Instructions to fit loader chains to arms

Introduction

Tools Required

Standard hex key set

Standard spanner set

150mm rule

Long nose pliers

Loctite 290

Straight ended 4mm hex key and extension bar

Parts Required

Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

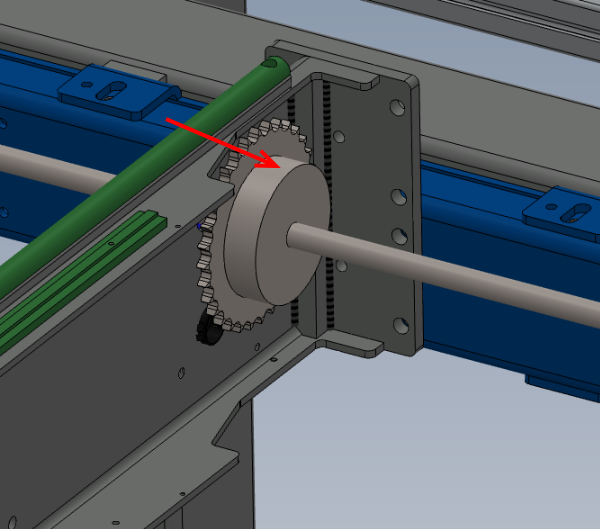

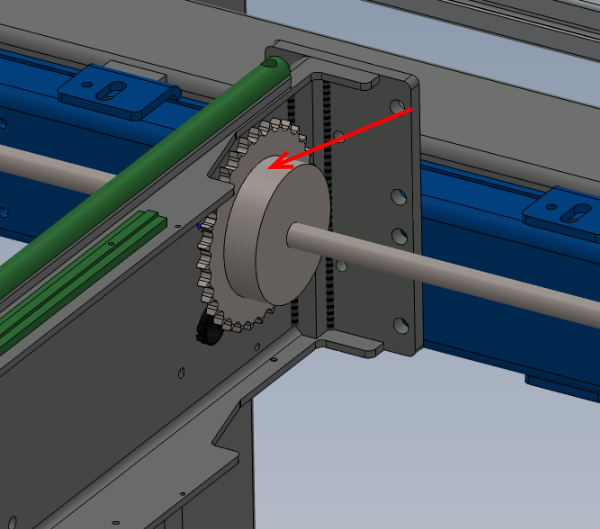

Étape 2 - 1st stage fix of drive sprockets

Add M8 x 20 kcp grubscrew to each chain drive sprocket. Do not add adhesive at this point

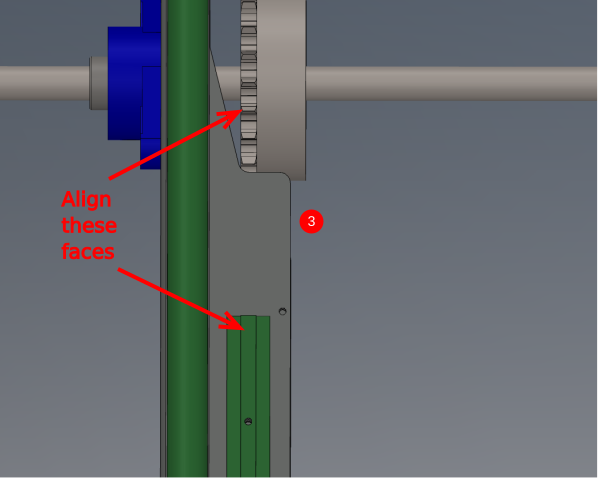

Align sprocket with faces shown and tighten grubscrew ensuring the

****flat on the driveshaft ***

is aligned with the fixing grubscrew .

Repeat for all 8 remaining sprockets

Étape 3 - Fit chains

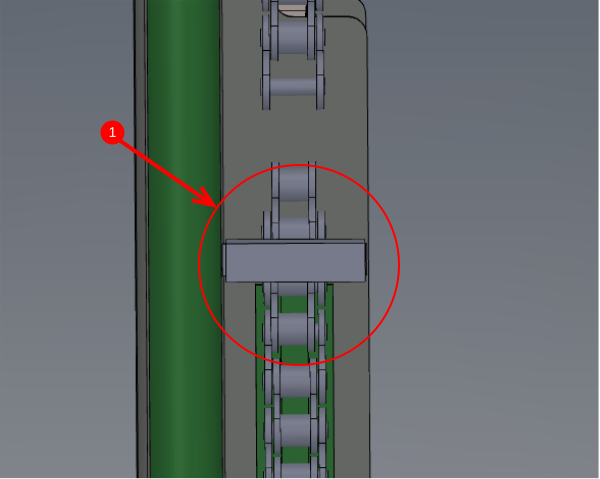

Remove chain joining link from chain assembly and fit chain in position

It is vital all chains are fitted in the same position, to do this

1 When fitting chain use datum point to align chain paddle

2 Attach chain link joiner

Repeat for all 8 remaining chains

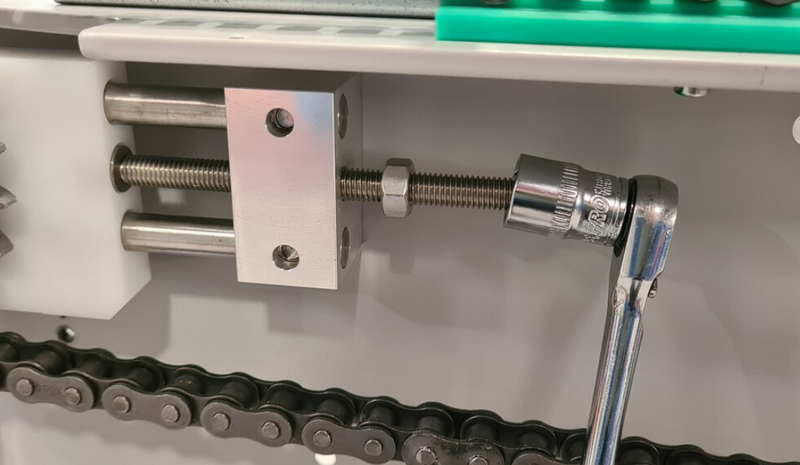

If chains are tight to connect adjust M8 set bolt to reduce tension on chains

Étape 4 - Quality check

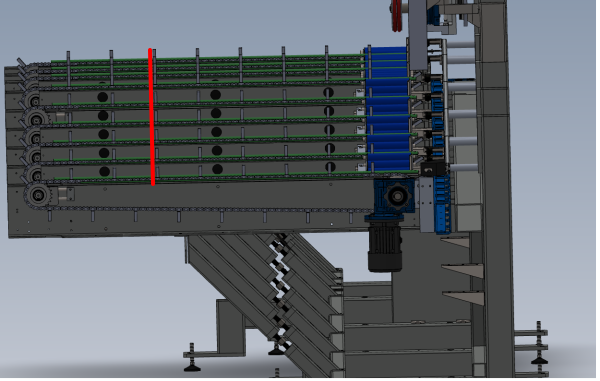

Once all chains are fitted a visual check should be performed to confirm alignment . When looking over the length of the table, all chain flights should be inline

Étape 5 - Finalise Sprocket fasteners

It is vital to tension the securing grubscrew for the drive sprockets correctly

Use a straight ended 4mm hex key and extension bar to apply as much tension as possible to the m8 grubscrew

Then add 2 drops of self wicking thread locker to complete the tension process

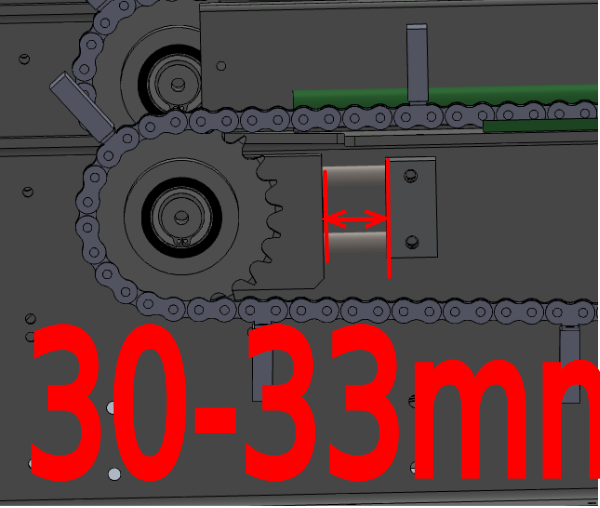

Étape 6 - Tension chains

Using the M8 adjusting set bolt, set shown gap to the range shown. (30-33mm approx)

This will give a starting position for chain adjustment

Once set , gauge feel of the chains to note any difference in tension between all chains

Check clearance between bottom flights on chains and bottom of arm

Adjust individual chains to match correctly tensioned chains, and ensure all chain flights are clear from bottom arm face

Once set, lock off M8 locking nut

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português