Correct alignment protocol for subframe alignment

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Dowel in position

- 4 Étape 3 - Fit tie bars

- 5 Étape 4 - Add Z support jigs

- 6 Étape 5 - Y axis shafts

- 7 Étape 6 - Fit bearing blocks

- 8 Étape 7 - Finalise Y axis shafts

- 9 Étape 8 - Finalise M8 socket caps

- 10 Étape 9 - Fit Hard stops

- 11 Commentaires

Introduction

Tools Required

300mm engineers level

2 meter straight edge

1 meter straight edge

Standard hex key set

Standard spanner set

Z support jigs

Parts Required

D0000095 Bottom Plate x 2

D0006484 Front Tiebeam x 1

D0006485 Rear Tiebeam x 1

D0007681 Shaft Adjust Plate x 2

D0007683 Lower Beam Mount x 1

D0007684 Lower Beam Mount - Mirror x 1

D0007695 Platform (D8714) x 1

D0007787 Upper Beam Mount x 1

D0007835 Hard Stop x 2

D0008087 Z Servo Housing x 2

H0006025 Shaft 40mm: 939mm Flowline Y-axis x 2

H0007711 Shaft 40mm: 1350mm Microline Z (c/w M16 x 45 bolts) x 2

R0015296 Bench Assemble bearings AssembliesÉtape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

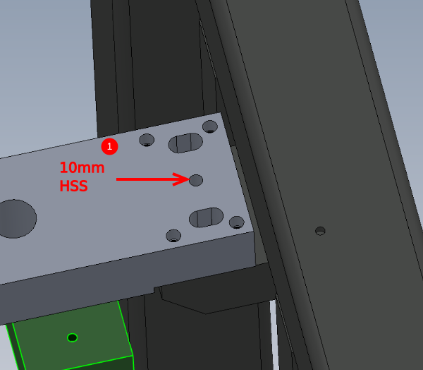

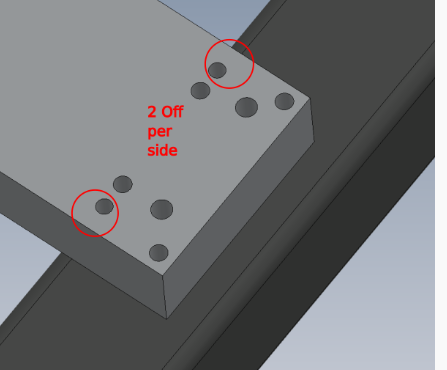

Étape 2 - Dowel in position

Subframe now requires dowelling in position

1 Drill upper beam mount with 10mm HSS 2 off , hole depth should be 20mm minimum into steel mounting tab . Use 10mm x 60mm spiral pin to fix

2 Dowel lower beam mounts . 4 off Drill indicated holes to 9.5 mm , then use 10mm hand reamer to finish . Fix with 10mm x 50 mm hardened dowel

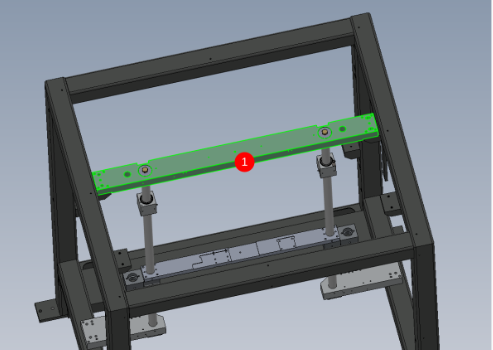

Étape 3 - Fit tie bars

use

D0006484 Front Tiebeam x 1

D0006485 Rear Tiebeam x 1

1 Fit 4 off 8mm x 24 mm hardened dowels to each tie bar as shown

2 Align D0006485 Rear Tie beam with bearing blocks and use 8 off M8 x 50 socket caps to fix. Use fasteners to evenly pull faces together , alternate between top and bottom fasteners to pull faces together parallel

3 Align D0006484 Rear Tie beam with bearing blocks and use 8 off M8 x 50 socket caps to fix. Use fasteners to evenly pull faces together , alternate between top and bottom fasteners to pull faces together parallel

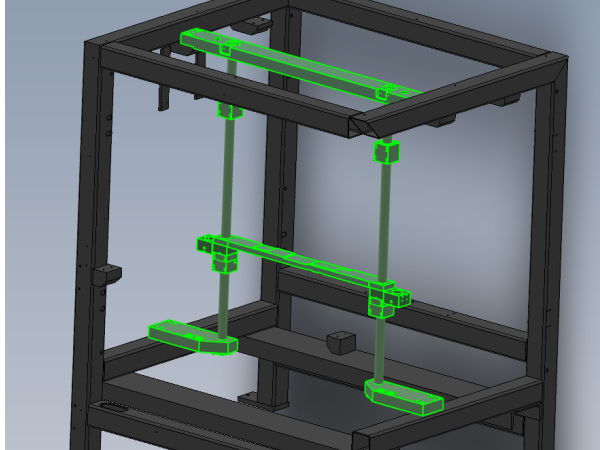

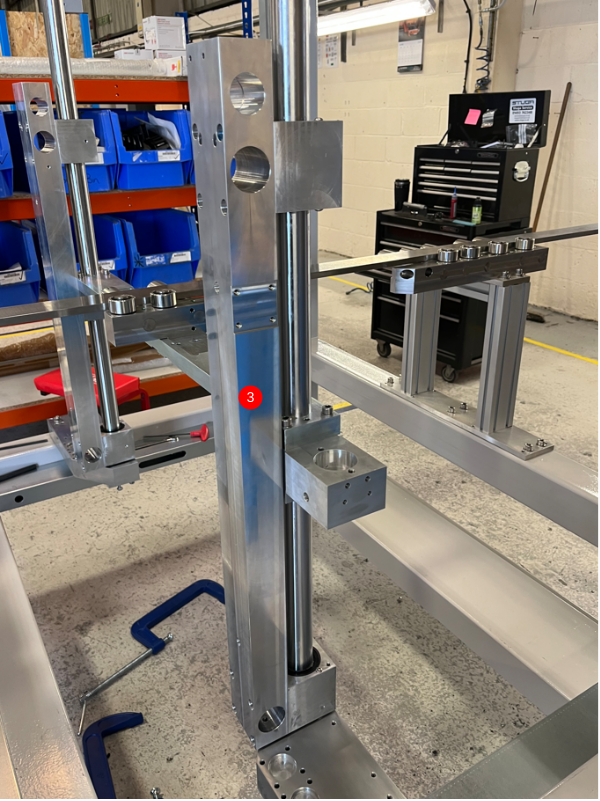

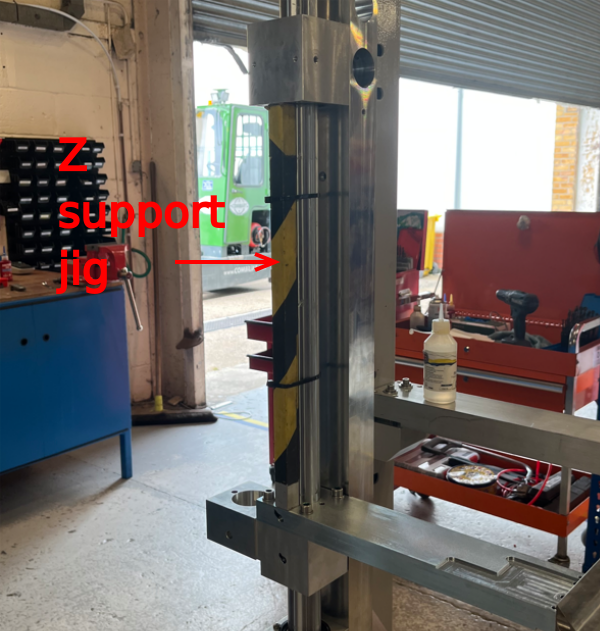

Étape 4 - Add Z support jigs

Lift fitted tie bars up and insert 1 off per bar support jig as shown .

Secure with 2 off large tie wrap per jig

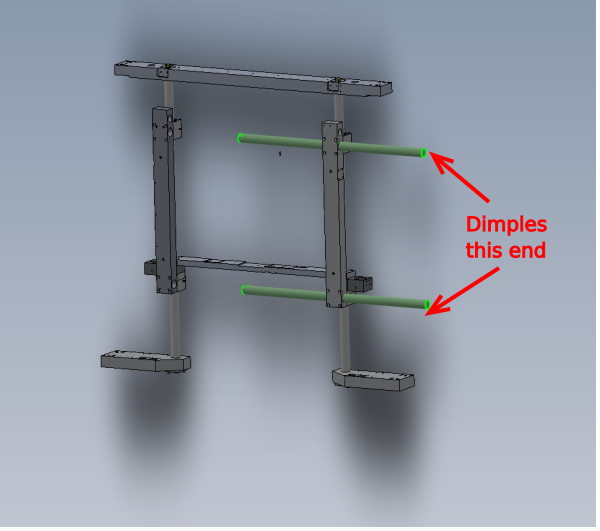

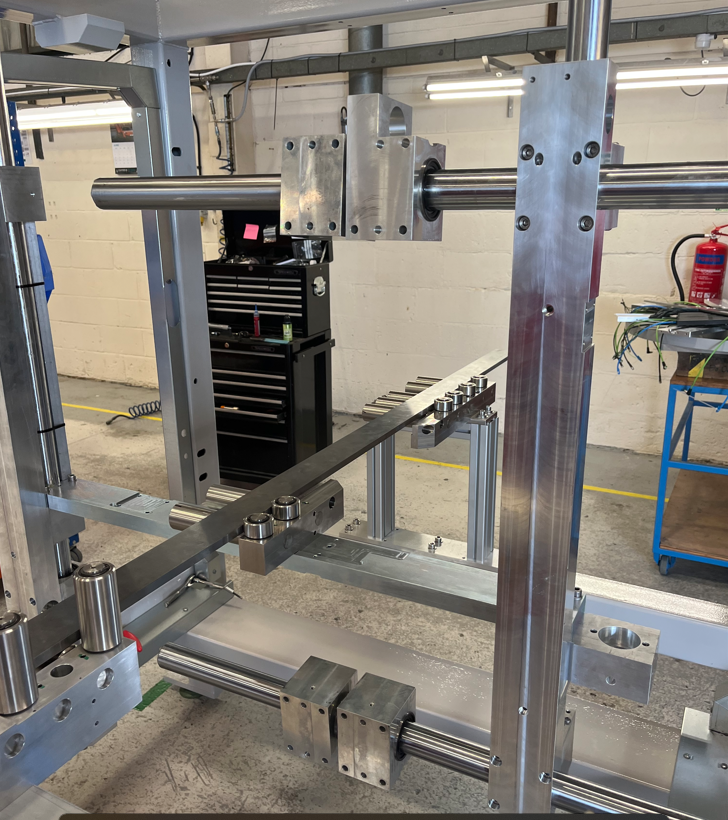

Étape 5 - Y axis shafts

Slide 2 off H0006025 Shaft 40mm: 939mm Flowline Y-axis into the position shown.

Ensure dimple position on shaft is marked clearly on end shaft as shon

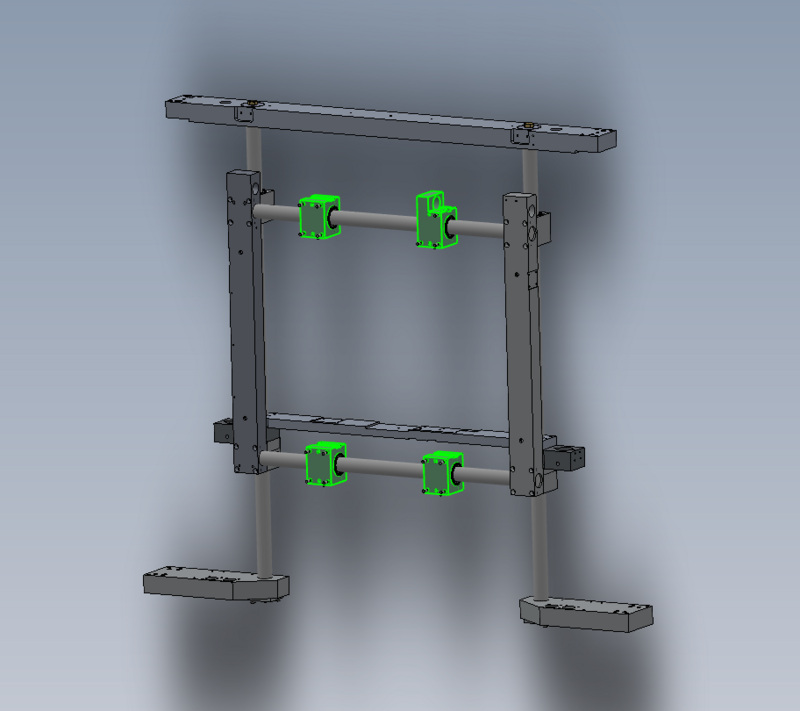

Étape 6 - Fit bearing blocks

Fit 4 off bearing blocks from assembly R0015296 Bench Assemble bearings Assemblies

Orientate as shown .

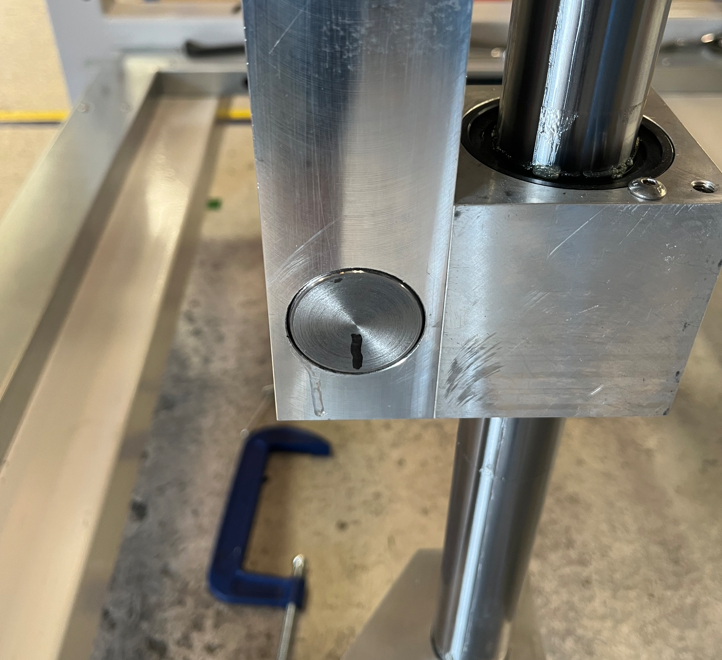

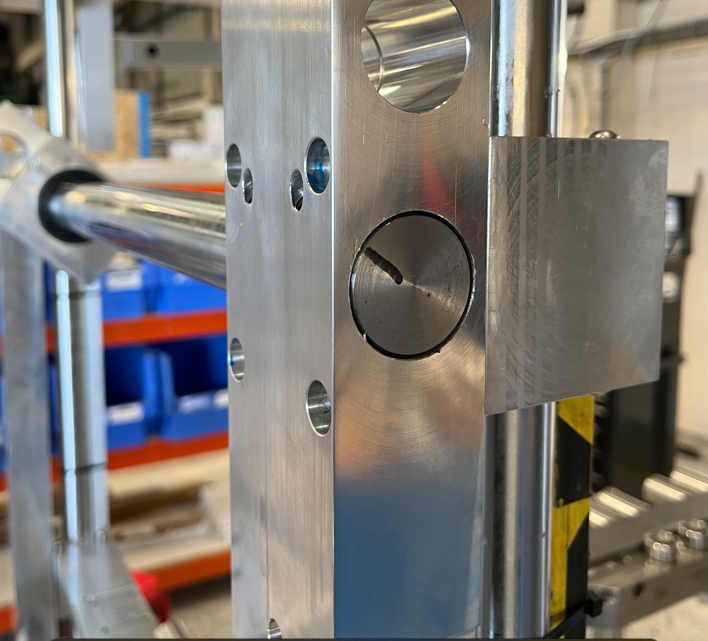

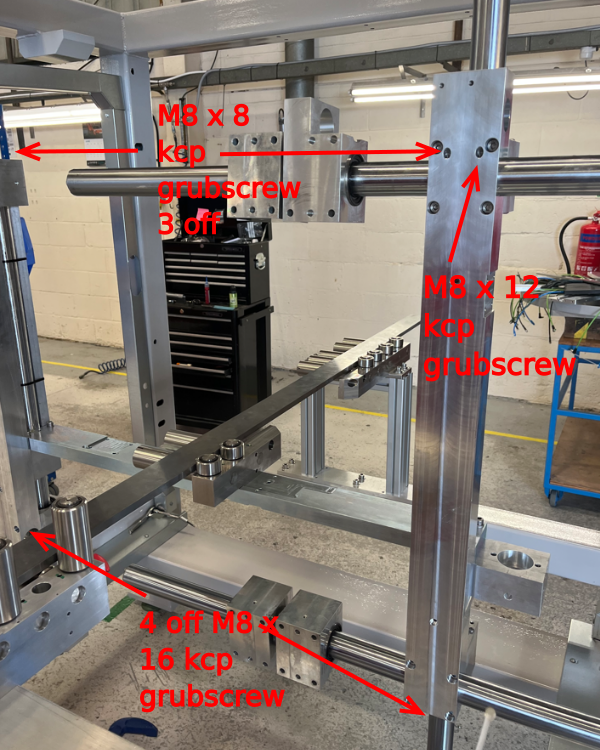

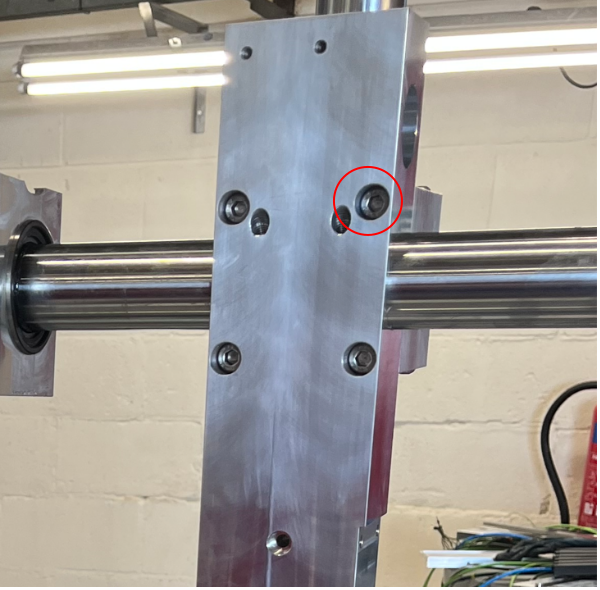

Étape 7 - Finalise Y axis shafts

Slide Y axis shafts into final position

1 Align dimples using shaft end mark .

Top shaft is at 45 degrees

Bottom shaft is at 180 degrees

See image for grubscrew sizes

Étape 8 - Finalise M8 socket caps

Individually remove each M8 socket cap (16 off) that secure the tie bars , apply adhesive and apply final tension

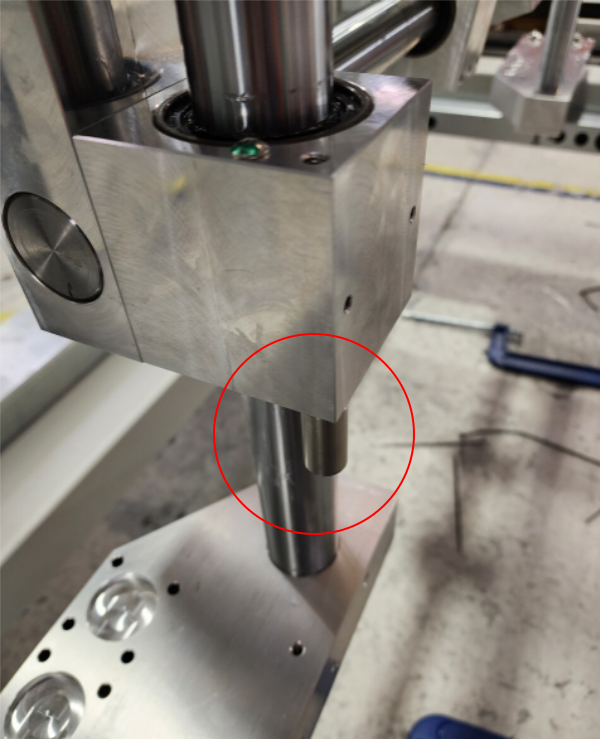

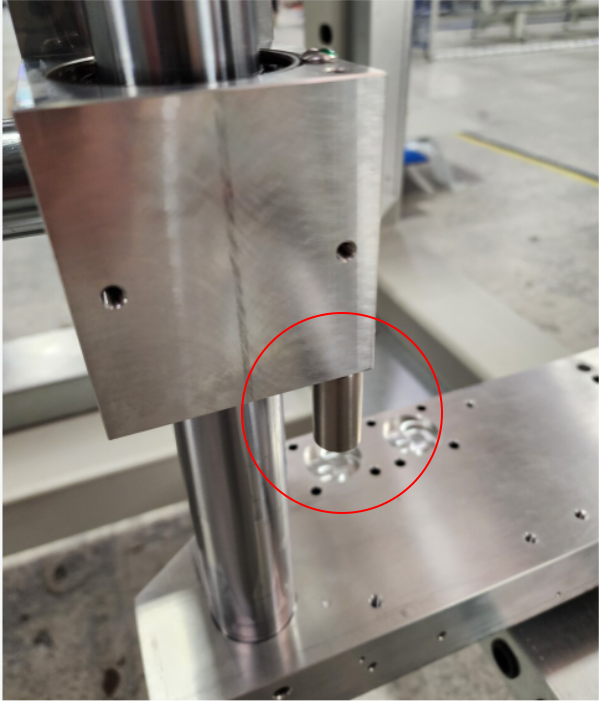

Étape 9 - Fit Hard stops

Fit 2 off hard stops to lower vertical shaft bearing blocks.

Use 2 off M6 x 30 socket caps to fix

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português