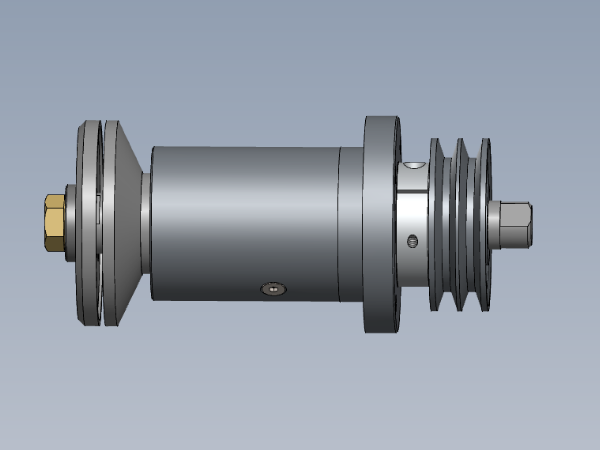

Bench assembly of saw main blade spindle

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Check fitment

- 4 Étape 3 - Check fitment

- 5 Étape 4 - Bearing fitment

- 6 Étape 5 - Assemble bearings on spindle shaft

- 7 Étape 6 - Check outer spacer resistance

- 8 Étape 7 - Adjustment of outer spacer resistance

- 9 Étape 8 - Finalise lock ring

- 10 Étape 9 - Heat Bearing housing

- 11 Étape 10 - Fit spindle assembly

- 12 Étape 11 - Cool assembly

- 13 Étape 12 - Quality check

- 14 Étape 13 - Fit taper lock pulley

- 15 Étape 14 - Attach blade mounting flanges

- 16 Commentaires

Introduction

Tools Required

Standard hex key set

Heat gun

Parts Required

B0000027 Ball Bearing 30 I/D 62 O/D 16 Long + seals (Branded) x 3

B0000048 Taperlock Set SPZ 80-2 1210-24 x 1

B0000060 Double Angular Bearing 30 I/D 62 O/D 23.8 Long + seals x 1

D0004026 Bearing Housing x 1

D0004027 Saw Spindle x 1

D0004030 Lock Ring x 1

D0004031 Saw Washer x 1

D0004271 Front Saw Flange x 1

D0004272 Backing Saw Flange x 1

D0004771 Inner Bearing Spacerx 1

D0004772 Outer Bearing Spacer x 1

D0004852 Key for D4027x 1

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

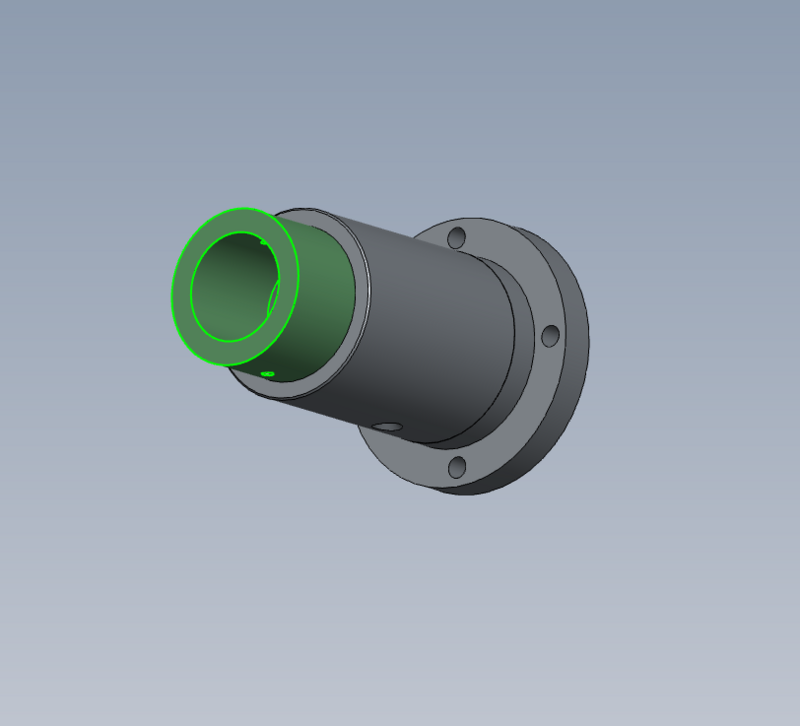

Étape 2 - Check fitment

Check fitment of D0004772 Outer Bearing Spacer into D0004026 Bearing Housing

Spacer should pass through bearing housing when aligned correctly .

Check for burrs on bearing if spacer doesn't pass through

Étape 3 - Check fitment

Check fitment of D0004030 Lock Ring onto D0004027 Saw Spindle

Lock ring should wind to base of thread by hand

Étape 4 - Bearing fitment

Ensure correct bearing fitment is adhered to

Bearings fitted should have resistance fit.

If bearings are slide fit, Loctite 641 must be used with adequate de-greasing

If bearing are tight, inspect parts to drawing

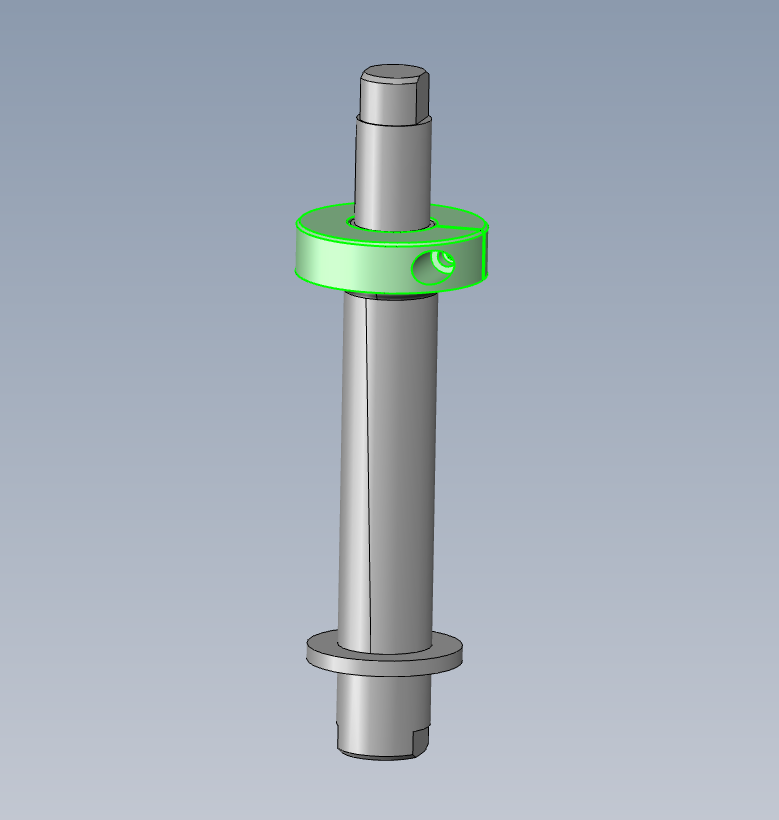

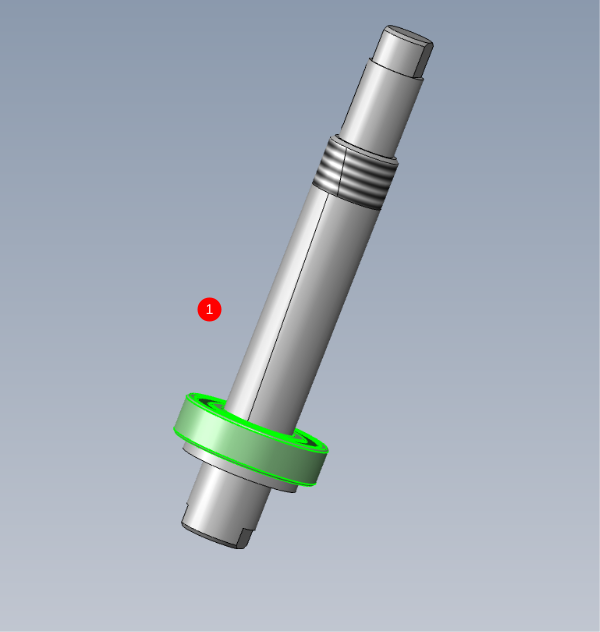

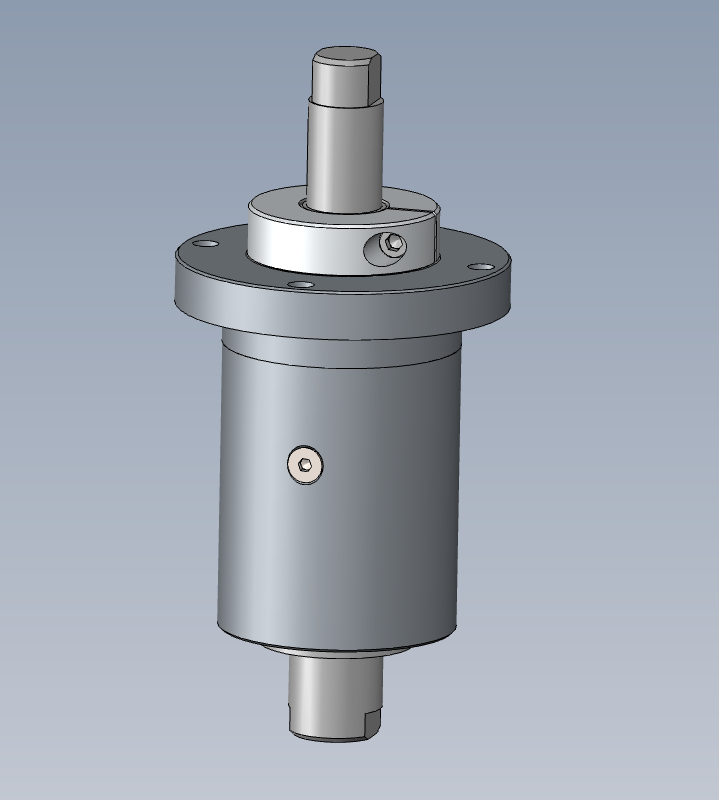

Étape 5 - Assemble bearings on spindle shaft

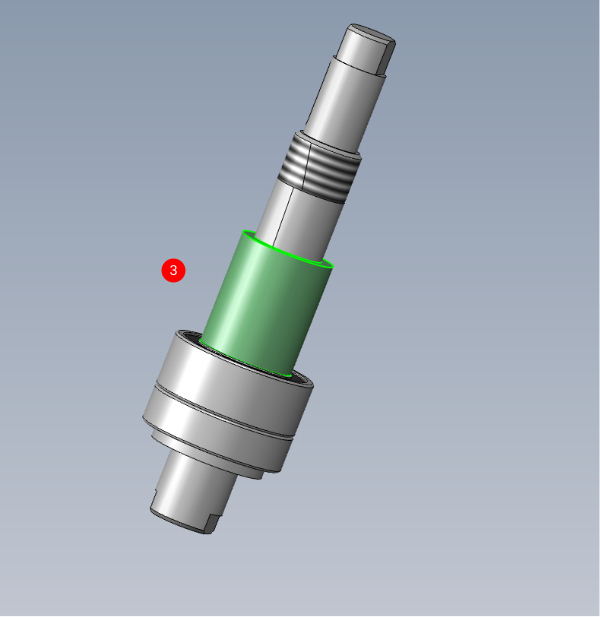

1 Fit B0000027 Ball Bearing as shown using press

2 Fit B0000060 Double Angular Bearing as shown

3 Fit D0004771 Inner Bearing Spacer

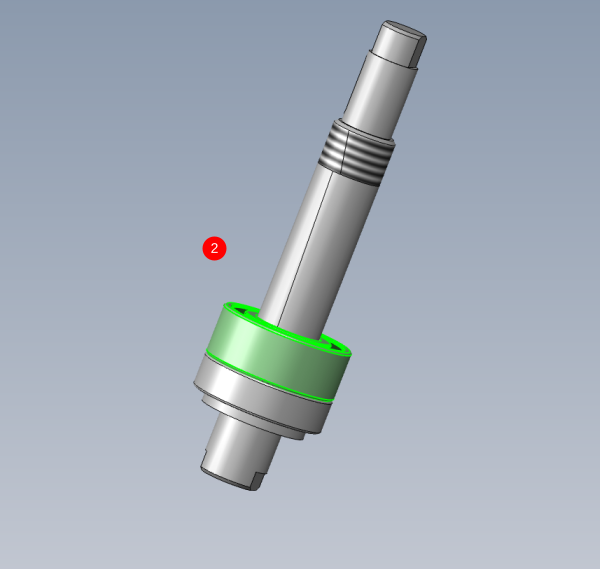

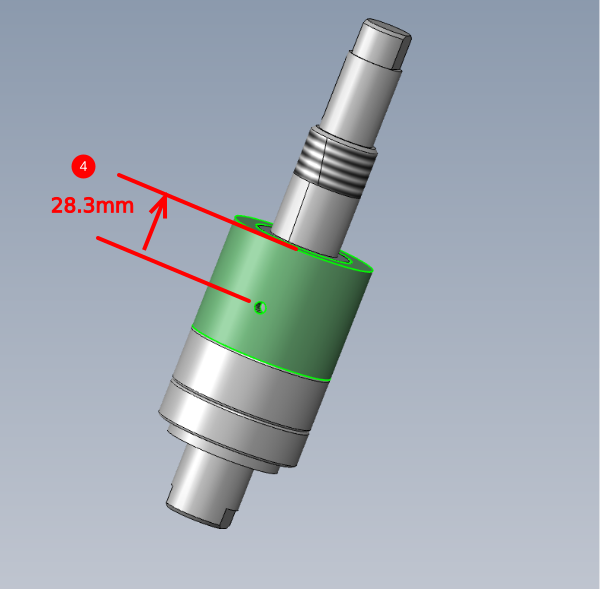

4 Fit D0004772 Outer Bearing Spacer , ensuring orientation as shown using measurement as reference

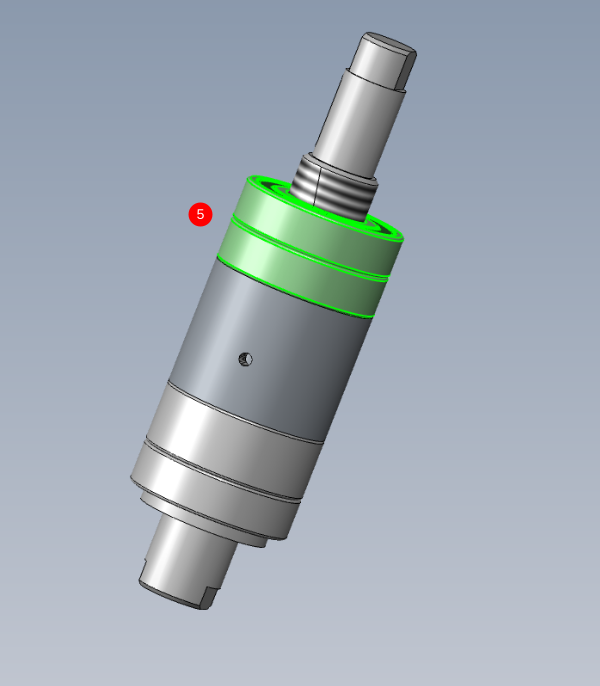

5 Fit 2 off B0000027 Ball Bearing

6 Fit and apply tension to D0004030 Lock Ring

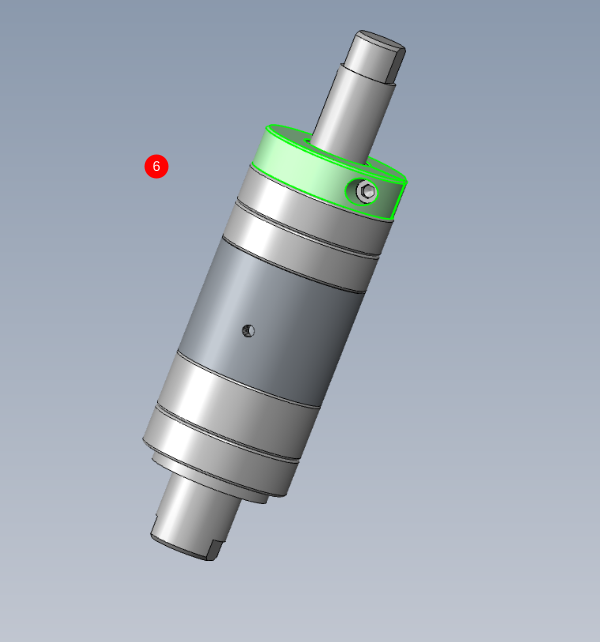

Étape 6 - Check outer spacer resistance

The outer spacer should have resistance when assembled in the direction shown.

It should be possible to move it by hand, but not easily

Étape 7 - Adjustment of outer spacer resistance

To adjust outer spacer pressure, the following steps can be performed

To increase the pressure , reduce length of inner spacer

To reduce the pressure, reduce the length of the outer spacer

1 To adjust the identified part, remove fitted bearings and remove inner or outer spacer from assembly

2 Use sanding pad to polish face of identified spacer to adjust length. Ensure rotating movements are used when adjusting to ensure parallel of faces is maintained

3 Only make small adjustments,the re assemble to check fitment

Continue until desired fitment is obtained

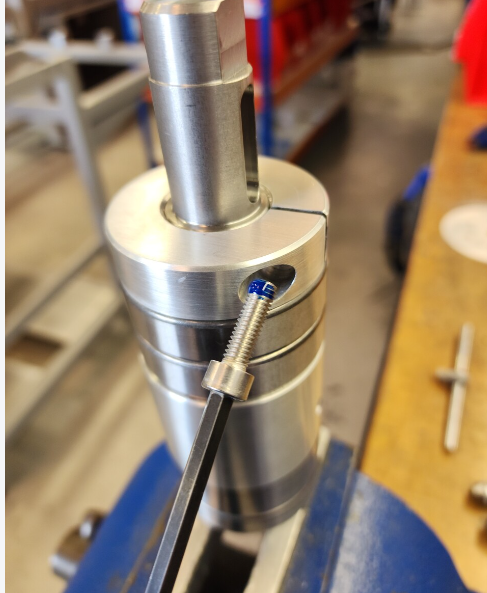

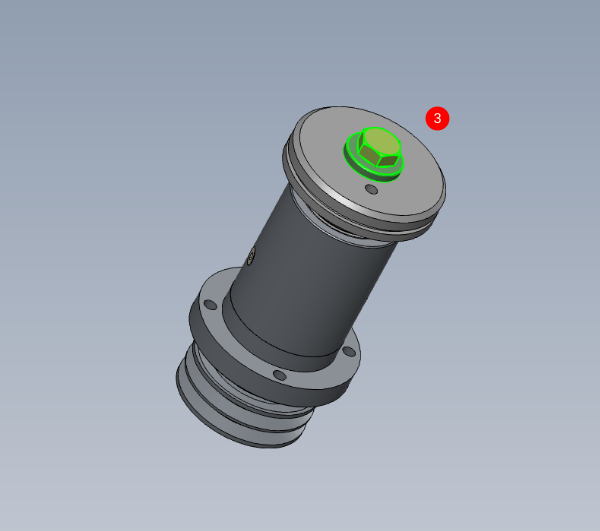

Étape 8 - Finalise lock ring

Use M6 x ?? caphead as shown and fit to lock ring.

Apply final tension

Check fitment again of outer spacer

If deviation has occurred,adjust rotational tension of lock ring slightly and re tension M6 cap head

Continue until desired fitment is acquired and fasteners are finalised

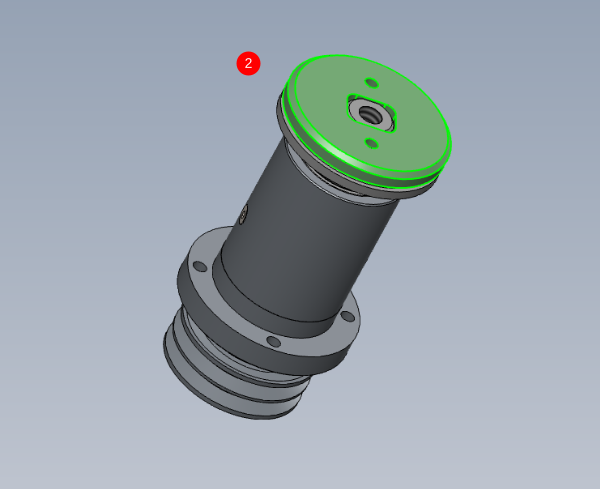

Étape 9 - Heat Bearing housing

D0004026 Bearing Housing will require heating with heat gun to swell bore for spindle assembly fitment

1 Degrease thoroughly with FE10 solvent and dry

2 Use heat gun to apply heat to bearing housing . Heat for roughly 5 minutes

Étape 10 - Fit spindle assembly

When bearing housing is hot, slide in the spindle assembly and align the 2 m6 tapped holes in the spindle assembly to the bearing housing countersunk holes

Add 2 off M6 x 12 counter sunk bolts and tighten

Étape 12 - Quality check

Once assembly has cooled, check rotation of spindle assembly

Rotation should be smooth and consistent with no tight spots

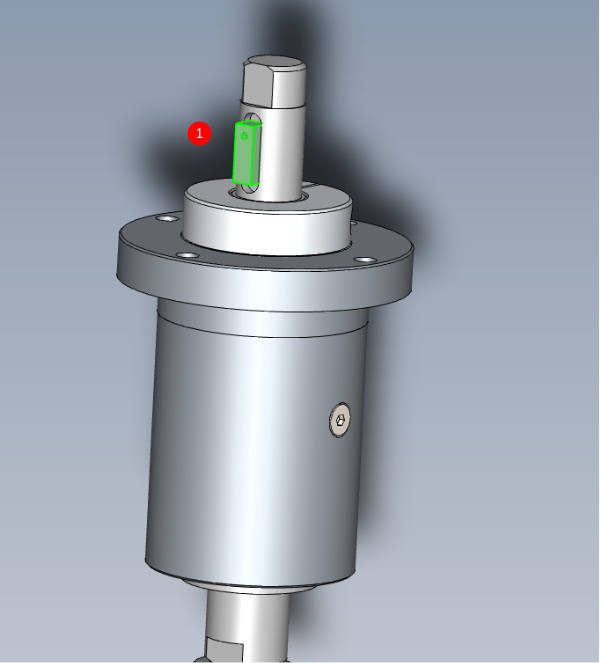

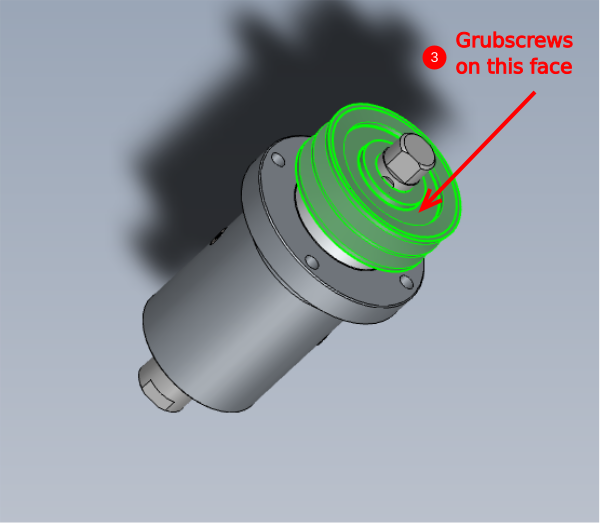

Étape 13 - Fit taper lock pulley

1 Insert D0004852 Key as shown

2 Remove 2 off grubscrews from B0000048 Taperlock Set Apply copper slip, then re fit

3 Fit taperlock to align over key and apply light tension to grubscrews to secure temporary position of taper lock pulley

Étape 14 - Attach blade mounting flanges

1 Fit D0004272 Backing Saw Flange as shown

2 Fit D0004271 Front Saw Flange as shown

3 Fit D0004031 Saw Washer and captivate lightly with M16 x 1.5 x 45 hex set yellow passivated

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português