Bench assembly instructions for SY assembly

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Assemble Z support assemblies

- 4 Étape 3 - Step 15 - Mount cylinder assemblies

- 5 Étape 4 - Mount cylinder assemblies

- 6 Étape 5 - Handing orientation of turret stops R-L

- 7 Étape 6 - Handing orientation of turret stops L-R

- 8 Étape 7 - Assemble turret stops

- 9 Étape 8 - Fit sy datum block

- 10 Commentaires

Introduction

Tools Required

Standard Hex Key set

Standard Spanner set

1 Meter straight edge

Feeler Gauges

Parts Required

B0000044 Linear Rail MSB25 260mm Long (AMT) x 2

B0000046 Slide Base Bearing Block (Straight Grease Nipple) x 4

B0000173 blanking cap x 10

B0000234 Straight Grease Nipple M6 ST/ST x 4

B0000245 Needle Bearing 12 D 16 D 10 Long (ENA) x 12

B0001060 Grease Fitting M6x0.75 to Ø4 x 4

B0001061 Grease fitting M6 x 1 to 4mm x 4

B0001123 Double angular contact bearing 6 I/D 17 O/D 9 long x 2

B0001185 Leadscrew nut Igus x 1

C0001005 Stepper Motor AS1050 x 1

D0005184 Guide Roller x 6

D0005186 Guide Pin Washer x 6

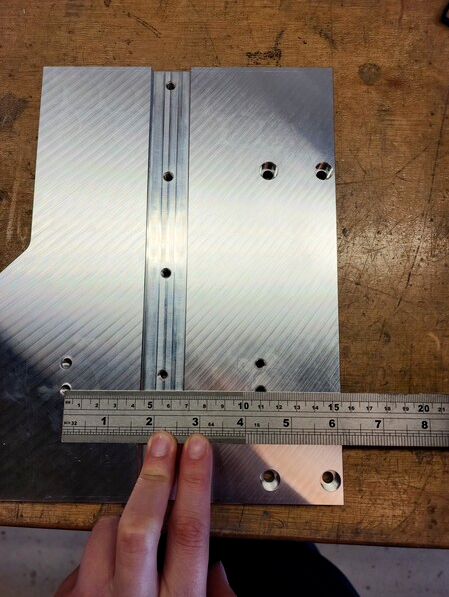

D0015172 Centralise Plate (with SY) x 1

D0015173 Saw SY Saddle Brace x 1

D0015174 Roller Fence (With SY) x 2

D0015175 Saw Saddle Carriage Block x 2

D0015176 Cylinder Mount Block x 2

D0015178 Z Block x 2

D0015207 Outer Bearing Housing x 1

D0015208 Leadscrew Bearing Block x 1

D0015209 Leadscrew Attachment Bracket x 1

D0015222 SY Grease Manifold x 2

D0015240 Collar Clamp: SY Axis ZX5 x 1

D0015316 Leadscrew Bearing Block Cover x 1

D0015415 Turret Pickup Arm ZX5 x 2

D0015416 Bracket: Turret Stop RH ZX5 x 1

D0015417 Bracket: Turret Stop LH ZX5 x 1

D0015698 Flag Block x 1

D0015777 Leadscrew SY x 1

D0016336 SY table blower x 1

E0000336 Sensor: M8; 2mm, PNP N/O, M8 conn x 1

H0005185 Shaft 12mm: 90.5 Saw Fence Roller Pin x 6

M0001209 Bracket m8 proximity sensor 90 degree x 1

P0000200 Elbow Adaptor 6mm - M5 x 7

P0001127 Guide cylinder 20 x 30 compact x 2

P0001157 Turret Stop: 6 Station Right Handed Somatec x 1

P0001158 Turret Stop: 6 Station Left Handed Somatec x 1Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

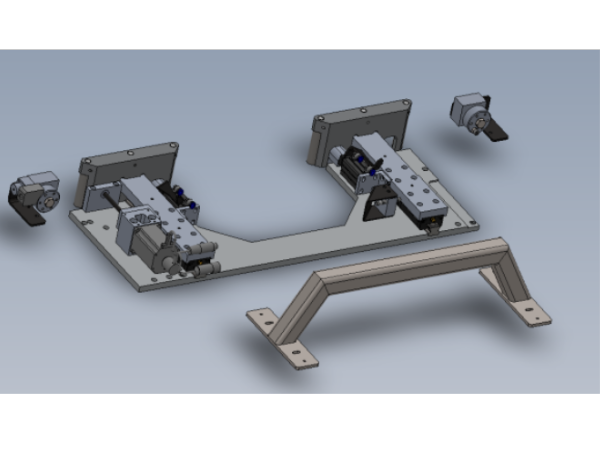

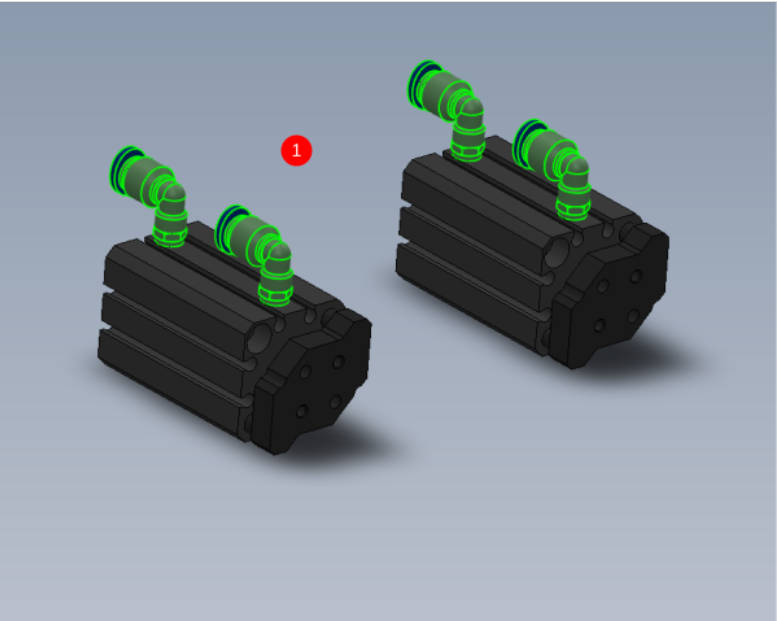

Étape 2 - Assemble Z support assemblies

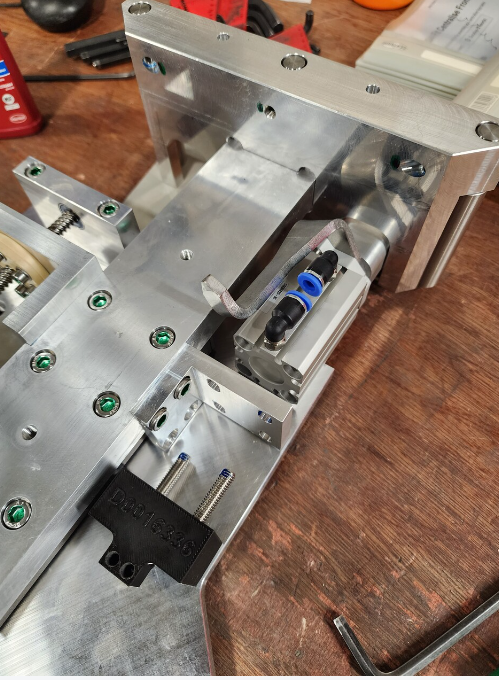

1 Fit 4 off P0000200 Elbow Adaptor 6mm to 2 off P0001127 Guide cylinder 20 x 30 as shown

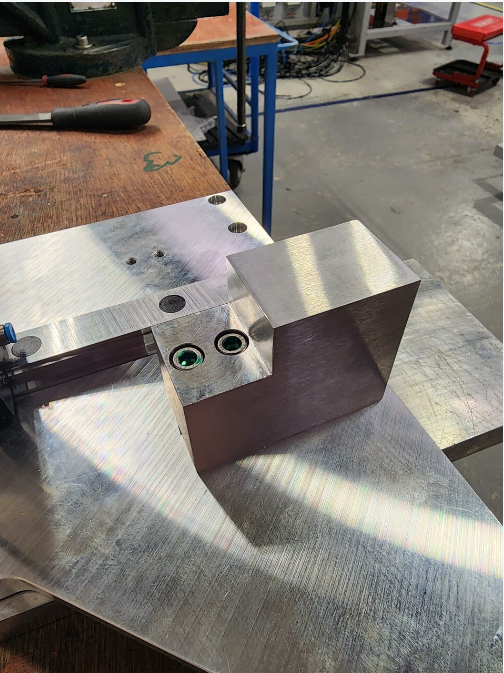

2 Use M4 x 50 socket caps to assemble D0015178 Z Block and D0015415 Turret Pickup Arm ZX5 on cylinder as shown . Assemble one of each hand as shown

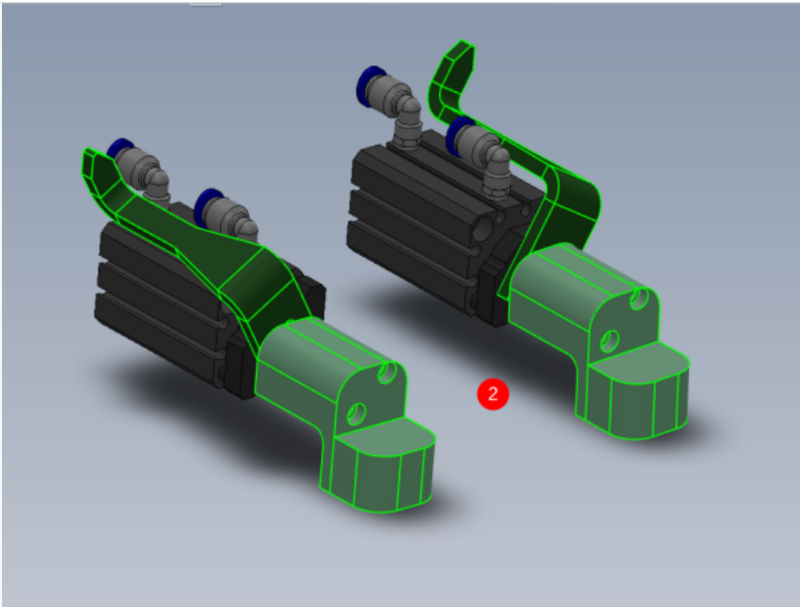

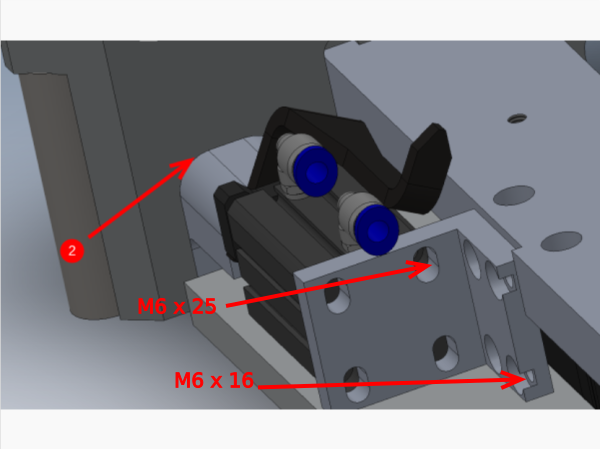

Étape 3 - Step 15 - Mount cylinder assemblies

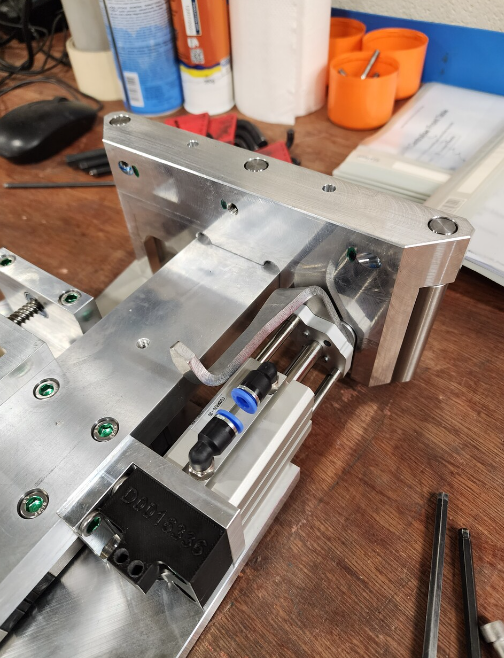

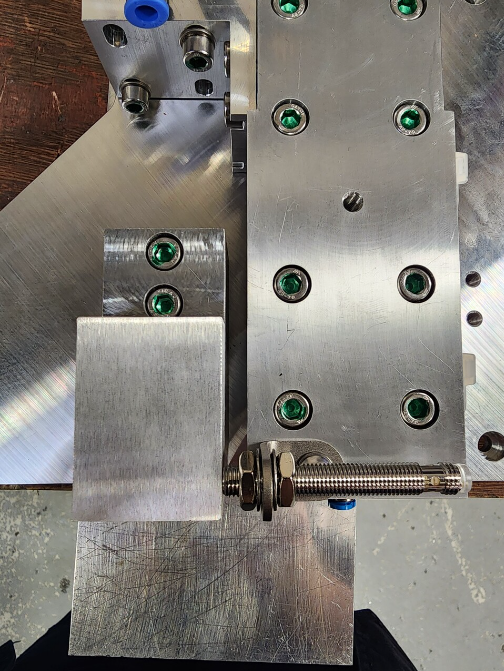

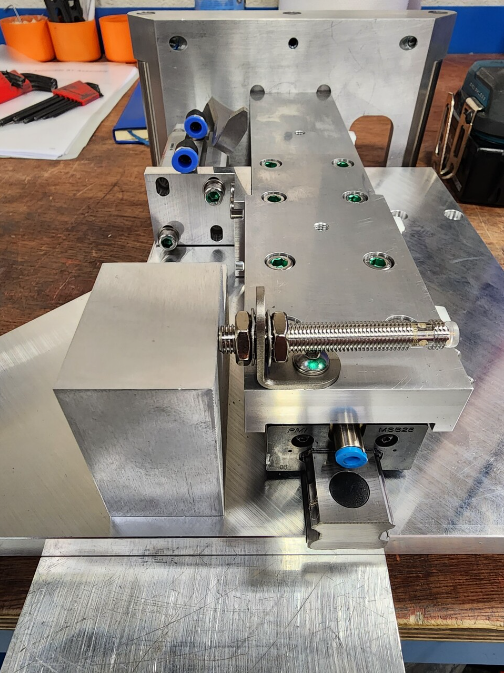

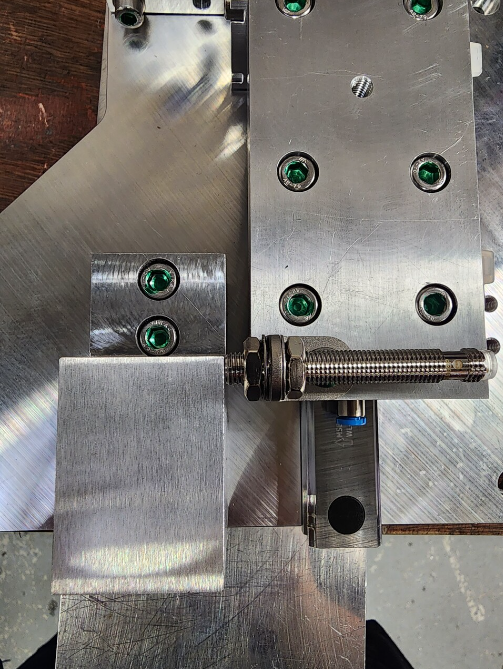

1 Mount bracket to bearing block as shown using M6 x 16 socket caps and M6 x 20 socket caps both with A form washers on eject side

2 Mount bracket to bearing block combining blower block using M6 x 40 socket caps on saw infeed side

2 Ensure free movement is possible when z block slides through roller housing , check for clearance at indicated point

3 Attach table blower to infeed side cylinder assembly.. Fasteners and details required

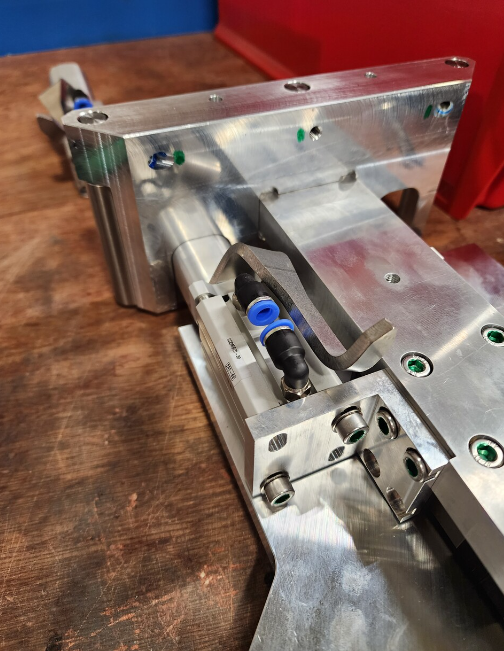

Étape 5 - Handing orientation of turret stops R-L

Ensure configuration shown in these pictures are replicated on assembly

Pay close attention to sensor position in relation to number markers

Étape 6 - Handing orientation of turret stops L-R

Ensure configuration shown in these pictures are replicated on assembly

Pay close attention to sensor position in relation to number markers

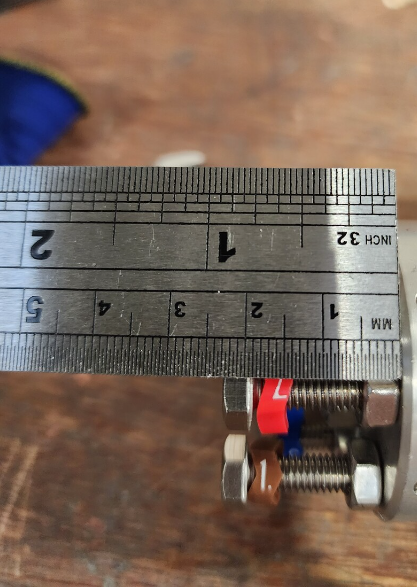

Étape 7 - Assemble turret stops

Assemble turret units as shown

1 P0001157 Turret Stop: 6 Station Right Handed Somatec x 1

P0001158 Turret Stop: 6 Station Left Handed Somatec x 1

Use M6 x 25 set bolts and M6 nuts

Once stop positions have been identified set stop bolts to the following (measurement taken from face of turret stop to underside of hex head)

Pos 1 20mm

Pos 2 19mm

Pos 3 18mm

Pos 4 17mm

Pos 5 17mm

Pos6 17mm

Étape 8 - Fit sy datum block

Fit Sy datum block as shown , Fix with M6 40 socket cap 2 off

check that block is set to run parallel with datum sensor

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português