Bench assembly instructions for z axis components

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Clean Threads

- 4 Étape 3 - Assemble support cylinder 1

- 5 Étape 4 - Assemble support cylinder 2

- 6 Étape 5 - Assemble tensioners

- 7 Étape 6 - Check fit of D0001926

- 8 Étape 7 - Fit bearing

- 9 Étape 8 - Tension drive coupling

- 10 Étape 9 - Finalise drive coupling

- 11 Étape 10 - Finalise idler coupling

- 12 Étape 11 - Check fit of leadscrew to coupling

- 13 Étape 12 - Check bearing fit

- 14 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Emery tape

Standard HSS drill set

Hand reamer

Standard tap set

Part Required

B0000086 Ball Bearing 15 D 32 D 9 Long + seals x 4

B0000139 Double Angular Bearing 20 D 47 D 20.6 Long + seals x 2

B0000351 Bearing 40mm O/D 17mm I/D 17.5mm Wide x 2

C0001122K Servo Motor: Beckhoff AM8032-1E10 (Keyed) x 1

D0001926 Servo Drive Coupling M20 (Ø14mm) Beckhoff x 1

D0006501 Z Leadscrew Sleeve x 2

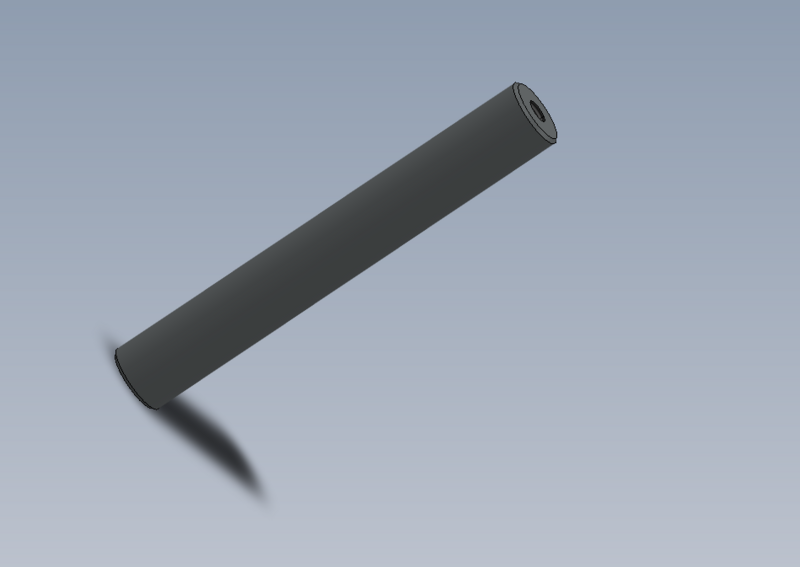

D0007629 Cylinder rod Extension x 4

D0007732 Sprocket Idler Shaft x 2

D0007733 Sprocket Mounting Block x 2

D0008090 Retaining Collar x 1

H0007715 Z Sprocket 33 Teeth 3/8'' pitch x 2

H0007790 Leadscrew Z(Includes Re-balling) x 2

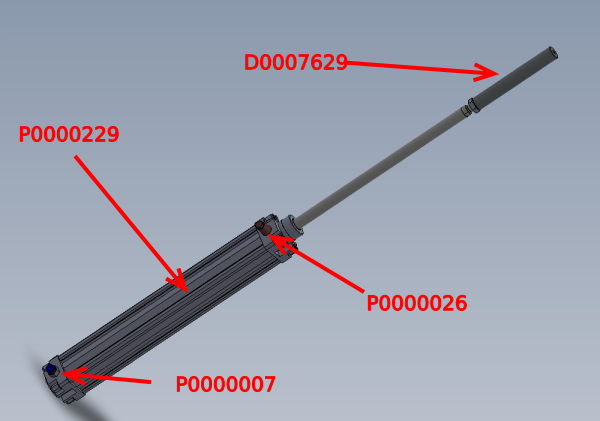

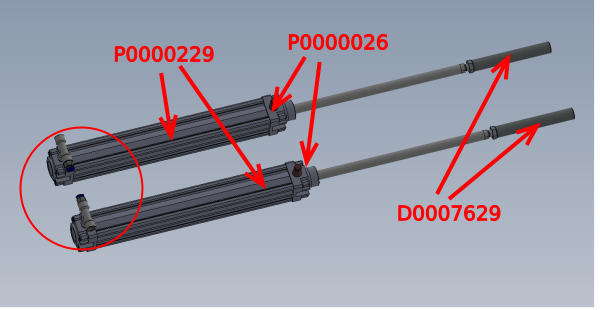

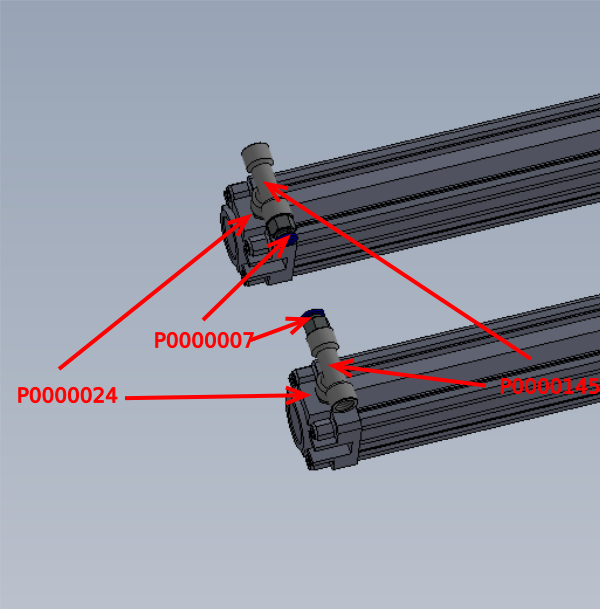

P0000007 Straight Adaptor 6mm - 1/8 BSP tapered thread x 2

P0000010 Elbow Adaptor 6mm - 1/8 BSPT (Taper thread) x 2

P0000023 Fitting: Hex Nipple 1/8 BSP x 2

P0000024 Fitting: Hex Nipple 1/4 BSP x 2

P0000026 Silencer 1/4 BSP x 4

P0000051 Fitting: Straight Adaptor 6mm - 1/4 BSPT x 4

P0000140 Fitting: Quick Exhaust Valve 1/8" x 2

P0000145 Tee-Equal 1/4BSP Galvanised x 2

P0000200 Elbow Adaptor 6mm - M5 x 2

P0000229 Pneumax VDMA 40 x 300 Magnetic x 4

P0001038 Fitting: SMC 1/8" BSP to Ø6mm Elbow White x 4

P0001174 Fitting: Pilot Check Valve 1/4" (Flow & ZX) x 2

Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 4 - Assemble support cylinder 2

Assemble a pair of cylinder assemblies as shown

PHOTOS REQUIRED

additionally fitted parts are

P0001038 Fitting: SMC 1/8" BSP to Ø6mm Elbow White x 4

P0001174 Fitting: Pilot Check Valve 1/4" (Flow & ZX) x 2

P0000140 Fitting: Quick Exhaust Valve 1/8" x 2

P0000200 Elbow Adaptor 6mm - M5 x 2

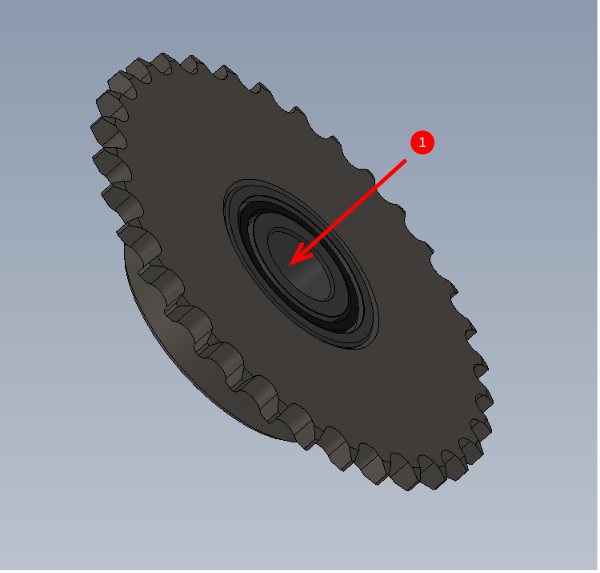

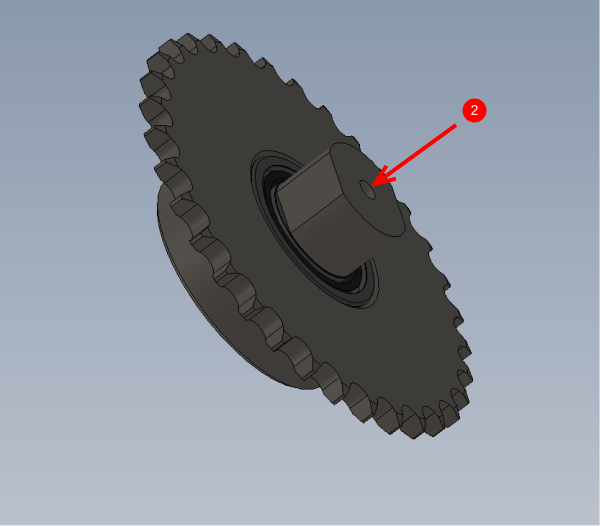

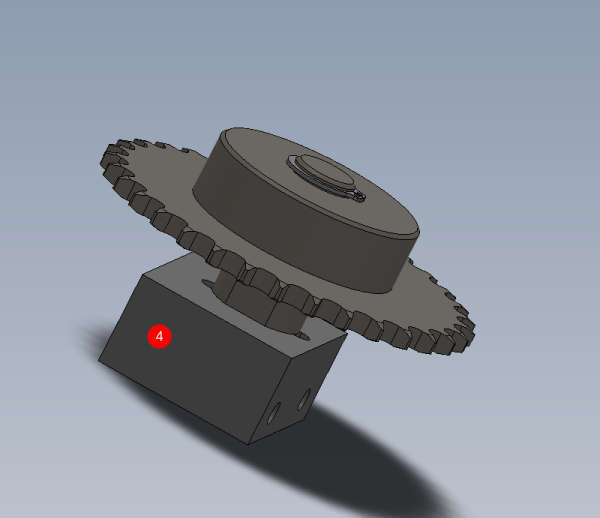

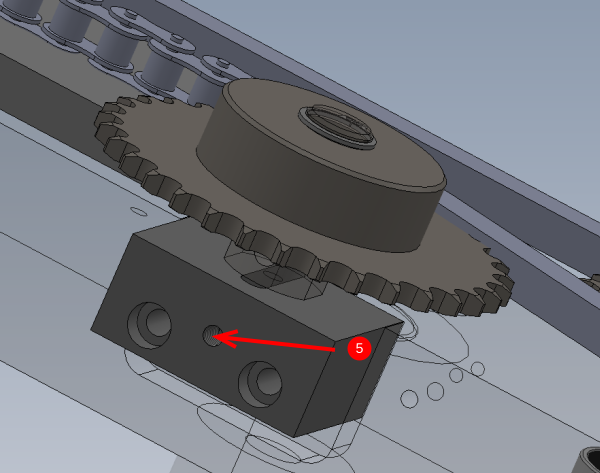

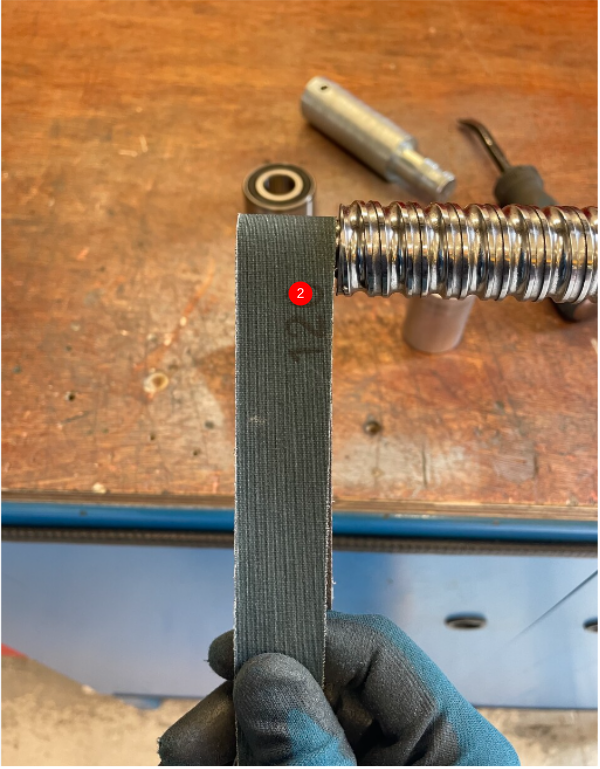

Étape 5 - Assemble tensioners

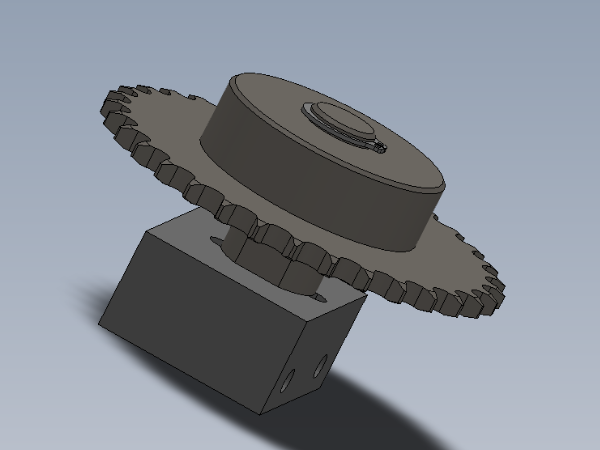

2 off

1 Press B0000351 Bearing 40mm O/D 17mm I/D 17.5mm Wide into H0007715 Z Sprocket 33 Teeth 3/8'' pitch . Observe fit, if loose solvent to degrease and apply bearing fit. If tight inspect drawing and check bore size

2 Press in D0007732 Sprocket Idler Shaft , again observing fit as above

3 Fit 16mm external circlip

4 Attach D0007733 Sprocket Mounting Block using M6 x 40 socket cap and heavy M6 washer (do not apply adhesive to this bolt )

5 Add M6 x 30 grubscrew and M6 standard nut to indicated face (picture required)

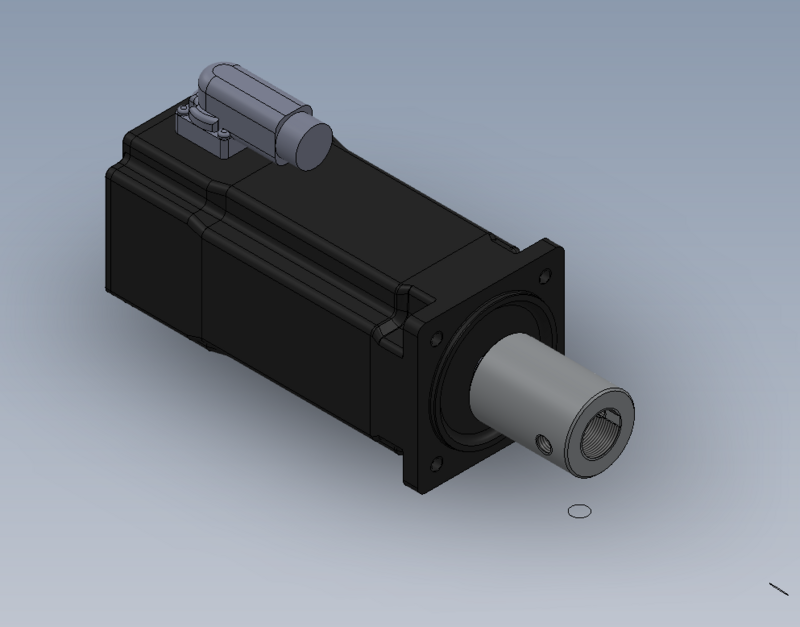

Étape 6 - Check fit of D0001926

Ensure D0001926 Servo Drive Coupling M20 (Ø14mm) Beckhoff x 1

fits onto C0001122K Servo Motor: Beckhoff AM8032-1E10 (Keyed) x 1

Fit should be a snug slide fit

Part can be reamed with hand reamer if fit is tight

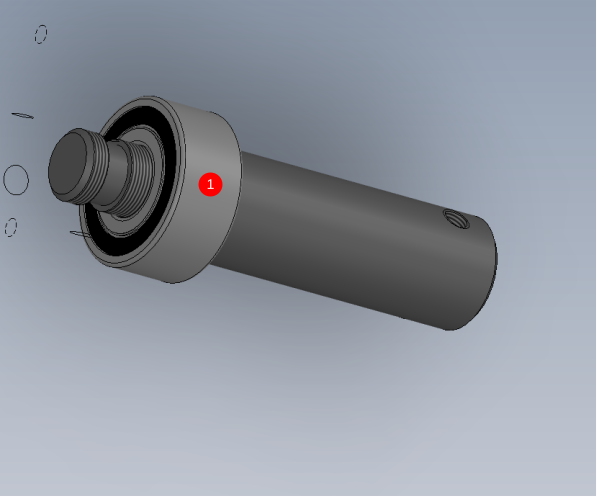

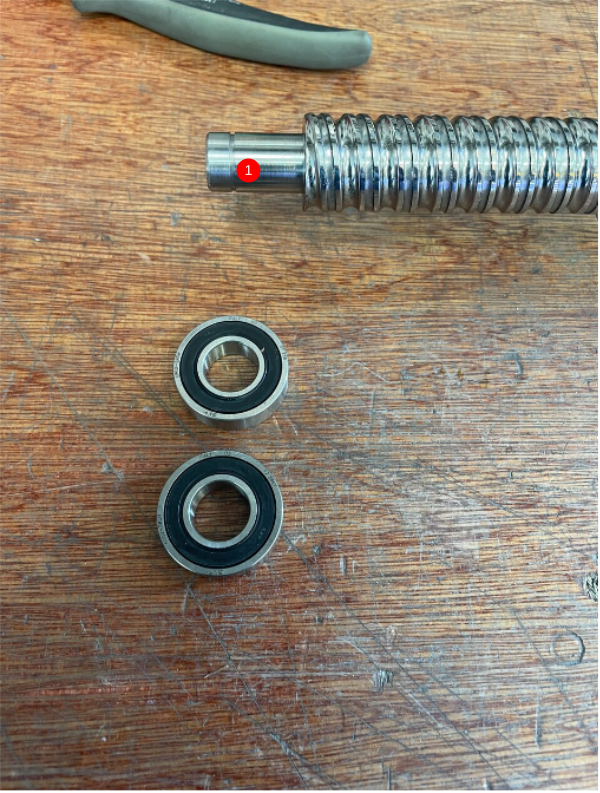

Étape 7 - Fit bearing

2 off

1 Check and adjust fit of B0000139 Double Angular Bearing 20 D 47 D 20.6 Long + seals onto D0006501 Y Leadscrew Sleeve

2 Fit should be a smooth press fit onto sleeve. Indicated face can be polished down with fine emery to obtain desired fit

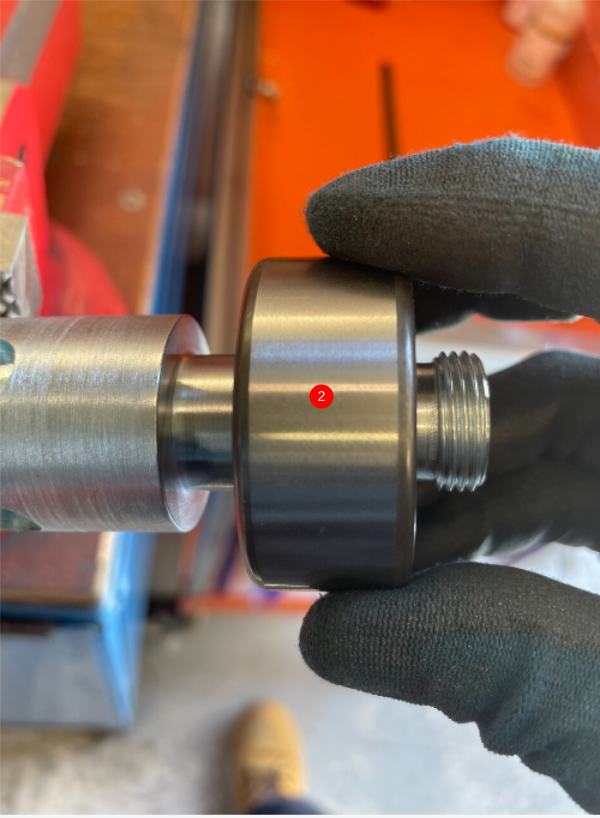

Étape 8 - Tension drive coupling

1 Add m8 socket caps as shown to hold assembly in vice

2 Use 2 off m8 long socket caps and Standard M8 nuts and lock onto drive coupling .

Tension using long M8s as leverage

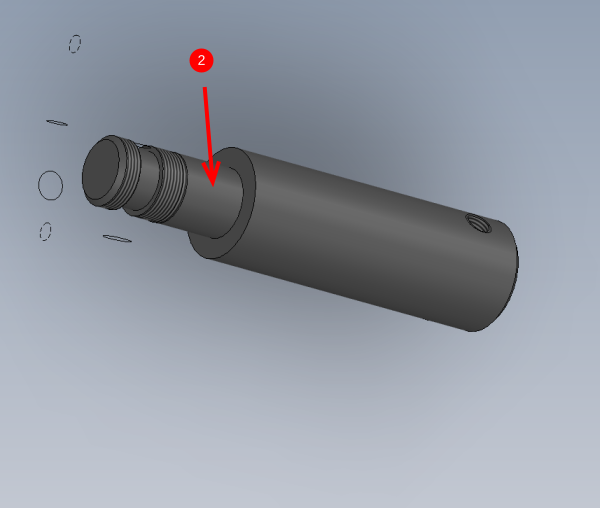

Étape 9 - Finalise drive coupling

1 off

1 Remove 1 off Long M8 socket cap and tension an M8 x 12 kcp grubscrew into the hole (do not add adhesive )

2 Remove second Long M8 socket cap and dimple inner shaft using 6.8mm drill

Clean with compressed air and add M8x 8 kcp with adhesive and tension

3 Remove m8 x 12 kcp grub screw and repeat above step

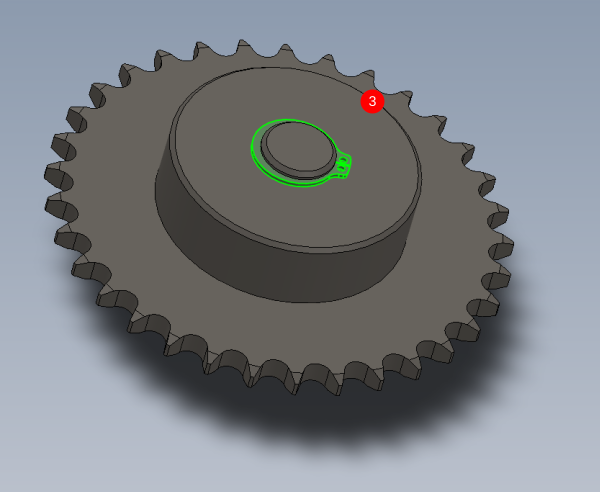

Étape 10 - Finalise idler coupling

1 off

Use the same steps above to assemble idler drive coupling as shown using D0008090 Retaining Collar x 1

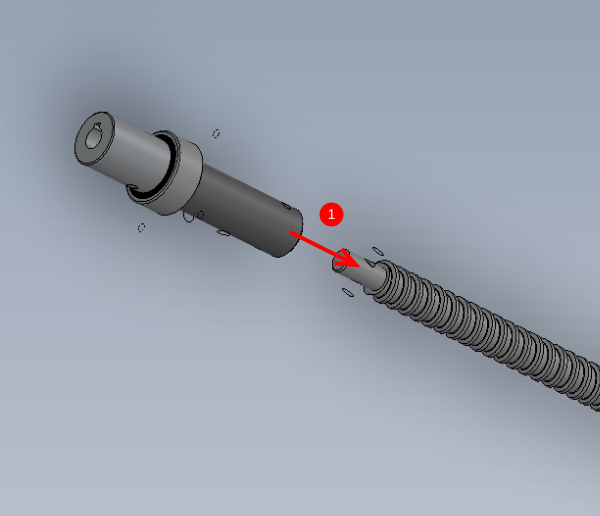

Étape 11 - Check fit of leadscrew to coupling

2 off

1 Check fit of coupling to leadscrew H0007790 Leadscrew

2 Use reamer / Emery tape if fit is tight

Étape 12 - Check bearing fit

1 Check bearing B0000086 Ball Bearing 15 D 32 D 9 Long + seals fit is acceptable on leadscrew H0007789

2 Adjust with emery tape if fit is tight

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português