Correct alignment protocol for subframe alignment

Introduction

Tools Required

300mm engineers level

2 meter straight edge

1 meter straight edge

Standard hex key set

Standard spanner set

Parts Required

D0000095 Bottom Plate x 2

D0006484 Front Tiebeam x 1

D0006485 Rear Tiebeam x 1

D0007681 Shaft Adjust Plate x 2

D0007683 Lower Beam Mount x 1

D0007684 Lower Beam Mount - Mirror x 1

D0007695 Platform (D8714) x 1

D0007787 Upper Beam Mount x 1

D0007835 Hard Stop x 2

D0008087 Z Servo Housing x 2

H0006025 Shaft 40mm: 939mm Flowline Y-axis x 2

H0007711 Shaft 40mm: 1350mm Microline Z (c/w M16 x 45 bolts) x 2

R0015296 Bench Assemble bearings Assemblies

Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

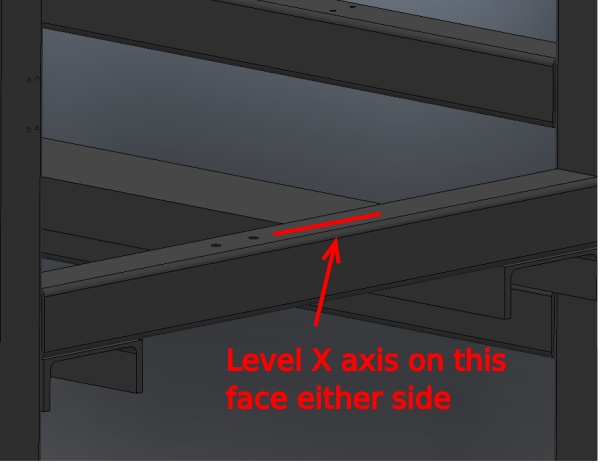

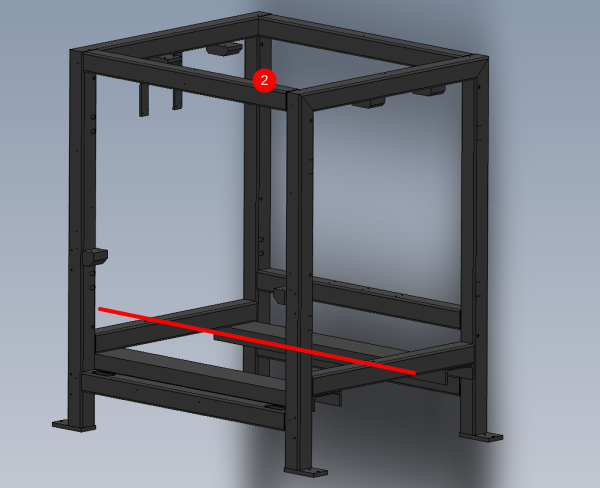

Étape 2 - Level Frame

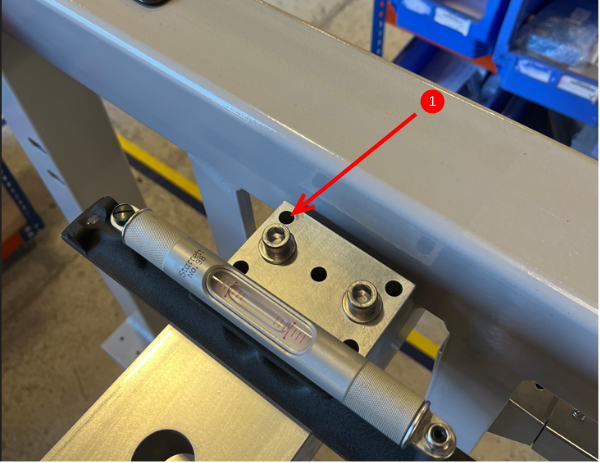

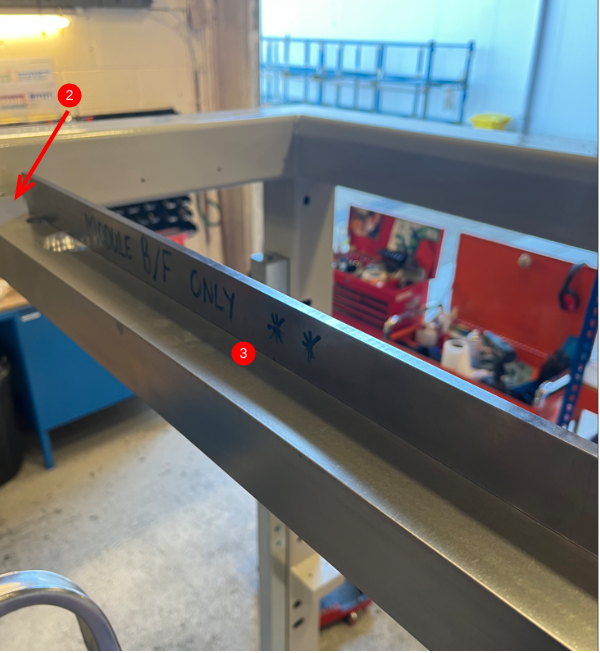

1 Use engineers level to level frame at the indicated points . Any discrepancy between the two faces should be adjusted to be even both sides .

2 Use 2 meter straight edge and 300mm engineers level to level Y axis of machine at the indicated points

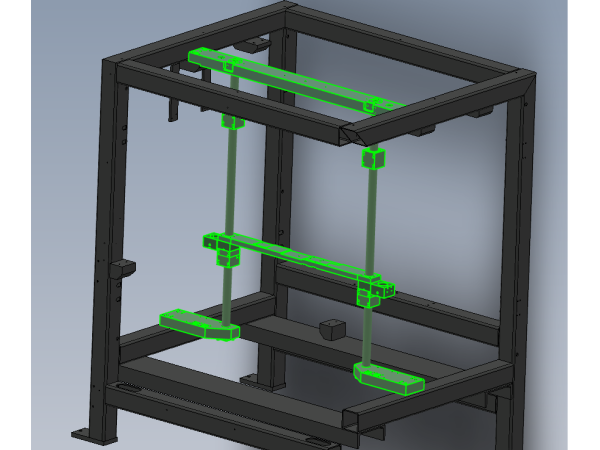

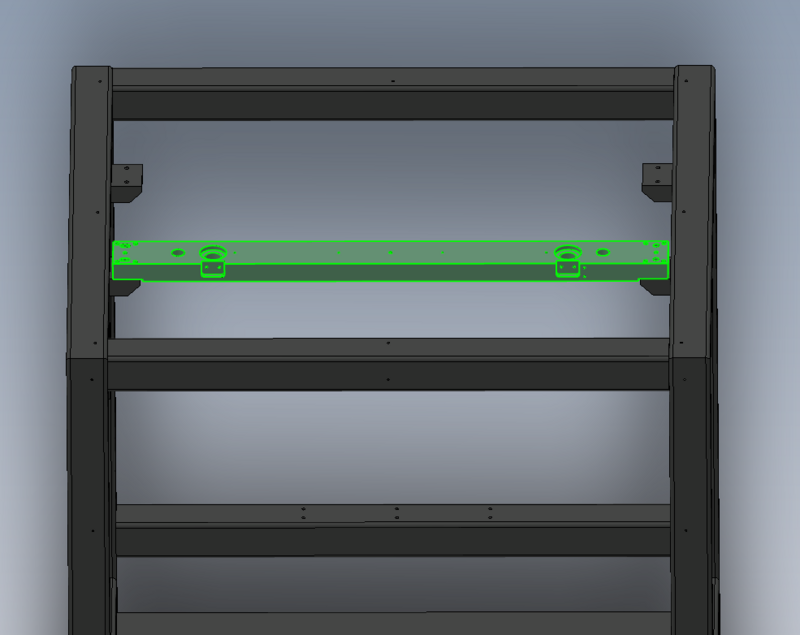

Étape 3 - Instal Upper beam mount

Mount and orientate D0007787 Upper Beam Mount x 1 as shown

Fix with M12 x 70 socket caps and A form washers , do not apply adhesive

Add 8 off M10 x 30 flat bottomed grubscrews

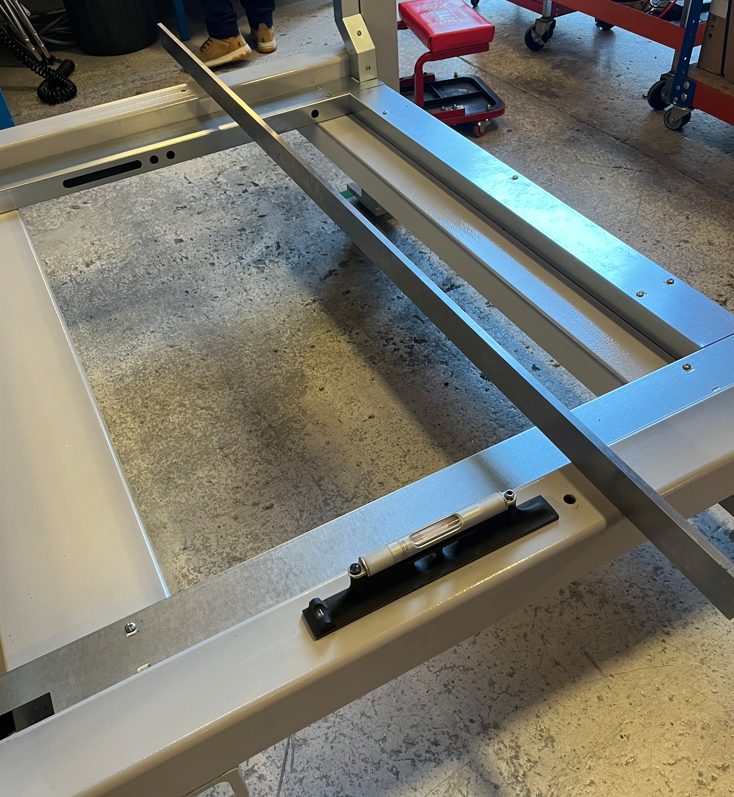

Étape 4 - Level upper beam mount

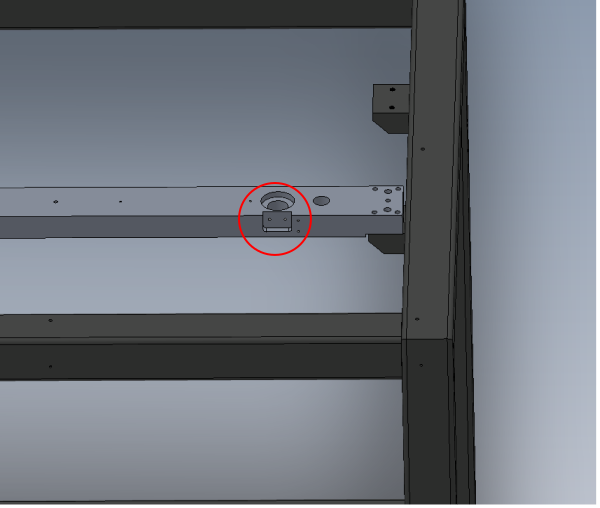

1 Level X axis on both sides of the beam at the indicated point using M10 grubscrews to adjust

2 Adjust Y Axis using grubscrews . only adjust one end up, as height needs to remain as close as possible to frame monting point.

Use 1 meter straight edge and engineers level

3 Check and adjust flatness by using 1 meter straight edge to gauge. Bias can be used on jacking grubscrews to manipulate the upper beam mount flat.

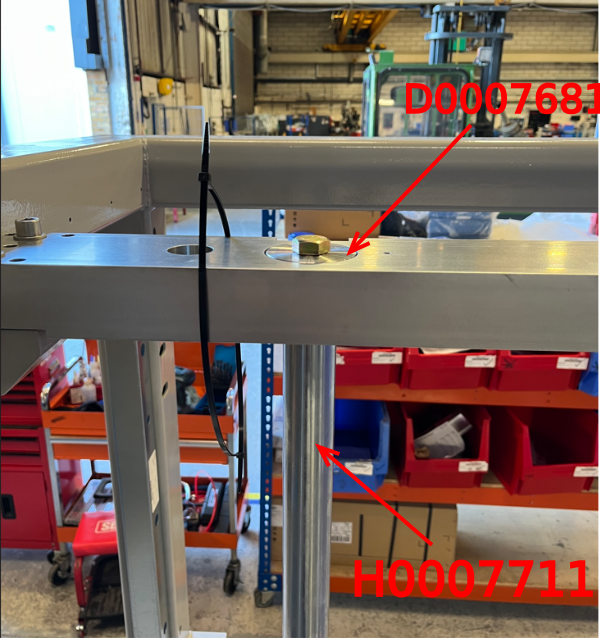

Étape 5 - Install Z axis shafts

Mount H0007711 Shaft 40mm: 1350mm Microline Z (c/w M16 x 45 bolts) x 2

and suspend in place with M16 x 45 hex head bolts and D0007681 Shaft Adjust Plate x 2

Add 2 off large black tiewrap per side as shown

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português