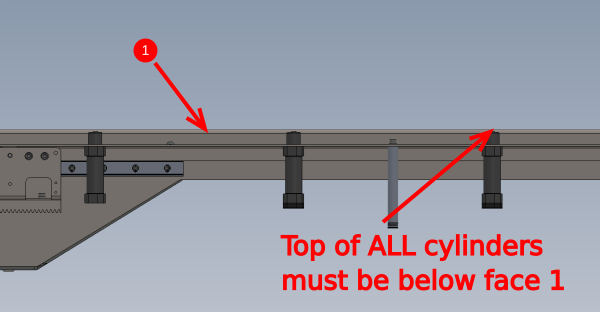

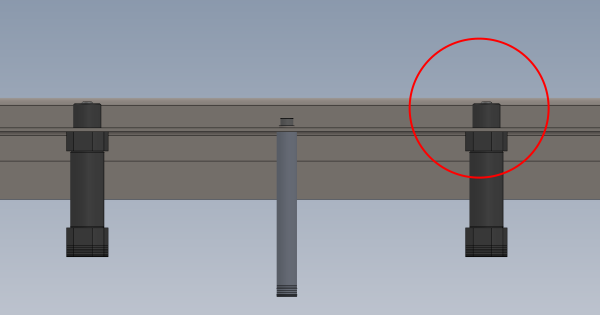

Étape 7 - Cylinder heights checked on all areas

All cylinders should be checked for correct height position in regards to top face of transfer arms

All cylinders should be below the top face of the transfer arm,

Check with 2 meter straight edge over tops of transfer arms

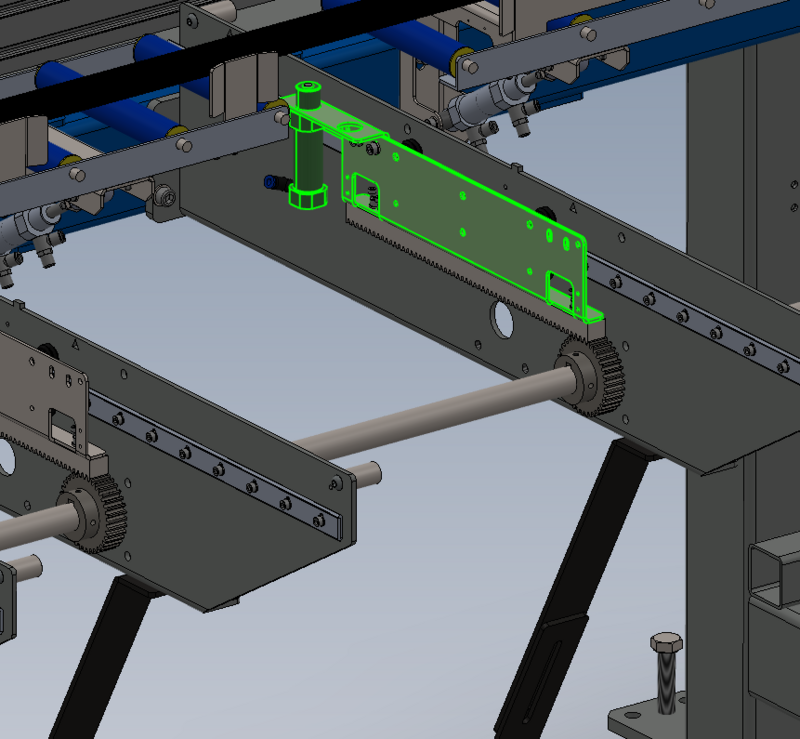

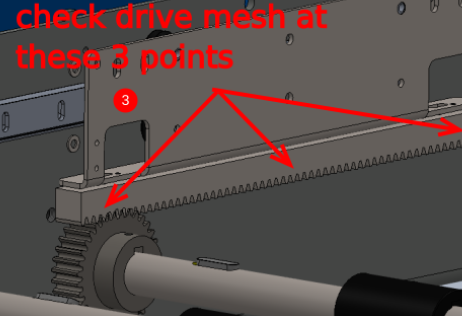

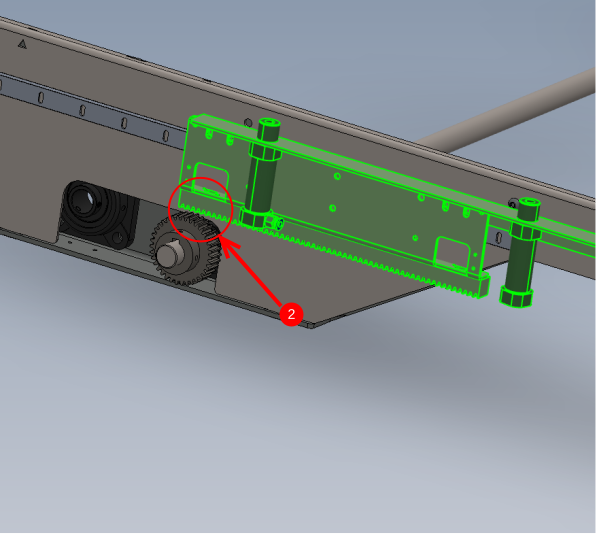

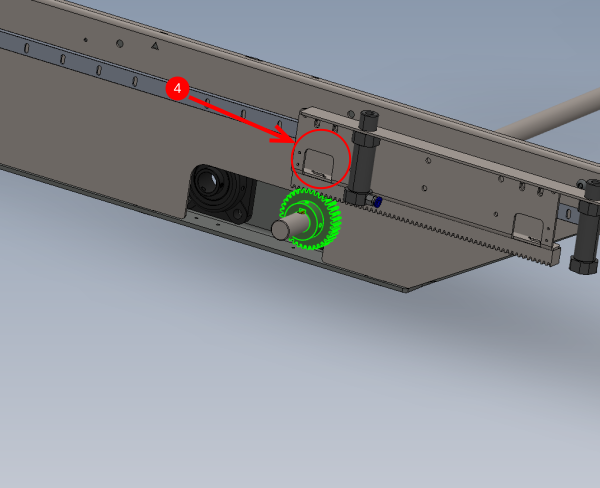

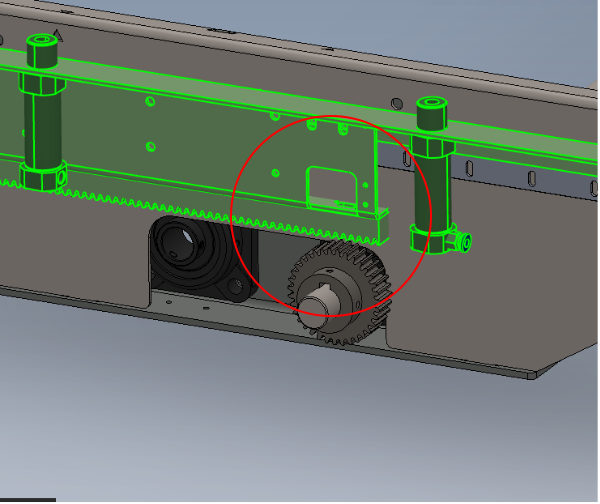

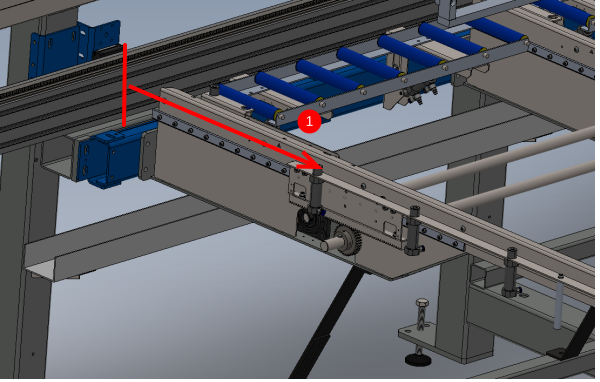

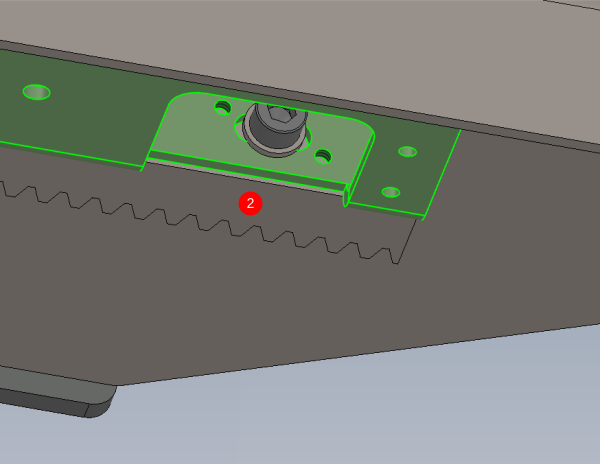

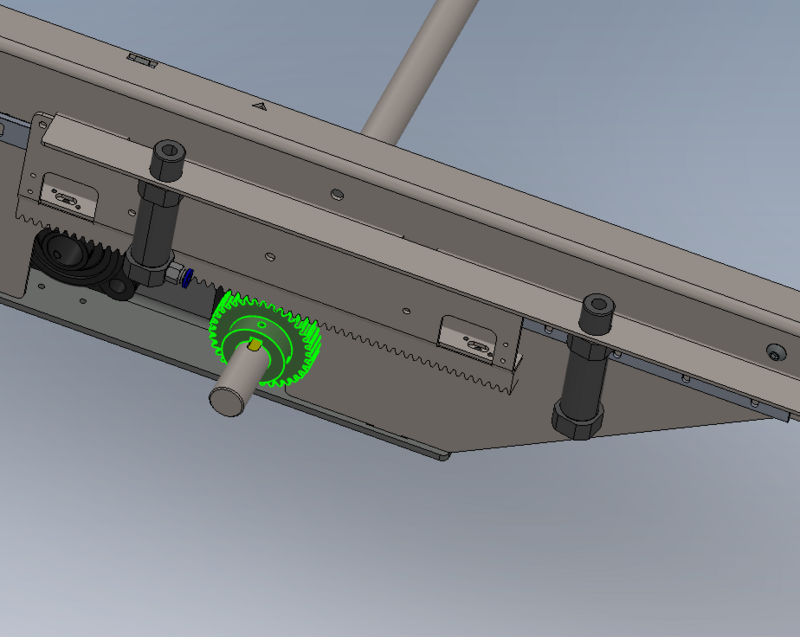

Étape 8 - Set rack meshing

Mesh requires setting between slider unit and drive pinion

It is vital that the correct drive meshing is achieved.

Complete the following steps to mesh pinion and drive correctly

Étape 9 - Check for clearance

Once drive racks have been set, it is vital to check that no interference between rack and arm is present. Move racks along full length of travel and check for any fouling

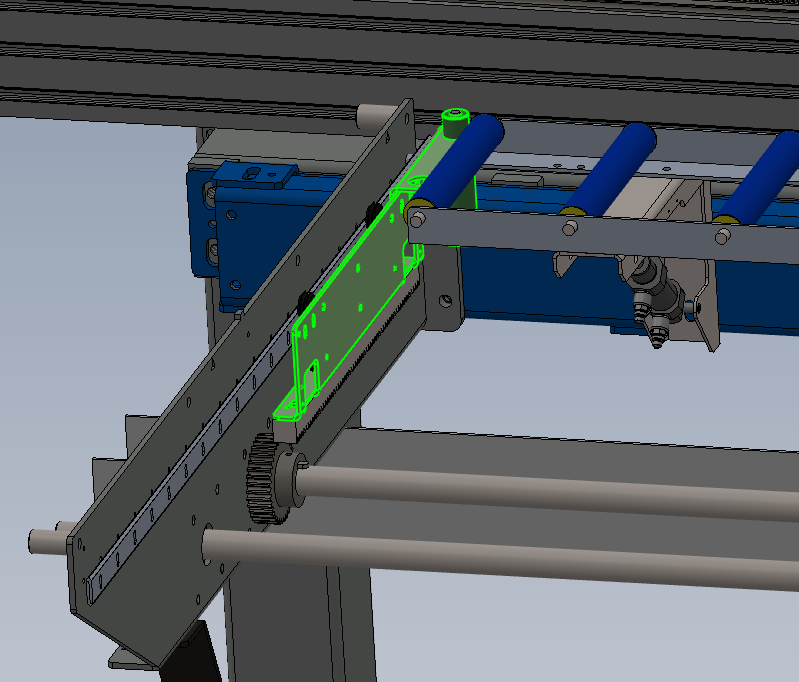

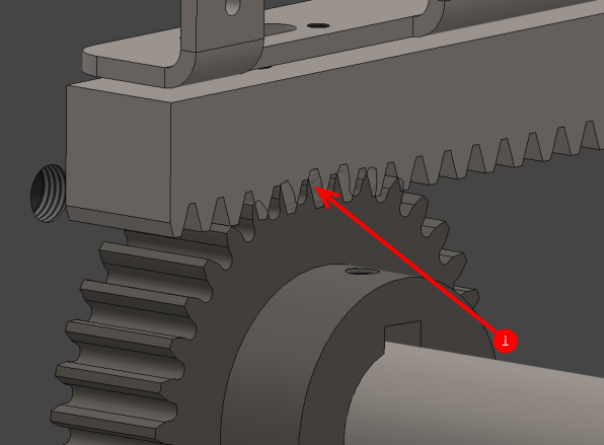

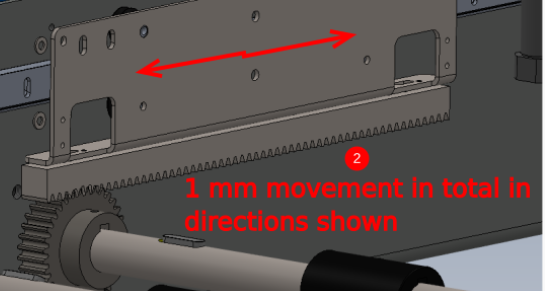

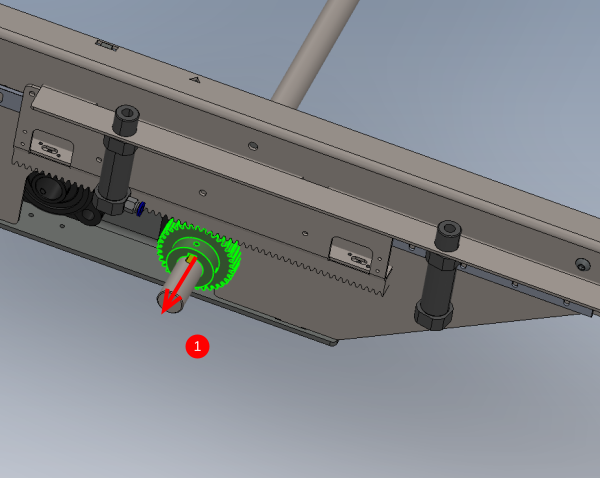

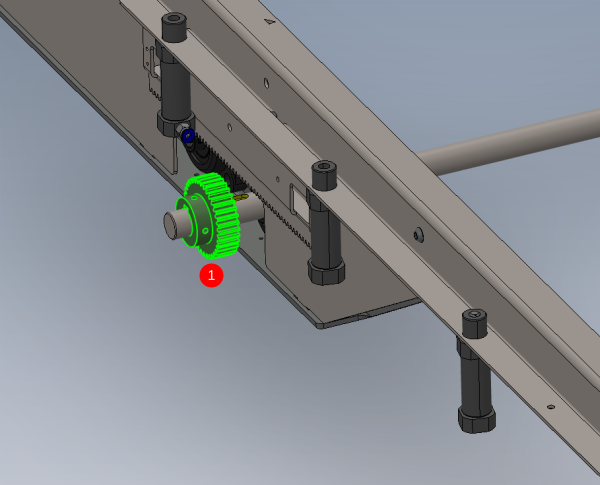

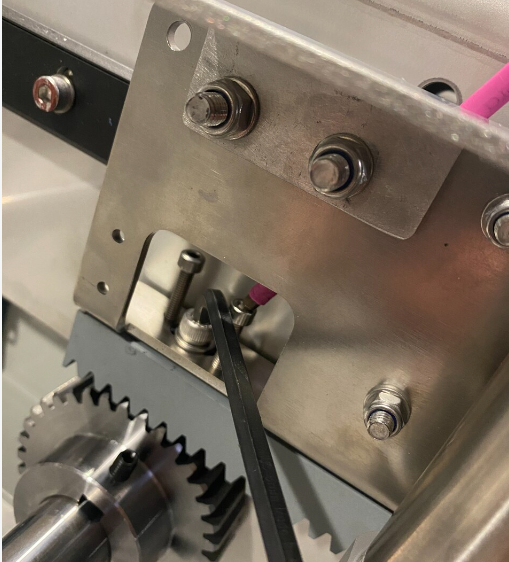

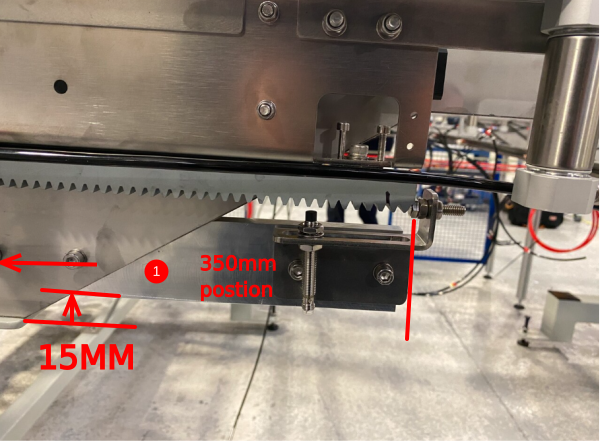

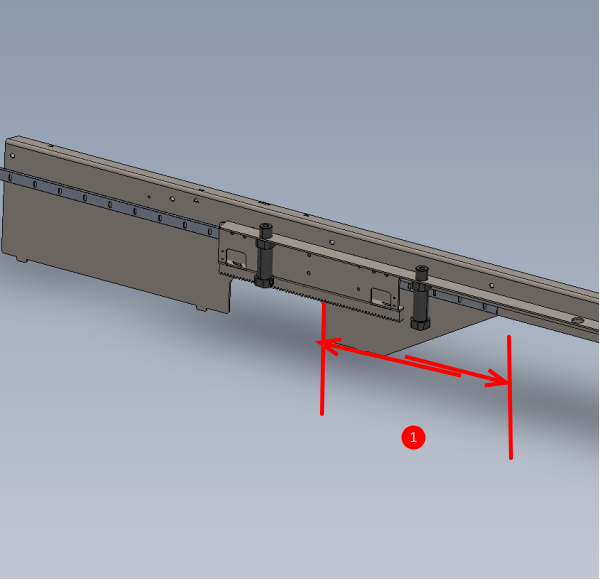

Étape 12 - Set rack mesh 1

1 Slide drive pinion away from rack , this pinion shou. be loose and free moving

2 Move cylinder rail to position shown

3 Slide Pinion into position under drive rack

4 Adjust Backlash between rack and pinion to give no more than 1mm movement

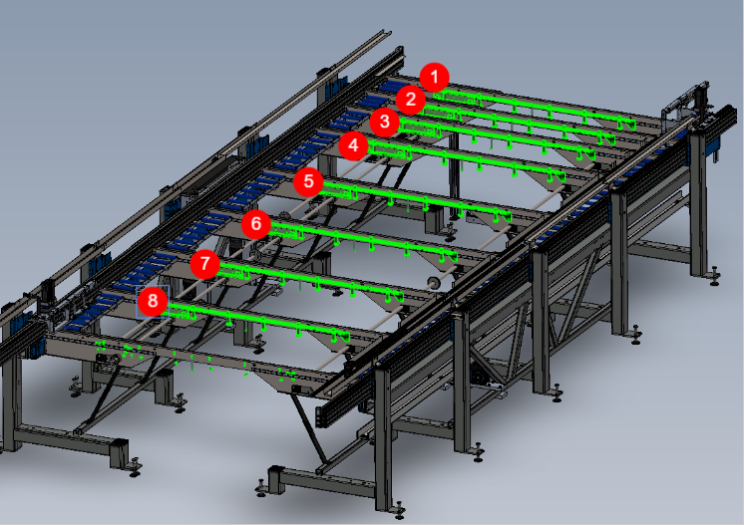

Étape 15 - Align Cylinders to Hepco

Set cylinder rails to hepco rail by completing the following steps

1 Set cylinder rails 1 and 8 to same measurement to hepco beam, using same technique of sliding drive pinion out of the way to enable movement

2 For finer tuning of position, Use slots in rack mounting and drive gear position to adjust

Étape 16 - Attach pneumatic jig

Attach pneumatic jig to cylinders , to enable cylinder pistons to be extended

Étape 18 - Adjust cylinder rails 2-7

Using the same method, position the remaining cylinder assemblies to the wire line

Étape 19 - Quality check

Double check setting by measuring from cylinder piston to hepco rail on each cylinder assembly

All measurements should be the same -+ 0.5mm

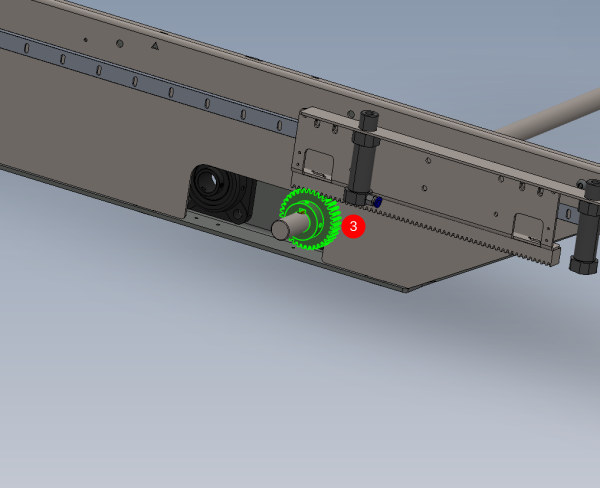

Étape 20 - Finalise drive pinions

Remove, apply adhesive and finalise 2 off M6 grubscrew per each drive pinion

Étape 21 - Add Hard stops

Fit hard stop assemblies once alignment is set

Fasteners and size required

Étape 22 - Delrin wheel Quality check

Once all settings have been set, Delrin wheel tension should be rechecked before final sign off

All delrin wheels should be set and be able to be stopped from rotating when held with light finger pressure. . Ensure all delrin wheels are checked on transfer assembly to ensure correct setting

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português