Fitment of trunking to main frame

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Clean threads

- 4 Étape 3 - Mount lower trunking

- 5 Étape 4 - Assemble upright 1

- 6 Étape 5 - Assemble upright 2

- 7 Étape 6 - Drill assembled uprights to frame vertical face

- 8 Étape 7 - Fix horizontal section

- 9 Étape 8 - Assemble upright 3 and 4

- 10 Étape 9 - Fix to frame

- 11 Étape 10 - Cut lids

- 12 Étape 11 - Fit wire basket to rear

- 13 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Standard HSS drill set

Standard tap set

Disc cutter

Parts Required

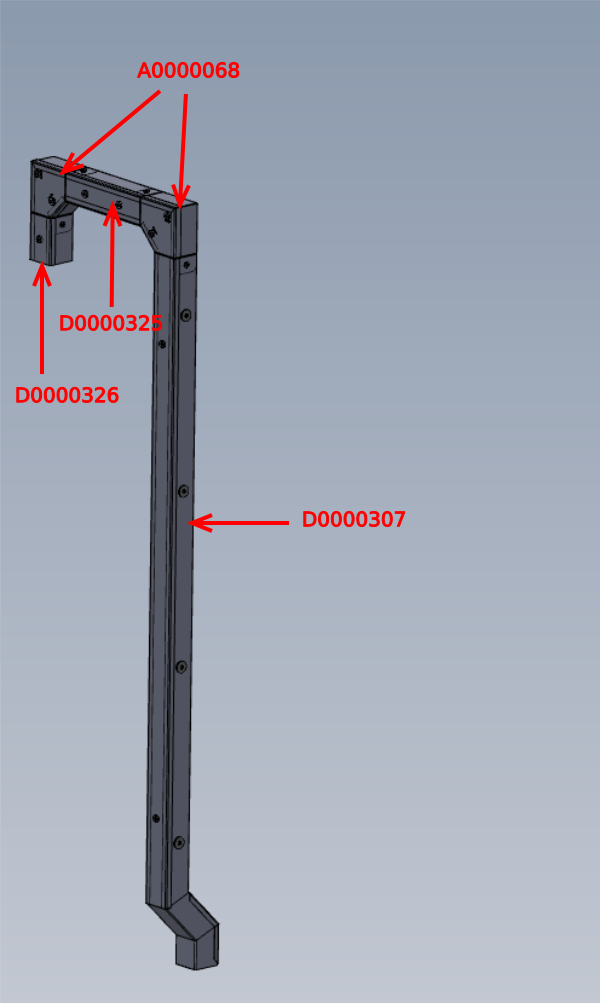

A0000068 Top lid gusset 50x50 bend 90° Armorduct x 4

A0001065 wire basket x 0.5

A0001061 Retainer: Wire Basket Cable Tray x 2

D0000301 M/C centre trunking front lower ZX4 x 1

D0000305 M/C centre trunking rear lower ZX4 x 1

D0000306 M/C centre trunking infeed lower (D8736) x 1

D0000307 M/C centre trunking infeed front offset x 1

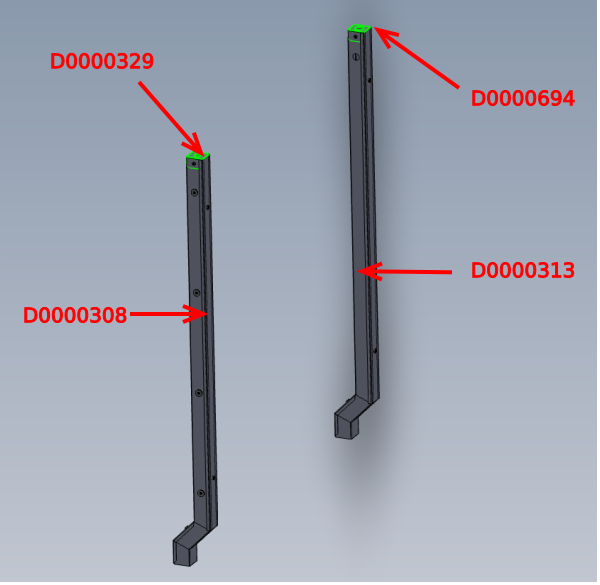

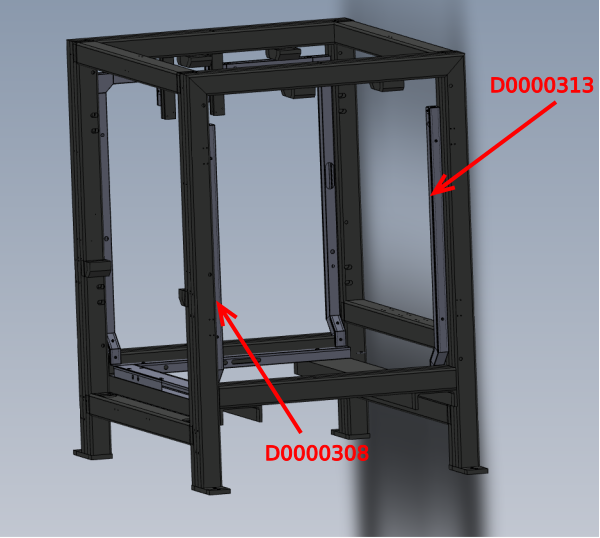

D0000308 M/C centre trunking infeed rear offsetx 1

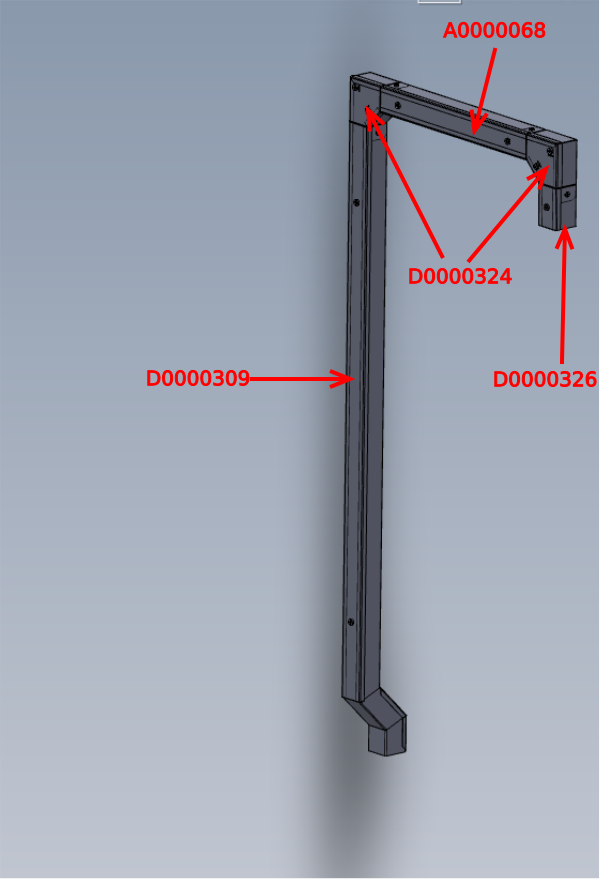

D0000309 M/C centre trunking outfeed front offset x 1

D0000313 M/C centre trunking outfeed rear offset x 1

D0000324 M/C centre trunking outfeed front upper x 1

D0000325 M/C centre trunking infeed front upper x 1

D0000326 M/C centre trunking front drop x 2

D0000327 M/C centre trunking outfeed lower x 1

D0000329 M/C centre trunking infeed rear end x 1

D0000694 M/C centre trunking outfeed rear end x 1

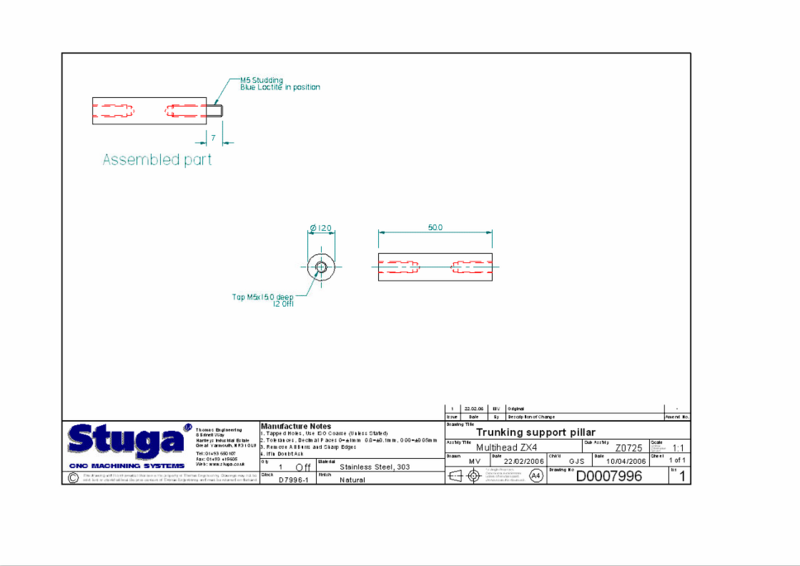

D0007996 Trunking support pillar x 1

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Clean threads

All holes on machining centre frame require threads cleaning to remove debris from coating process

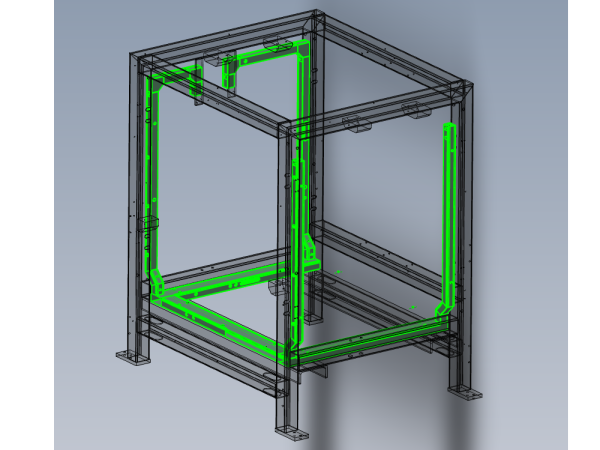

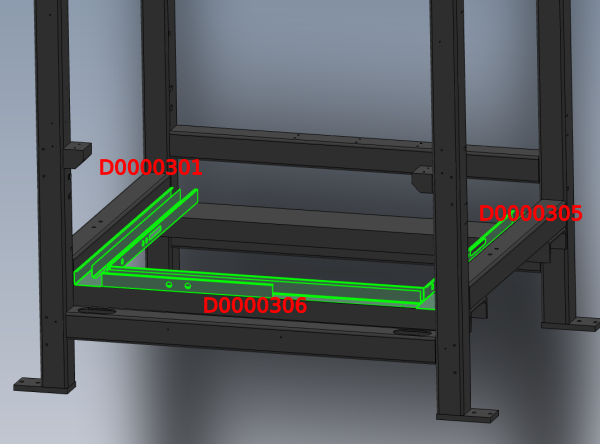

Étape 3 - Mount lower trunking

Use the following parts

D0000301 M/C centre trunking front lower ZX4 x 1

D0000306 M/C centre trunking infeed lower (D8736) x 1

D0000305 M/C centre trunking rear lower ZX4 x 1

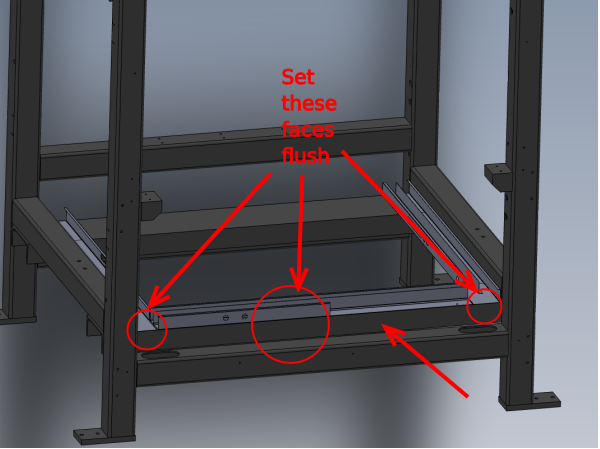

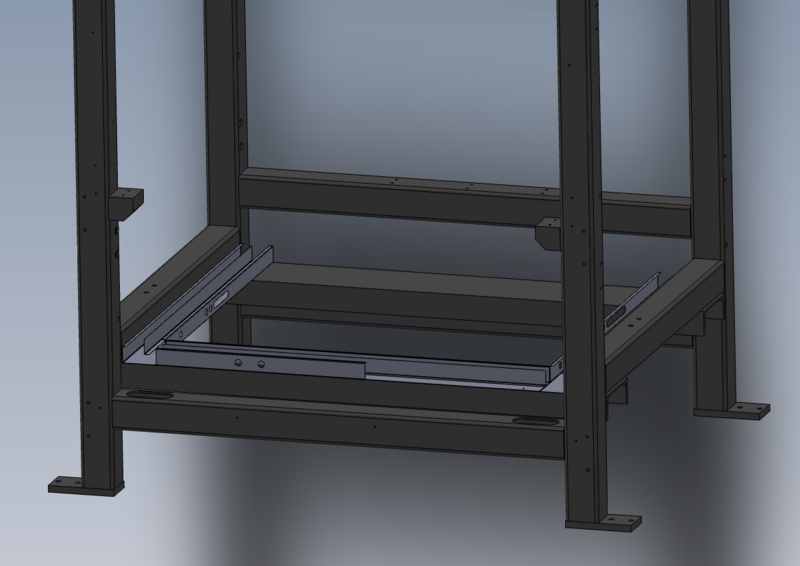

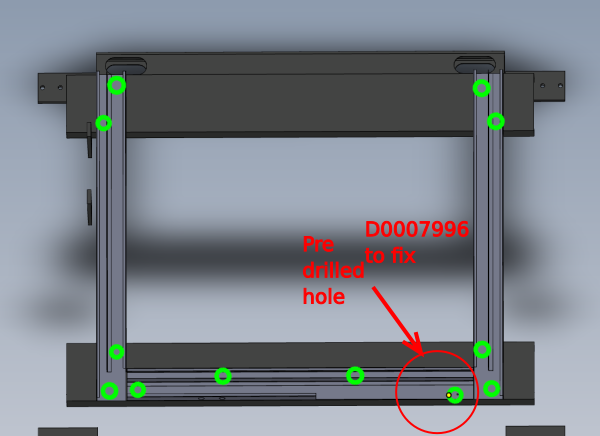

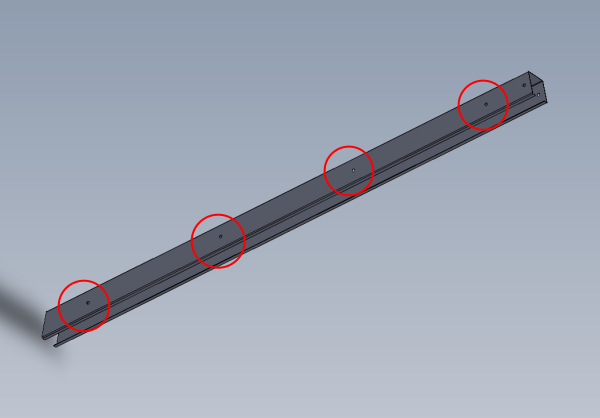

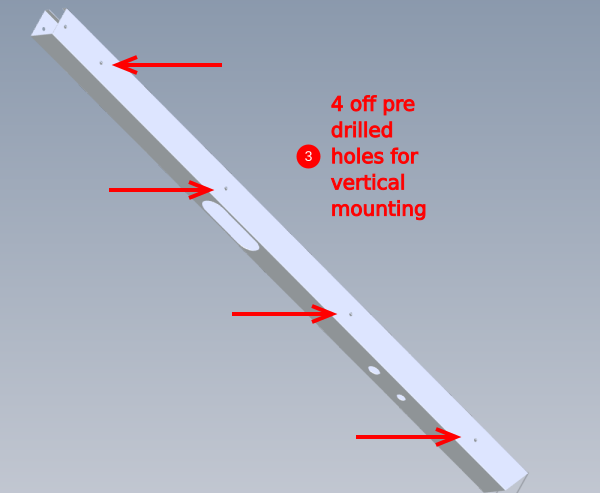

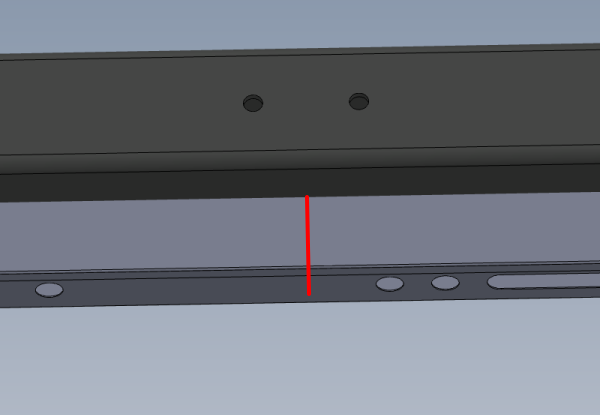

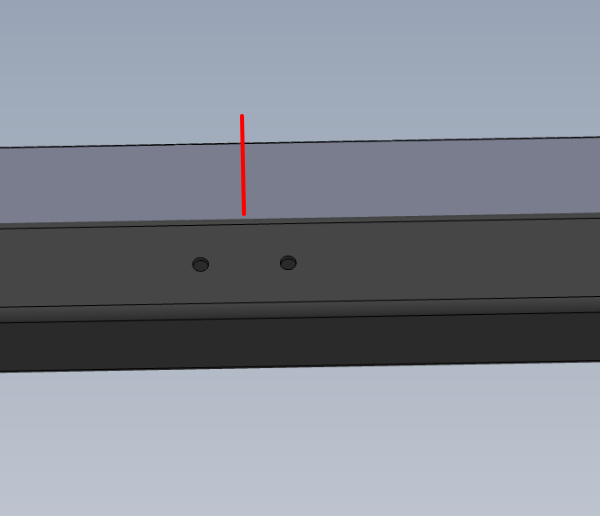

Add 6mm clearance holes to each piece of trunking as indicate to allow M5 fixings to be added to frame frame . Note hole indicated is pre drilled in trunking

Once clearance holes are added to trunking, position trunking as shown and drill and Tap M5 . Use M5 x 10 button sockets and penny washers to fix.

On the pre drilled hole use D0007996 Trunking support pillar x 1 to fix to frame

Once fixed, refit trunking lids to mounted sections

Étape 4 - Assemble upright 1

Bench assemble trunking as shown

Enlarge holes indicated to 7mm diameter

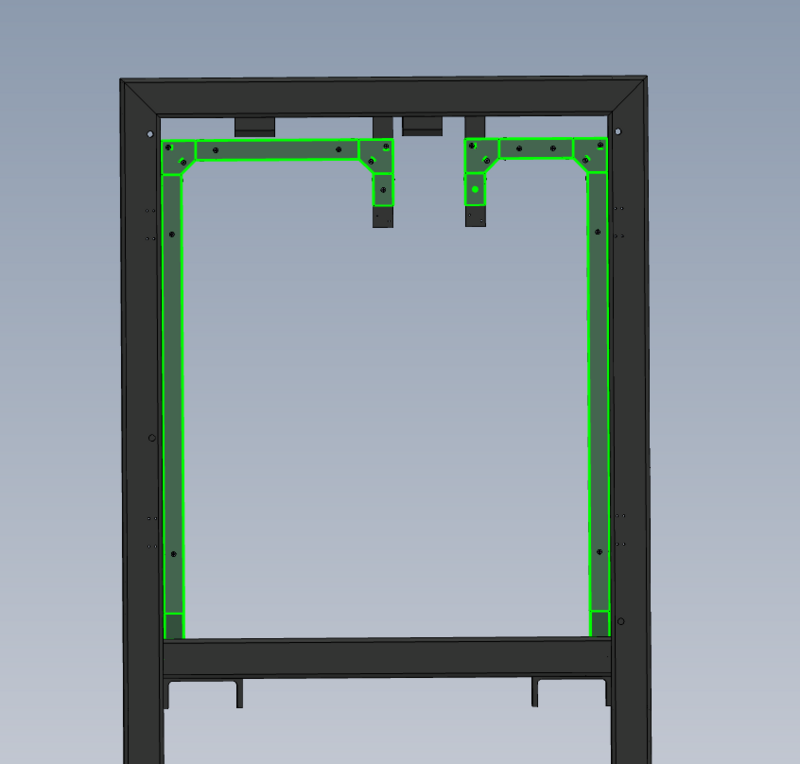

Étape 6 - Drill assembled uprights to frame vertical face

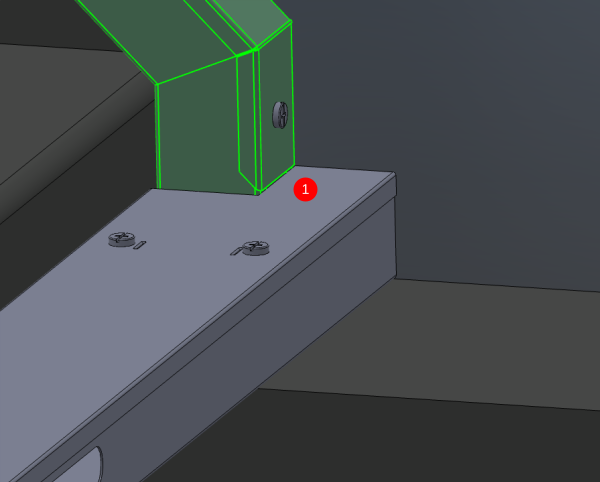

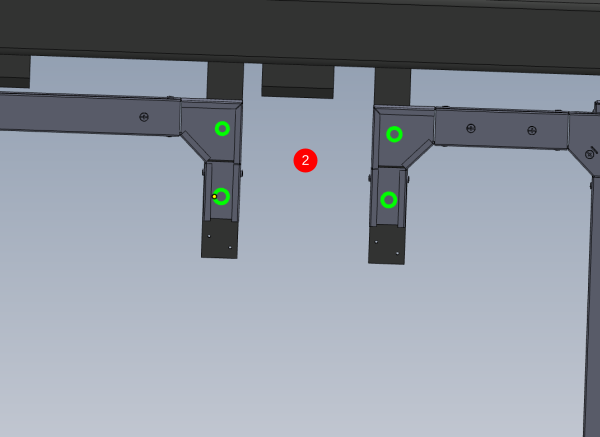

Position as shown

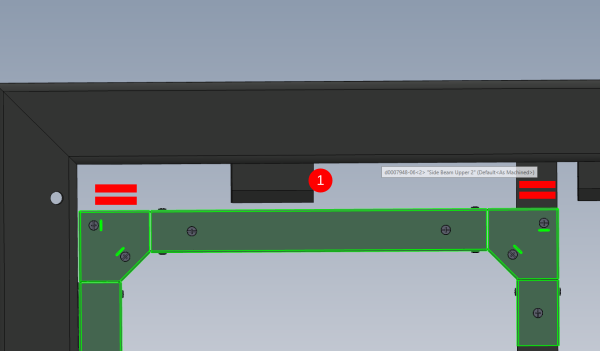

1 Align to lower trunking cutout

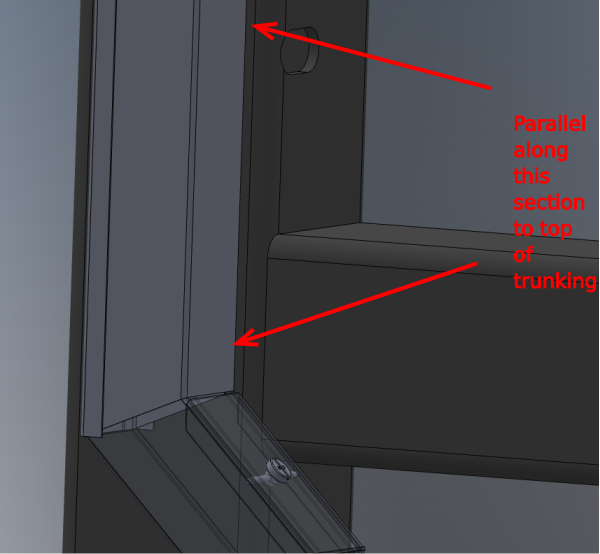

2 Ensure indicated face is parallel along upright

3 Mark off through trunking and then drill 4 off M6 tapped holes into frame

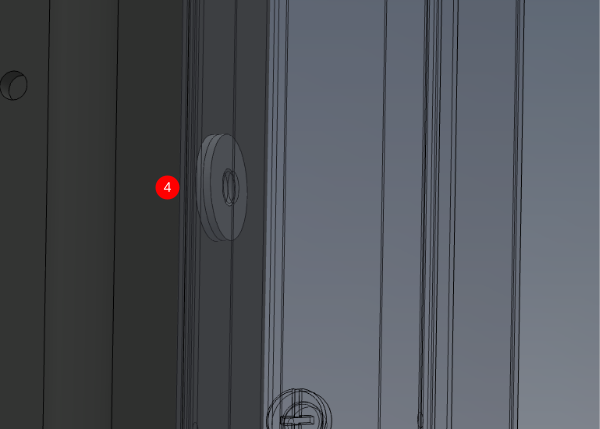

4 Secure trunking to vertical face using M6 hex sets and penny washers . Use a M6 motor plate between trunking and frame to space trunking away from frame to allow lid fitment

Repeat for both assembled uprights

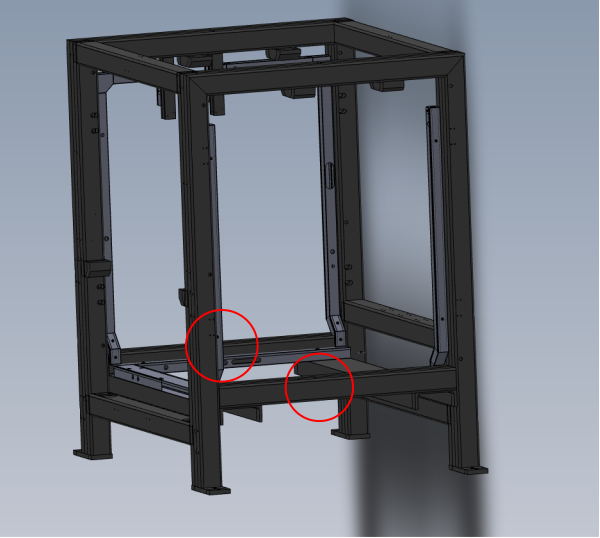

Étape 7 - Fix horizontal section

1 Ensure indicated faces are set to equal measurement

2 Drill 4 off indicated holes to secure trunking to vertical frame drops.

Drill trunking 6mm diameter clearance

Tap vertical drops M5

Secure with M5 x 10 button sockets and penny washers

Étape 10 - Cut lids

Use disc cutter to cut lids as indicated

Mark position on machine

Remove and cut

Refit

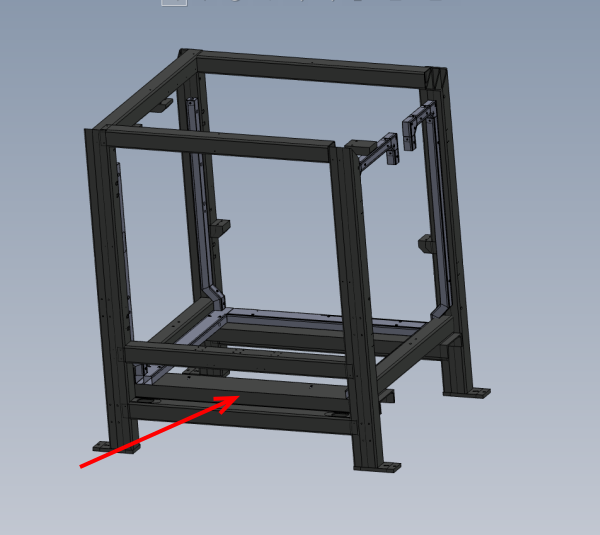

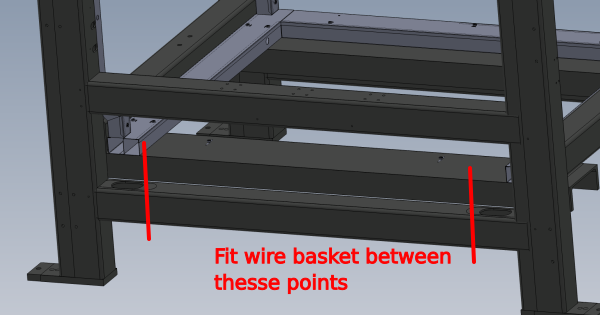

Étape 11 - Fit wire basket to rear

PHOTOS REQUIRED

Cut A0001065 wire basket to fit between indicated section. Use 2 off A0001061 Retainer: Wire Basket Cable Tray to fix ,these require drilling and tapping M6

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português