Instructions for bench assembly of v notch components

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Saw motor bar assemblies

- 4 Étape 3 - Prepare Adjustment bolts

- 5 Étape 4 - Check M16 thread and add M8 set bolt

- 6 Étape 5 - M0001093 Shaft Clamping Element (Ø15-20 shafts)

- 7 Étape 6 - Assemble motor mounts

- 8 Étape 7 - Fit to Saw motor bar

- 9 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Standard HSS drill set

Vernier 150mm

1 meter straight edge

1" parallel blocks

40mm shaft pin jigs

Feeler gauge set

Internal circlip pliers

External circlip pliers

8mm hand reamer

Parts Required

B0000109 Linear Bearing (IKO) 40 D x 62 D x 80 L x 8

B0000427 Leadscrew Ø25x10 435 Long x 1

B0001047 Fixed Bearing Support Block Ø17 x 1

B0001120 Circlip 62mm External x 16

B0001127 ROTEX GS Coupling Ø14/Ø15 Bore & Key (98 Shore Spider) x 1

B0001134 Ball Bearing 15ID 35OD 11 Long x 10

C0001122K Servo Motor: Beckhoff AM8032-1E10 (Keyed) x 1

D0010132 SZ Drive Mount Plate x 1

D0010563 Y Axis Servo Mount x 1

D0015147 V Notch Upper Support Bar x 1

D0015148 V Notch Lower Support Bar x 1

D0015149 VZ Shaft End Plate x 4

D0015150 Shaft 40mm: 1350 ZX V Notch Saw Motor Slide x 4

D0015152 V-Notch Upper Moving Bar x 1

D0015153 V-Notch Rear Moving Bar x 1

D0015154 V-Notch Front Moving Barx1

D0015157 Saw Motor Bar x 4

D0015158 Shaft 40mm: 190mm ZX V Notch Saw Motor Slide x 8

D0015159B Saw Motor Adjustment Screwx 4

D0015160 Saw Motor Block x 4

D0015164 VY Leadscrew Block x 1

D0015166 VY Motor Mounting Plate x1

D0015258 Upper Link Mount 1 x 1

D0015259 Upper Link Mount 2 x 1

D0015260 Upper Link x 2

D0015261 Lower Link x 2

D0015262 Lower Link Mount x 2

D0015263 Mid Link Shaft x 2

D0015264 Lower Link Shaft x 2

M0001093 Shaft Clamping Element (Ø15-20 shafts) x 16

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 3 - Prepare Adjustment bolts

4 off D0015159B Saw Motor Adjustment Screw require M8 x 70 set bolts cutting to suit M8 thread depth on adjuster bolts

Adjust each bolt individually as discrepancies in thread depth are possible

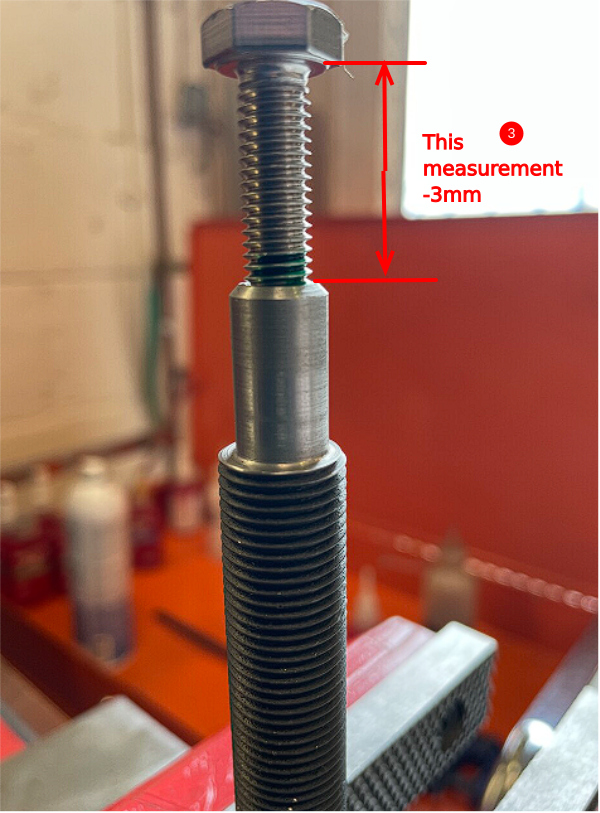

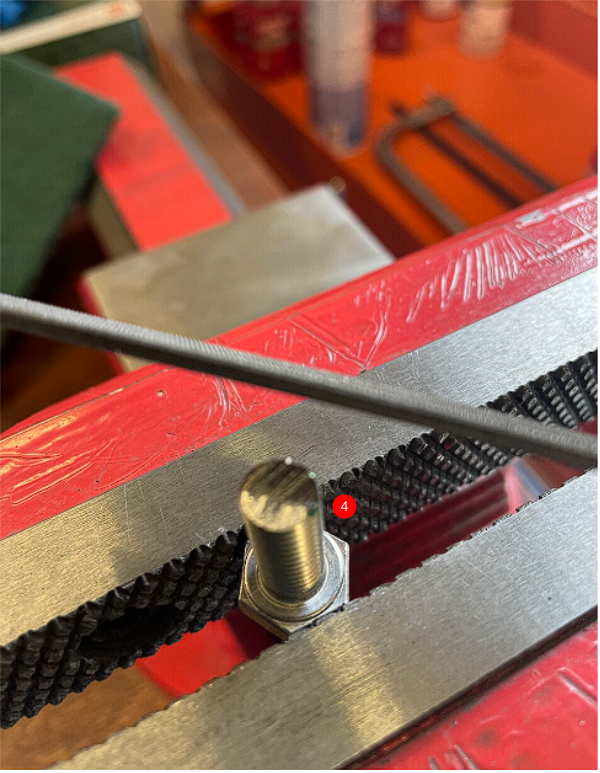

Étape 4 - Check M16 thread and add M8 set bolt

1 Fit M16 x 1.5 nut to each screw . Ensure nut winds fully to face of bolt

2 Fit M8 x 70 set bolt to each bolt. Treat the M8 and M16 adjuster bolt as pairs from this point and do not mix up. Wind the M8 set fully into the adjuster bolt and tighten

3 Measure the gap indicated , and minus 3mm. This will give you the exact amount that needs removing from the M8 bolt

4 Remove M8 from adjuster bolt, and cut exact amount calculated off the end of the M8 bolt . Dress end

5 Add M8 penny washer to cut M8 bolt , refit to adjuster bolt. Tighten fully.

6 M8 Set bolt should fully tighten and leave a gap big enough for penny washer to float around

Repeat for remaining 3 adjuster bolts

Étape 5 - M0001093 Shaft Clamping Element (Ø15-20 shafts)

M0001093 Shaft Clamping Element require the issued M6 x 35 cap head to be swapped for a M6 x 30 socket cap.

Swap bolts in all 16, paying attention to correct re assembly

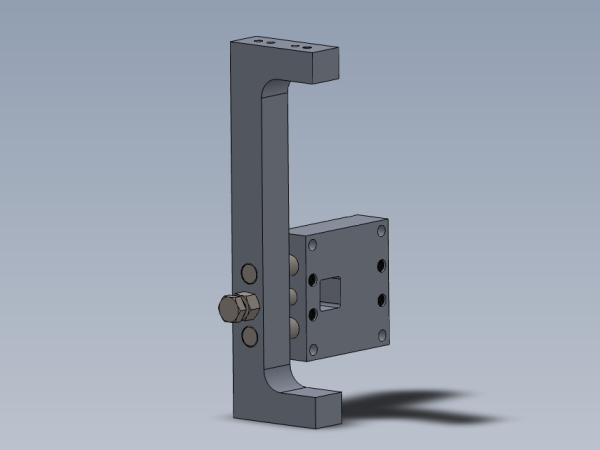

Étape 6 - Assemble motor mounts

4 off

Fit 2 off D0015158 Shaft 40mm: 190mm ZX V Notch Saw Motor Slide into D0015160 Saw Motor Block with 4 off M0001093 Shaft Clamping Element

Ensure flats of M0001093 Shaft Clamping Element are aligned correctly to allow shaft to pass through

Only apply light tension to these bolts as adjustment will be required later on

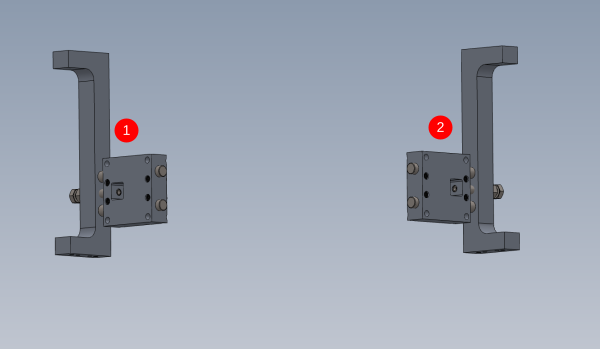

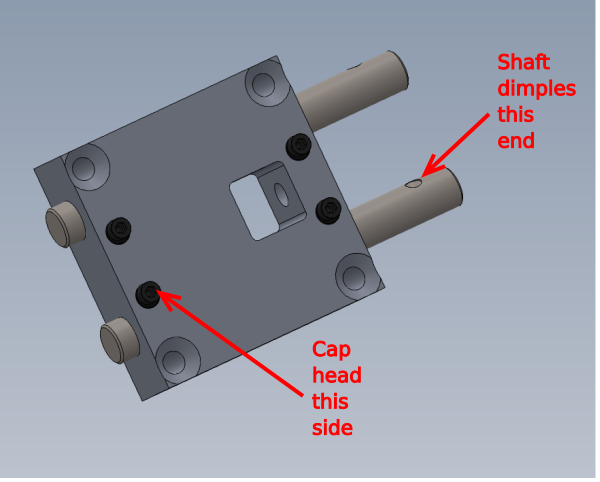

Étape 7 - Fit to Saw motor bar

Fit assemblies as shown

Secure shafts with M8 x 12 KCP grubscrews

Make 2 off each hand

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português