| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 5 : | Ligne 5 : | ||

|Categories=Production | |Categories=Production | ||

|Difficulty=Medium | |Difficulty=Medium | ||

| − | |Duration= | + | |Duration=2 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

Version actuelle datée du 3 avril 2024 à 12:22

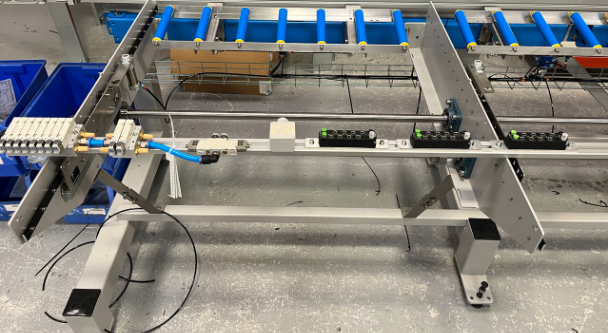

Bench assembly instructions for pneumatics rail

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Handing

- 4 Étape 3 - Assemble valve 1

- 5 Étape 4 - Assemble valve bank 1

- 6 Étape 5 - Assemble valve bank 2

- 7 Étape 6 - Assemble Connection box

- 8 Étape 7 - Fix ethercat boxes to mounting plates

- 9 Étape 8 - Attach trunking

- 10 Étape 9 - Attach assemblies

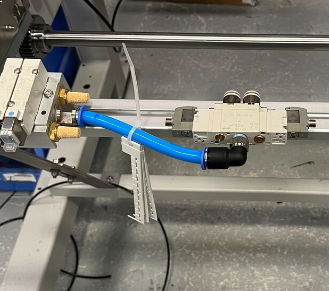

- 11 Étape 10 - Fit connecting 12mm Blue pipework

- 12 Étape 11 - Secure Ethercat identification markers

- 13 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Pipe cutters

Standard HSS drill set

Step cutting drill

Standard screwdriver set

Parts Required

D0010167 x 3

C0001018 x 3

D0016300 x 1

P0001139 x 1

P0001102 x 2

P0001032 x 2

P0001068 x 1

P0001101 x 3

P0001163 x 8

P0001071 x 1

P0001186 x 10

P0001151 x 1

A0000240 x 1

P0000159 x 5Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all pneumatic threaded connections

Pen mark all fasteners to show finalised

Étape 2 - Handing

Assemble as shown for R to L machine

Mirror assembly for L to R machine

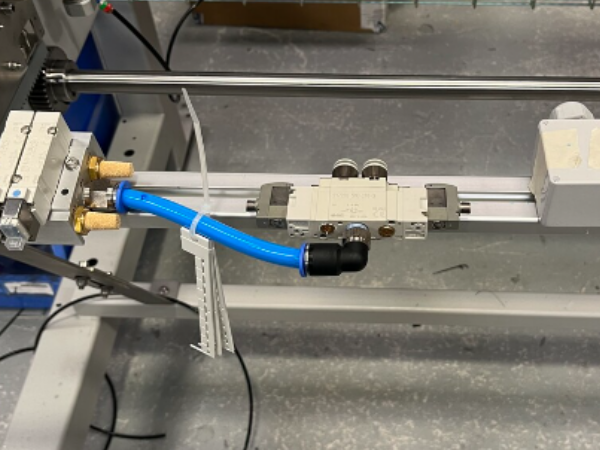

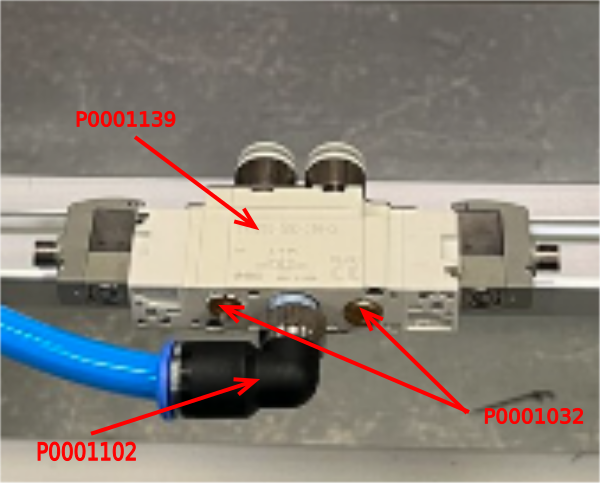

Étape 3 - Assemble valve 1

Attach Fitting P0001102 to valve P0001139 as shown . Add 2 off P0001032 silencers as indicated

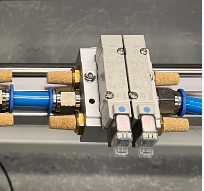

Étape 4 - Assemble valve bank 1

Assemble valve bank 1 as shown using

P0001068 valve base x 1

P0001186 valve x 2

P0001101 fitting x 2

P0001163 fitting x 4

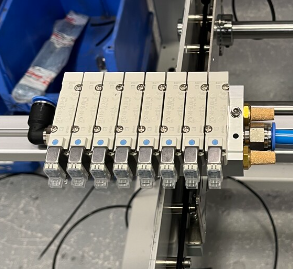

Étape 5 - Assemble valve bank 2

Assemble valve bank 2 as shown using

P0001071 valve base x 1

P0001186 valve x 8

P0001101 fitting x 1

P0001102 fitting x 1

P0001163 x 4

P0000159 x 4 ( information required for which ports to blank)

Étape 6 - Assemble Connection box

Connection box A0000240 will require holes adding to use.

Drill 2 off 5mm holes on back face to allow mounting on rail as shown. Use M4 socket caps and washers

Drill top face to mount A0000105 gland and fix with A0000255 nut

Étape 7 - Fix ethercat boxes to mounting plates

Mount ether cat boxes C0001018 to mounting plates D0010167 using m3 x 20 panhead bolts

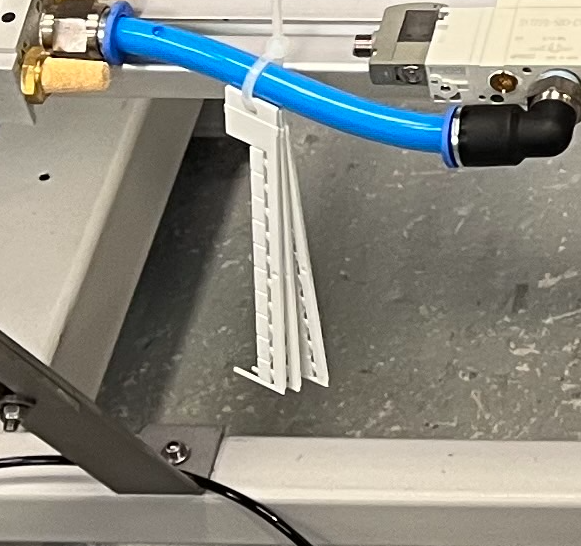

Étape 8 - Attach trunking

Attach a length of 75mm x 25mm trunking @ 1310mm, 120mm from non slotted end to rear of maytec and use M5 x 6 button sockets to secure

Ecr raised to add holes to maytec section on 05/09/23

Holes will required drilling until ecr finalises

1st m5 hole 130mm from non slotted hole end , then spaced at 250mm Drill and tap m5

Étape 9 - Attach assemblies

Attach built assemblies to mounting bar D0016300 as shown using the following fixings

Space as follows

1st ethercat box 100mm from end of maytec non slotted end, second ethercat box butted against 1st.

All other components should be spaced at 100mm except for Valve 1 and Valvebank 1 which are spaced at 150mm

Valve 1 uses bracket P0001151 to attach using M4 x 12 socket caps and A form washers

Valve bank 1 and 2 secured with M4 x 40 socket caps and M8 motor plate washers, spaced away from maytec rail with 2 M8 washers to enable valve to sit straight

Ethercat mount plates use m6 x 16 socket caps and a form washers

Connection box uses M4 x 12 socket caps and washers

Étape 11 - Secure Ethercat identification markers

Make sure identification markers are safely stored with assembly ready for electrical terminations at a later point

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português