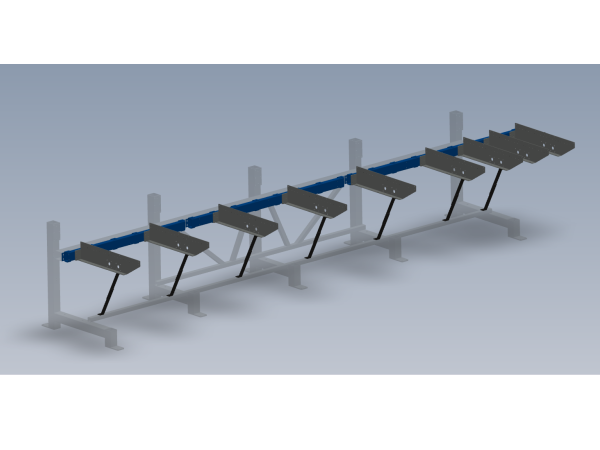

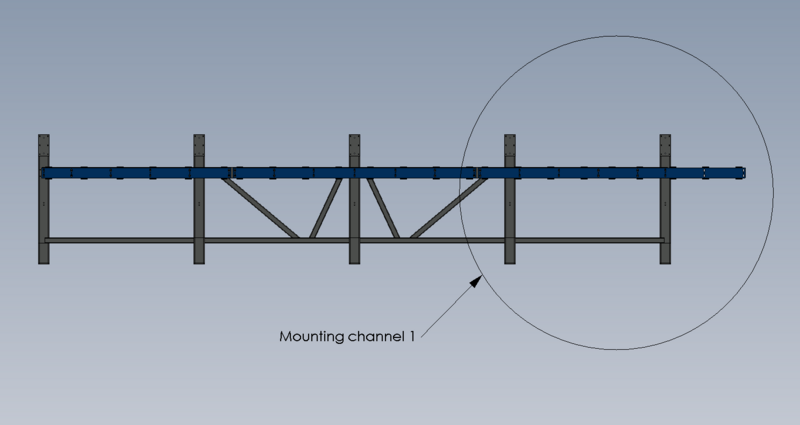

Alignment of loading arm assembly

Introduction

procedure for correct alignment of mounting sections to main frame, and relative setting of load arms

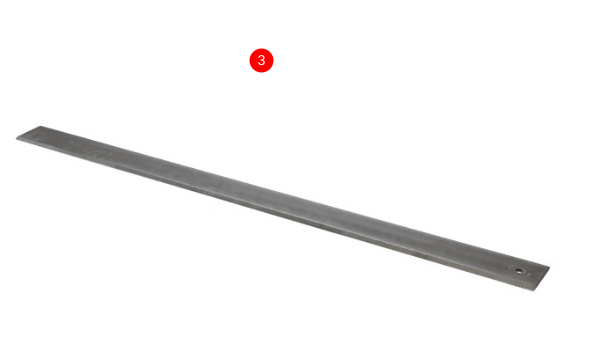

parts required

D0015038B 1 off

D0015039B 1 off

D0015257 1 offÉtape 1 - Fitting of Mounting Channel 3

1 Fit mounting channels to frame using m12 Set bolts and A form washers.Do not add adhesive to bolts at this stage . Do not tension bolts.

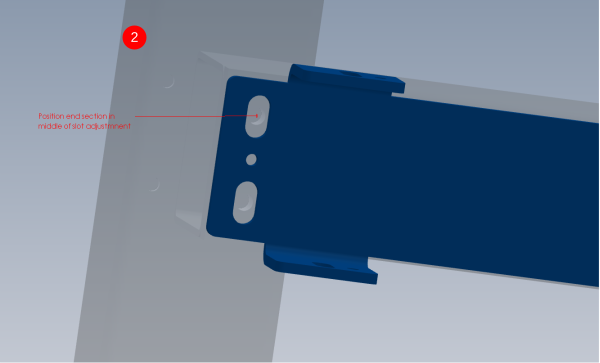

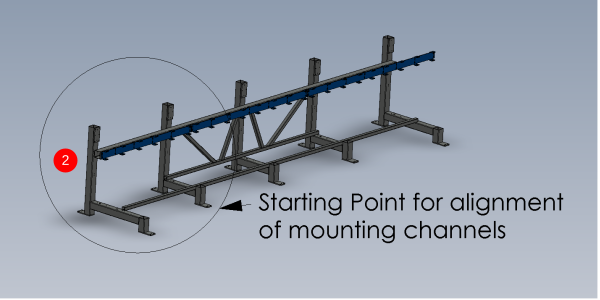

2 Set the first mounting channel to the middle of the adjustment slot at the extreme end of the frame

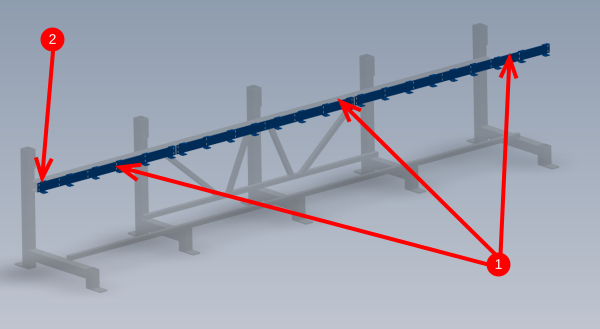

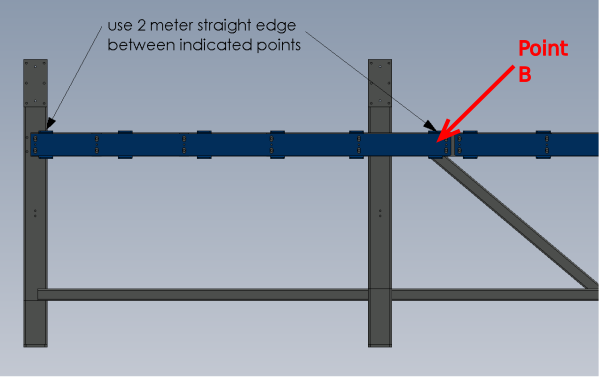

3 Place 2 meter straight edge between indicated points , and raise or lower point b to bring straight edge level with engineers level

4 Tighten bolts to hold in place

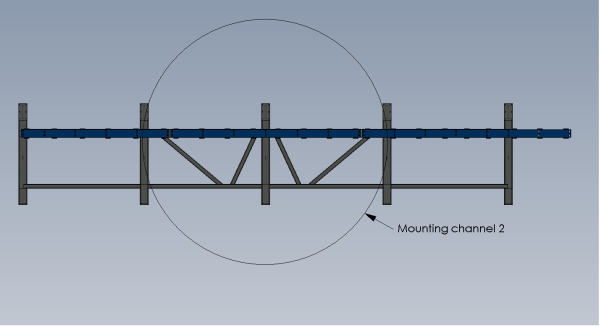

Étape 2 - Fitting of Mounting channel 2

1 Move channel 2 section up or down to copy height of adjacent channel 3. Use the tabs as the reference points

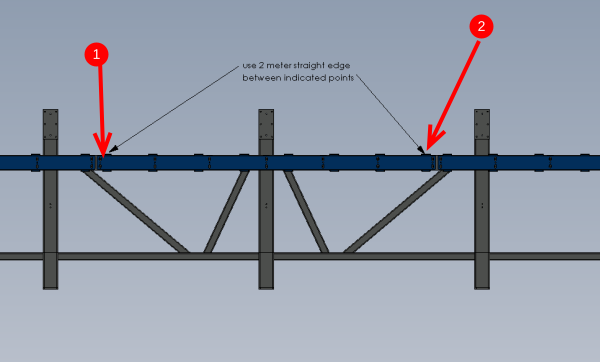

2 Use 2 meter straight edge and level between points indicated

Move channel 2 at the end indicated, to give a level reading

3 Tighten bolts to hold in place

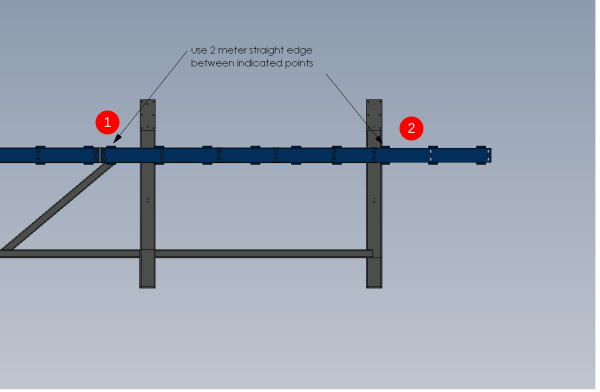

Étape 3 - Fitting of mounting channel 1

1 Move channel 1 section up or down to copy height of adjacent channel 2. Use the tabs as the reference points

2 Use 2 meter straight edge and level between points indicated

Move channel 1 at the end indicated, to give a level reading

3 Tighten bolts to hold in place

Étape 4 - Quality Check Required

Once at this stage with mounting channels being set in position, a quality check is required from a Supervisor.

Étape 5 - Finalising Fixings

1 Remove Set bolt

2 Add adhesive Loctite 243 to bolt.

3 Refit and tighten

4 Mark head with ink to show completion of fixing

5 Repeat for all M12 fixings holding on mounting sections 1,2 and 3

Étape 6 - Dowel in Position

1 Drill 8mm Diameter holes in all roll pin holes situated between previous tightened m12 bolts ( 19 off in total reference detail 1 )

2 Insert 8mm x 24mm spiral pins to 8mm holes

3 Clean drilled areas of swarf and cutting fluid

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português