Installation and Alignment criteria for Autoflow Mk4

Sommaire

- 1 Introduction

- 2 Étape 1 - Machine Location/Position

- 3 Étape 2 - Module A Infeed table

- 4 Étape 3 - Levelling Datums

- 5 Étape 4 - Infeed Table Levelling Process

- 6 Étape 5 - Adjust remaining pads

- 7 Étape 6 - Position Machining/Saw unit

- 8 Étape 7 - level datums

- 9 Étape 8 - Set levels

- 10 Étape 9 - Finalise Position Machining centre X axis

- 11 Étape 10 - Finalise Position Machining Centre Y axis

- 12 Étape 11 - Finalise Machining centre height

- 13 Étape 12 - Adjust Centre support

- 14 Étape 13 - laser Alignment Height

- 15 Étape 14 - Laser Alignment Backfences

- 16 Étape 15 - Finalise Front guard Support

- 17 Étape 16 - Assemble JX Axis

- 18 Commentaires

Introduction

Information to clarify correct process for installation of J0001000H Autoflow Mk4

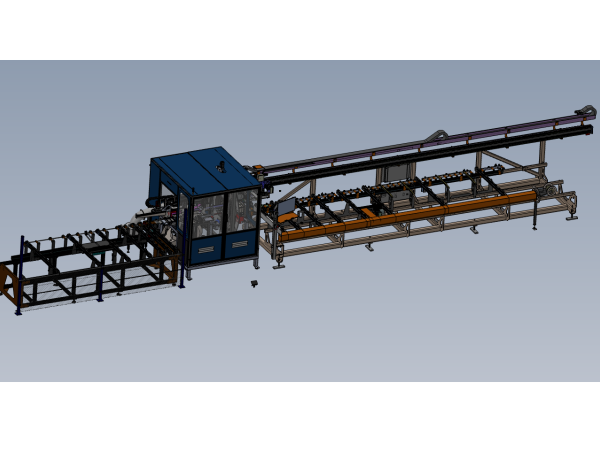

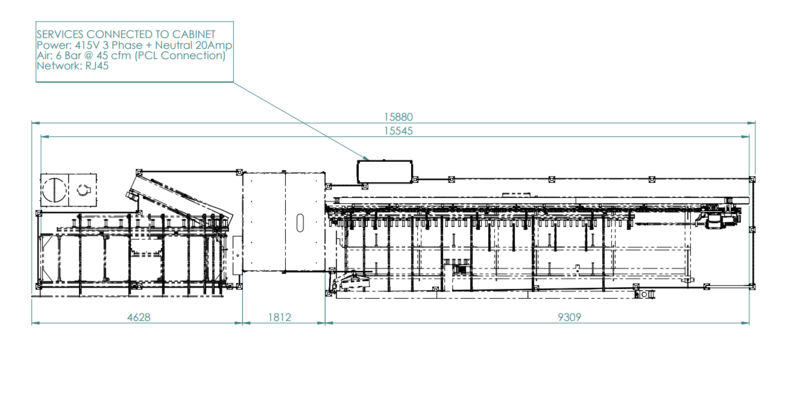

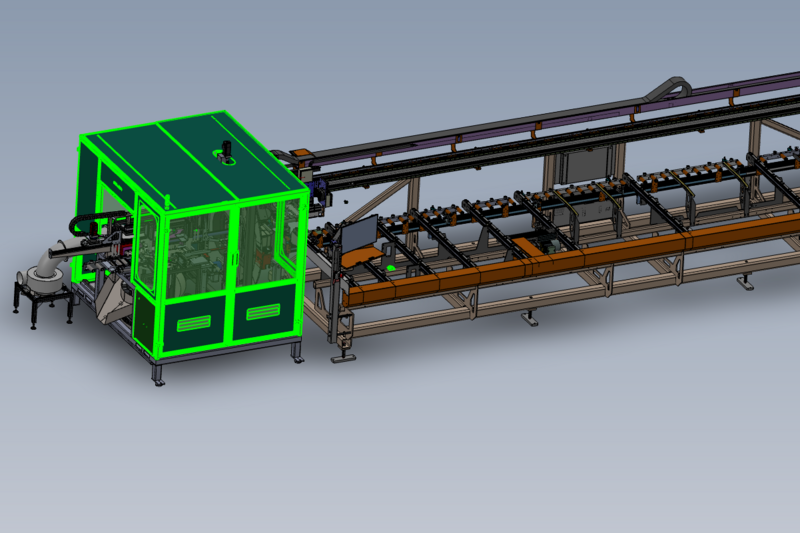

Étape 1 - Machine Location/Position

Use footprint drawing to determine machine location for installation

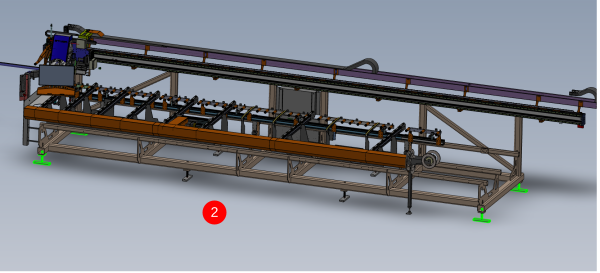

Étape 2 - Module A Infeed table

Identify correct position for installation of Infeed frame. Ensure consideration is given to walkways and installation of machine guarding at later part of installation

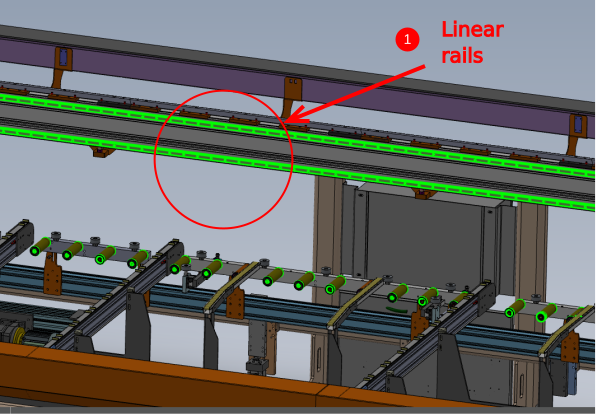

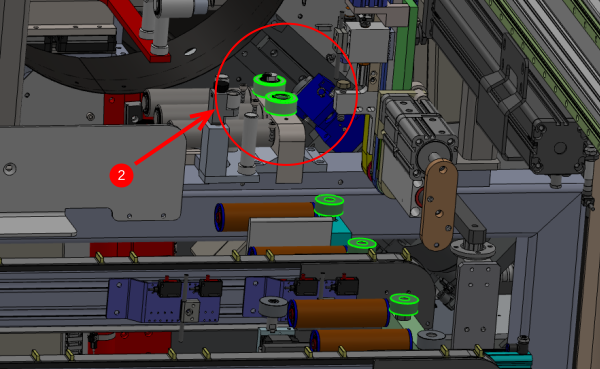

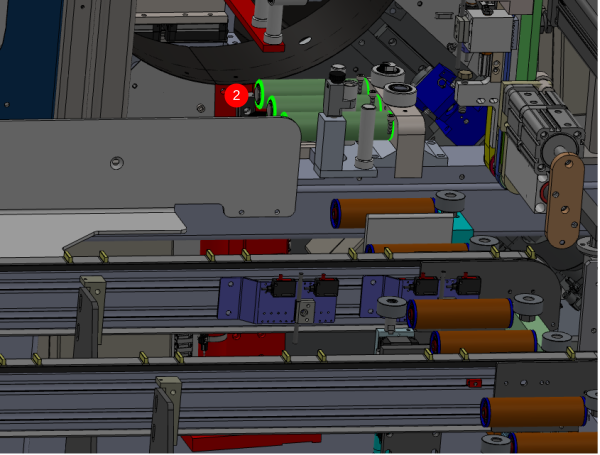

Étape 3 - Levelling Datums

Indicated are the leveling datums for the Infeed table

X Axis as indicated by 1

Y axis as indicated by 2

Étape 4 - Infeed Table Levelling Process

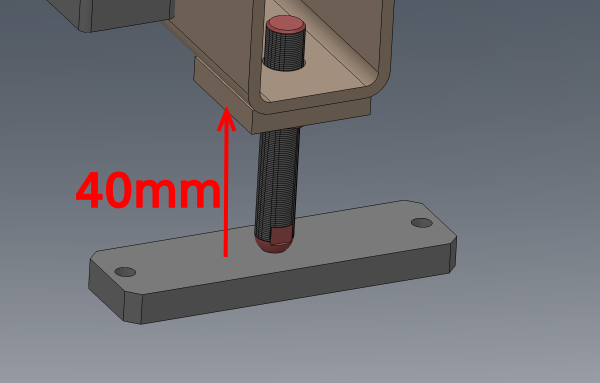

1 Ensure indicated central 4 adjusting bolts/ pads are lifted out of the way , so they do not impede the levelling process

2 Set gap of indicated pads to the starting measurement shown of 40mm

3 Adjust Y axis position to read level at indicated points using pads indicated in number 2 only

4 Adjust X axis position using same pads as previous,and ensure Y axis level is not compromised by adjusting pads in pairs

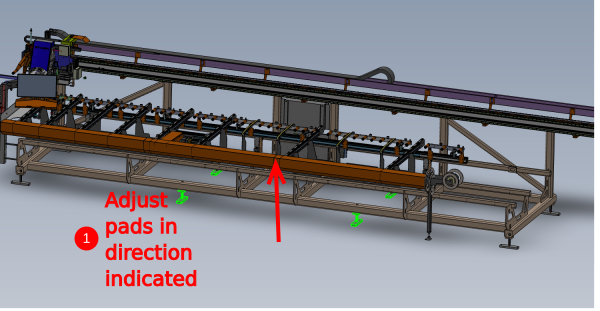

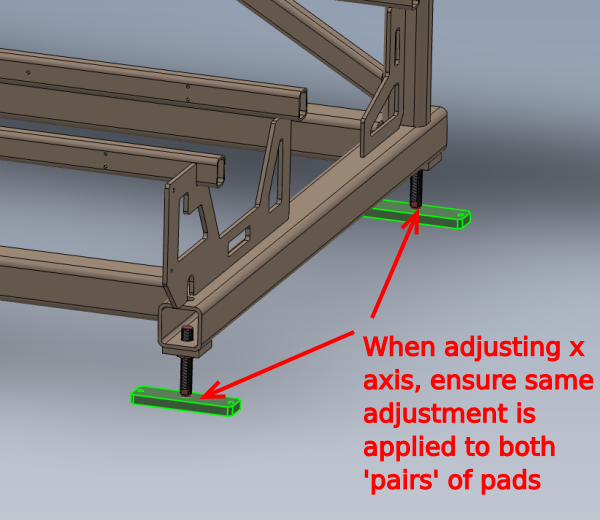

Étape 5 - Adjust remaining pads

Remaining pads should now be adjusted down to touch floor.

Ensure no additional pressure is applied to they which will cause levels to be affected

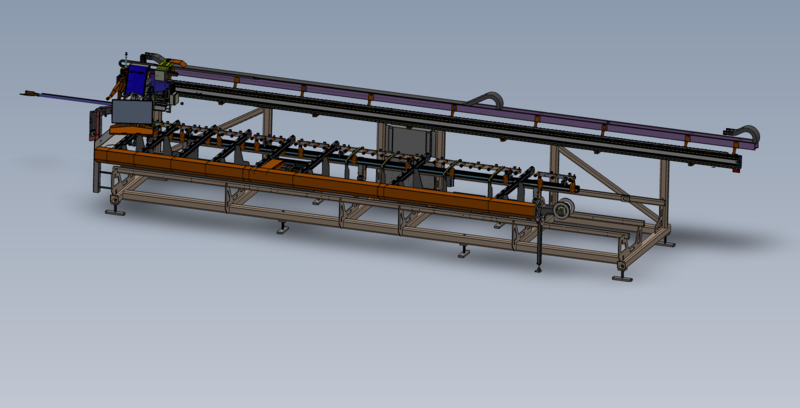

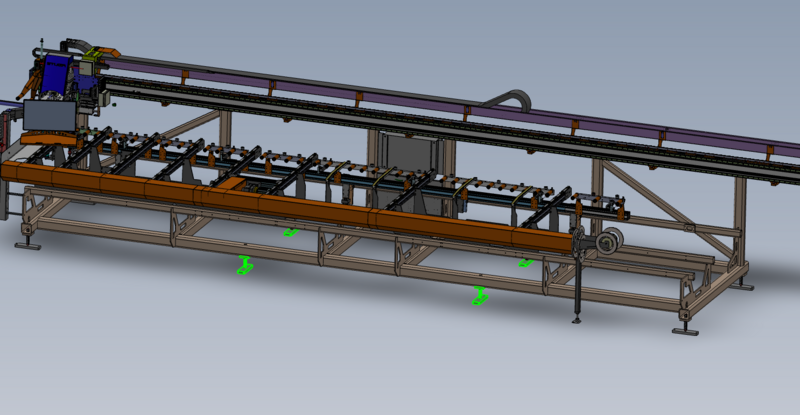

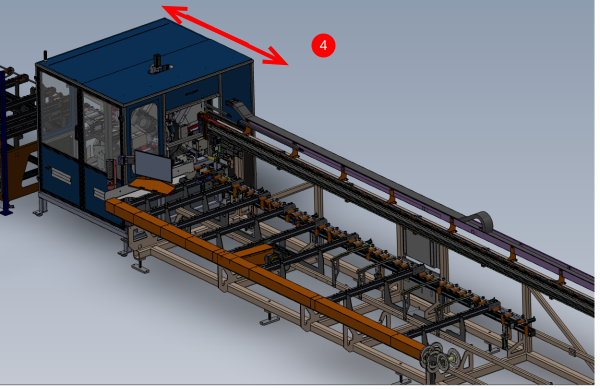

Étape 6 - Position Machining/Saw unit

Position Module B/F into the approximate area according to the floor plan

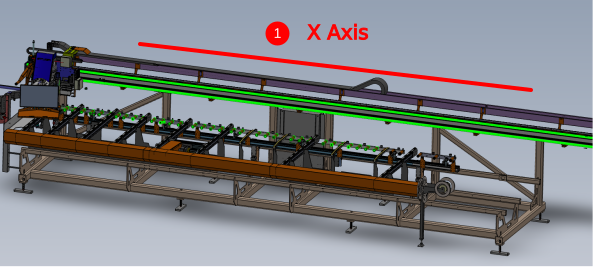

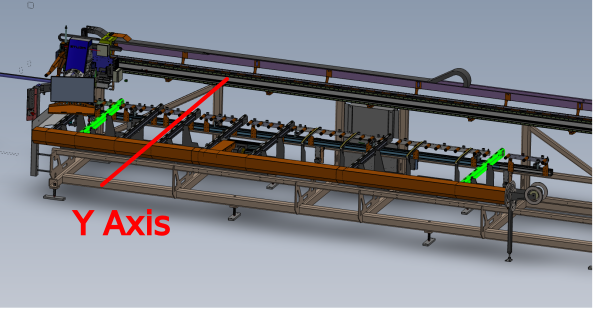

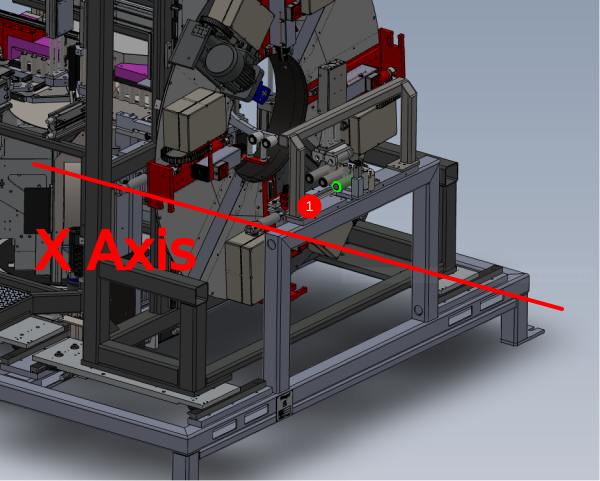

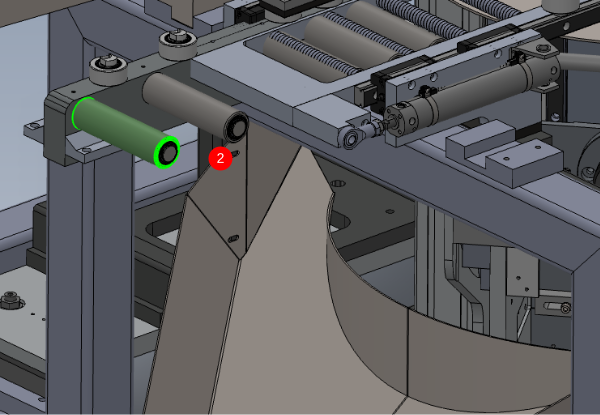

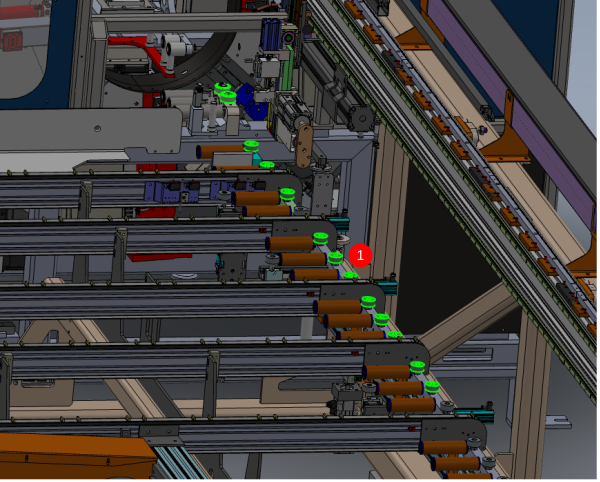

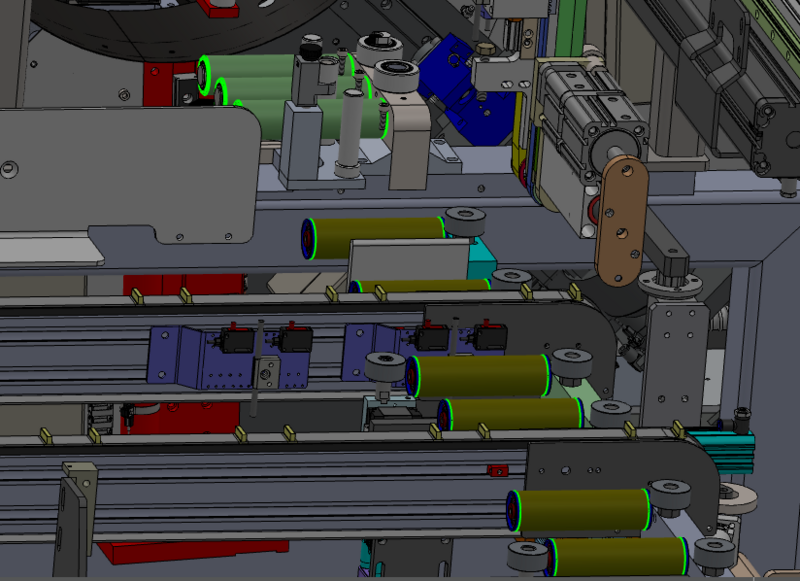

Étape 7 - level datums

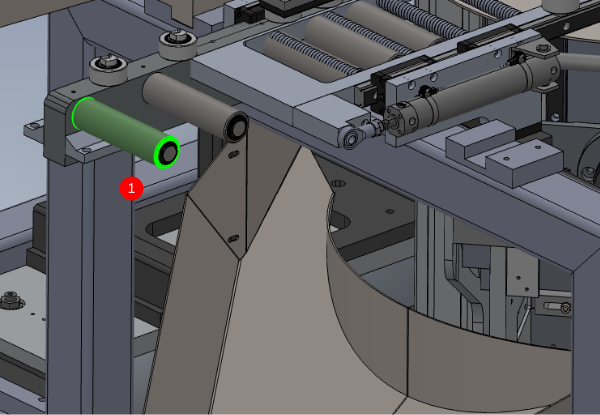

Datums for levels are as shown

1 X Axis . Only first and last datum rollers should be used initially for levelling

2 Y Axis should be set from fixed cut table

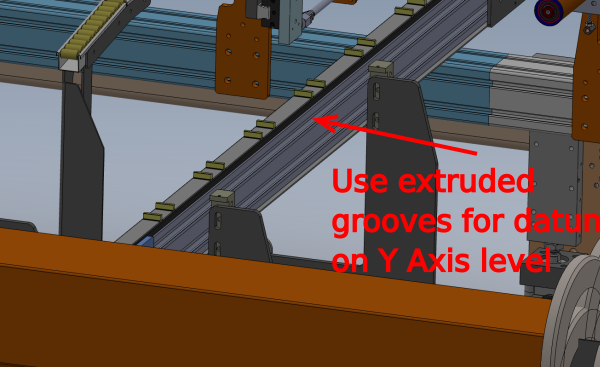

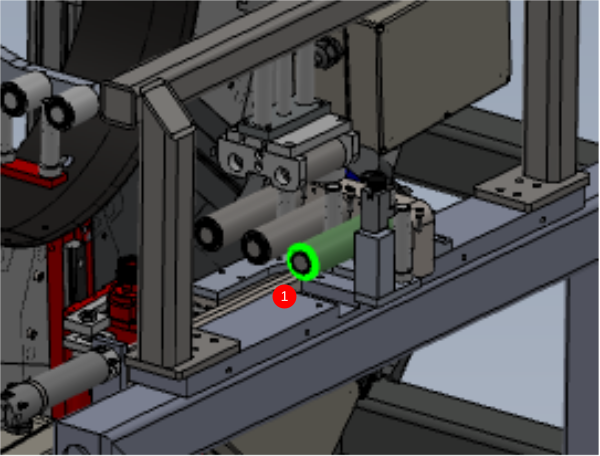

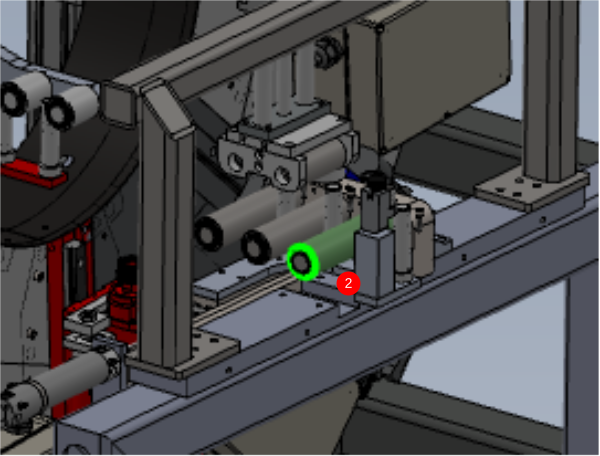

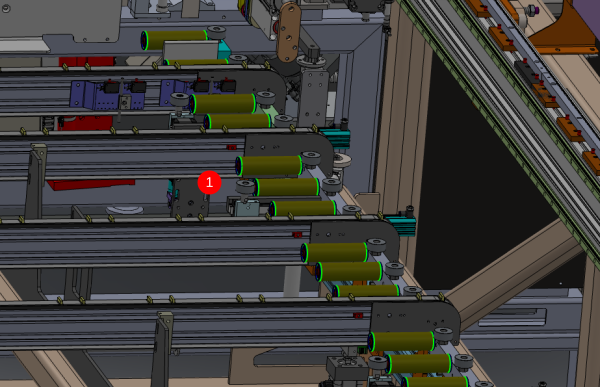

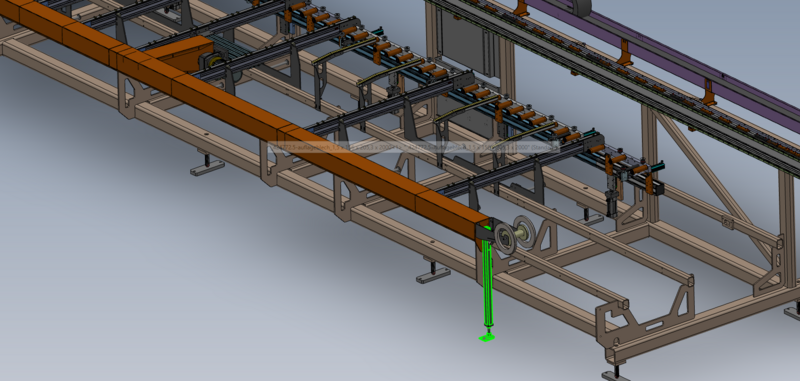

Étape 8 - Set levels

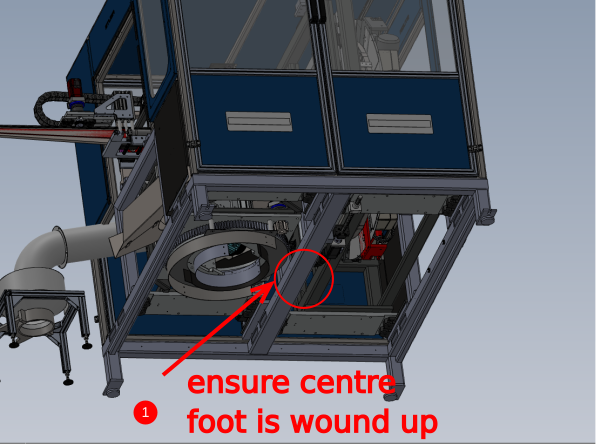

1 Ensure centre support foot is wound up away from floor to not impede initial level setting

2 Use a 2 meter straight edge and engineers level to bridge between 2 indicated datum points for X axis datum . Adjust perimeter pads only to bring this level (centre rollers tables may appear low when straight edge is used. This is normal and will be adjusted out later)

3 Use engineers level on the indicated face to adjust Y axis level. Ensure floor pads are adjusted in pairs to maintain X axis level that has been set

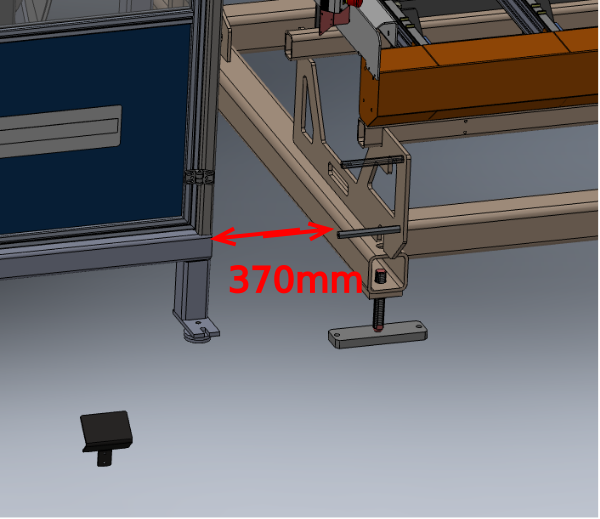

Étape 9 - Finalise Position Machining centre X axis

Spacing between Infeed and Machining centre should be set to 370mm as indicated. This measurement is taken from internal faces of frame box section.

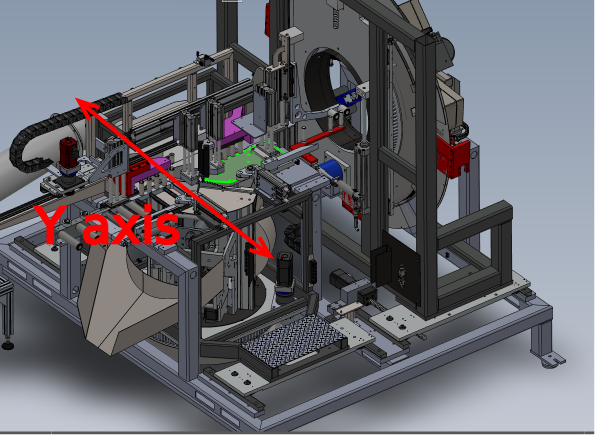

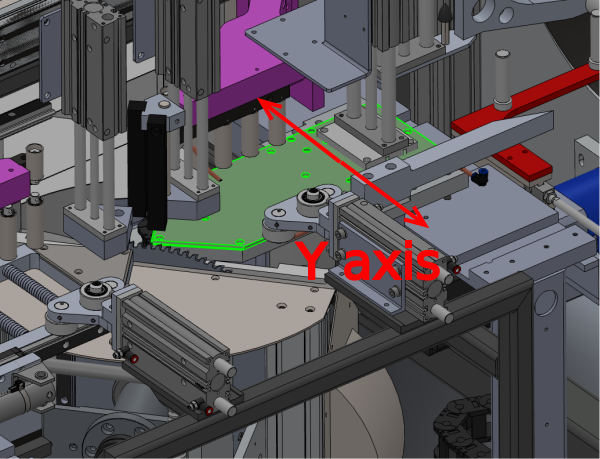

Étape 10 - Finalise Position Machining Centre Y axis

1 Use 2 meter straight edge against indicated rollers on infeed table .

2 Adjust position of Machining centre so indicated rollers align to straight edge set against infeed rollers

Étape 11 - Finalise Machining centre height

1 Use 2 meter straight edge on indicated rollers to project height to Machining centre

2 Use indicated rollers to accept projection from Infeed table

3 Adjust 4 corner pads of Machining centre equally to match height to straight edge .

4 Increase height of Machining centre by 0.5mm to allow slight bump up from Infeed rollers to Machining centre

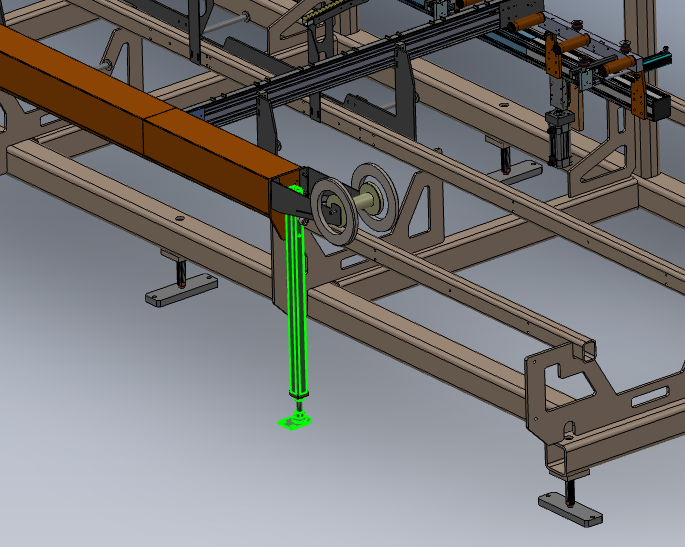

Étape 12 - Adjust Centre support

1 Centre support foot can now be set on Machining centre. Insert 2 meter straight edge and bridge 2 datum points for x axis on the machining centre ( same as previous step)

2 If all rollers are contacting straight edge, adjust centre support to take weight of Machining centre but not adjust roller position

3 If discrepancy is visible, centre support can be adjusted to align centre rollers to straight edge

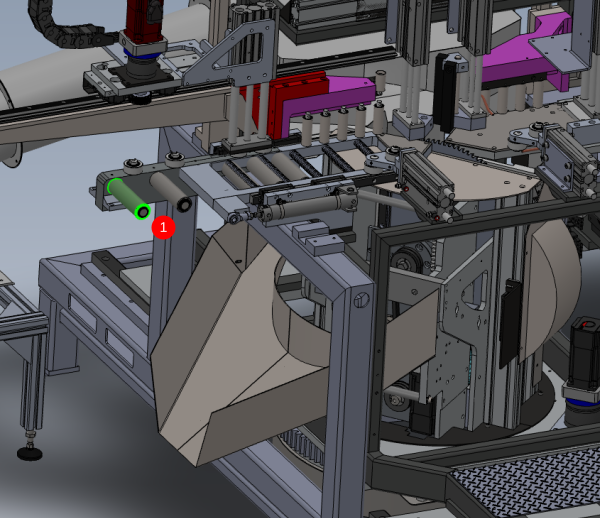

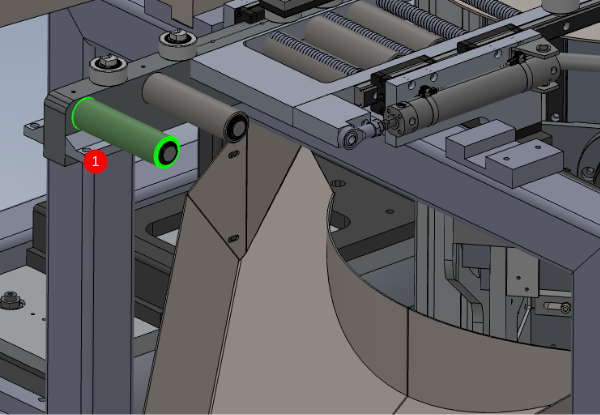

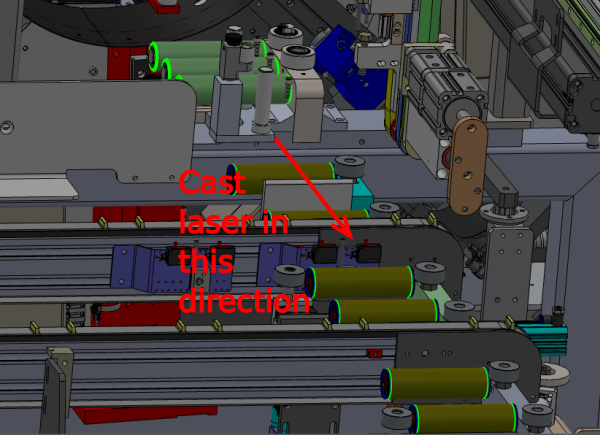

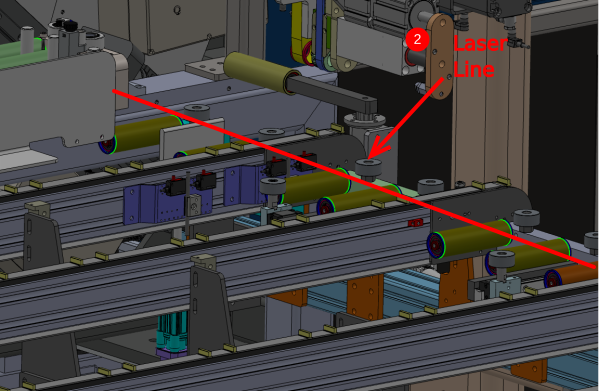

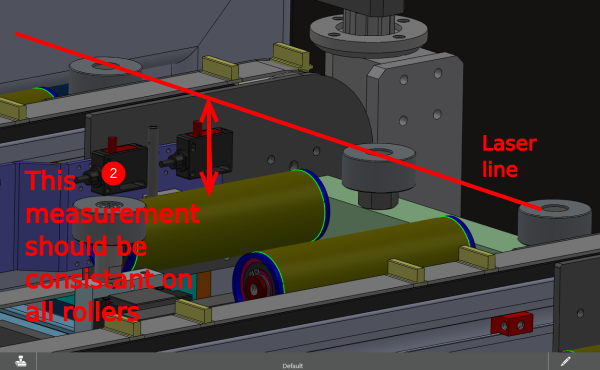

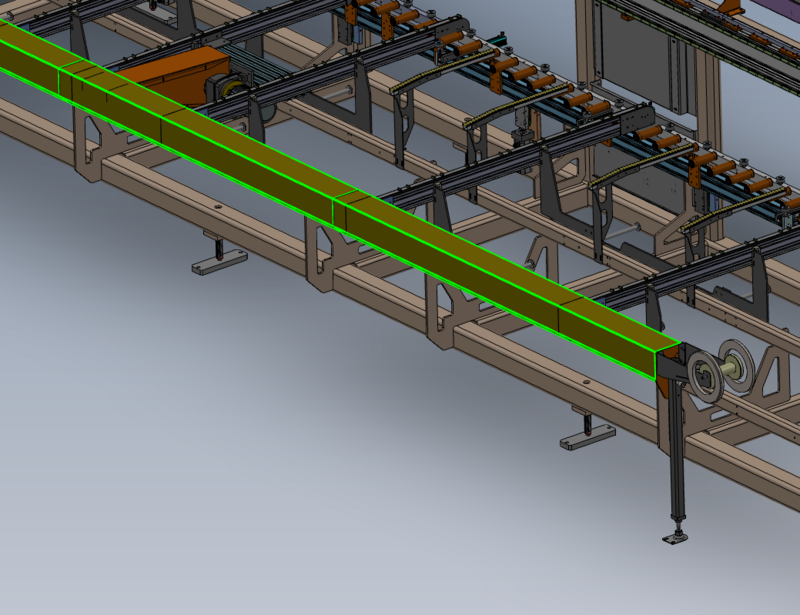

Étape 13 - laser Alignment Height

Laser alignment is now required to ensure all alignment is correct

1 Use a laser to cast from indicated rollers in the direction shown

2 Ensure measurement indicated is constant on every roller on infeed table

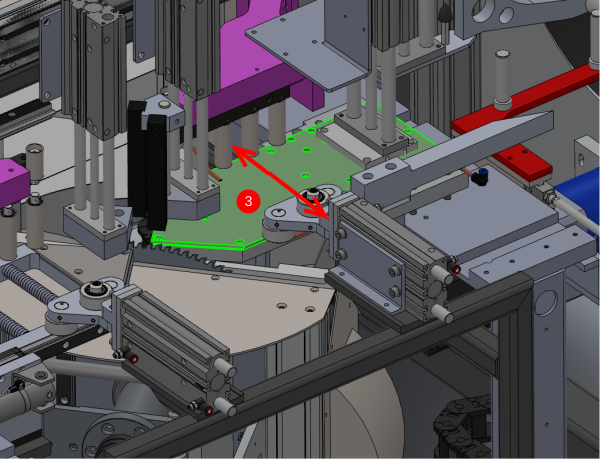

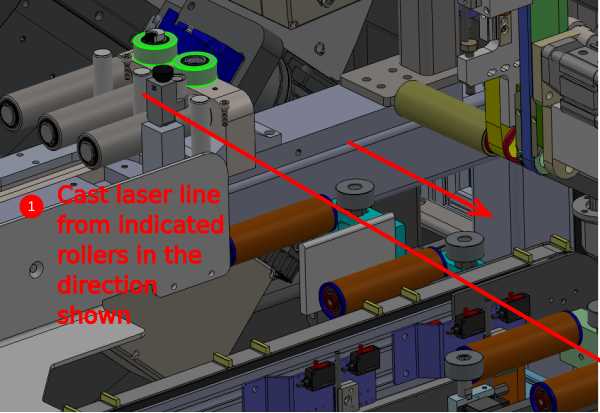

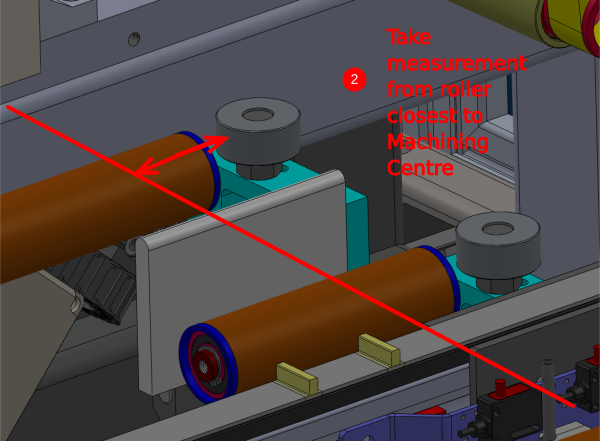

Étape 14 - Laser Alignment Backfences

1 Use a laser to cast from the indicated point in the direction shown

2 Take indicated measurement From roller closest to Machining centre

3 Take the same measurement at the last roller on the Infeed. These measurements need to be the same to ensure correct alignment

4 If the measurement is different, the Machining centre will require adjusting slightly to correct this pivot the Machining centre Rear in the indicated directions to correct laser error

5 Recheck Step 10 if adjustments are made

All Previous parameters for alignment must be rechecked (steps 7 to 13) once final adjustments have been done

Étape 15 - Finalise Front guard Support

Now alignment between Infeed table and Machining centre is complete , the front tray support can set

Adjust support so front tray is held level to rest of assembly

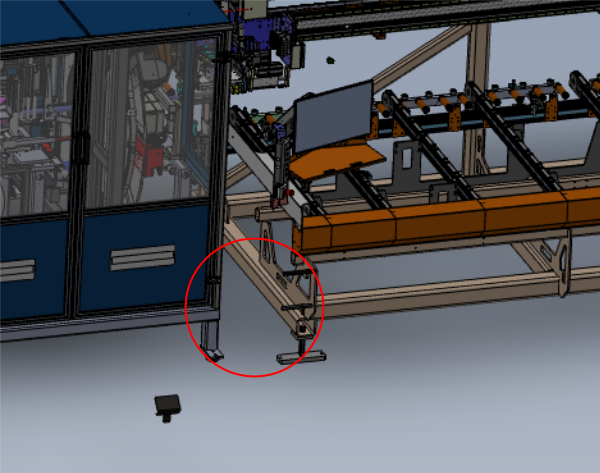

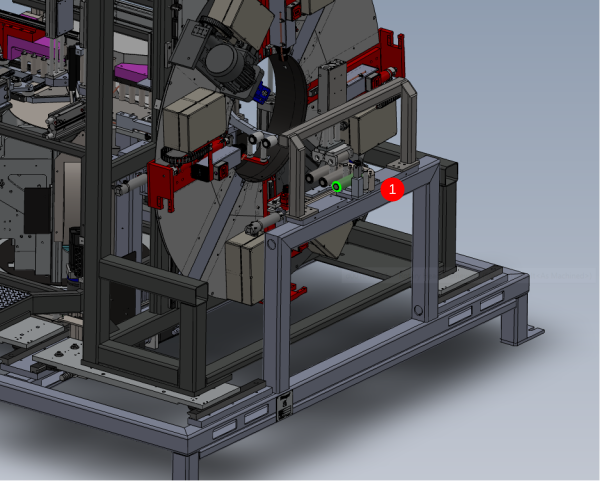

Étape 16 - Assemble JX Axis

The JX axis requires assembling to allow setting of the outfeed table

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português