Instructions to instal Pneumatic connections onto module

Sommaire

- 1 Introduction

- 2 Étape 1 - Mount Pneumatic rail

- 3 Étape 2 - Install Y244 material load sensor blowers

- 4 Étape 3 - Install Y125 Pop up C pipework

- 5 Étape 4 - Install Y124 Roller beds

- 6 Étape 5 - Y126 / Y127 beam position

- 7 Étape 6 - Y232 Y233 and Y234

- 8 Étape 7 - Important

- 9 Étape 8 - Y121 Gripper height

- 10 Étape 9 -

- 11 Étape 10 - Connect ring main

- 12 Commentaires

Introduction

Tools Required

Pipe cutters

Number identification

Flush cutters

Parts Required

P0000160 Flow regulator 6mm inline x 2P0000551 6mm inline Quick Exhaust Fitting x 3

P0001008 Regulator: ARG20 0 - 8.5 Bar c/w Gauge x 1

P0001023 Fitting: SMC 6mm mini Y x 4

P0001030 Fitting: SMC 6mm Equal Tee x 27

P0001108 12mm Tee connector x 2

R0015071 Pneumatics rail

A0000343 energy chain x 1

A0000344 energy chain bracket set x 1

D0015577 fixed energy chain bracket x 1Étape 1 - Mount Pneumatic rail

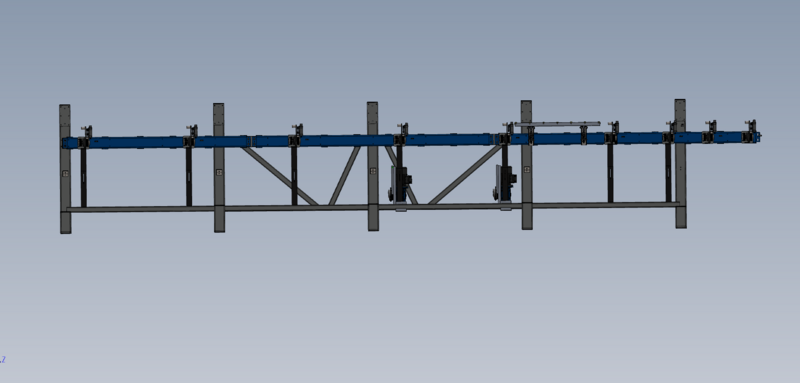

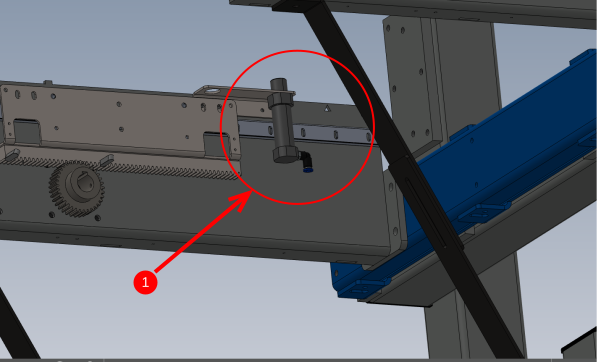

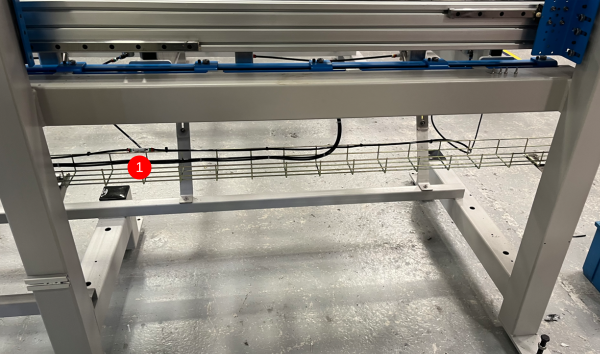

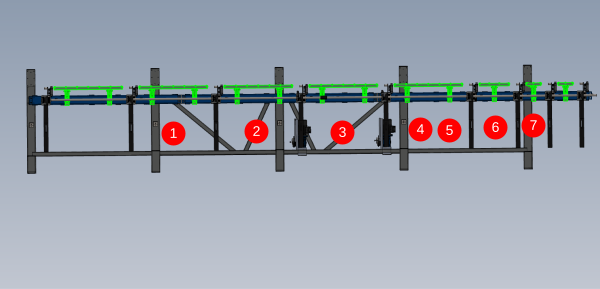

Mount pre assembled pneumatic rail R0015071 into the position shown . Fix with M6 fasteners (size of fasteners and height of rail on frame required)

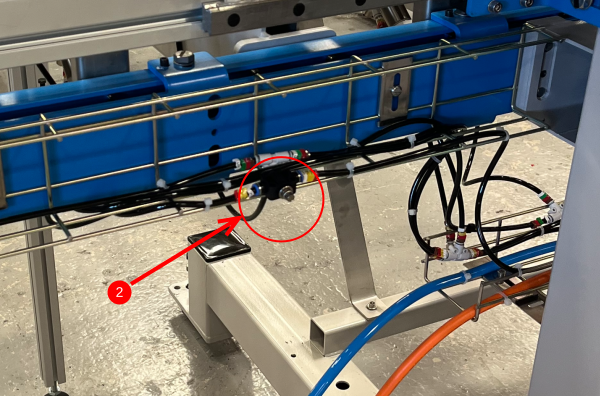

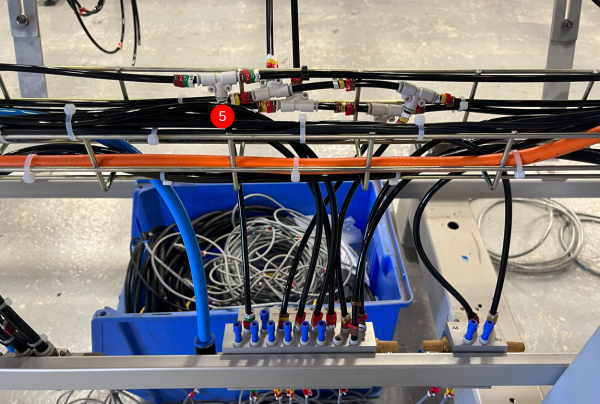

Étape 2 - Install Y244 material load sensor blowers

6mm Black air pipe

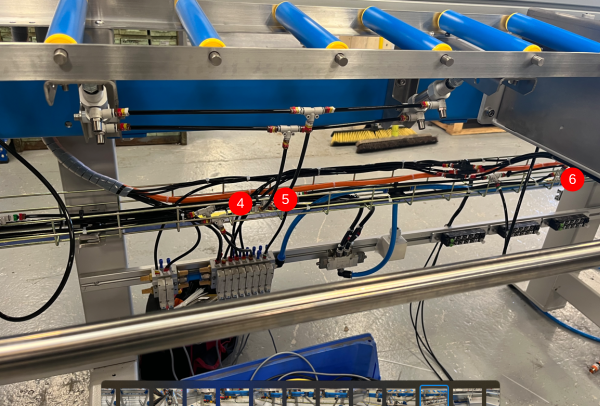

Identify pipe as 2449

- attach long enough pipe to reach wire basket directly behind (2) . Ensure slack is left to allow for roller movement up

- Add pipe to Y Connector on roller table blower assembly

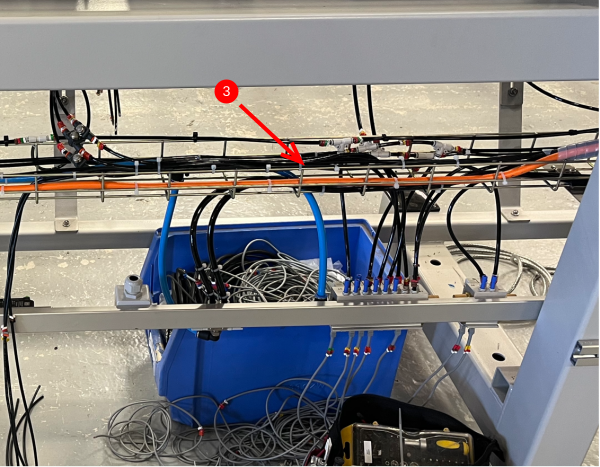

- Attach to indicated sections (3) of wire basket

- Connect to (4 -active) port of valve slice

Étape 3 - Install Y125 Pop up C pipework

6mm black air pipe

Pipe identified as 1259

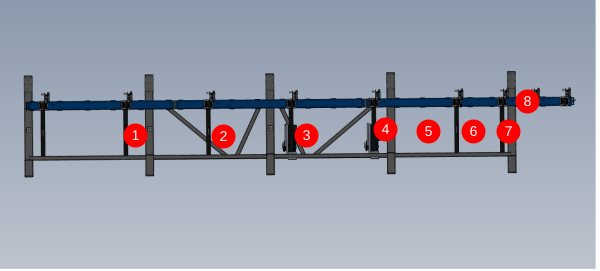

9 off pop up C cylinders to be connected (1)

Ensure enough slack is left on pipe between basket and cylinder to allow full range of movement

- (1) 6mm tee feeds cylinder above and to the left

- (2) 6mm tee feeds cylinder above and ring main left and right

- (3) 6mm tee feeds cylinder above and ring main left and right

- (4) 6mm tee feeds cylinder above and ring main left and right

- (5) 6mm tee feeds valve below and ring main left and right

- (6) 6mm tee feeds cylinder above and ring main left and right

- (7) 6mm tee feeds cylinder above and ring main left and right

- (8) 6mm tee feeds cylinder above and cylinder to the right

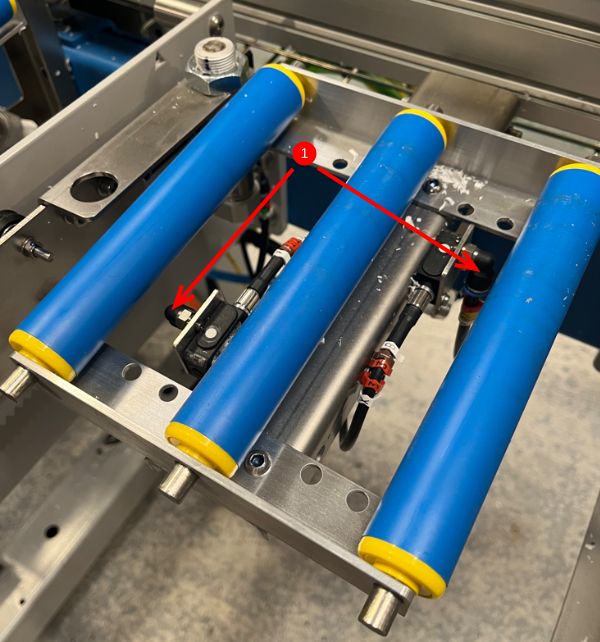

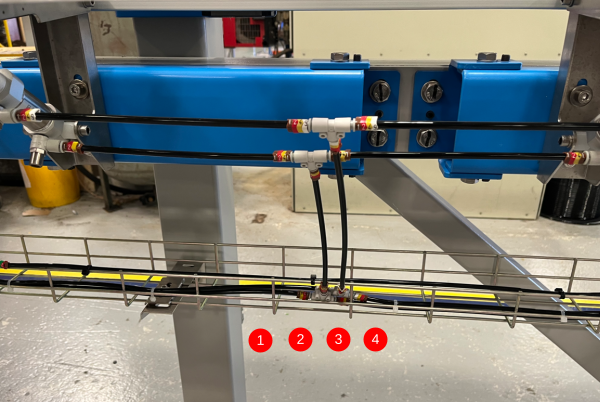

Étape 4 - Install Y124 Roller beds

6mm black air pipe

Pipes identified as 1249 and 1241

Cylinder nose 1249

Cylinder base 1241

(1) (2) (3) (4) connect all as shown using 6mm tee fittings position (1) feeds roller to the left as well as one above

(4) Feeds ring main to valve

(5) Feeds cylinder above and ring main to the right

(6) Feeds cylinder above and ring main to the right

(7) Feeds cylinder above and cylinder to the right

Étape 5 - Y126 / Y127 beam position

pipe identifications

1269 and 1279

Fitting on cylinder closest to extractor should be 1279

Other fitting will be 1269

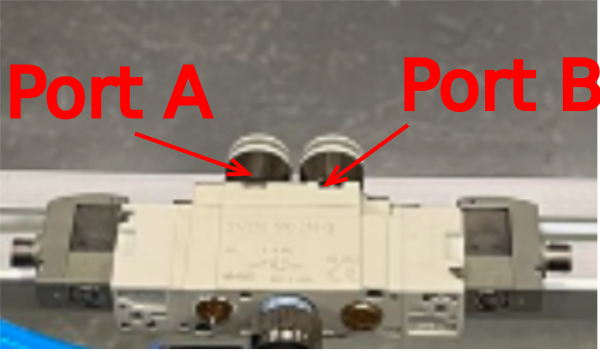

1269 pipe should connect to B on valve 1279 should connect to A on valve

Connect with 10mm black airpipe to standalone valve

Electrical connection will match port connections of two pipes

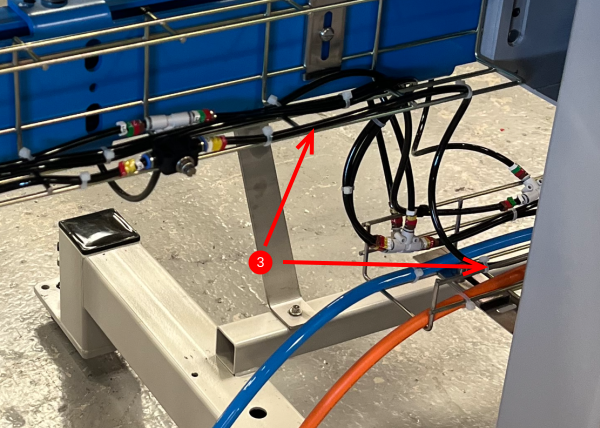

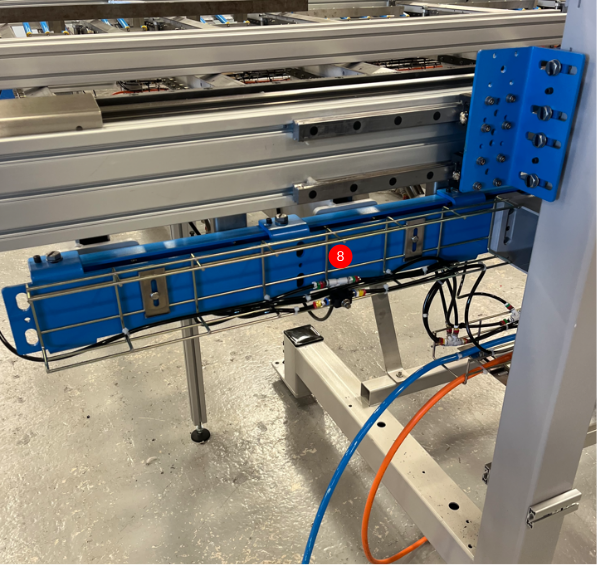

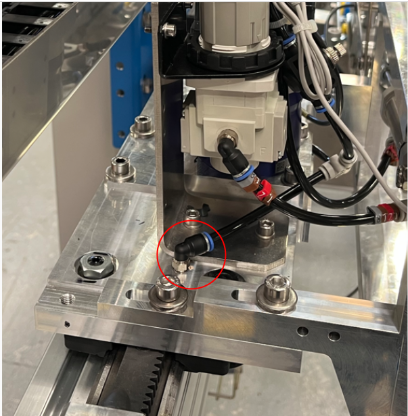

Étape 6 - Y232 Y233 and Y234

Identification as

2329 2339 2349

Home port (2) should be blanked at valve bank

Run from active port on valve bank (port 4) to transfer beam number 4 .

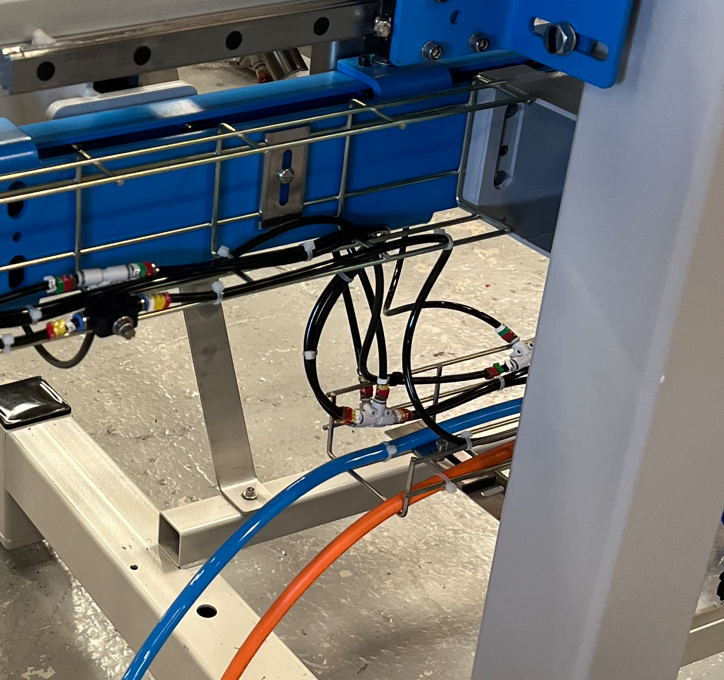

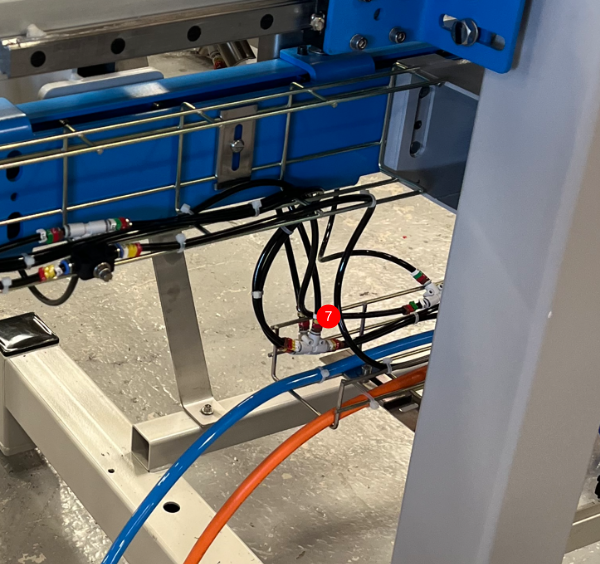

Fit A000343 energy chain @44? links

A0000344 energy chain brackets as shown

Mount to D0015577 fixed bracket and attach to support arm as shown

Must have a P0000551 qev fitted to each line

Étape 7 - Important

It is vital that when installing pipes into the main X axis energy chain, that cable retaining points are used

All cables and pipes should be secured with tie wraps to the 'fingers' on the energy chain brackets at BOTH ends

Étape 8 - Y121 Gripper height

Gripper height is lifted for home position

identification

1211 Home port of valve bank (2) to nose of cylinder

1212 base of cylinder to out port on regulator

1219 In port of regulator to active port on valve bank (4)

Étape 9 -

Identification 1229

Must have flow regulation P0000160

Connect to active port (4) on valve bank

Étape 10 - Connect ring main

Connect 12mm blue airpipe from valve banks to end of frame for machine connections. Ensure 3 meters of pipe is trailing from basket, ready for connection to ring main at a later point

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português