bench assembly instructions for main rotary base of saw

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Degreasing

- 4 Étape 3 - Fit bearing to turntable shaft

- 5 Étape 4 - Fit outer cage of bearing

- 6 Étape 5 - Fit bearing assembly

- 7 Étape 6 - Prepare gearbox for fitting

- 8 Étape 7 - Fit gearbox to turntable housing

- 9 Étape 8 - Finalise gearbox mounting

- 10 Étape 9 - Apply grease

- 11 Étape 10 - Prepare components

- 12 Étape 11 - Fit hard stop

- 13 Étape 12 - Fit bearing cage and turntable plate

- 14 Étape 13 - Assemble base

- 15 Étape 14 - Fit turntable to base

- 16 Étape 15 - Fit Servo motor

- 17 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Heat gun

Large Internal Circlip pliers

Standard circlip pliers

8mm hand reamer

Grease gun

Torque wrench

Parts Required

B0000028 Thrust Bearing 140 I/D 180 O/D 31 Long (FAG) x 1

B0000032 Linear Bearing: Ø30 x 50 Compact (Metal Case Only) x 4

B0001087 Angular Contact Bearing 70 I/D 125 O/D 24 Long x 1

B0001088 Circlip 125mm Internal x 1

C0001122K Servo Motor: Beckhoff AM8032-1E10 (Keyed) x 1

C0001179-100 Gearbox NPTO 100-1 x 1

D0004019E Turntable Mk5 (5334E) x 1

D0004033E Alignment Disc Mk5 x 1

D0004147E Turntable Shaft Mk5 x 1

D0004320E Thrust Bearing Housing Mk5 x 1

D0004336 Stay Bar x 2

D0004514E Turntable Base Mk5 x 1

D0004516 Front Bearing Block (5294) x 2

D0010778 Turntable Stop Arm x 1

D0010796 Turntable Housing Cover x 1

H0004631 Shaft 30mm: Base Slide x 2

M0001176 M6 Stainless lock washer x 4

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

Étape 2 - Degreasing

It is vital all components which accept bearings are degreased with Fe10

Ensure this is done to all bores in this assembly

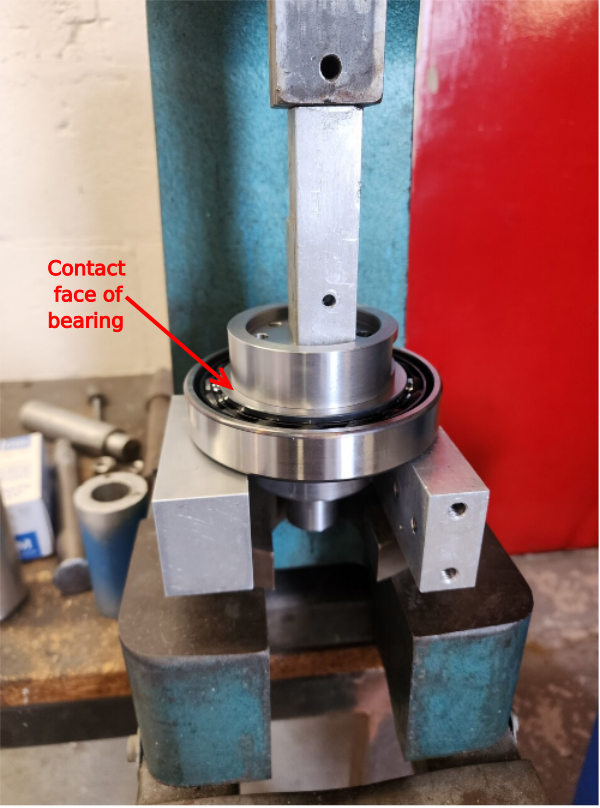

Étape 3 - Fit bearing to turntable shaft

Fit D0004147E Turntable Shaft Mk5 to B0001087 Angular Contact Bearing 70 I/D 125 O/D 24 Long x 1 as shown

If fit is loose, use loctite 641, if fit is tight inspect parts to drawings

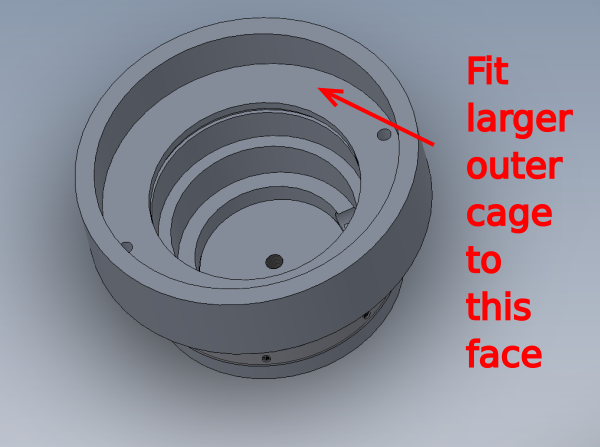

Étape 4 - Fit outer cage of bearing

PICTURES REQUIRED

Identify larger diameter outer cage of bearing assembly B0000028 Thrust Bearing 140 I/D 180 O/D 31 Long (FAG)

This can be done easily by using the D0004320E Thrust Bearing Housing Mk5 as a reference. One outer cage will easily fit into the housing, and 1 will not.

Clean then heat the bearing housing to expand, and then fit the larger outer bearing cage using loctite 641 . Ensure cage is sitting correctly on the bottom of the thrust housing

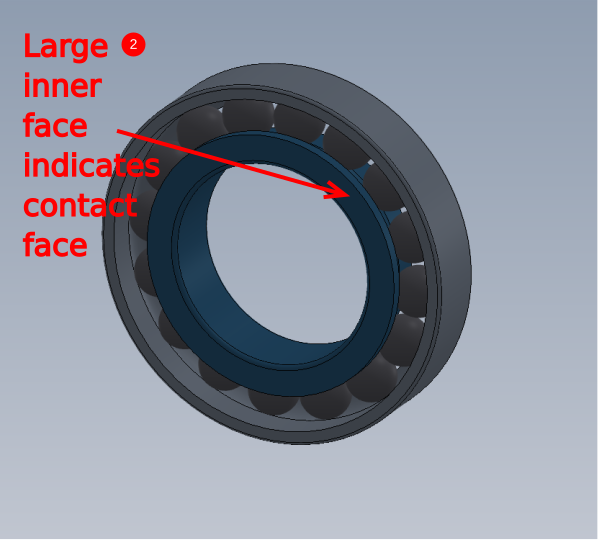

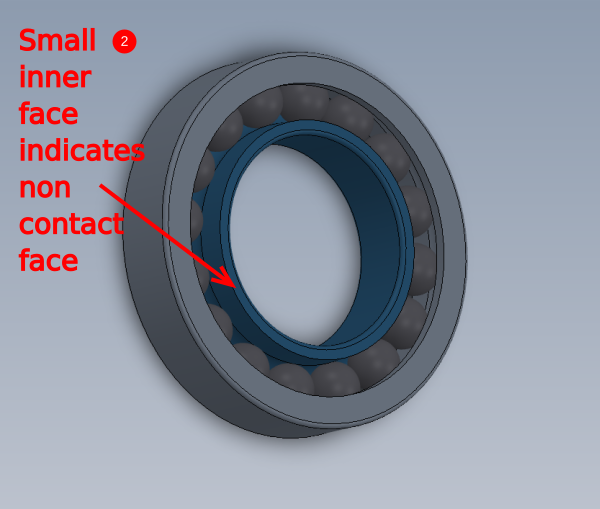

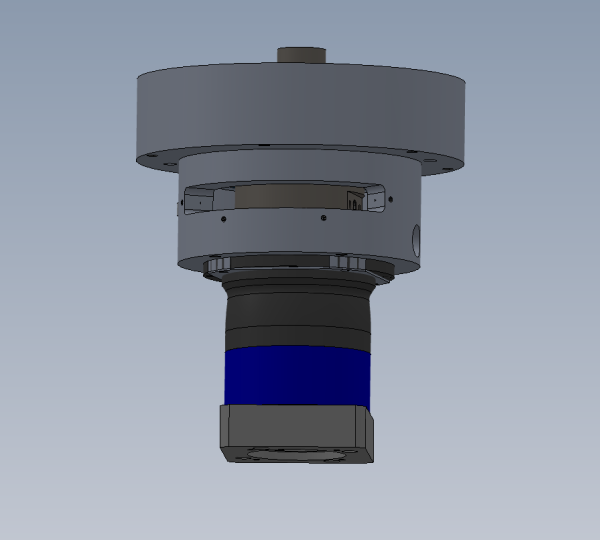

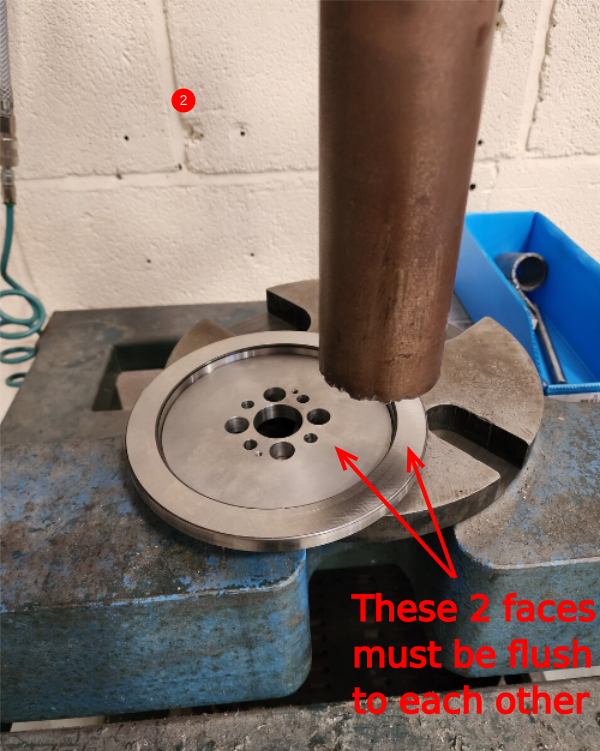

Étape 5 - Fit bearing assembly

Whilst the housing is still hot, fit the bearing assembly orientated as shown . Add loctite 641 to bore when fitting

Retain with B0001088 Circlip 125mm Internal using large circlip pliers to fit

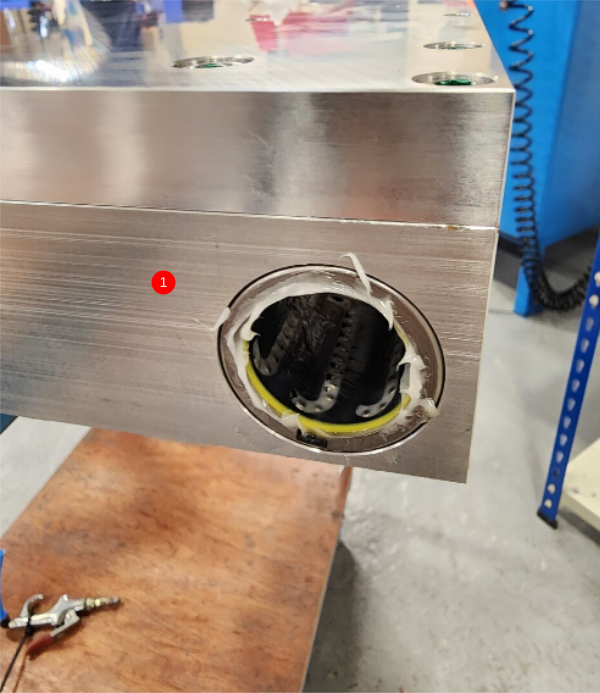

Étape 6 - Prepare gearbox for fitting

2 off shoulder bolts need fitting and modifying on gearbox before the gearbox can be fitted

Use loctite 270 and fit 2 off shoulder bolts (size required) to two opposing fixing points on gearbox mounting flange

Remove head of shoulder bolt with disc cutter and deburr and clean

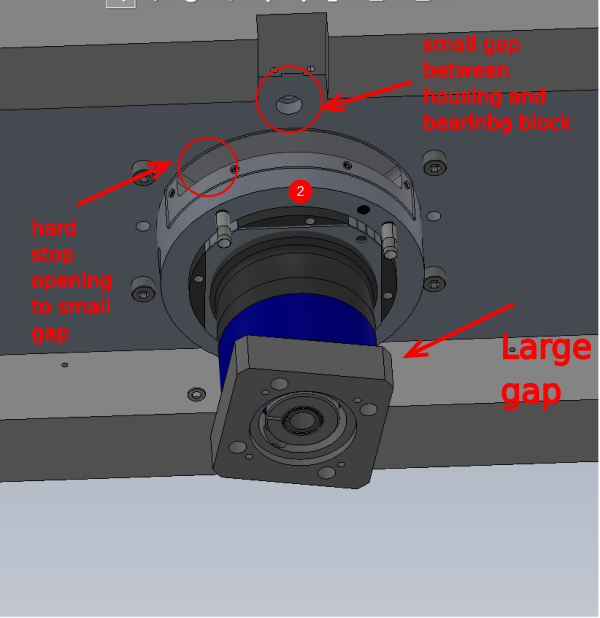

Étape 7 - Fit gearbox to turntable housing

Align two previous fitted shoulder bolts to the 2 off 8mm diameter holes in the turntable shaft , this will align mounting holes for next step

Use 6 off M5 x 16 socket caps and fix gearbox to housing orientated as shown

Ensure gearbox access hole is oriented as shown

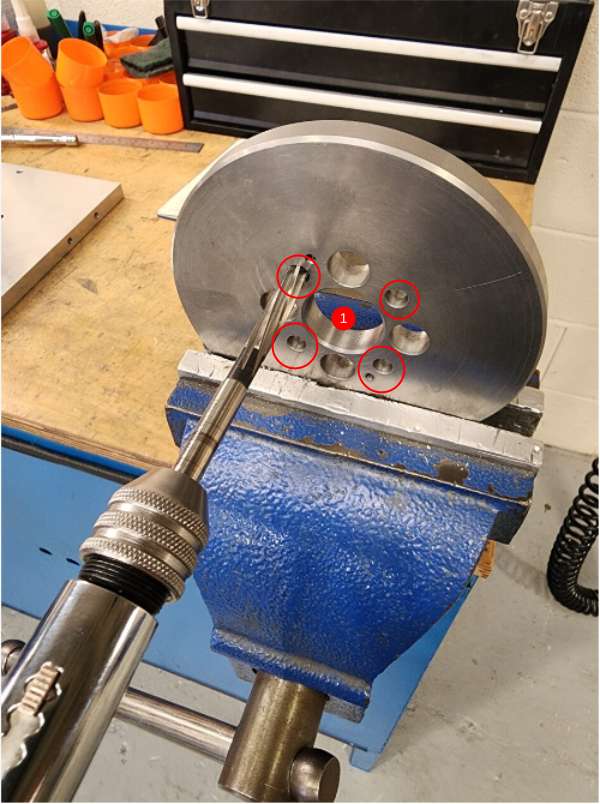

Étape 8 - Finalise gearbox mounting

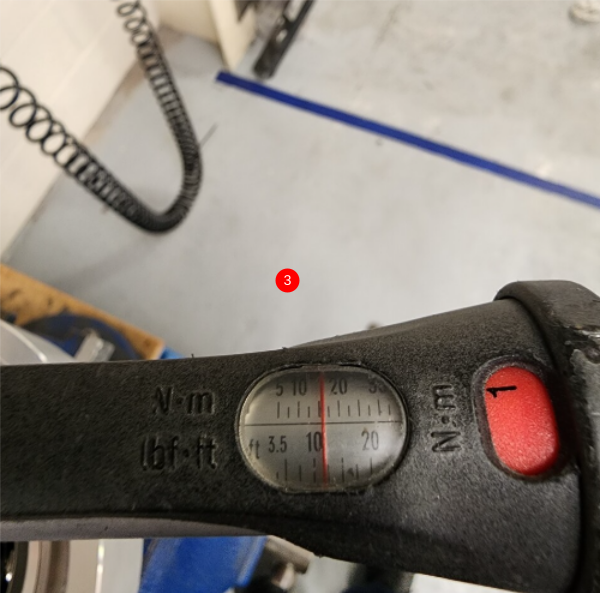

1 Use 4 off M6 x 20 blackadised Umbrako socket caps and 4 off M0001176 stainless lock washers.

2 Apply loctite 243 and fit to indicated bores

3 Tension to 15 nm using torque wrench

Étape 9 - Apply grease

1 Apply liberal grease to indicated area

2 Apply a bead of grease to the circumference of the indicated area

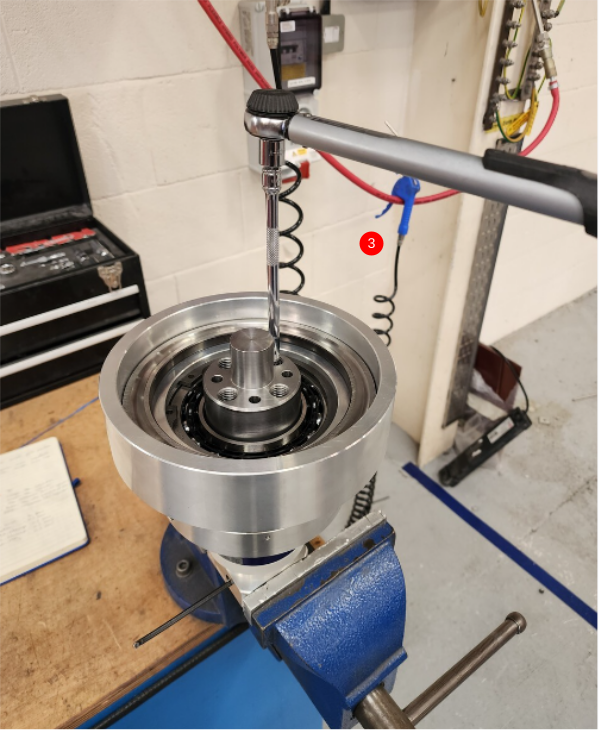

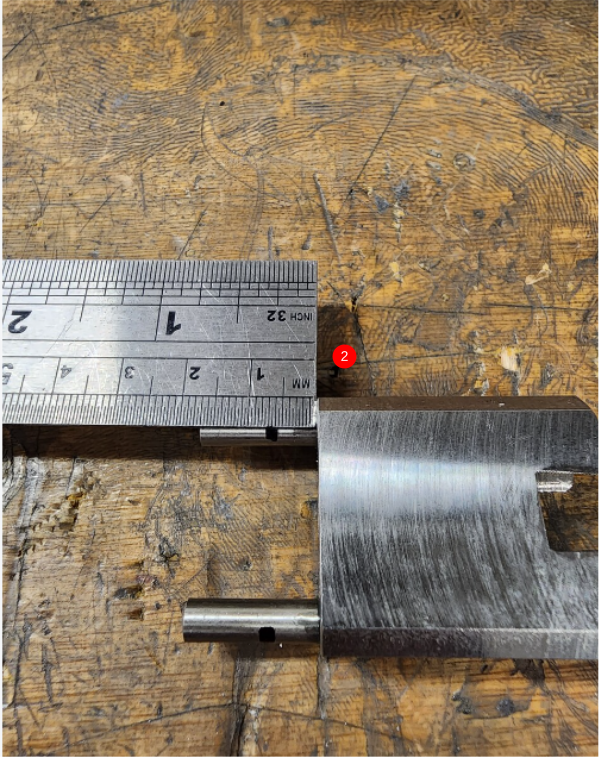

Étape 10 - Prepare components

1 Use 8mm hand reamer to clean holes indicated in D0004033E Alignment Disc Mk5

2 Attach smaller bearing outer cage to disc using press

3 Use 8mm hand reamer to clean indicated holes on D0004019E Turntable Mk5 (5334E)

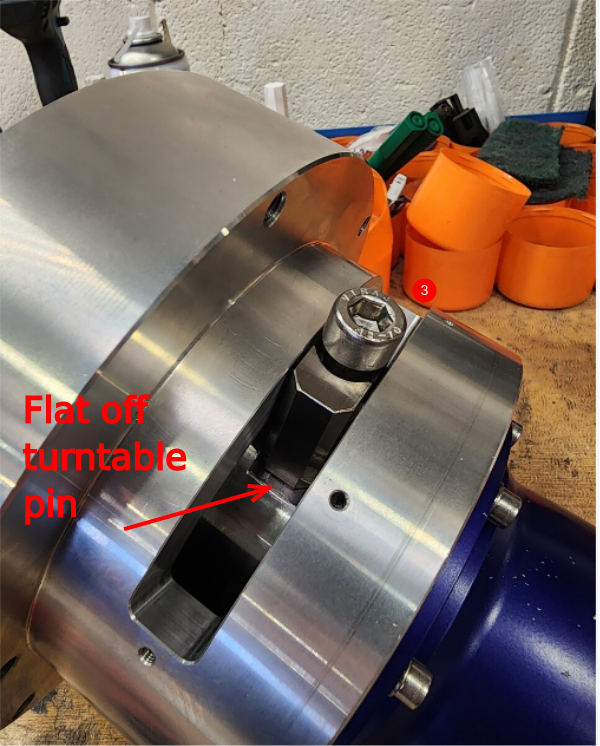

Étape 11 - Fit hard stop

1 Fit 2 off dowels to D0010778 Turntable Stop Arm (dowel size required). Use Loctite 270 to secure

2 Cut down dowels to 8mm protrusion

3 Fit to flat on turntable pin and secure with M10 socket cap (size required )

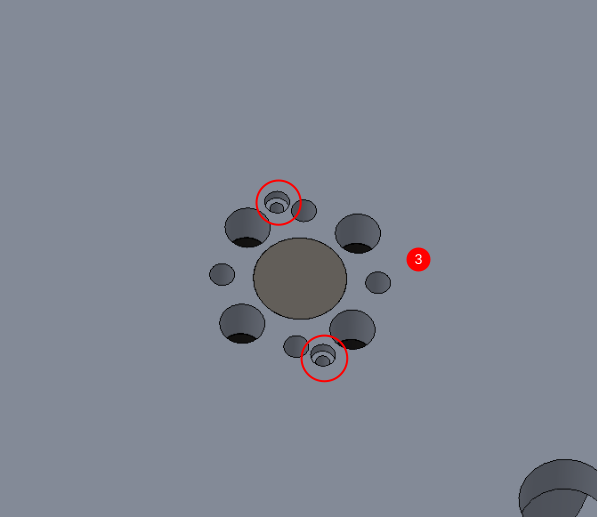

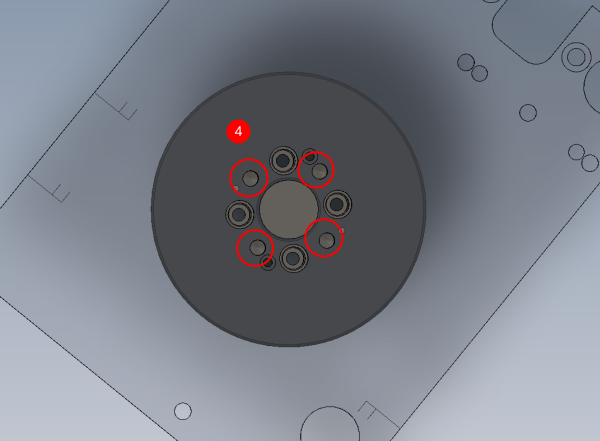

Étape 12 - Fit bearing cage and turntable plate

1 Fit bearing cage from B0000028 Thrust Bearing 140 I/D 180 O/D 31 Long (FAG), Apply more grease then position assembly shown on top and visually align 8mm reamed holes

2 Position D0004019E Turntable Mk5 as shown. Ensure hard stop is in centre position

All 8mm reamed holes should align through the 3 parts. Turntable shaft, alignment disc and turntable

3 Add 2 off m4 socket caps (size required)and tension lightly to indicated holes to fix together

4 Insert 4 off 8mm x 50mm hardened dowels to fix all three parts in correct alignment

5 Add 4 off m14 x (size required) socket caps and A form washers to finalise fixing of turntable plate

6 Remove 2 off previously fitted M4 socket caps, apply adhesive and apply final tension

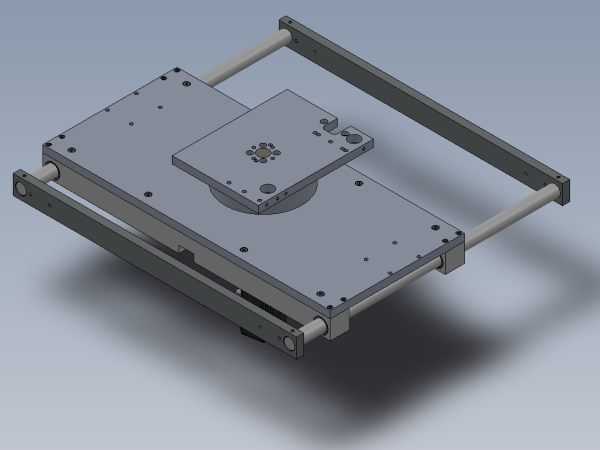

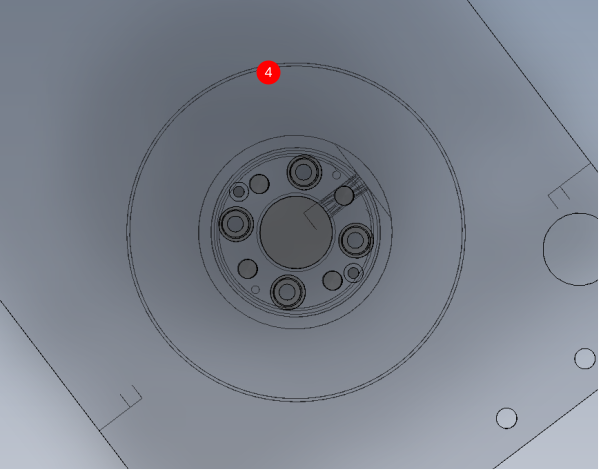

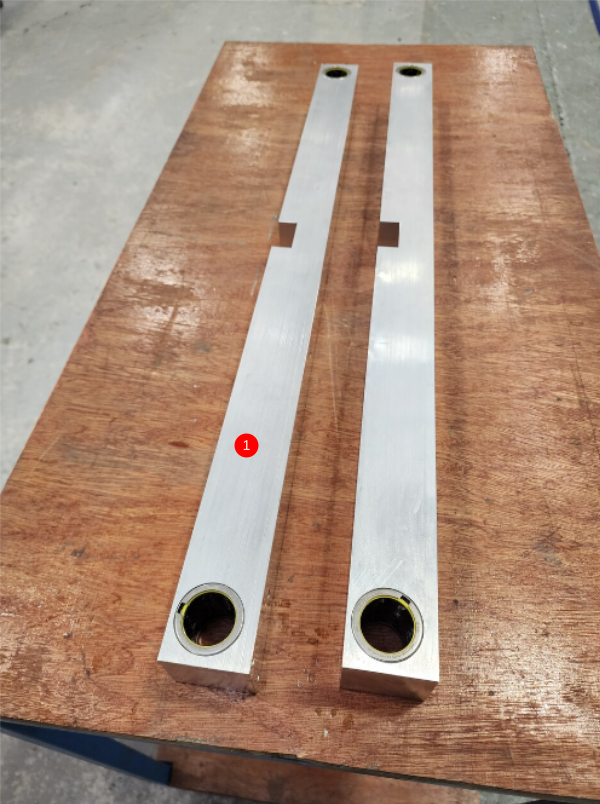

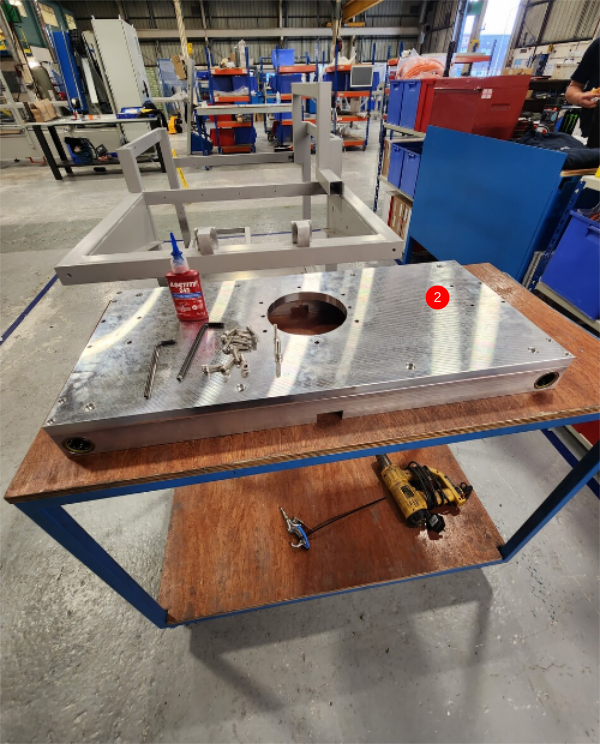

Étape 13 - Assemble base

1 Fit 4 off B0000032 Linear Bearing: Ø30 x 50 Compact bearings to D0004516 Front Bearing Block (5294) x 2 as shown , ensure bearings are greased after fitting

2 Attach D0004514E Turntable Base Mk5 as shown . Use M6 and M8 socket caps (sizes required) to fix . Ensure all external faces are flush with bearing blocks

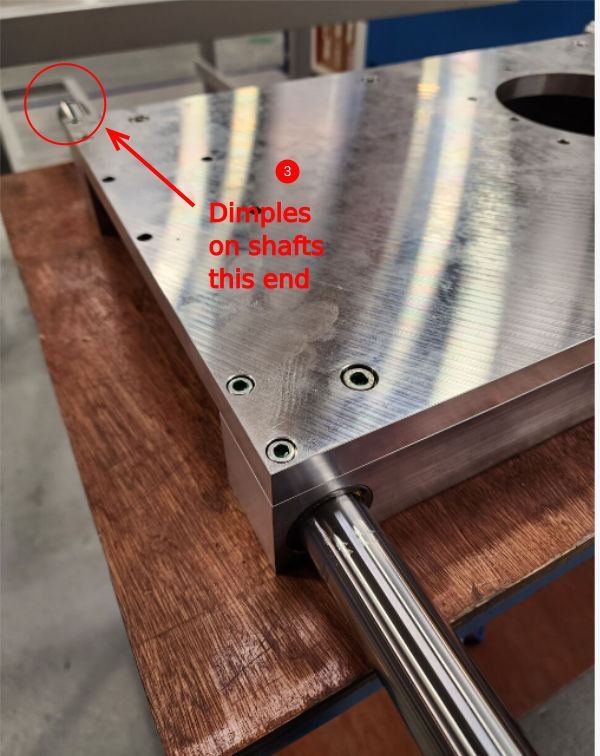

3 Clean 2 off H0004631 Shaft 30mm and insert through bearing blocks . Ensure dimple in shaft is at the indicated end

4 Fit D0004336 Stay Bar x 2 as shown. Use M8 x 12 kcp grubscrews to locate onto shaft dimple. End of shaft with no dimple, set staybar flush with shaft and tighten grubscrew onto shaft

If the stay bars are a tight fit, these will require polishing with emery tape to remove debris from coating process . Ensure gradually polishing of bores to ensure bores are taken oversize

5 Check and finalised all fixings

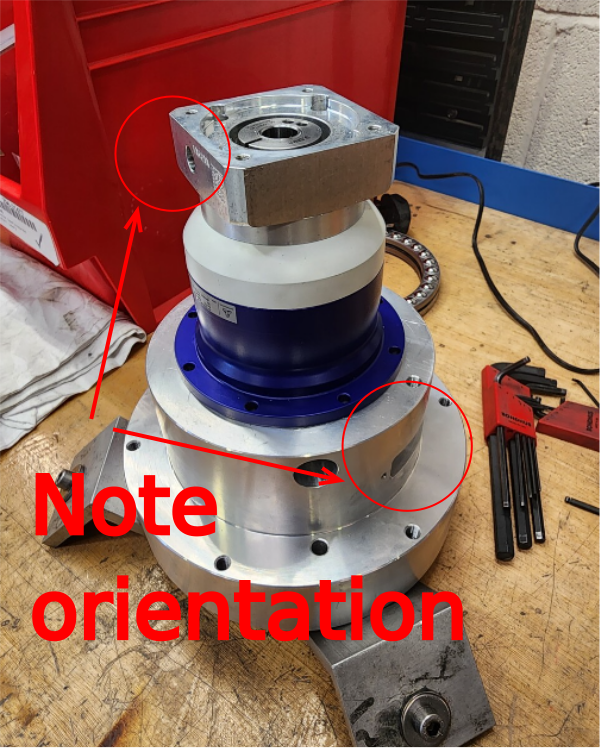

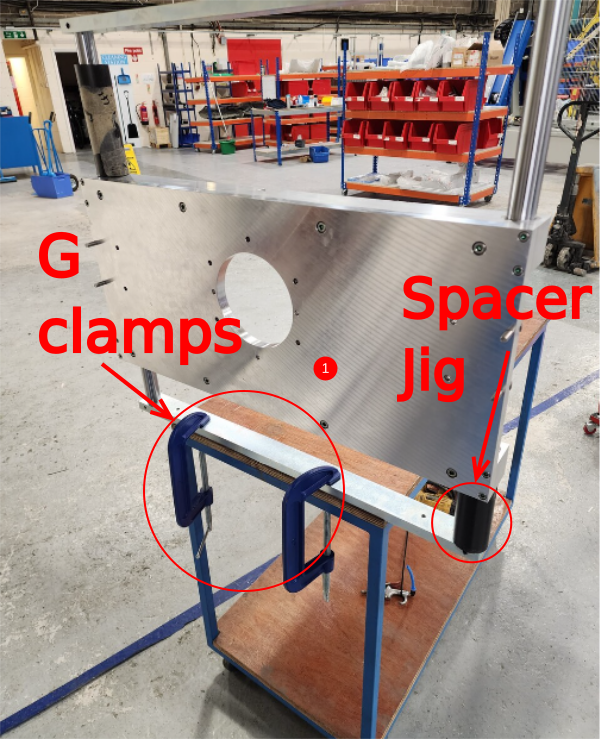

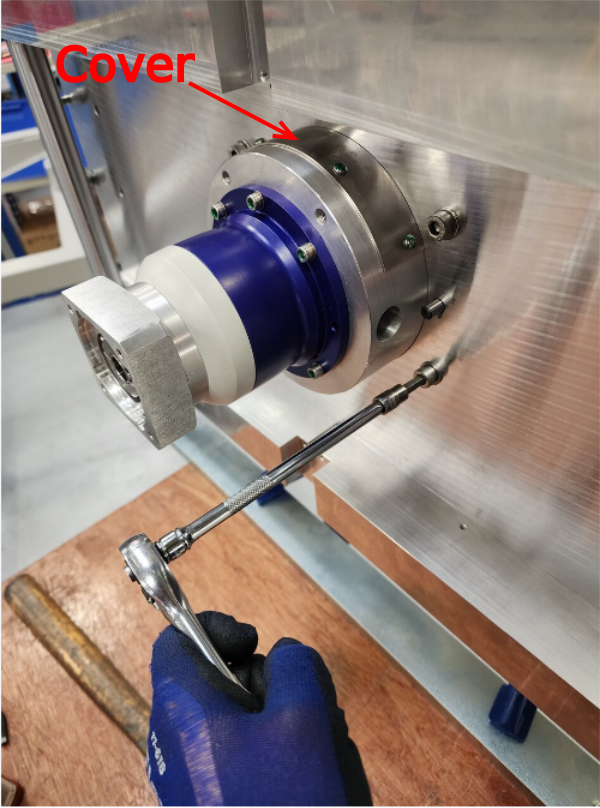

Étape 14 - Fit turntable to base

1 Mount Built base as shown, using clamps and spacer blocks

2 Insert built turntable, orientated as shown . Fix with M8 socket caps and A form washers (sizes required)

3 Fit D0010796 Turntable Housing Cover using m4 x 12 button sockets (size required)

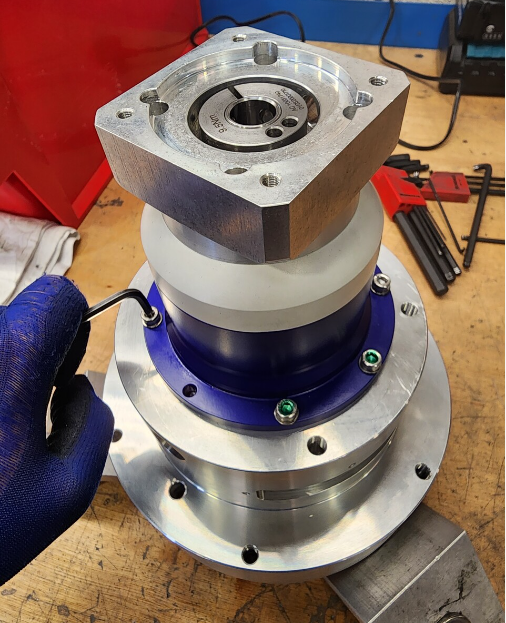

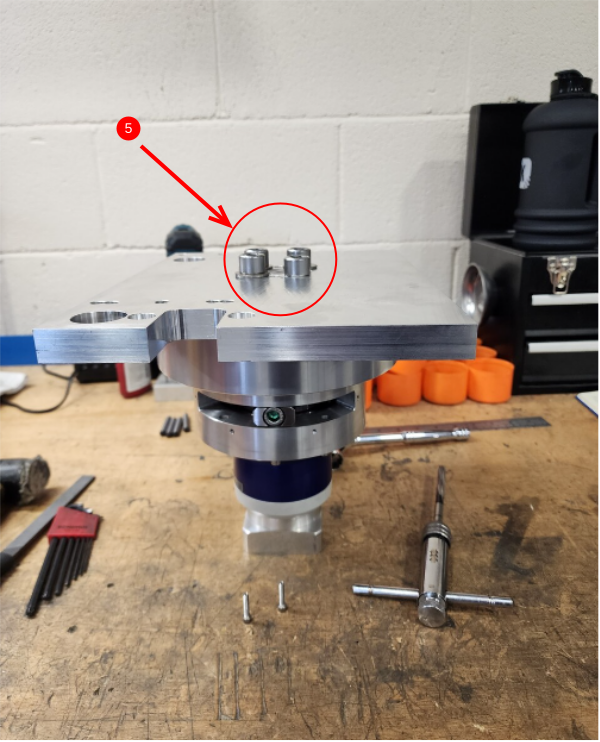

Étape 15 - Fit Servo motor

1 Remove key and Degrease thoroughly spindle on C0001122K Servo Motor: Beckhoff AM8032-1E10 (Keyed)

2 Insert motor into gearbox and orientated servo plug as indicated

Affix motor to gearbox using M5 socket caps (size required)

3 Tension friction coupling to 9.5nm using torque wrench , then insert gearbox bung . Write torque setting on indicated face

4 Fit protection shroud

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português