| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 5 : | Ligne 5 : | ||

|Categories=Production | |Categories=Production | ||

|Difficulty=Hard | |Difficulty=Hard | ||

| − | |Duration= | + | |Duration=5 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

Version actuelle datée du 3 avril 2024 à 12:26

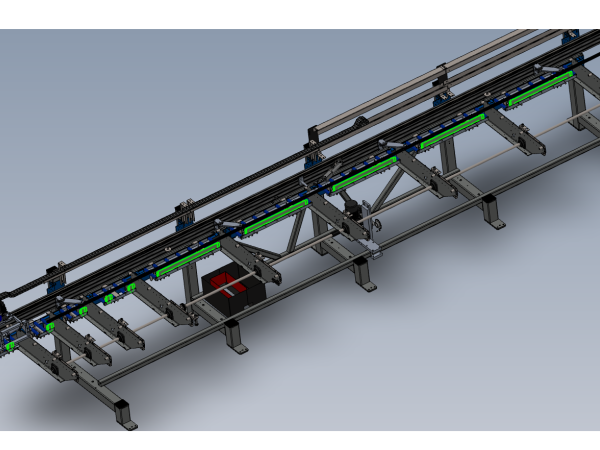

Procedure for correct alignment of module E back fences and channel bar

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Quality check

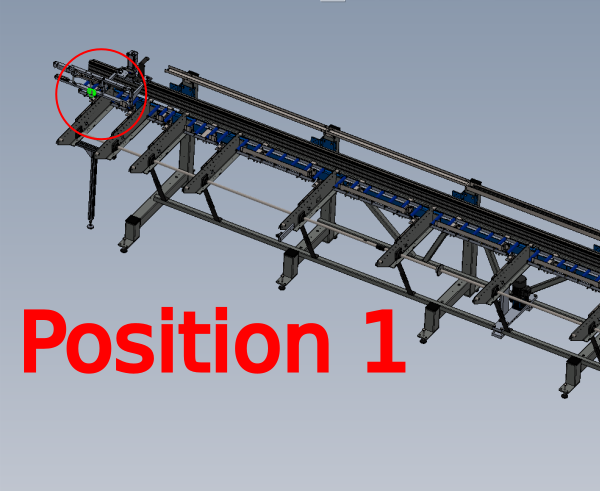

- 4 Étape 3 - Set position 1

- 5 Étape 4 - Measure Position 1

- 6 Étape 5 - Set position 10

- 7 Étape 6 - Add wire line to backfences

- 8 Étape 7 - Ensure only positions 1 and 10 are contacting

- 9 Étape 8 - Adjust each backfence

- 10 Étape 9 - Finalise alignment

- 11 Étape 10 - Quality /alignment check

- 12 Étape 11 - Back fence height quality check

- 13 Étape 12 - Gripper position setting

- 14 Étape 13 - Use setting jig

- 15 Étape 14 - Adjust gripper

- 16 Étape 15 - Check all positions

- 17 Étape 16 - Finalise all fasteners

- 18 Étape 17 - Fit channel bars

- 19 Étape 18 - Set channel Bar position

- 20 Étape 19 - Position gripper

- 21 Étape 20 - Adjust each swivel assembly

- 22 Étape 21 - Adjust bump stop

- 23 Étape 22 - Set height of channel bar

- 24 Étape 23 - Check clearance

- 25 Étape 24 - Fastener check

- 26 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Wire Line setting equipment

600mm rule

Workshop Gripper setting jig

2 meter straight edge

Parts Required

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Quality check

It is vital that the backfences are square to the rollers on the roller table assemblies.

If backfences are not square, varying readings will be encountered when setting back fence alignment

To check

Make sure backfence is secured to roller bed assembly

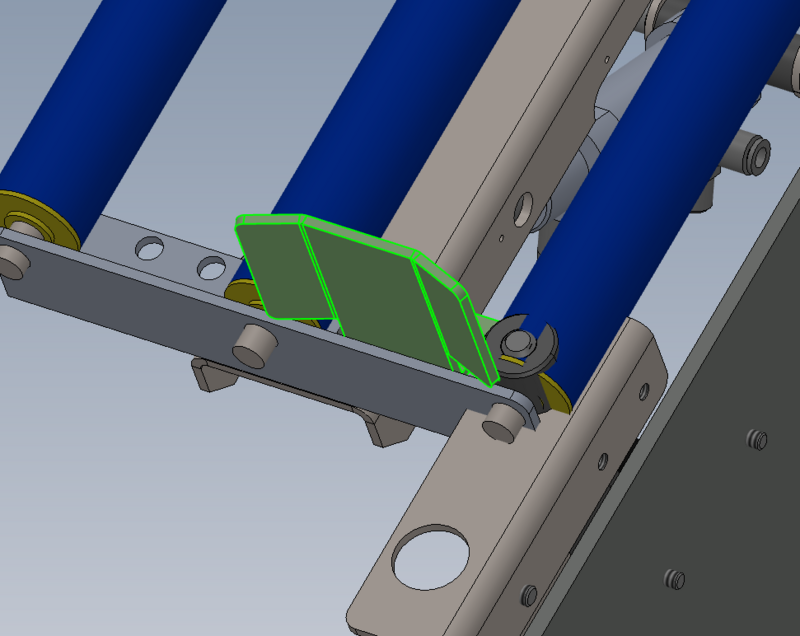

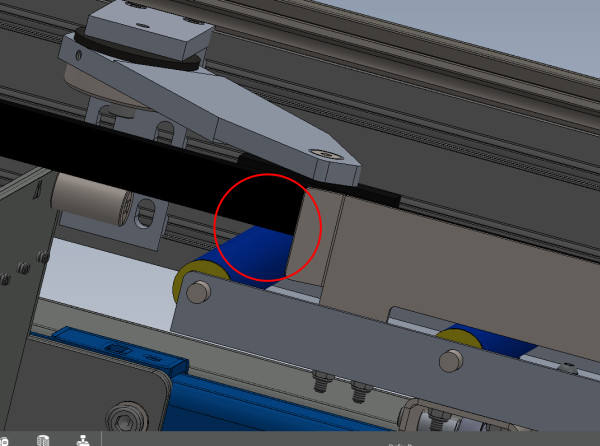

Use gripper setting jig and place on blue rollers, and push up to back fence

Backfence should be touching jig at top and bottom point. If not, back fence can be manipulated by hand to ensure it sits in a square position in relation gto the setting jig.

This check MUST be done before backfence alignment

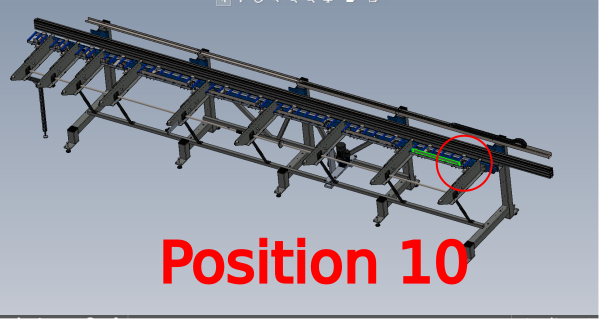

Étape 5 - Set position 10

Set position 10 to measure taken in previous step from position 1

Tolerance -+ 0.5mm

Étape 7 - Ensure only positions 1 and 10 are contacting

Ensure all positions of backfences except 1 and 10 are not touching wire line

Étape 8 - Adjust each backfence

Individually adjust each backfence to be less than 0.5mm from wireline but not touching

Étape 9 - Finalise alignment

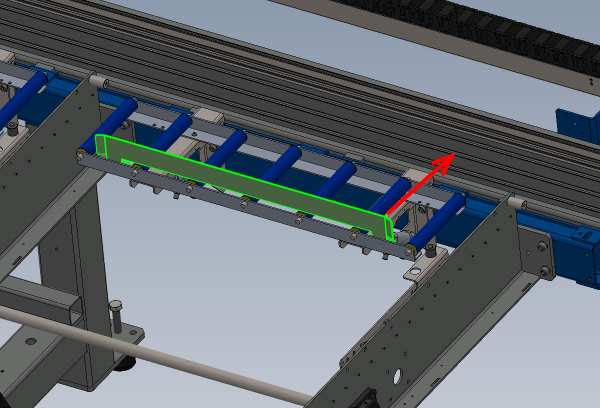

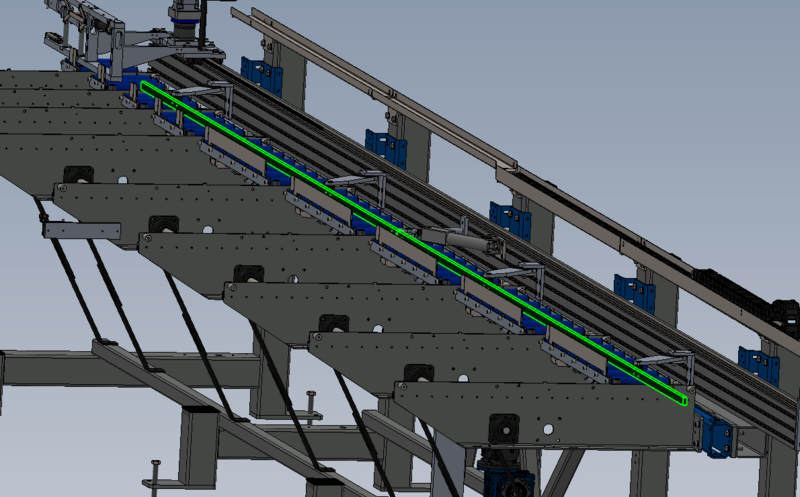

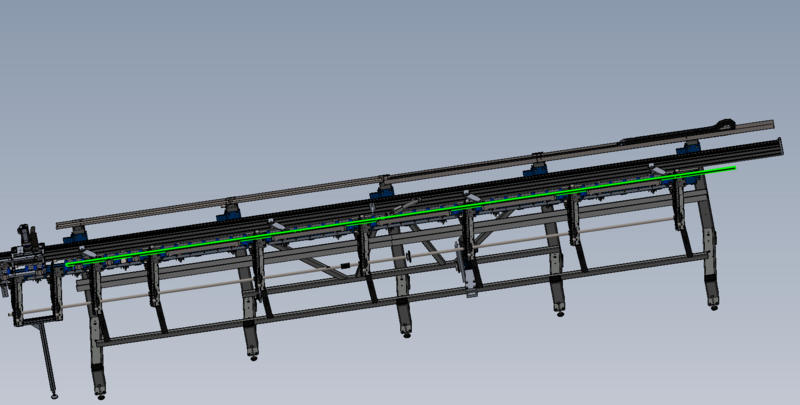

The first 2 meter section of backfences from position 1 should now be fine tuned with a 2 meter straight edge

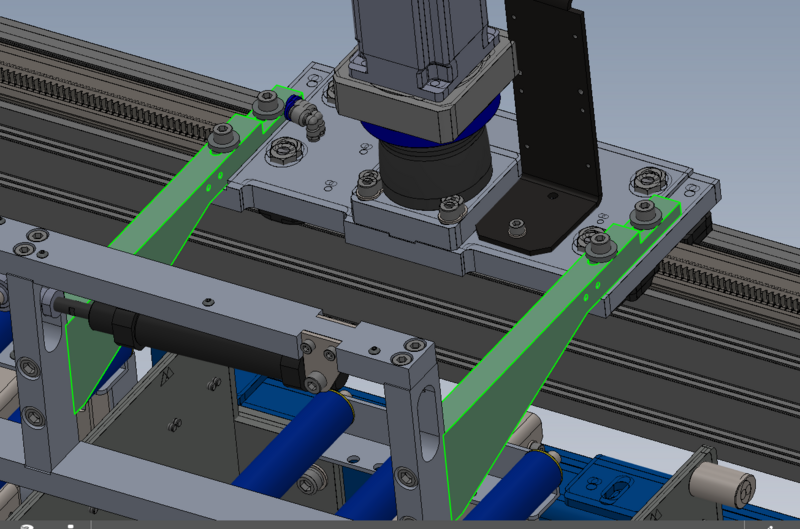

Position 2 meter straight edge against indicated points

Étape 10 - Quality /alignment check

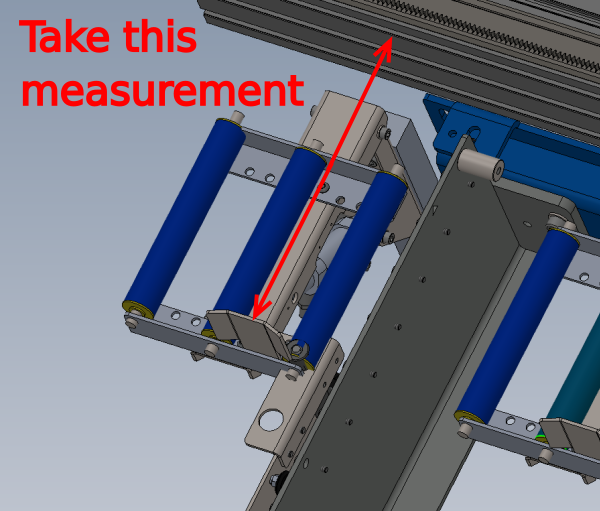

Use steel rule to measure each backfence position from hepco rail

Measurement taken in step 3 should indicated at all backfences if set correctly .

Tolerance -+ 0.5mm

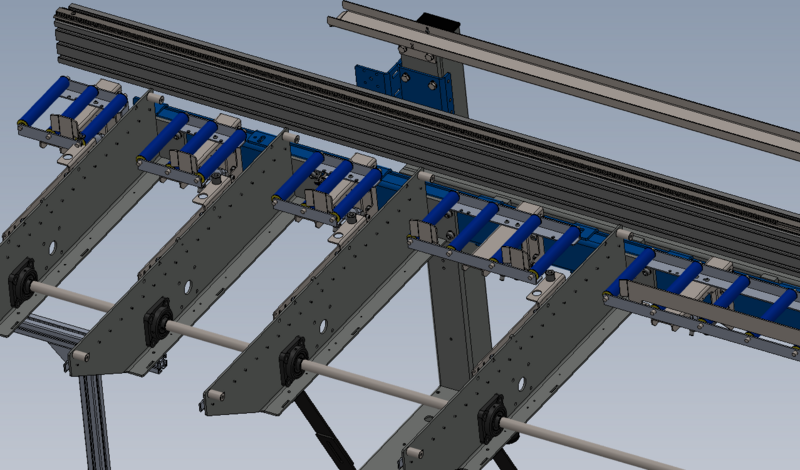

Étape 11 - Back fence height quality check

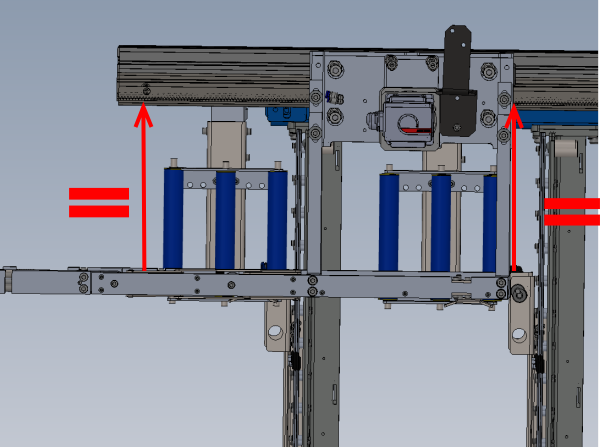

Backfence height needs to be checked in the roller lowered position.

To do this

1 Remove air from cylinders to allow rollers to drop

2 Use 2 meter straight edge to span between transfer arms

3 drag straight edge over backfences, straight edge should not touch backfence at any point

4 Check this on all roller beds on module E

Étape 12 - Gripper position setting

Gripper position requires setting now that back fences are aligned

The following steps should be followed for correct alignment

Étape 13 - Use setting jig

Ensure setting jig is set against position 1 backfences

Ensure setting jig is orientated correctly , correct offset of holes towards backfence

Étape 14 - Adjust gripper

Adjust gripper on mounting arms to align gripper teeth with setting jig

Ensure that when adjusting , gripper remains parallel to hepco beam . Check this by measuring the indicated points

Étape 15 - Check all positions

Once gripper position is set at position 1, it should be checked at all backfences for consistency

Report any discrepancy to supervisor

Étape 16 - Finalise all fasteners

Double check all fasteners used for adjustment have loctite 243, final tension applied and pen marked

Supervisor sign off required at this stage

Étape 18 - Set channel Bar position

Channel bar positions now need to be set relative to new gripper position

Étape 19 - Position gripper

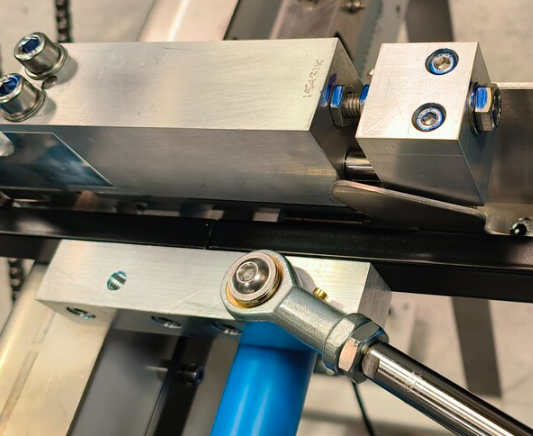

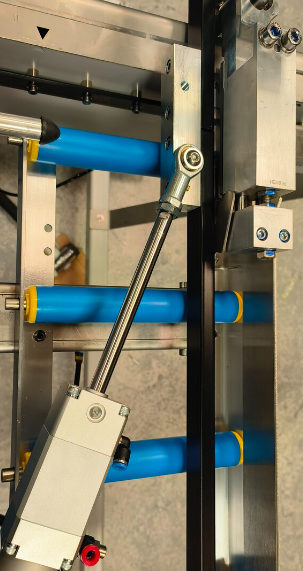

Position gripper in front cylinder assembly for channel bar

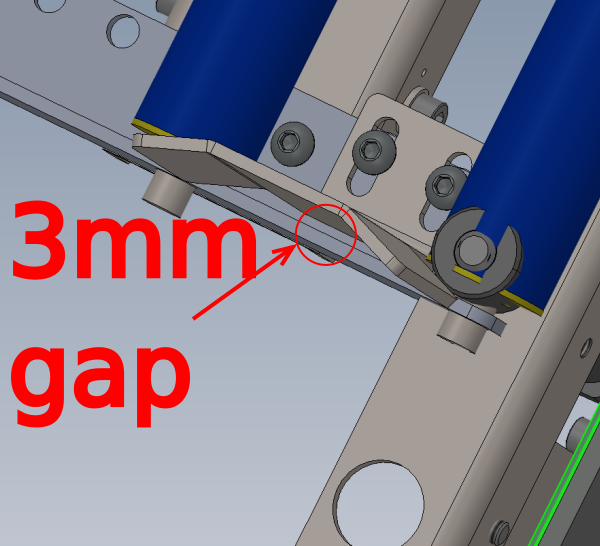

Adjust base of cylinder so that there is a 3mm gap present between gripper and channel bar, when cylinder is fully extended

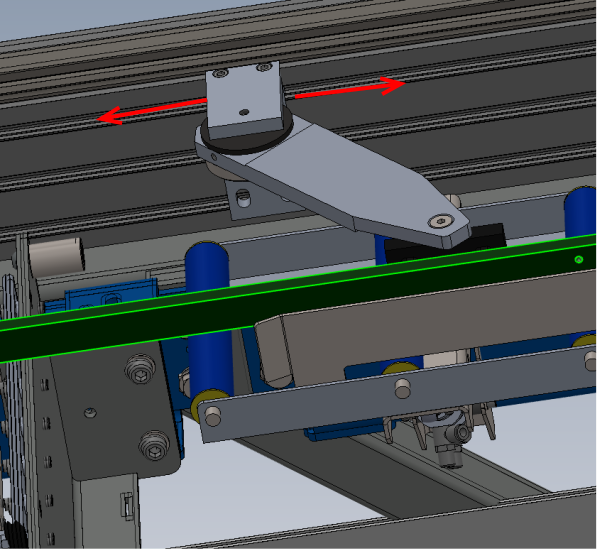

Étape 20 - Adjust each swivel assembly

Move gripper to each swivel assembly and adjust base to ensure 3mm gap when cylinder is fully extended

Repeat setting process for all swivel arms ( 4 off in total )

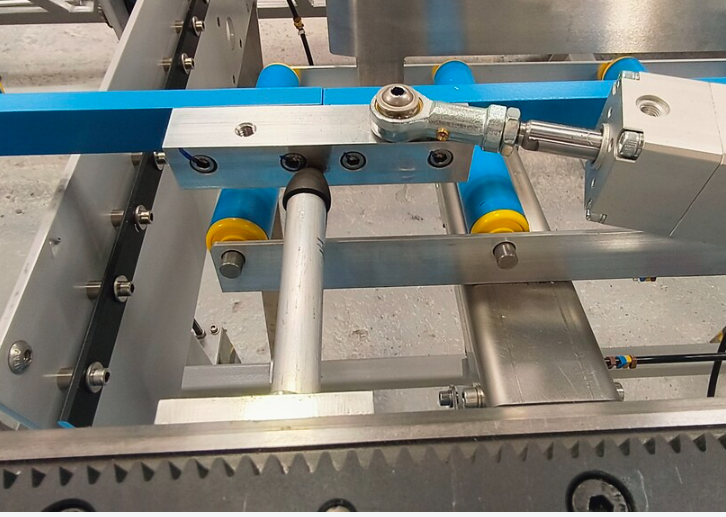

Étape 22 - Set height of channel bar

Channel bar should be checked at all swivel points for the correct height setting

Adjust height of assemblies to set indicated height to 3-4mm

Ensure all measurements are consistent at adjustable points

Étape 23 - Check clearance

Fully extend channel cylinder

Move gripper along entire axis

3mm gap between channel bar and gripper should remain consistent at all points

Supervisor sign off required at this point

Étape 24 - Fastener check

Check that all fasteners are correctly tensioned, have had Loctite 243 applied and are pen marked

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português