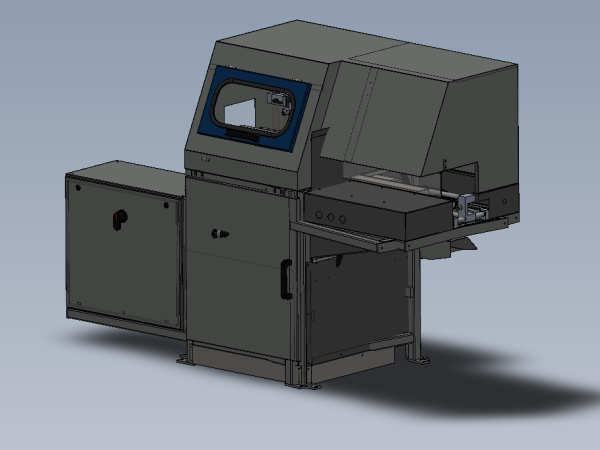

Guarding fitment instructions

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

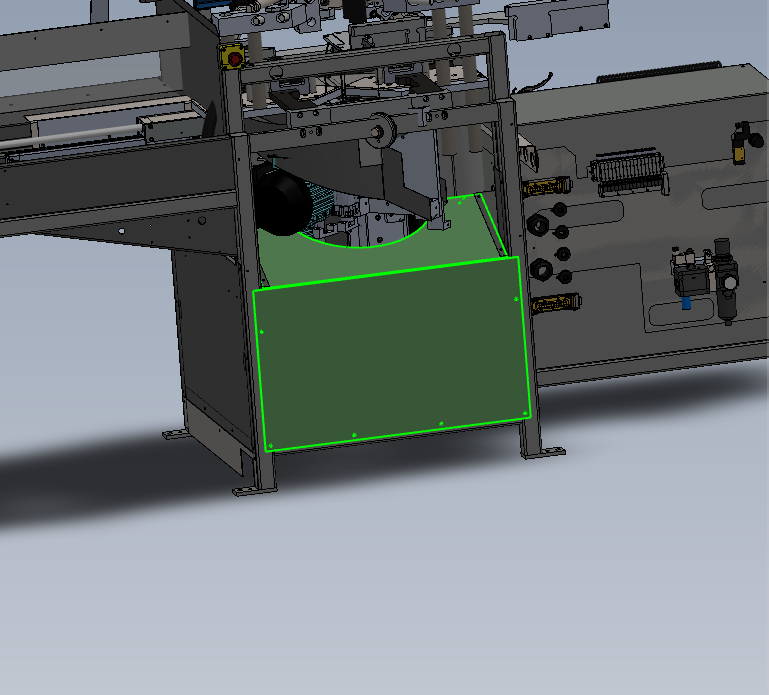

- 3 Étape 2 - Fit front door

- 4 Étape 3 - Rework D0016266

- 5 Étape 4 - Fit front door interlock assembly

- 6 Étape 5 - Attach interlock key and catch

- 7 Étape 6 - Align interlock and drill Catch

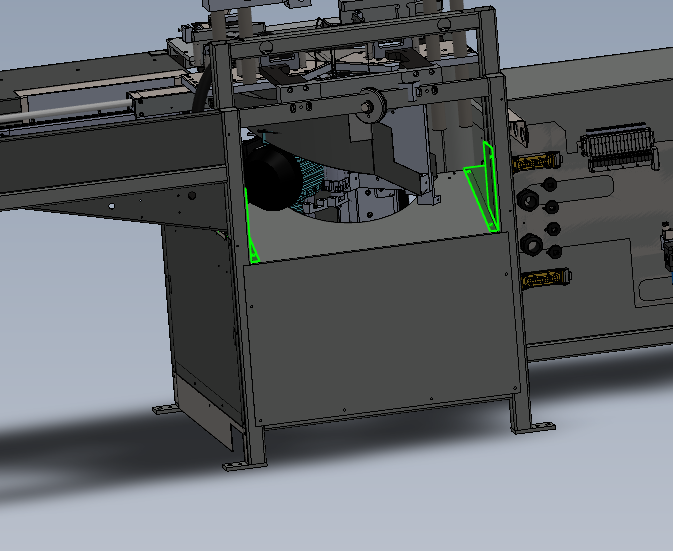

- 8 Étape 7 - Fit serial plate

- 9 Étape 8 - Fit hinge panel to frame

- 10 Étape 9 - Fit chute inserts

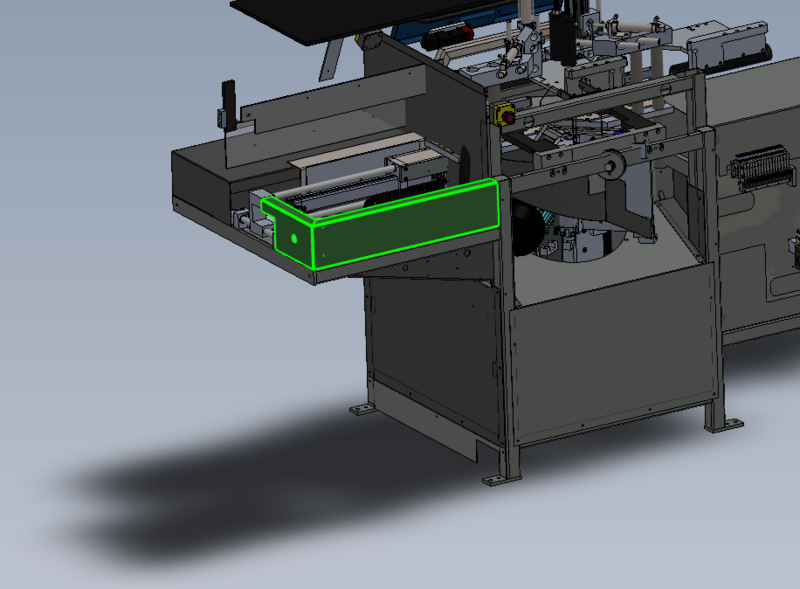

- 11 Étape 10 - Fit rear chute

- 12 Étape 11 - Fit rear tray

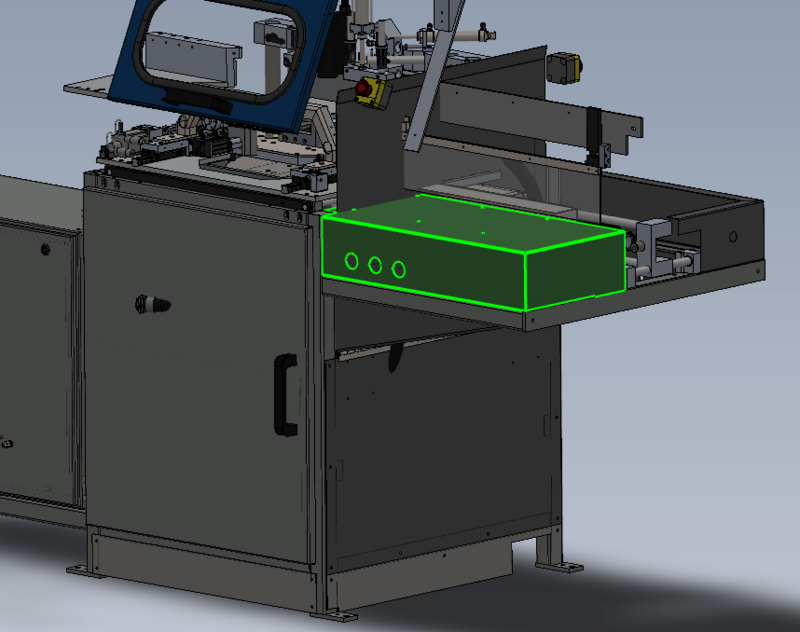

- 13 Étape 12 - Fit front tray

- 14 Étape 13 - Assemble and fit regulators

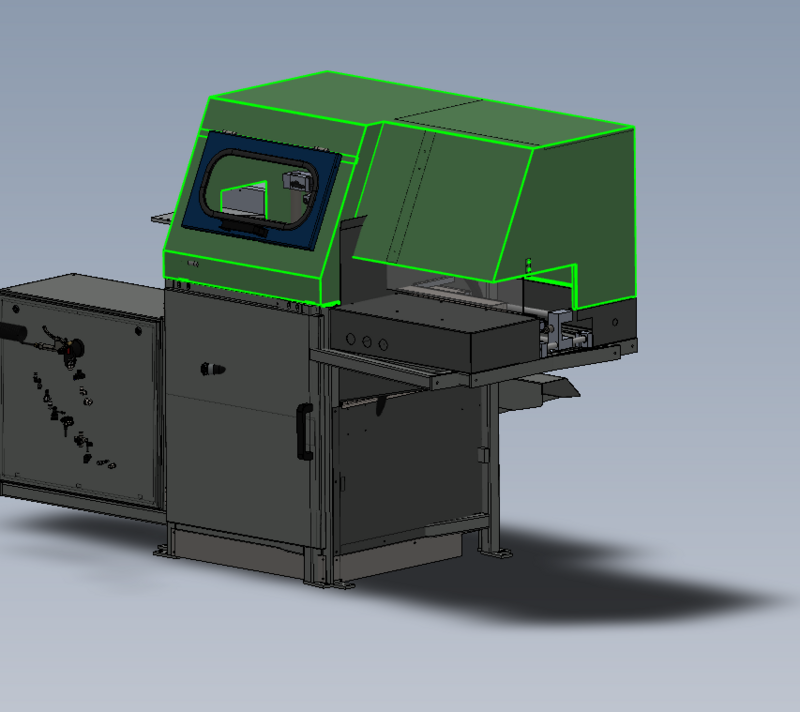

- 15 Étape 14 - Fit top hood

- 16 Étape 15 - Finalise position of tip strips

- 17 Étape 16 - Fit blade spanner

- 18 Étape 17 - Fit compliance guards

- 19 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Parts Required

D0001878 Rear Door Saw Mk4 (1879) x 1

D0004584 Outfeed Side Rest x 3

D0015703 Air Gun Bracket x 1

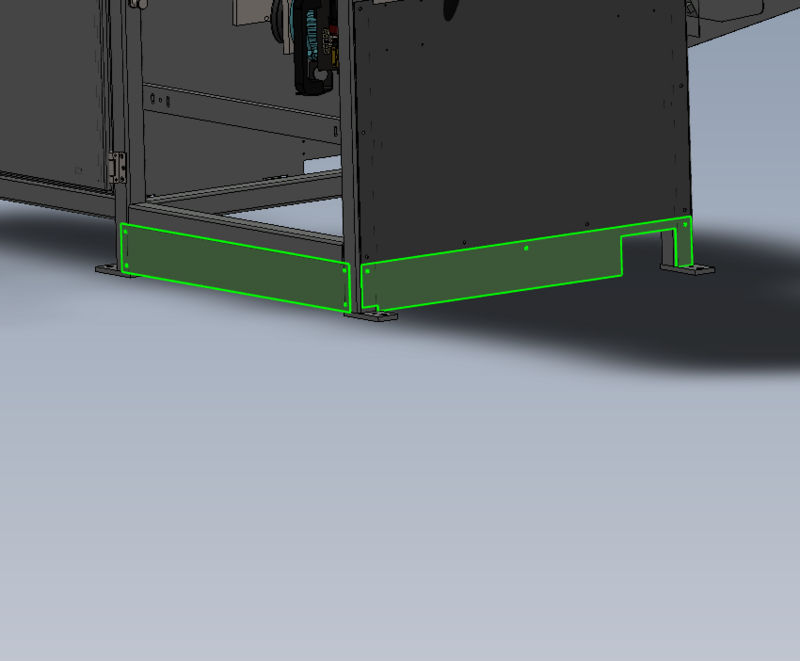

D0016203 Compliance Guard - Saw Lower Front x 1

D0016204 Compliance Guard - Saw Lower Side x 1

D0016265 Saw Front Door: Bernstein Mount Plate x 1

D0016266 Saw Front Door: Bernstein Guard x 1

E0001569 Guard Lock Switch: Bernstein Radius Actuator (Key) x 1

M0000055 Saw Blade Spanner (24mm Combination) x 1

M0001051 Bullet Catch 70 x 12 x 1

P0000010 Elbow Adaptor 6mm - 1/8 BSPT (Taper thread) x 6

P0001008 Regulator: ARG20 0 - 8.5 Bar c/w Gauge x 3

P0001009 Panel Mount Nut (To suit P0001008) x 3

R0015041 Bench Assemble Top Hood Assembly x 1

R0015337 Bench assemble guarding components x 1

R0015338 Bench assemble serial plate x 1

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

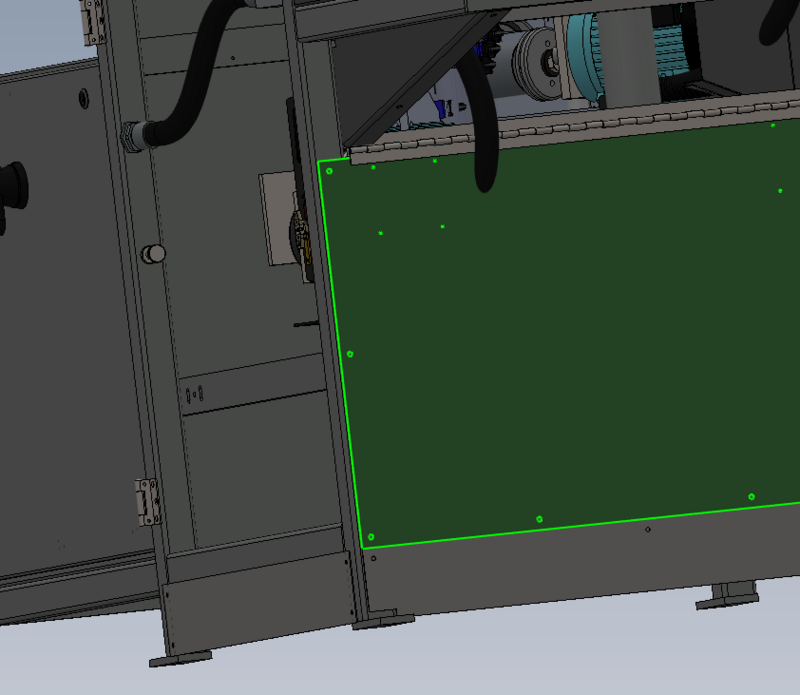

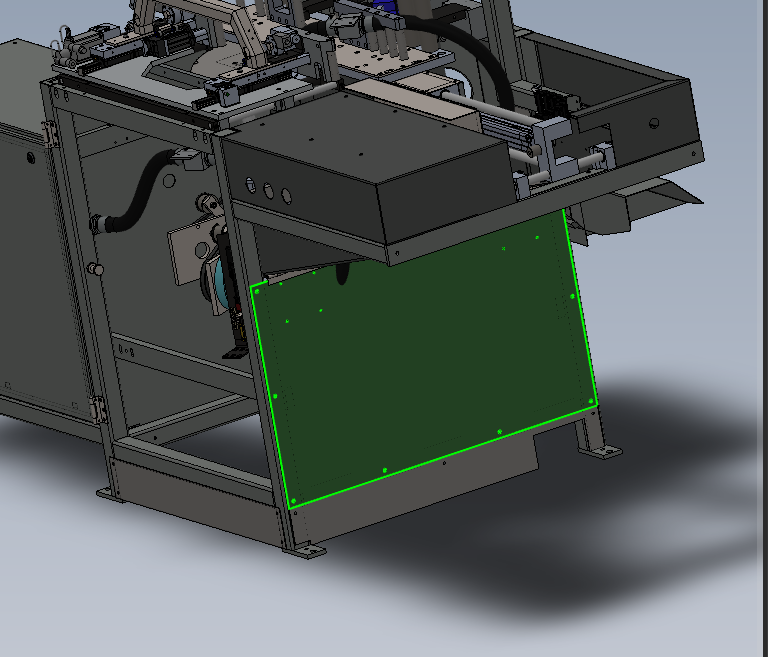

Étape 2 - Fit front door

Fit pre assembled front door to frame

Use 6 off M4 x 12 button sockets only to fix hinges to frame.

Ensure door sits square to frame

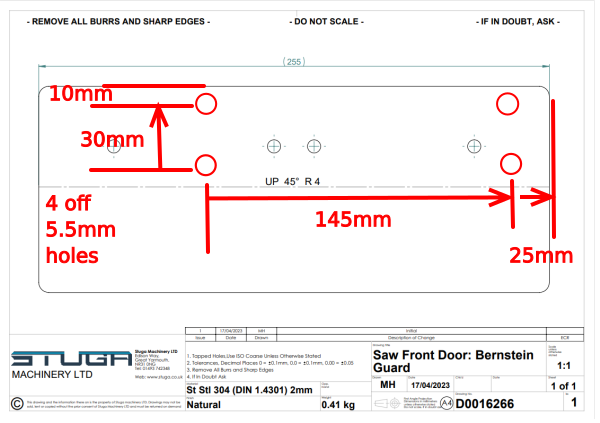

Étape 3 - Rework D0016266

ECR Raised 13/12/23

Rework part to attached dimensions until ECR process issues amended part

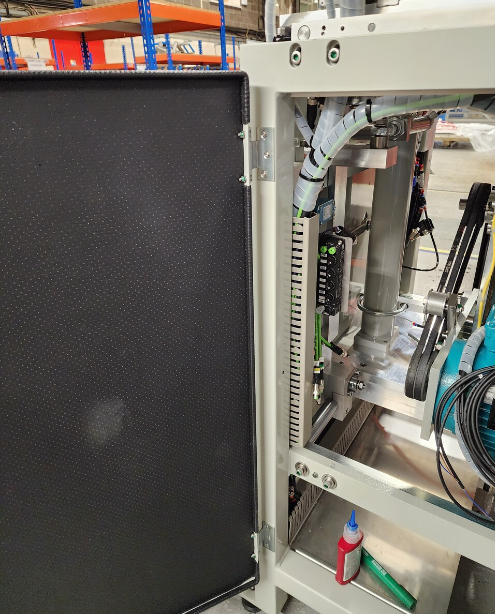

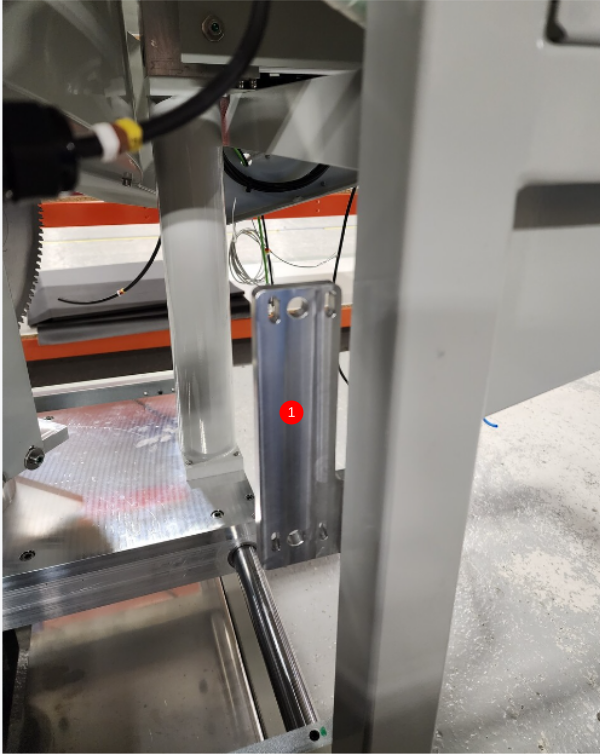

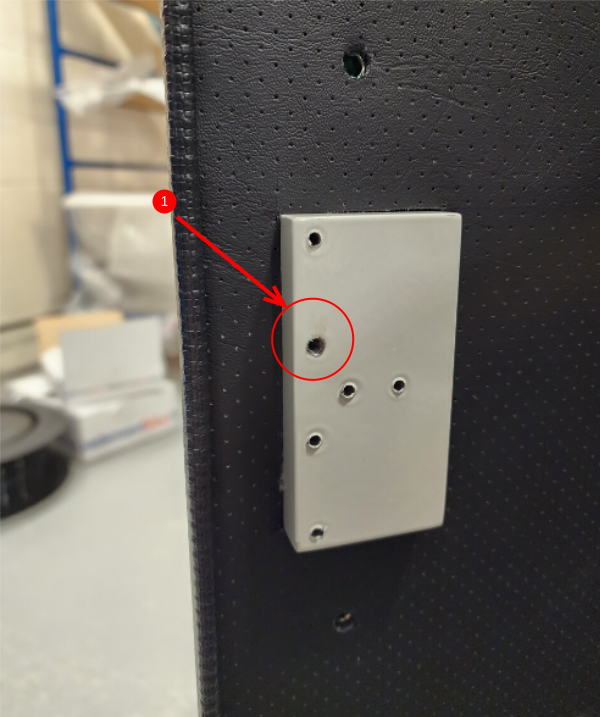

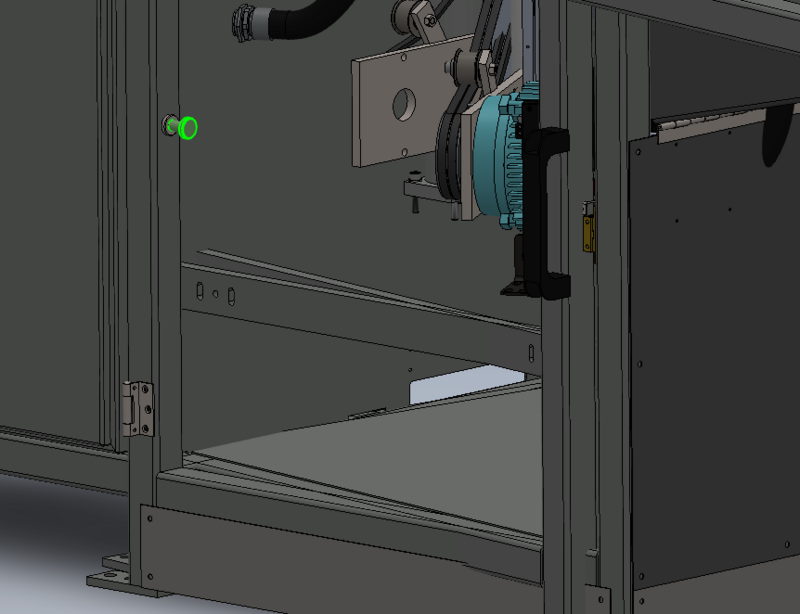

Étape 4 - Fit front door interlock assembly

1 Fit mounting bracket using 2 off M6 x 30 socket caps and heavy M6 washers

2 Attach interlock and guard panel using 4 off M5 x 60 socket caps, M5 penny washers and M5 Nyloc nuts

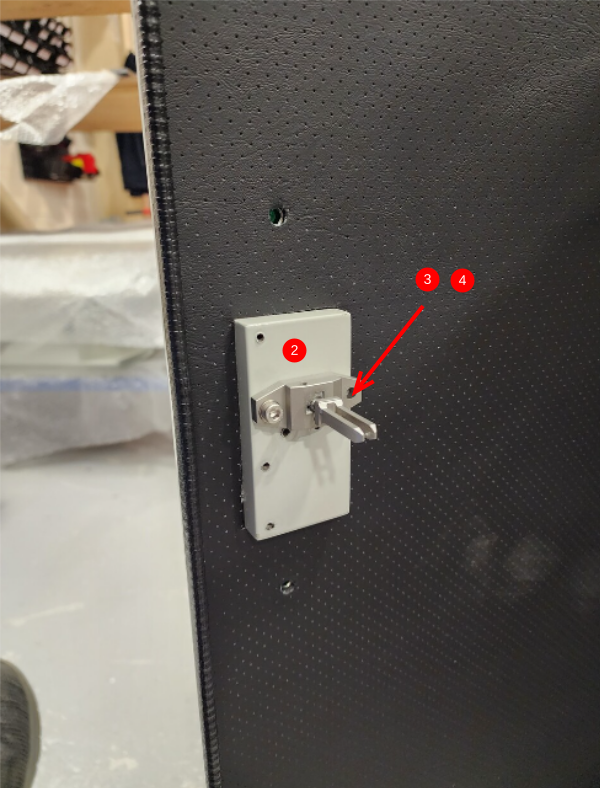

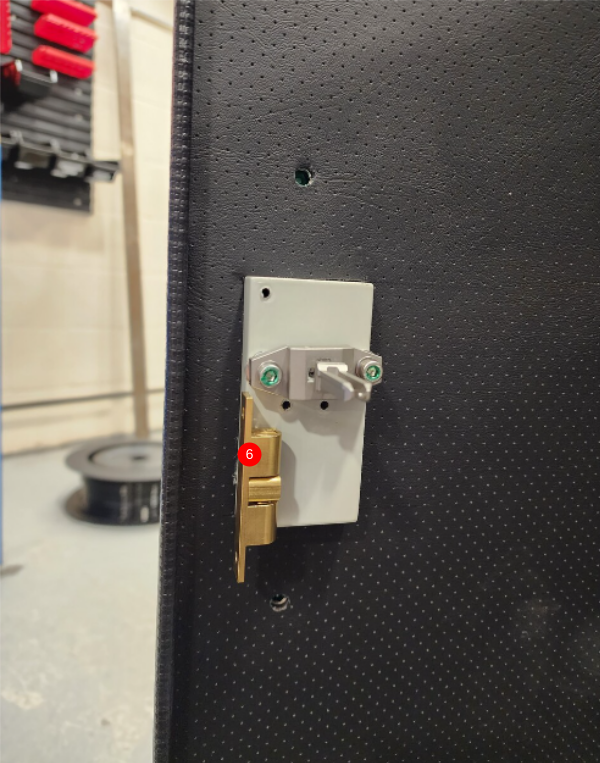

Étape 5 - Attach interlock key and catch

ECR raised to amend door fixing block holes

1 Drill and tap indicated hole to M5

2 Fit interlock blade using 1 off M5 x 20 socket cap and M5 A Forms washer , and align as shown

3 Mark position of second fixing hole and drill and tap to M5.

4 Finalise interlock with second M5 x 20 socket cap and A Form washer

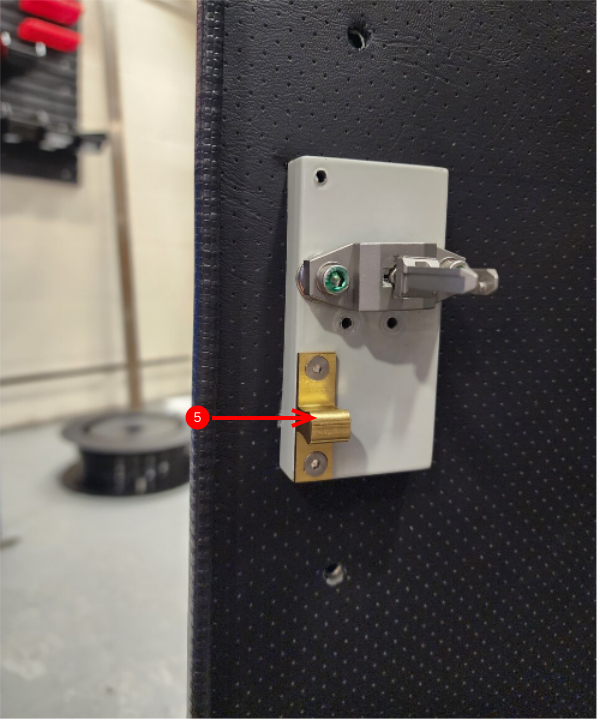

5 Tap holes to remove debris and Fit 1st part of door catch using 2 off M4 x 10 countersunk bolts

6 Fit Second part of catch as shown

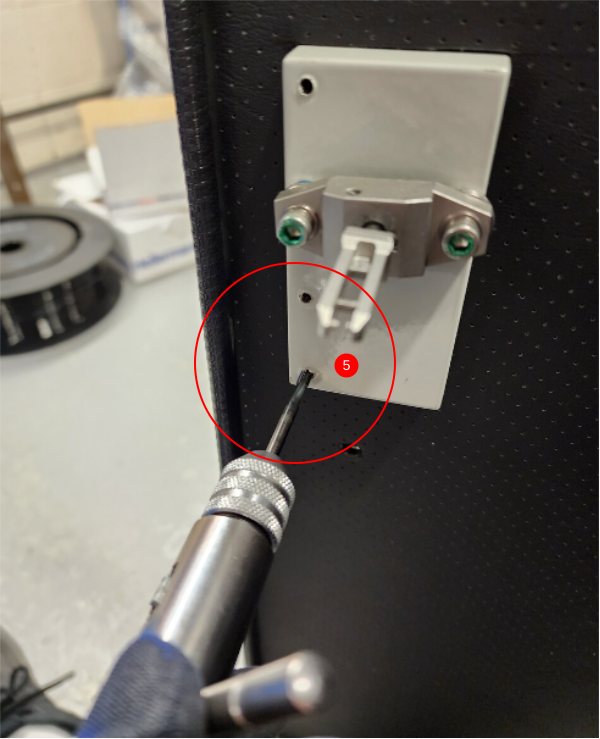

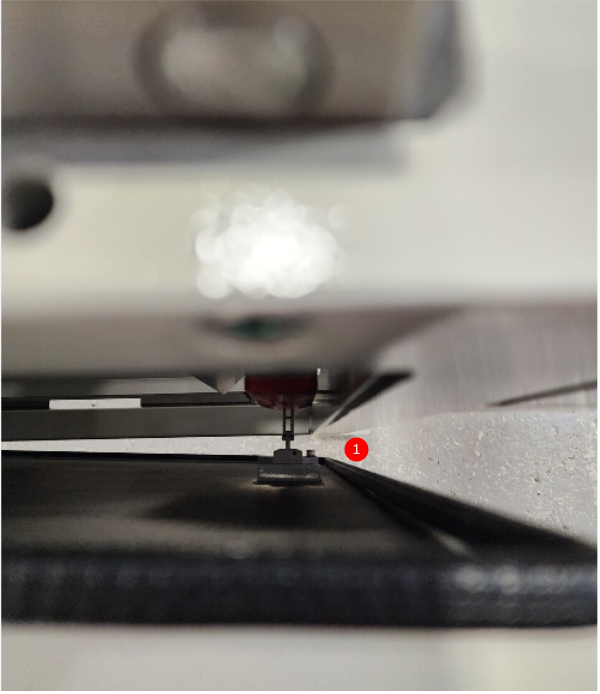

Étape 6 - Align interlock and drill Catch

1 Adjust interlock switch assembly to align exactly with fixed position of blade .

Entry of blade into switch must be smooth and perfectly aligned

2 Mark position of second part of catch assembly with door closed , and drill 2 off M4 tapped holes into frame . Fix with 2 off M4 x 10 countersunk fasteners

3 Check closing and opening of door once all components are fitted in correct and well aligned . Not excessive force should be needed to overcome latch assembly

Étape 13 - Assemble and fit regulators

Assemble 3 off regulators and fit to panel

Add identification labels to regulators

Étape 15 - Finalise position of tip strips

Finalise position of tip strips.

Please include correct setting for these parts

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português