| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=R0000711_Rotary_Base_Assembly_Screenshot_2023-05-26_095708.png |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version... ») |

|||

| Ligne 60 : | Ligne 60 : | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 30 mai 2023 à 09:51

Assembly instructions for installation of main rotary drive ring

Difficulté

Difficile

Durée

2 heure(s)

Introduction

Detailed steps to correctly install rotary gear and journals

Checks for correct installation of oil feed system

Tolerance limits and requirements

Parts required

D0006423-2mc Drive ring x 1

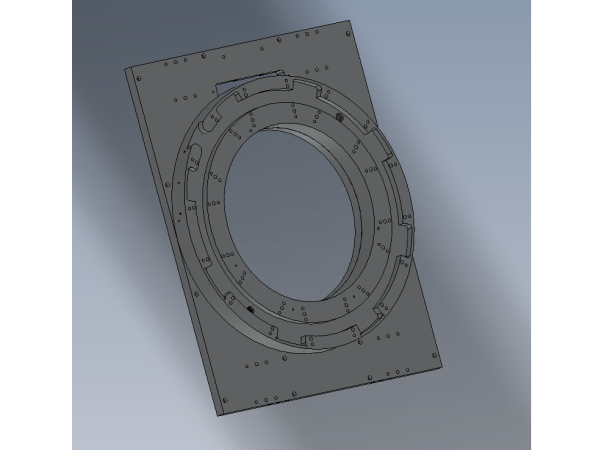

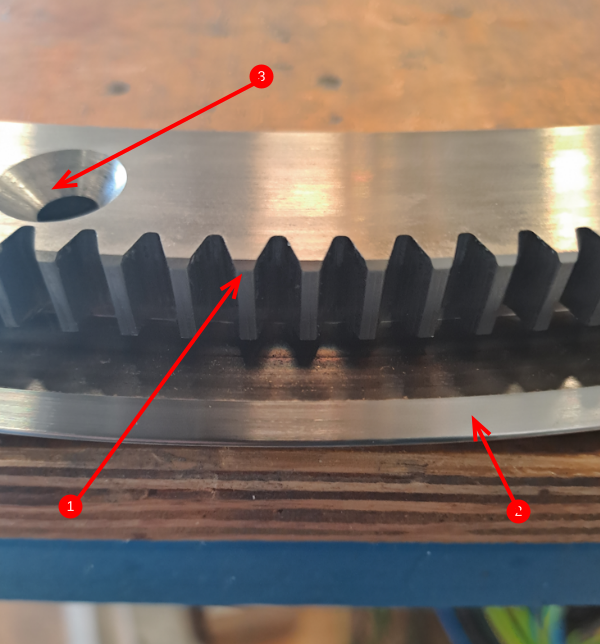

Étape 1 - Quality Check Drive ring

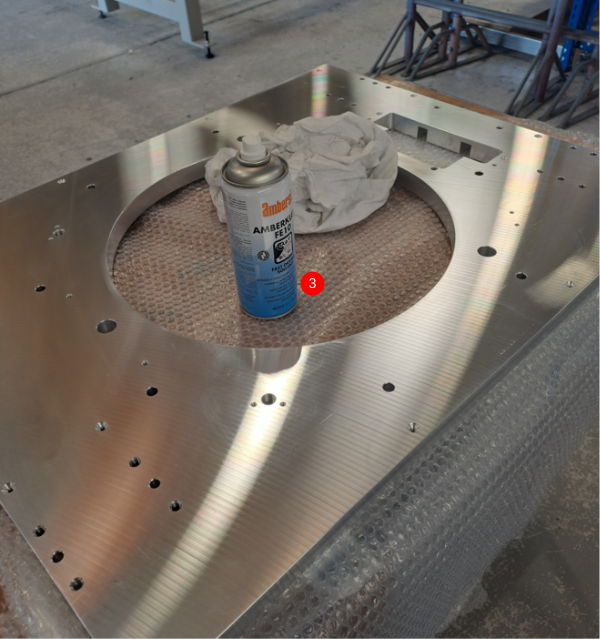

Rotary drive ring needs checking before fitment.

- Check teeth for burrs, damage and debris. Use compressed air to clean all areas

- V edge should be checked for damage. Check entire circumference with fingers to identify any damage, lumps or high low spots

- Check drive ring has been countersunk in the shown area

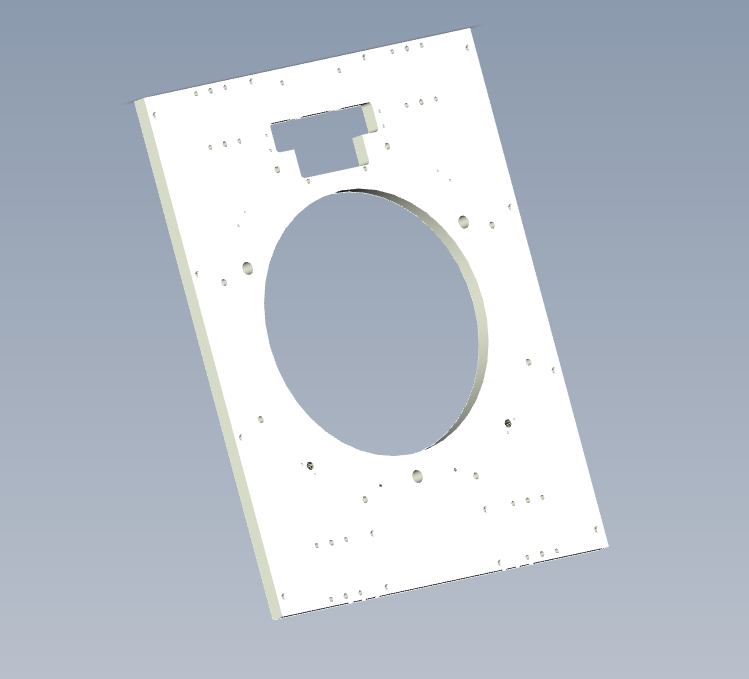

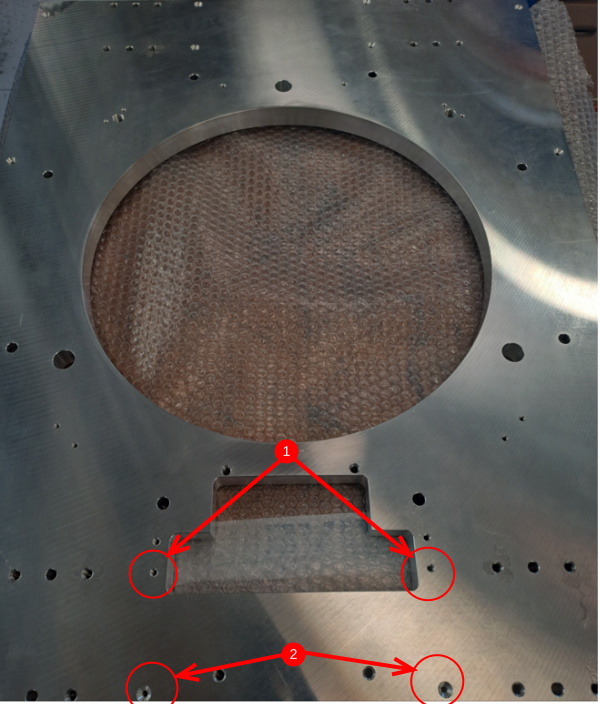

Étape 2 - Prepare Faceplate For assembly

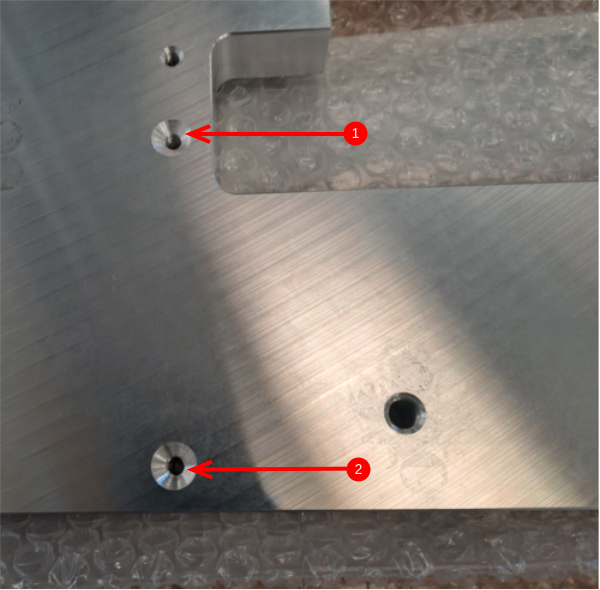

Check that Holes indicated (1) are countersunk the same as holes indicated (2 ). If not , countersink to correct

3. Clean all holes with compressed air

Thoroughly clean faceplate with solvent

Étape 3 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português