Fitting and alignment details

Introduction

Tools required

Standard hex key set

2 meter straight edge

1 meter straight edge

12" engineers level

12" inch engineers square

Feeler gauge set

Parts Required

Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

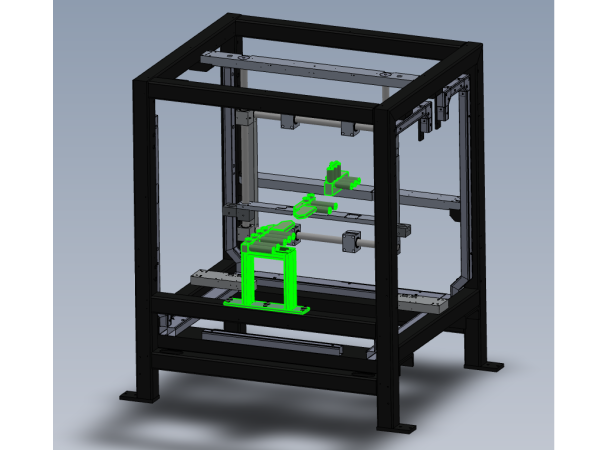

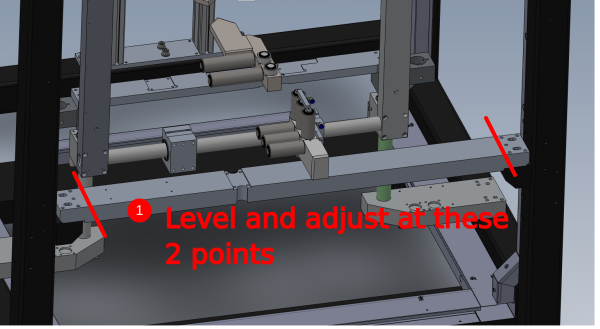

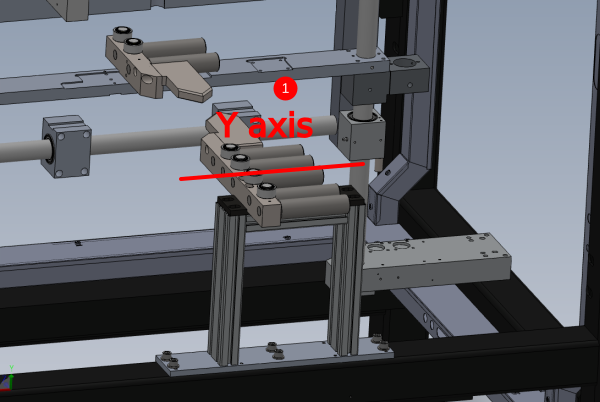

Étape 2 - Level Infeed datum rollers

1 Level On X axis using engineers level and adjusting grubscrews in indicated areas

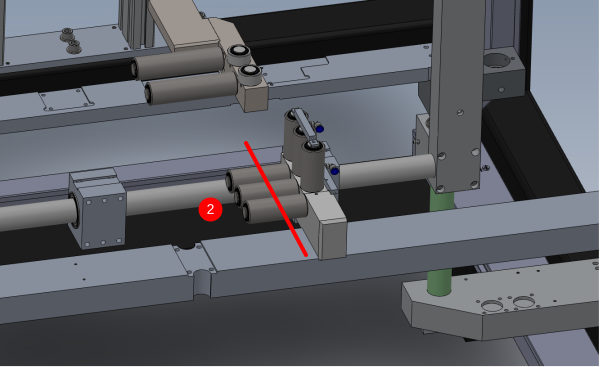

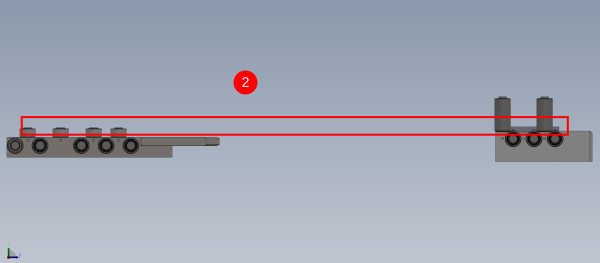

2 Level from Rollers at indicated point. Adjust previous level points evenly to adjust level reading on rollers

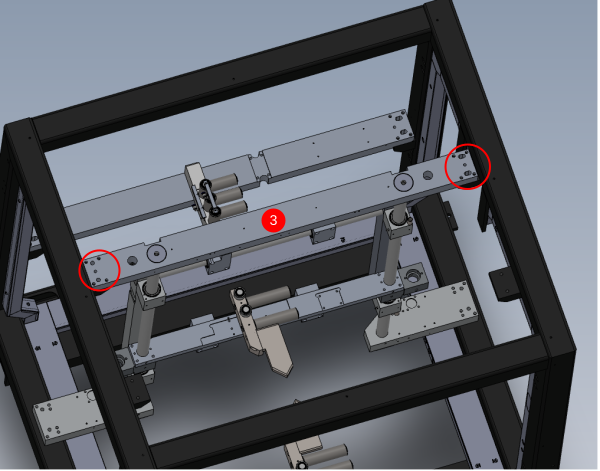

3 Remove Middle roller and top blower

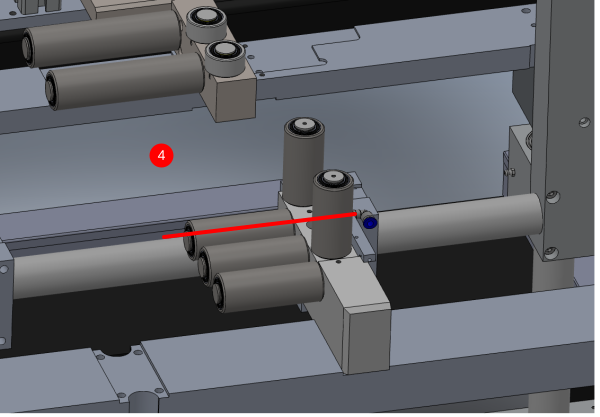

4 Use 300mm parallels to span rollers and engineers level to check and adjust Y axis level of rollers

Étape 3 - Level V notch datum rollers

1 Level Y axis with engineers level and 300mm parallels.

2 Adjust using M8 flat bottom jacking grubscrews

3 Check and adjust X axis level

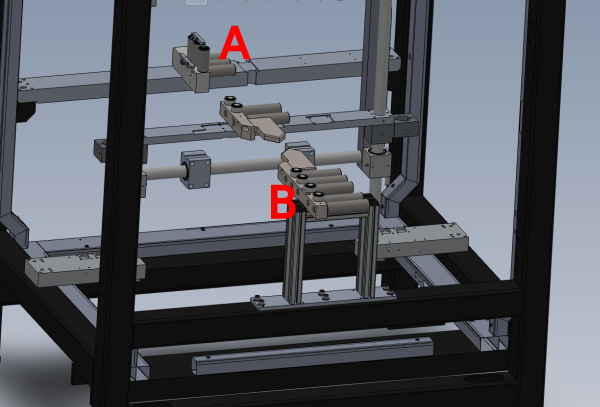

Étape 4 - Level between rollers

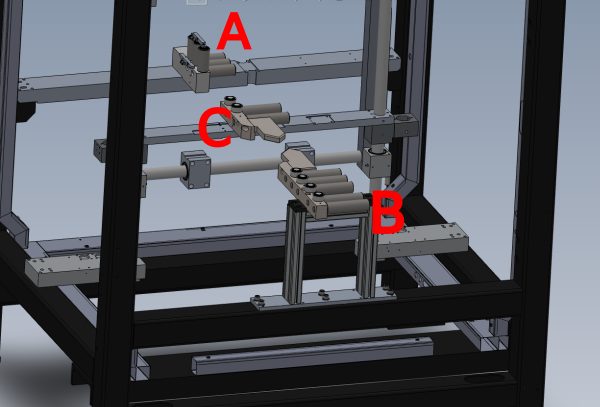

1 Use a 2 meter straight edge to span between rollers A and B

2 Use engineers level on straight edge to identify if either A or B is the low point

3 Raise A or B to bring level

Étape 5 - Check alignment and levels

1 Check all levels again after adjusting rollers A and B

2 Use 2 meter straight edge and feeler gauges to check alignment of rollers and cut table

Adhere to tolerance of - 0.002"

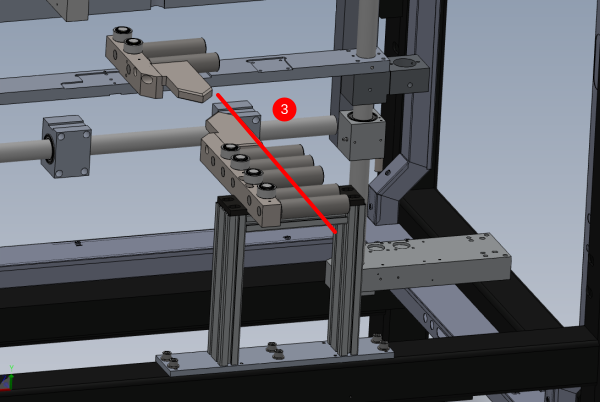

Étape 6 - Adjust Roller C

Span from roller A to B with 2 meter straight edge

Identify if roller C is high or low

If high, increase height of rollers A and B and re set levels

If low, follow next step for subframe adjustment

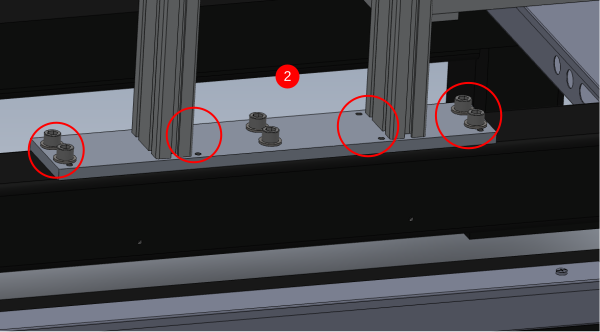

Étape 7 - Subframe adjustment

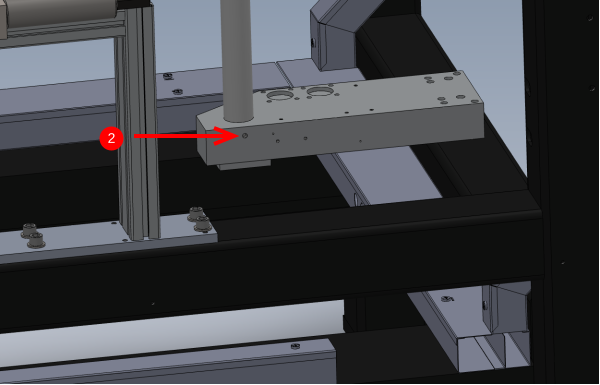

This step is required is centre rollers C require lifting

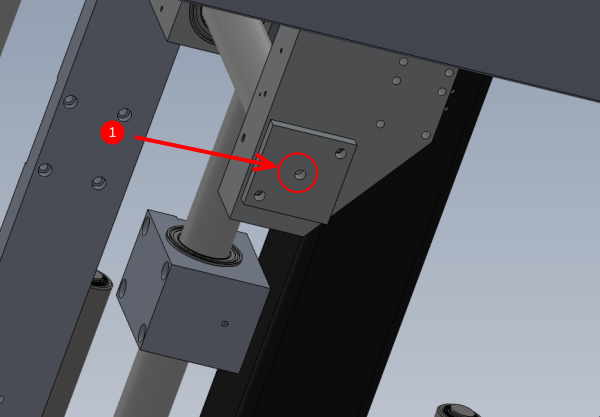

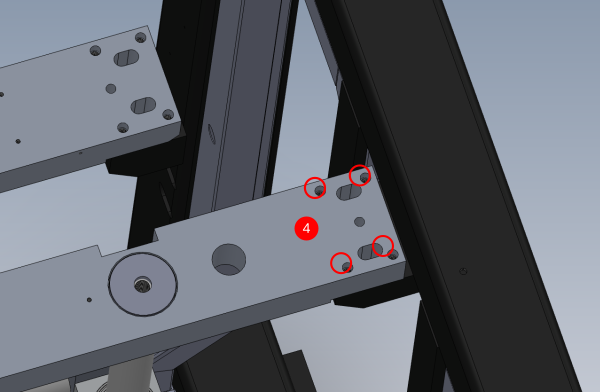

1 Release lock nut on plate 2 off

2 Release M8 grubscrew 2 off

3 Release M12 socket caps 4 off

4 Adjust in equal turns M10 jacking grubscrews

Re level and tighten subframe

Étape 8 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português