| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-18_134828.png |Main_Picture_annotation={"version":"2.4.6","objects":[{"t... ») |

|||

| Ligne 18 : | Ligne 18 : | ||

Standard hex key | Standard hex key | ||

| + | Standard spanner set | ||

| − | '''<u>Parts Required</u>'''</translate> | + | Feeler gauges |

| + | |||

| + | Engineers level | ||

| + | |||

| + | Adjustment shim | ||

| + | |||

| + | |||

| + | '''<u>Parts Required</u>''' | ||

| + | |||

| + | A0001069 Energy Chain Series B15.050 (48mm radius) Openable x 0.5 | ||

| + | |||

| + | A0001070 Igus Mounting Br Set for A0001069 Non-Pivot x 1 | ||

| + | |||

| + | A0001074 igus mounting bracket set x 1 | ||

| + | |||

| + | D0004551 Cylinder Spacer x 1 | ||

| + | |||

| + | D0004553 Cover Fixing Bar x 1 | ||

| + | |||

| + | D0004554 Bar Spacer Short x 1 | ||

| + | |||

| + | D0004555 Bar Spacer Long x 1 | ||

| + | |||

| + | D0004769 Ejector Clamp Pad to be made in conjuction with D5121 (5305) x 1 | ||

| + | |||

| + | D0004770 Infeed Clamp Pad to be made in conjunction with D5122 (5299) x 1 | ||

| + | |||

| + | D0005121 Ejector Clamp Stainless Pads (5306) x 1 | ||

| + | |||

| + | D0005122 Infeed Clamp Pad (5300)x 1 | ||

| + | |||

| + | D0005199 Ejector Cover x 1 | ||

| + | |||

| + | D0005412 Energy Chain Adapter Plate x 1 | ||

| + | |||

| + | H0004556 Fixing Bar Gap Cover (5297) x 1 | ||

| + | |||

| + | H0004656 Material Trip Stripx 1 | ||

| + | |||

| + | P0000368 Extension 1/8 bsp x 22 long x 1 | ||

| + | |||

| + | P0000443 Cleanline Cylinder 32 x 450 PN11246 x 1 | ||

| + | |||

| + | P0000444 Reed Switch: Pneumax 1580U (5.0m Lead) x 2 | ||

| + | |||

| + | P0001198 flow controller 6mm elbow 1/8 x 2</translate> | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Unless otherwise stated</translate> |

| + | |Step_Content=<translate>All bolts to have Loctite 243 adhesive applied unless otherwise stated | ||

| + | |||

| + | All Threaded Pneumatic connections to have Loctite 570 applied | ||

| + | |||

| + | All bolts to be pen marked once adhesive applied and correct tension added</translate> | ||

| + | |Step_Picture_00=R0015086_Assemble_Pneumatics_on_to_electrical_cabinet_loctite_243.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Level Infeed pad</translate> | ||

| + | |Step_Content=<translate>Attach Infeed pad | ||

| + | |||

| + | |||

| + | Use engineers level to check level | ||

| + | |||

| + | |||

| + | Add shim if required to adjust</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114133.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Attach Outfeed Pad</translate> | ||

| + | |Step_Content=<translate>Attach Eject pad using m6 ? socket caps | ||

| + | |||

| + | |||

| + | Do not apply adhesive, do not apply final tension</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114140.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Set flatness</translate> | ||

| + | |Step_Content=<translate>Use infeed pad as datum | ||

| + | |||

| + | |||

| + | Use 1 meter straight edge and feeler gauges | ||

| + | |||

| + | |||

| + | Adjust eject table to suit infeed pad</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114328.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Set front alignment</translate> | ||

| + | |Step_Content=<translate>Set front alignment using adjustment in counter bores in pads | ||

| + | |||

| + | |||

| + | Use 1 meter straight edge and feeler gauges to set</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114328.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Check parallel</translate> | ||

| + | |Step_Content=<translate>Use Steel rule to measure from pads to rear fence mount on frame from both tables | ||

| + | |||

| + | |||

| + | This measurement needs to be the same | ||

| + | |||

| + | |||

| + | Use adjustment in pads, and pillar supports to correct | ||

| + | |||

| + | |||

| + | Ensure front alignment of tables is held when adjusting</translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Finalise fasteners</translate> | ||

| + | |Step_Content=<translate>Finalise all fasteners with 243 and correct tension once adjustments are complete</translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

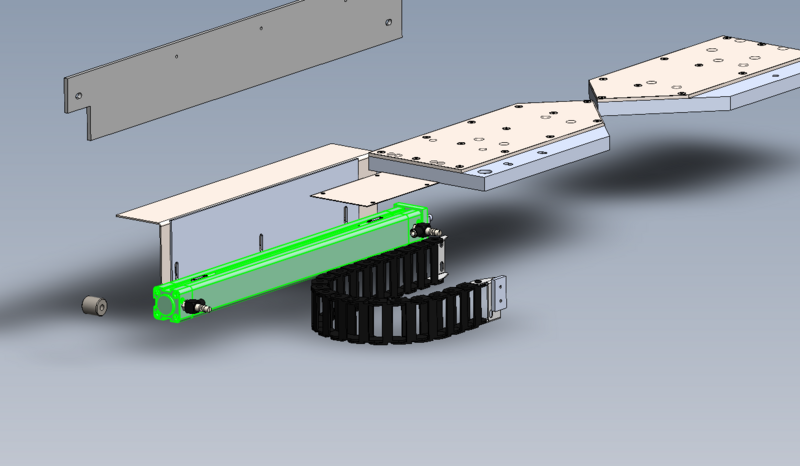

| + | |Step_Title=<translate>Fit eject cylinder</translate> | ||

| + | |Step_Content=<translate>fit eject cylinder with spacer | ||

| + | |||

| + | |||

| + | Ensure alignment | ||

| + | |||

| + | |||

| + | Ensure correct position of cylinder thread adjustment | ||

| + | |||

| + | <br /></translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114151.png | ||

| + | }} | ||

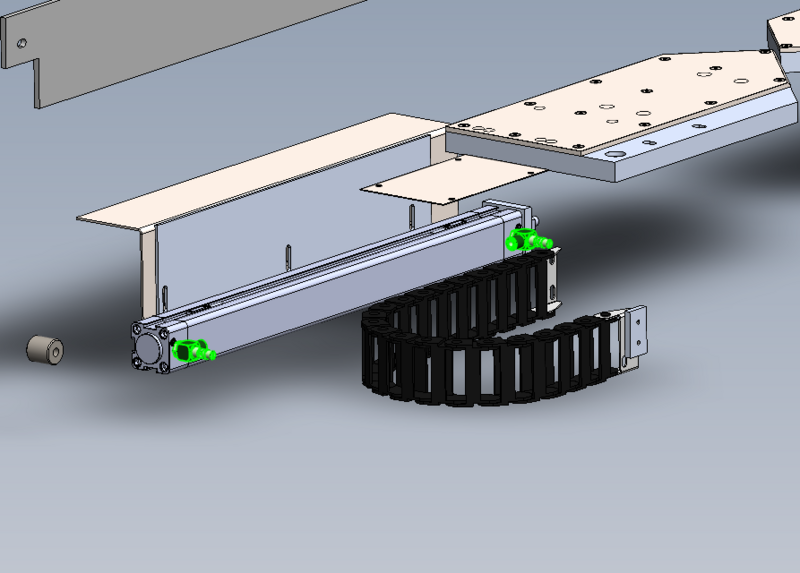

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit Cylinder fittings</translate> | ||

| + | |Step_Content=<translate>fit flow regs with one off extension</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114200.png | ||

| + | }} | ||

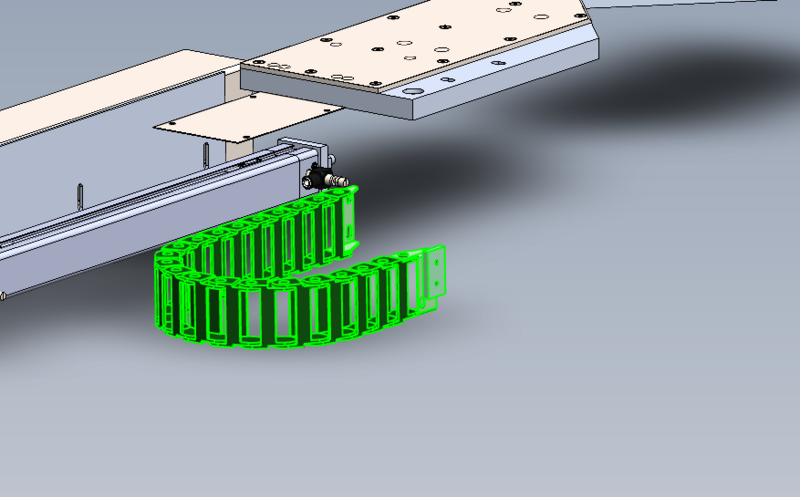

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit energy chain</translate> | ||

| + | |Step_Content=<translate>Fit energy chain with backing plate. | ||

| + | |||

| + | |||

| + | Ensure pivoting bracket is fitted to correct end</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114209.png | ||

| + | }} | ||

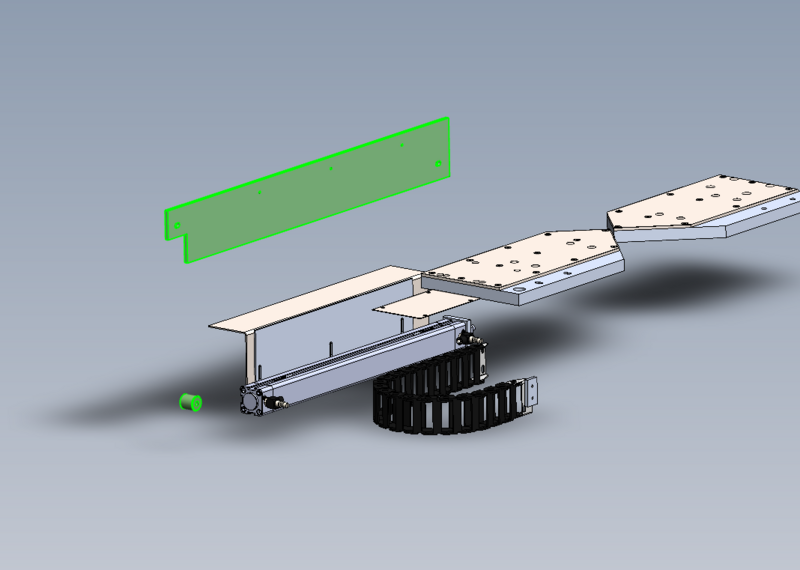

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit cover fixing bar</translate> | ||

| + | |Step_Content=<translate>Fit cover fixing bar with 2 off spacers and M8 sockets | ||

| + | |||

| + | |||

| + | Tap holes to clean m5 threads</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114218.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit gap covers</translate> | ||

| + | |Step_Content=<translate>Fit 2 off gap covers with m5 socket caps | ||

| + | |||

| + | |||

| + | do not finalise position S</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114225.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

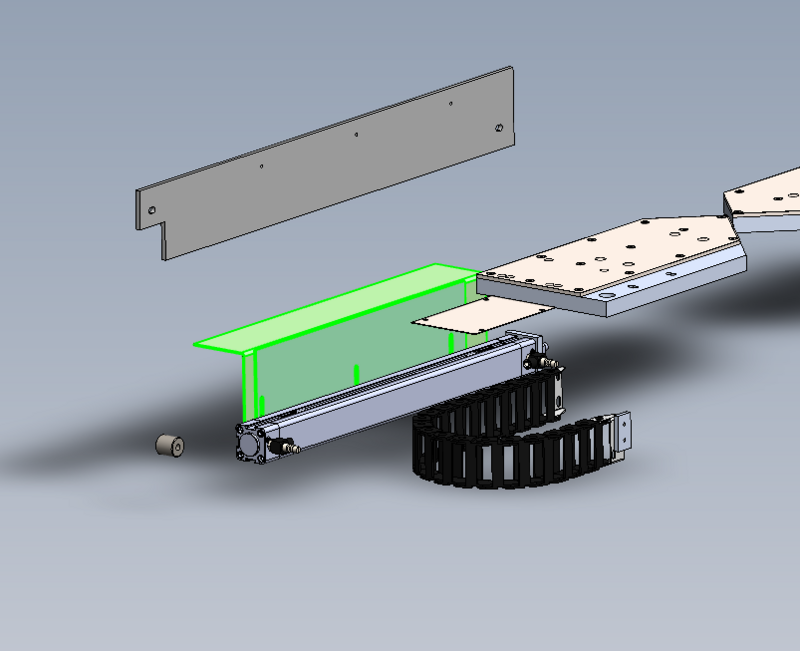

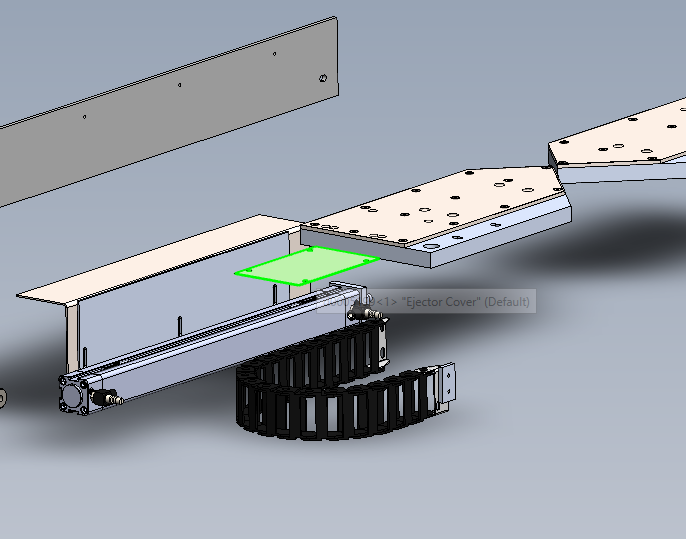

| + | |Step_Title=<translate>Fit ejector cover</translate> | ||

| + | |Step_Content=<translate></translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114231.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Set flatness</translate> | ||

| + | |Step_Content=<translate>Use infeed pad as datum | ||

| + | |||

| + | |||

| + | Use 1 meter straight edge and feeler gauges | ||

| + | |||

| + | |||

| + | Adjust eject table to suit infeed pad</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114328.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Set front alignment</translate> | ||

| + | |Step_Content=<translate>Set front alignment using adjustment in counter bores in pads | ||

| + | |||

| + | |||

| + | Use 1 meter straight edge and feeler gauges to set</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114328.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Check parallel</translate> | ||

| + | |Step_Content=<translate>Use Steel rule to measure from pads to rear fence mount on frame from both tables | ||

| + | |||

| + | |||

| + | This measurement needs to be the same | ||

| + | |||

| + | |||

| + | Use adjustment in pads, and pillar supports to correct | ||

| + | |||

| + | |||

| + | Ensure front alignment of tables is held when adjusting</translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Finalise fasteners</translate> | ||

| + | |Step_Content=<translate>Finalise all fasteners with 243 and correct tension once adjustments are complete</translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit eject cylinder</translate> | ||

| + | |Step_Content=<translate>fit eject cylinder with spacer | ||

| + | |||

| + | |||

| + | Ensure alignment | ||

| + | |||

| + | |||

| + | Ensure correct position of cylinder thread adjustment | ||

| + | |||

| + | <br /></translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114151.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit Cylinder fittings</translate> | ||

| + | |Step_Content=<translate>fit flow regs with one off extension</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114200.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit energy chain</translate> | ||

| + | |Step_Content=<translate>Fit energy chain with backing plate. | ||

| + | |||

| + | |||

| + | Ensure pivoting bracket is fitted to correct end</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114209.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit cover fixing bar</translate> | ||

| + | |Step_Content=<translate>Fit cover fixing bar with 2 off spacers and M8 sockets | ||

| + | |||

| + | |||

| + | Tap holes to clean m5 threads</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114218.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit gap covers</translate> | ||

| + | |Step_Content=<translate>Fit 2 off gap covers with m5 socket caps | ||

| + | |||

| + | |||

| + | do not finalise position S</translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114225.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit ejector cover</translate> | ||

|Step_Content=<translate></translate> | |Step_Content=<translate></translate> | ||

| + | |Step_Picture_00=R0000571_Fit_and_Level_Cut_Tables___Finalise_Eject_Screenshot_2023-10-19_114231.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 19 octobre 2023 à 12:44

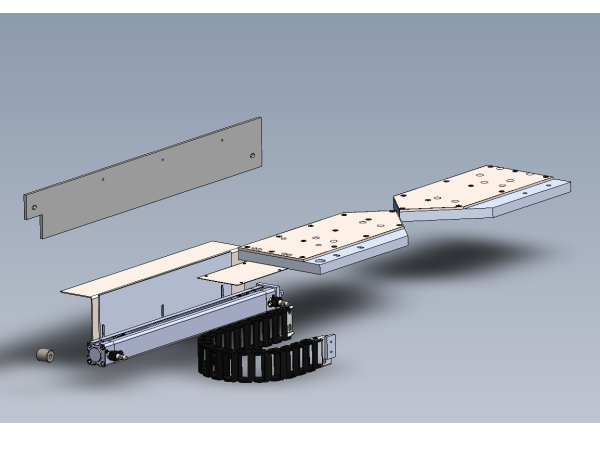

Alignment and fitment details for cut tables and eject drive

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Level Infeed pad

- 4 Étape 3 - Attach Outfeed Pad

- 5 Étape 4 - Set flatness

- 6 Étape 5 - Set front alignment

- 7 Étape 6 - Check parallel

- 8 Étape 7 - Finalise fasteners

- 9 Étape 8 - Fit eject cylinder

- 10 Étape 9 - Fit Cylinder fittings

- 11 Étape 10 - Fit energy chain

- 12 Étape 11 - Fit cover fixing bar

- 13 Étape 12 - Fit gap covers

- 14 Étape 13 - Fit ejector cover

- 15 Étape 14 - Set flatness

- 16 Étape 15 - Set front alignment

- 17 Étape 16 - Check parallel

- 18 Étape 17 - Finalise fasteners

- 19 Étape 18 - Fit eject cylinder

- 20 Étape 19 - Fit Cylinder fittings

- 21 Étape 20 - Fit energy chain

- 22 Étape 21 - Fit cover fixing bar

- 23 Étape 22 - Fit gap covers

- 24 Étape 23 - Fit ejector cover

- 25 Commentaires

Introduction

Tools Required

1 meter straight edge

500mm rule

Standard hex key

Standard spanner set

Feeler gauges

Engineers level

Adjustment shim

Parts Required

A0001069 Energy Chain Series B15.050 (48mm radius) Openable x 0.5

A0001070 Igus Mounting Br Set for A0001069 Non-Pivot x 1

A0001074 igus mounting bracket set x 1

D0004551 Cylinder Spacer x 1

D0004553 Cover Fixing Bar x 1

D0004554 Bar Spacer Short x 1

D0004555 Bar Spacer Long x 1

D0004769 Ejector Clamp Pad to be made in conjuction with D5121 (5305) x 1

D0004770 Infeed Clamp Pad to be made in conjunction with D5122 (5299) x 1

D0005121 Ejector Clamp Stainless Pads (5306) x 1

D0005122 Infeed Clamp Pad (5300)x 1

D0005199 Ejector Cover x 1

D0005412 Energy Chain Adapter Plate x 1

H0004556 Fixing Bar Gap Cover (5297) x 1

H0004656 Material Trip Stripx 1

P0000368 Extension 1/8 bsp x 22 long x 1

P0000443 Cleanline Cylinder 32 x 450 PN11246 x 1

P0000444 Reed Switch: Pneumax 1580U (5.0m Lead) x 2

P0001198 flow controller 6mm elbow 1/8 x 2Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

Étape 2 - Level Infeed pad

Attach Infeed pad

Use engineers level to check level

Add shim if required to adjust

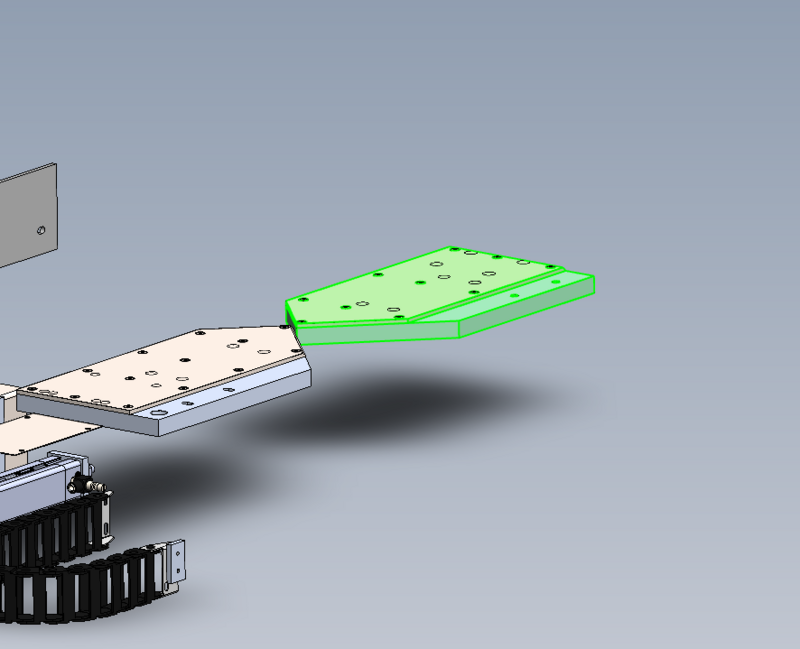

Étape 3 - Attach Outfeed Pad

Attach Eject pad using m6 ? socket caps

Do not apply adhesive, do not apply final tension

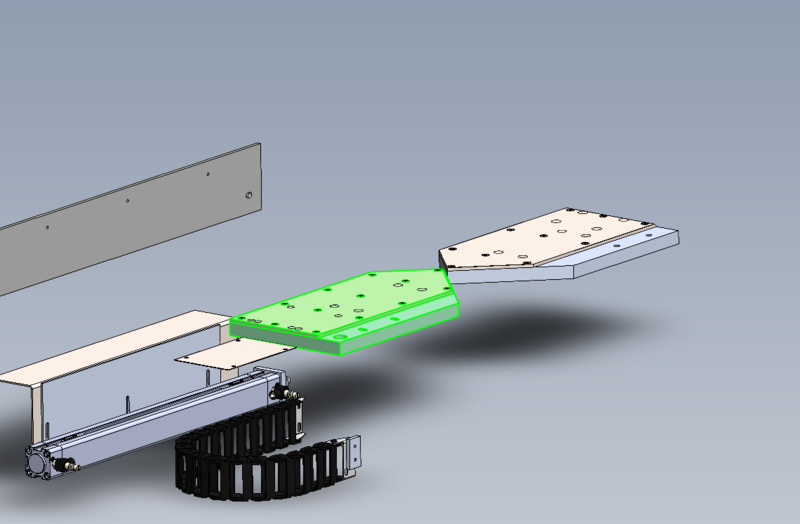

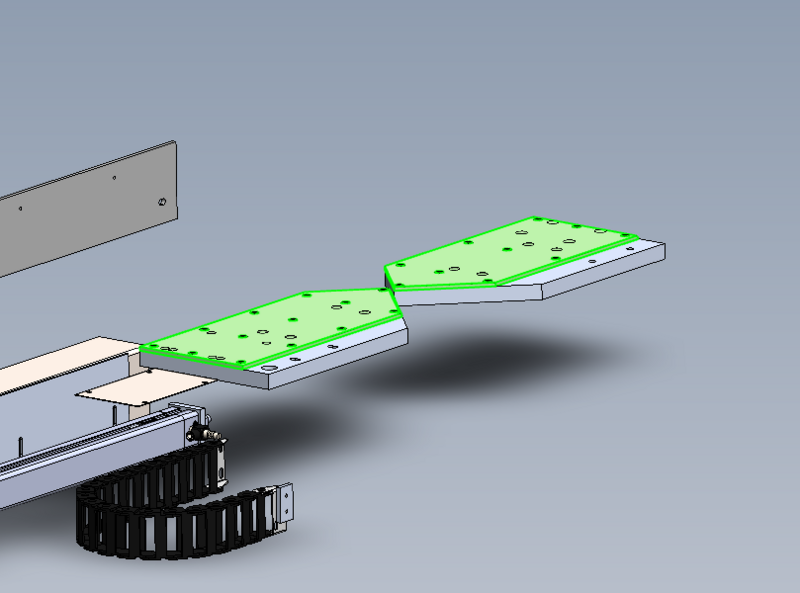

Étape 4 - Set flatness

Use infeed pad as datum

Use 1 meter straight edge and feeler gauges

Adjust eject table to suit infeed pad

Étape 5 - Set front alignment

Set front alignment using adjustment in counter bores in pads

Use 1 meter straight edge and feeler gauges to set

Étape 6 - Check parallel

Use Steel rule to measure from pads to rear fence mount on frame from both tables

This measurement needs to be the same

Use adjustment in pads, and pillar supports to correct

Ensure front alignment of tables is held when adjusting

Étape 7 - Finalise fasteners

Finalise all fasteners with 243 and correct tension once adjustments are complete

Étape 8 - Fit eject cylinder

fit eject cylinder with spacer

Ensure alignment

Ensure correct position of cylinder thread adjustment

Étape 10 - Fit energy chain

Fit energy chain with backing plate.

Ensure pivoting bracket is fitted to correct end

Étape 11 - Fit cover fixing bar

Fit cover fixing bar with 2 off spacers and M8 sockets

Tap holes to clean m5 threads

Étape 14 - Set flatness

Use infeed pad as datum

Use 1 meter straight edge and feeler gauges

Adjust eject table to suit infeed pad

Étape 15 - Set front alignment

Set front alignment using adjustment in counter bores in pads

Use 1 meter straight edge and feeler gauges to set

Étape 16 - Check parallel

Use Steel rule to measure from pads to rear fence mount on frame from both tables

This measurement needs to be the same

Use adjustment in pads, and pillar supports to correct

Ensure front alignment of tables is held when adjusting

Étape 17 - Finalise fasteners

Finalise all fasteners with 243 and correct tension once adjustments are complete

Étape 18 - Fit eject cylinder

fit eject cylinder with spacer

Ensure alignment

Ensure correct position of cylinder thread adjustment

Étape 20 - Fit energy chain

Fit energy chain with backing plate.

Ensure pivoting bracket is fitted to correct end

Étape 21 - Fit cover fixing bar

Fit cover fixing bar with 2 off spacers and M8 sockets

Tap holes to clean m5 threads

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português