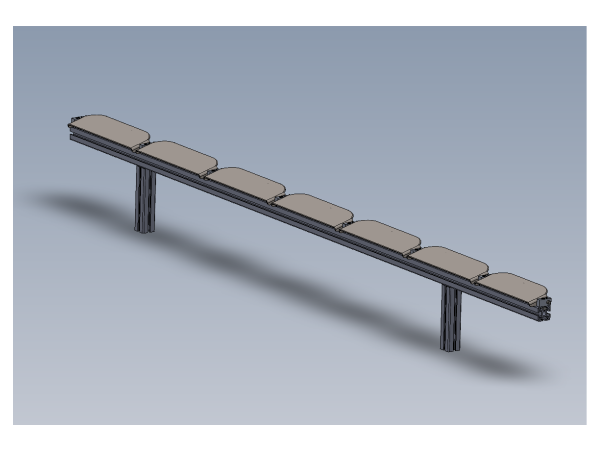

Bench assembly details for sensor rail

Introduction

Tools Required

Standard hex key set

Parts Required

B0001099 Bush flange 10 i/d 12 o/d x 14

C0001018 EP2338-0001 EtherCAT Box 8 Configurable IO x 1

D0010167 Ethercat Mount Plate x 1

D0015353 Sensor Flapper Pivot x 8

D0015355 Sensor Flapper Plate (312) x 6

D0015357 Sensor Flapper Plate (270) x 1

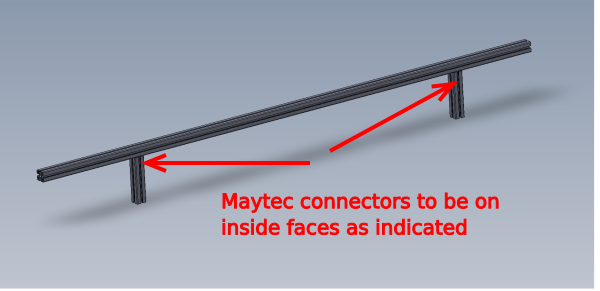

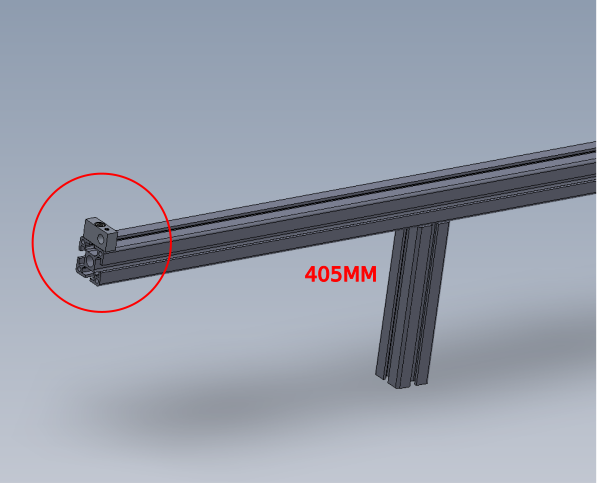

D0015363 Sensor Flapper Support Transfer SEE NOTE x 1

D0016322 Welded 90° Bracket: 76mm x 38mm x 38mm x 2

E0000336L Sensor: M8; 4mm, PNP N/O, M8 conn x 7

F0000537 dowel pin 10 x 40 x 8

M0001016 Angle 74 x 38 x 2

M0001209 Bracket m8 proximity sensor bracket 90 deg x 7

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 570 on all threaded pneumatic connections

Pen mark all bolts when finalised

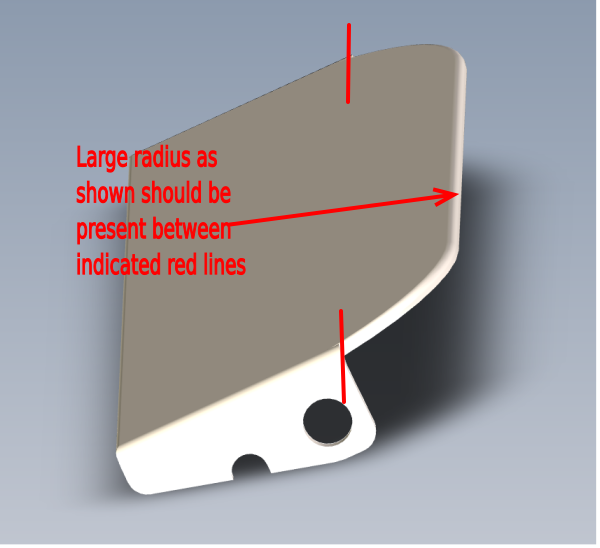

Étape 2 - Quality check

Check components

D0015355 Sensor Flapper Plate (312) x 6

D0015357 Sensor Flapper Plate (270) x 1

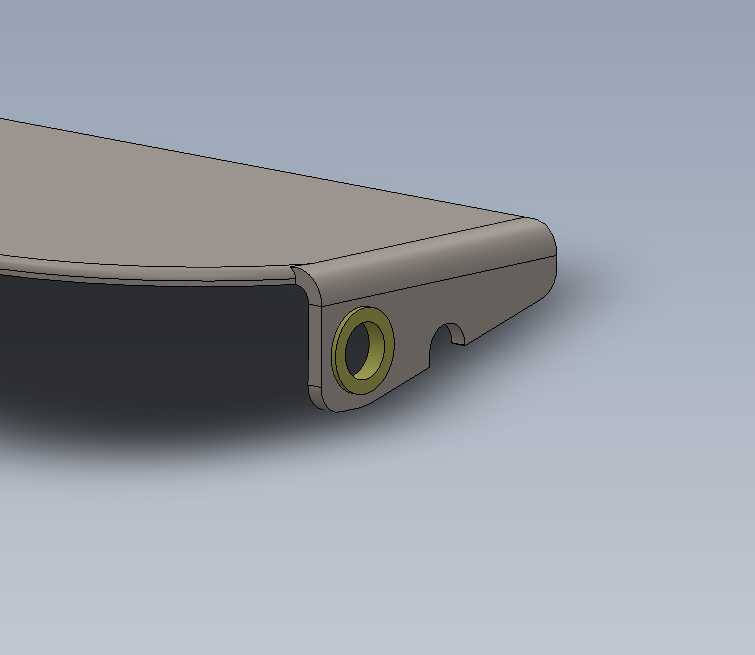

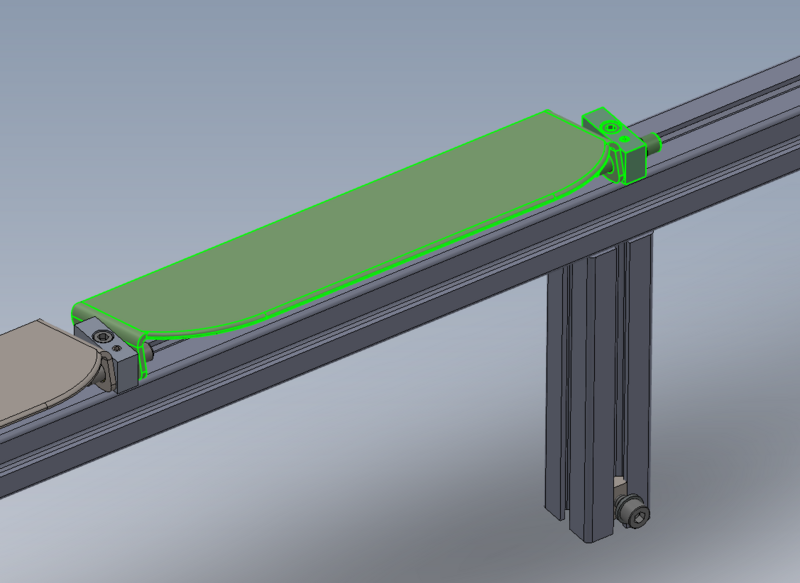

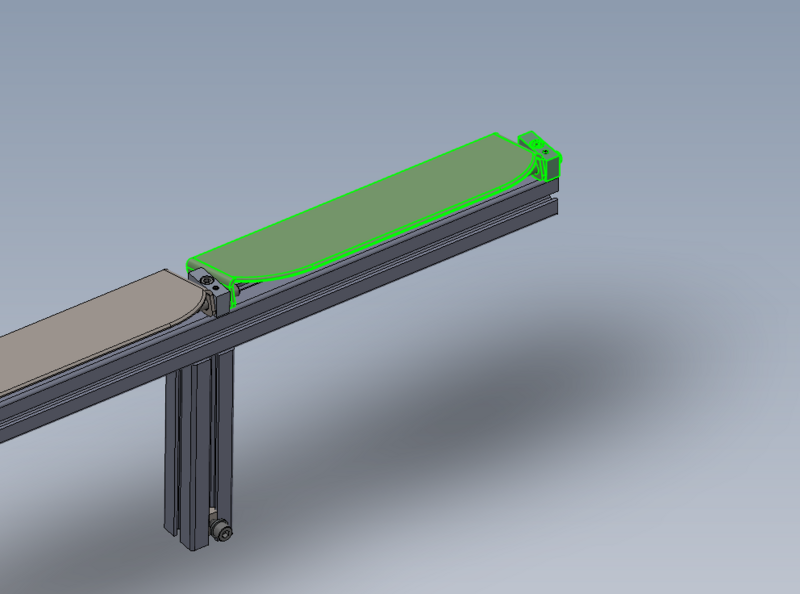

Ensure indicated have a radius on the indicated faces and are smooth and burr free

Étape 4 - Fit bushes

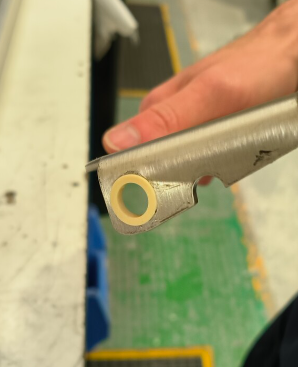

Fit B0001099 Bush flange 10 i/d 12 o/d x 14 into D0015355 Sensor Flapper Plate (312) x 6 and D0015357 Sensor Flapper Plate (270) x 1 as shown

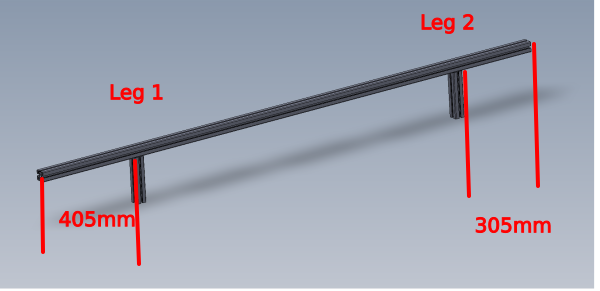

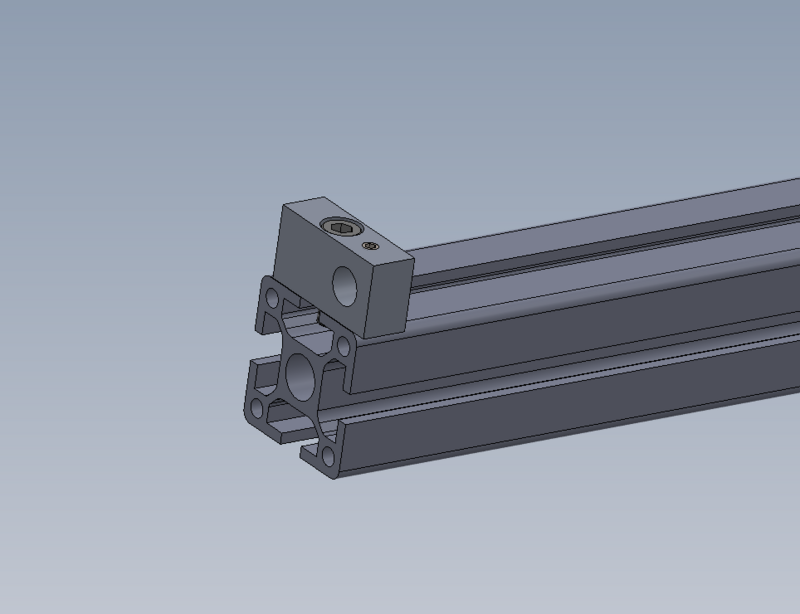

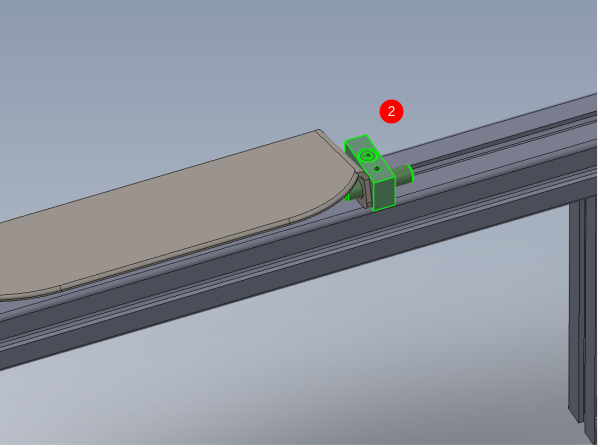

Étape 5 - Fit 1st Pivot

Fit 1st D0015353 Sensor Flapper Pivot as shown

Fix with F0000299 m6 d nut and M6 x 20 socket cap

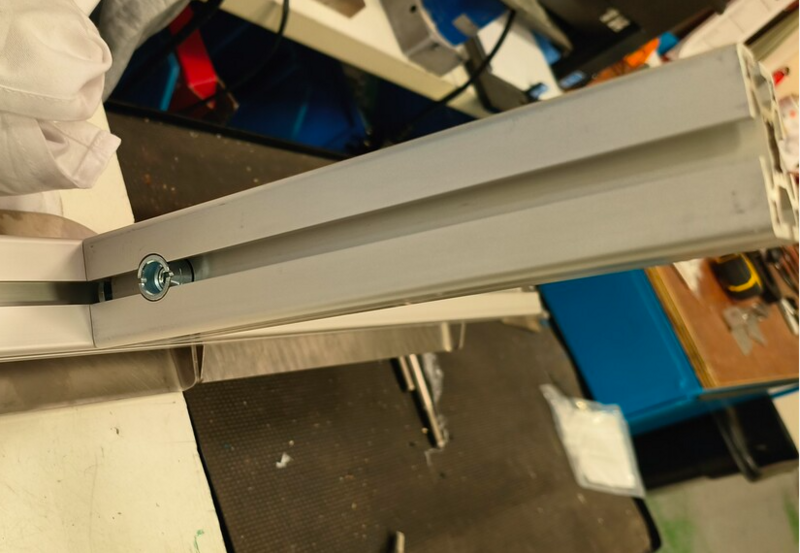

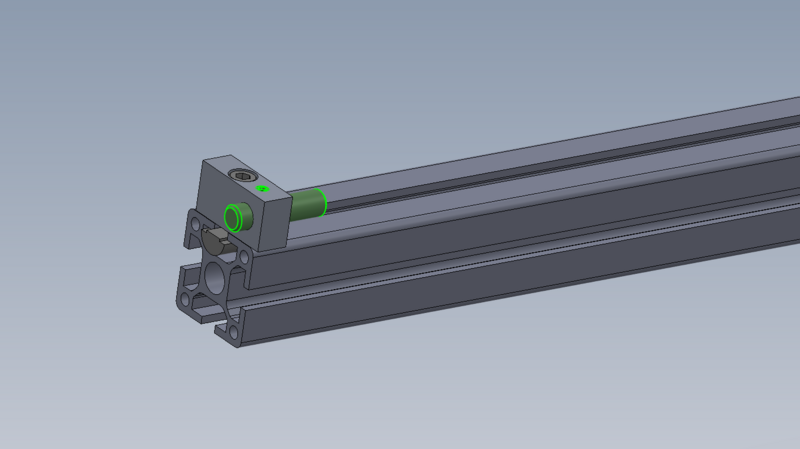

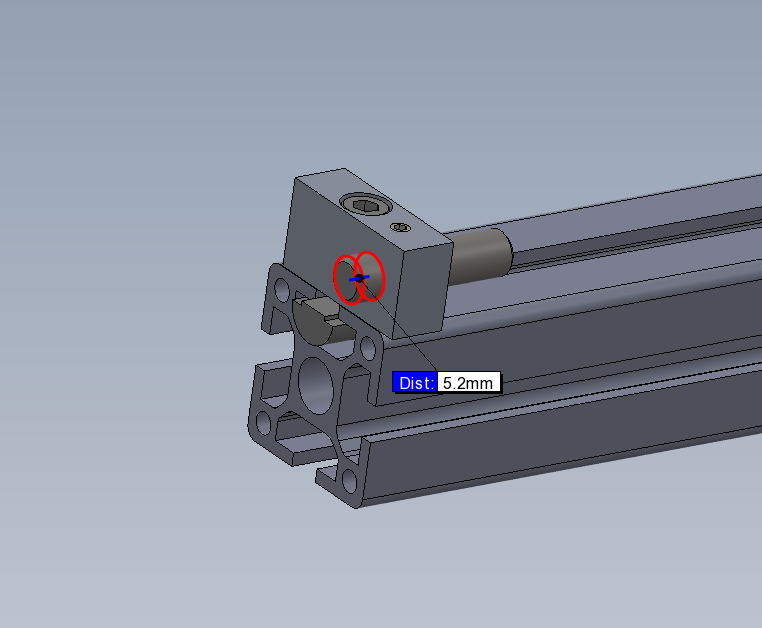

Étape 6 - Add dowel

Fit F0000537 dowel pin 10 x 40 as shown, leaving 5mm of protrusion

Secure with M5 x 12 kcp grubscrew

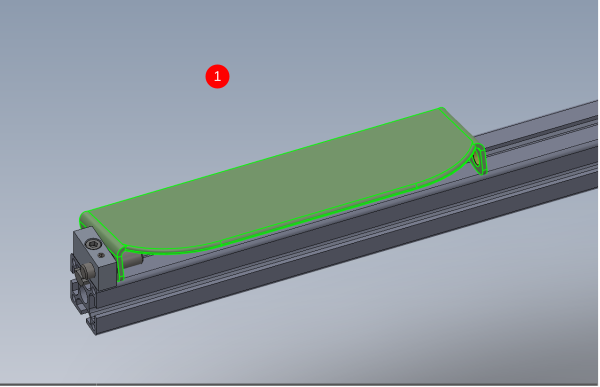

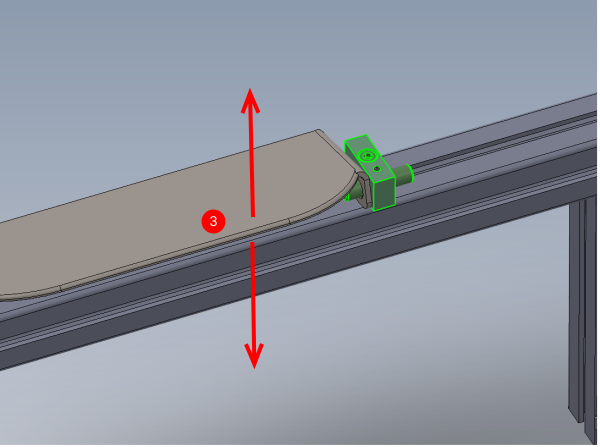

Étape 7 - Fit 1st plate

1 Position as shown D0015357 Sensor Flapper Plate

2 Captivate with pivot block and dowel as shown, using same fixings as previous pivot block . Ensure dowel sits central in pivot block.

3 Ensure sensor plate is free to move in the direction shown when fitted. Leave as minimal gap as possible between pivot blocks and sensor plate

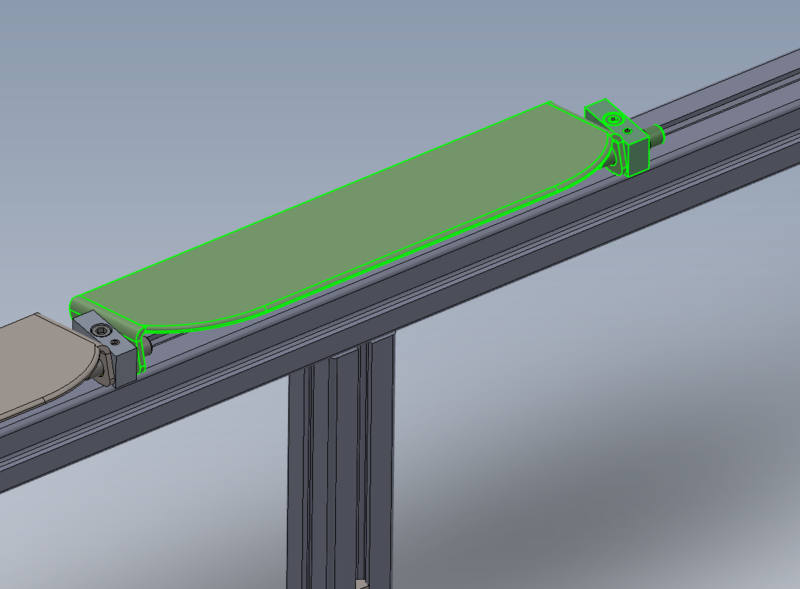

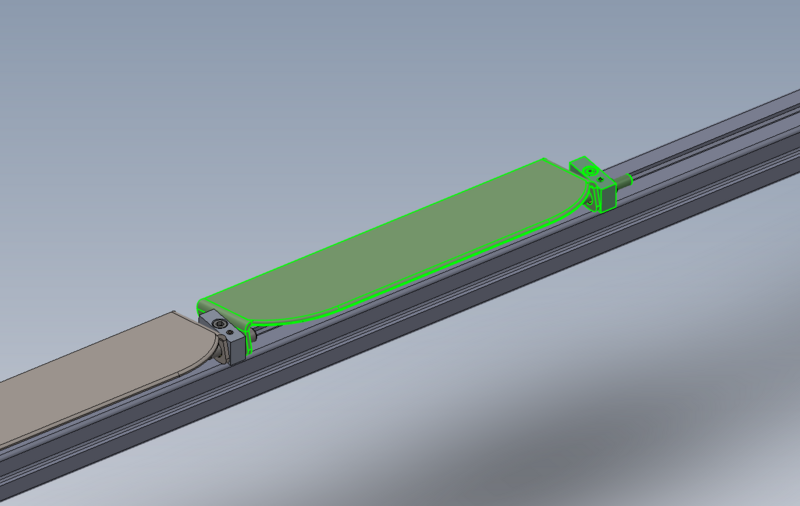

Étape 8 - Fit 2nd plate

Fit D0015355 Sensor Flapper Plate (312) and fix with same method as previous steps

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português