Pneumatic connections and cable information

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Attach tie bases to frame

- 4 Étape 3 - Connect Safety gate cylinder feeds

- 5 Étape 4 - Cut Siren cable

- 6 Étape 5 - Create loom

- 7 Étape 6 - continue loom

- 8 Étape 7 - connect push eject cylinder feeds

- 9 Étape 8 - Continue looms

- 10 Étape 9 - Coil cable loom

- 11 Étape 10 - Valve bank connections

- 12 Étape 11 - Loom quality

- 13 Étape 12 - Pneumatic operations check

- 14 Commentaires

Introduction

Tools Required

Standard hex key set

6mm black Air pipe

Pipe identification numbers

Pneumatic Pipe cutters

W0001002 cable (from consumable stock )

Parts Required

M0001127 Cable Tie Base (m6) (from consumable stock)

P0000046 Fitting: 'Y' Adaptor 6mm x 2

Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

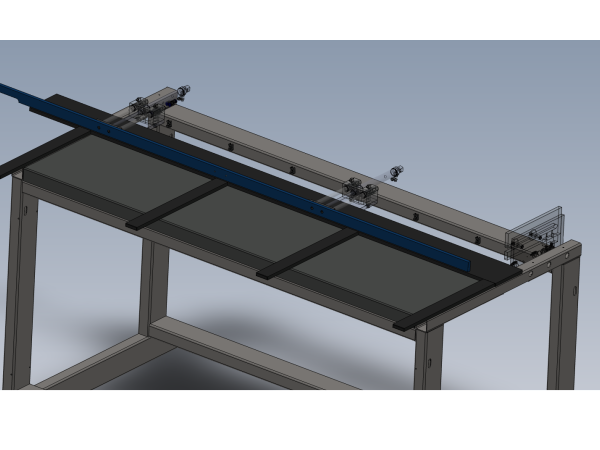

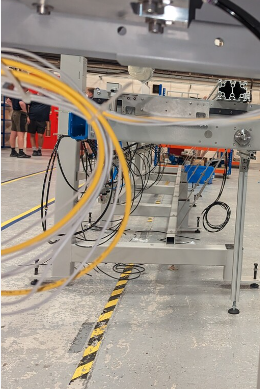

Étape 2 - Attach tie bases to frame

Attach 7 off M0001127 Cable Tie Base (m6) as shown using M5 x 10 button sockets

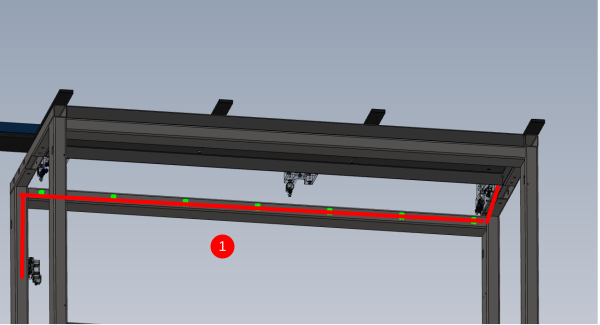

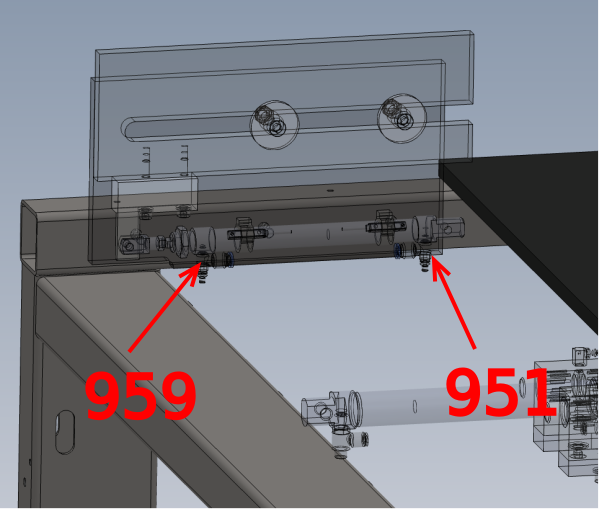

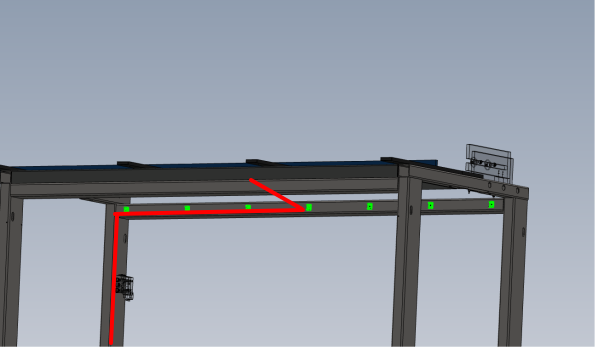

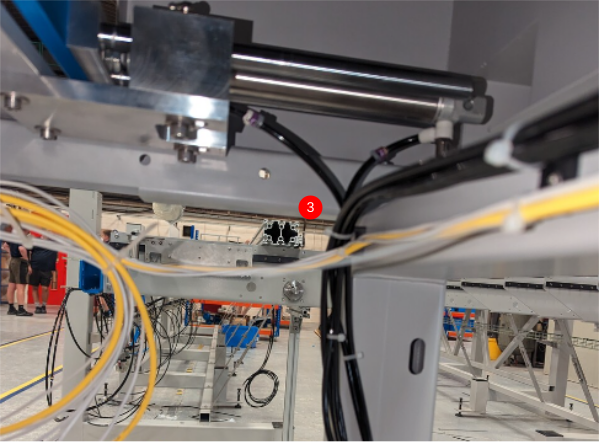

Étape 3 - Connect Safety gate cylinder feeds

Identification numbers

951

959

1 Cut 2 6mm black air pipes long enough to run the indicated route

2 Identify each pipe, one 951 and one 959

3 Connect pipes to gate as indicated and leave pipes to loom later

Étape 4 - Cut Siren cable

Cut Length of W00010002 cable to follow the route shown , and mark both ends clearly Y94

Étape 5 - Create loom

Start to create loom from safety gate

Attach to first tiebase and separate pneumatic cables to top lug and cables to lower

Pipes 951 and 959, Y94 cable, and reed switches X189 and X190 should be loomed in as shown

Y94 should be left with enough length to connect to cut guard beacon when fitted

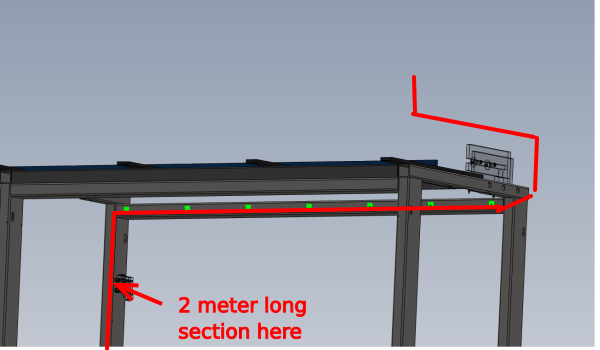

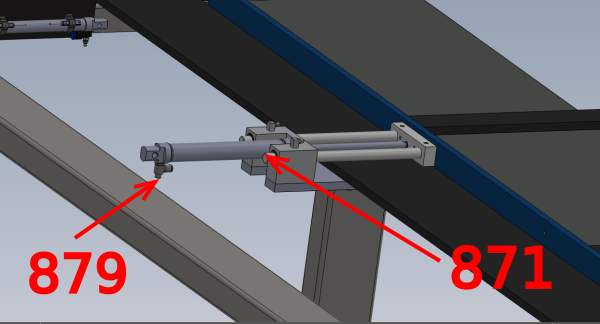

Étape 7 - connect push eject cylinder feeds

Cut 2 lengths of 6mm black airline at the right length to follow the indicated route

Pipe identifications

871 and 879

Connect pipes to indicated ports on cylinder

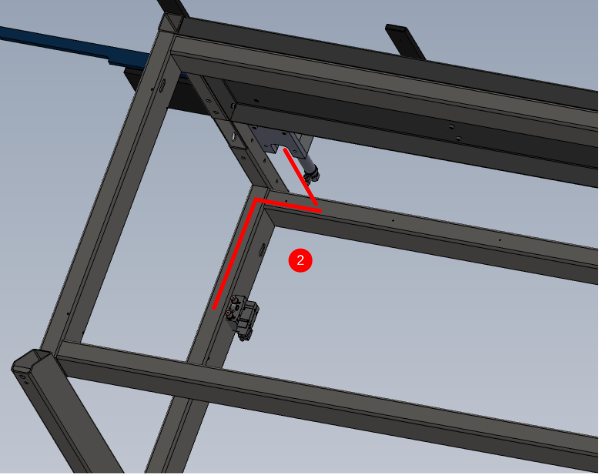

Étape 8 - Continue looms

1 Continue looms bring in the two pipes and continue to the next push cylinder assembly

2 Cut 2 more 6mm black air pipes to run the indicated route and identify and connect as the previous step

3 Add to loom and continue to end of frame

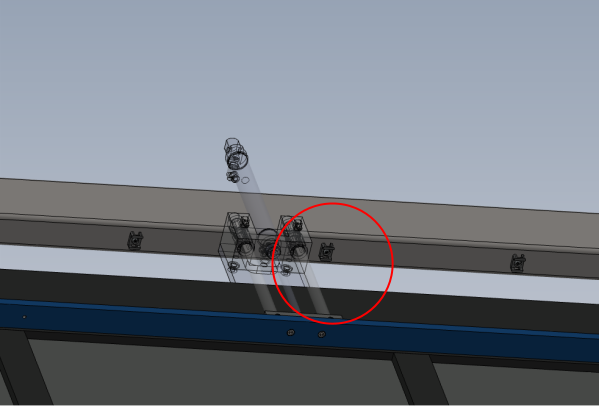

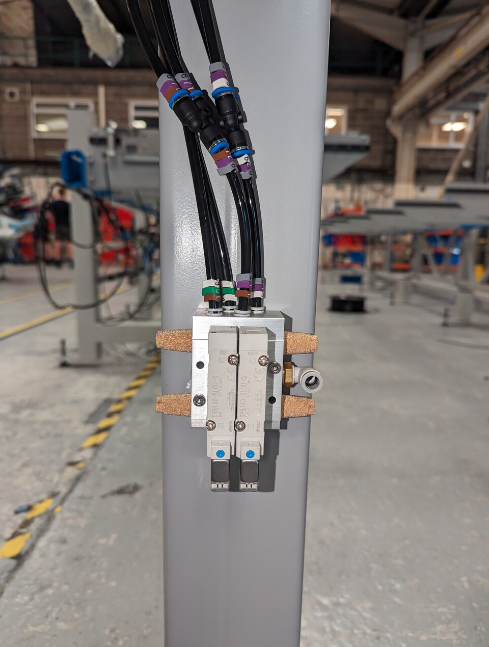

Étape 10 - Valve bank connections

1 Use P0000046 6mm y connection to connect pipes 879 together as shown

Use P0000046 6mm y connection to connect pipes 871 together as shown

2 Use 6mm black air pipe to connect each Y connector to valve bank .

Connect 871/9 to rightside valve.

Connect 871 to port A2 above valve

Connect 879 to port A4 above valve

3 Connect 951 to second valve. port A2

connect 959 to second valve, port A4

Étape 11 - Loom quality

Ensure all looms are correctly tethered to retention points , and are not twisted or buckled .

Ensure all breaks of pipe work are numbered for identification

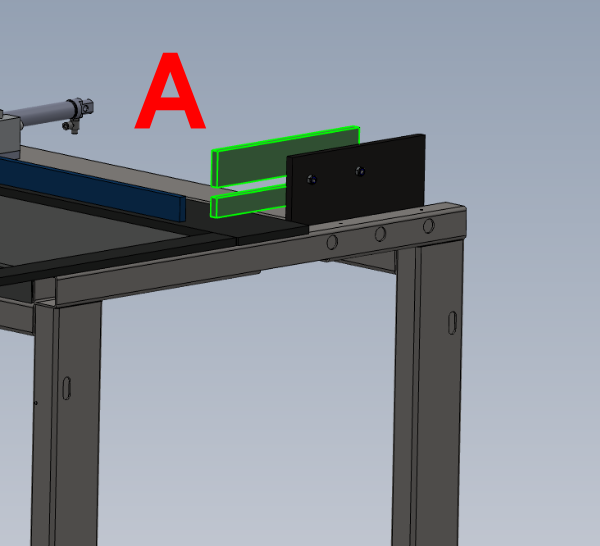

Étape 12 - Pneumatic operations check

1 Connect mains air to 8mm and purge system to mains pressure

2 Check for audible air leaks , and correct if found

3 Check home positions. With the air connected the following home positions should be checked

A Y95 Safety gate should be extended out

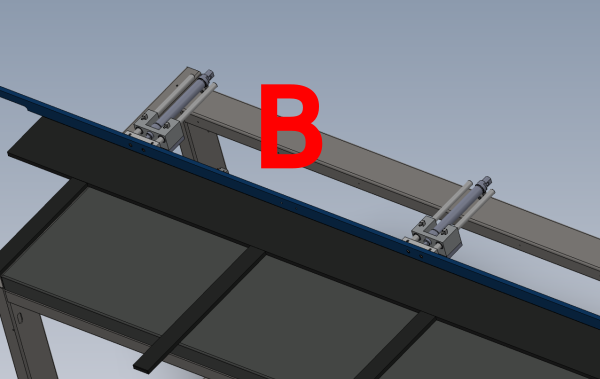

B Y87 Cylinder push should be retracted

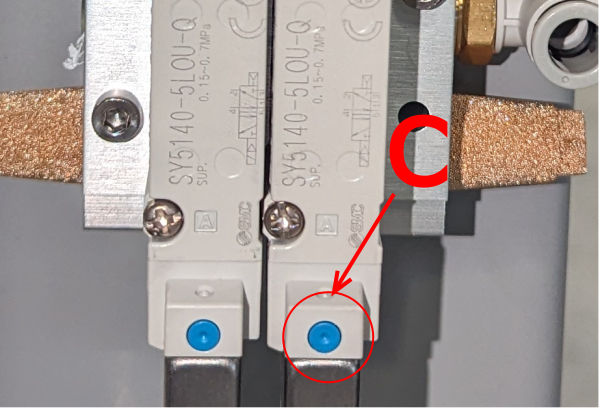

4 Manually fire valve on Y95 by pressing over ride button and holding in (C) check that cylinder moves and no air leaks are present when fired

Repeat for Y87 output

Remove air supply once testing is complete

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português