How to set up an Ancil saw for rake cutting

VS Rake Cutting

Following and idea generated by a customer, the variable angle capability of the saw can be utilised to cut the rake angle of a VS profile.

- A piece that has already been cut with a 90 and 45 degree end is scanned with a barcode reader and loaded back onto the infeed on its large outer side with the square end at the pusher.

- The pusher moves the bar over the saw blade and then reverses out of the way

- The variable angle blade cuts a +/- shallow angle cut on the square end and the piece is ejected

How it works

- Profiles that have the ability to be raked cut are identified on the Profile Parameters Tab by setting the vsTilt tickbox (new PeP parameter)

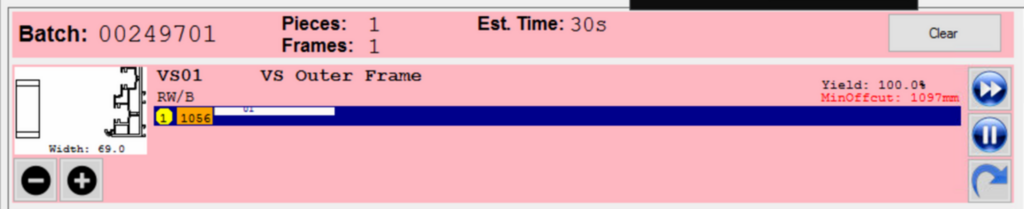

- The barcode reads the batch and piece number and looks up the piece in the 44o file for that batch

- The saw angle is calculated by looking at the angle data for the piece (0900, 0450, etc).

- When the main batch is first loaded, any cuts that are 0000, 0900 or lower than 10 degrees (0100) are converted to 0090 in the main 449 / 44o file

- After barcode scanning and loading as a single piece, each 0090 cut is converted into a slight angle off 90 degrees. The actual angle cut is specified with parameter vsAngle (90 +/- vsAngle)

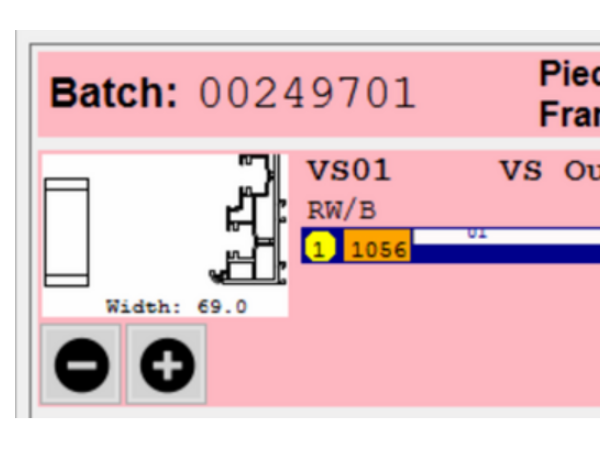

- A single piece temporary batch is created with the same batch number with the correct angle instructions for the saw (uses the same system as the Ecoline single piece batching)

Notes

- Front end 6.4.97.1

- Barcode Reader

- vsEnable=1

- vsAngle=[rake angle]

- Profiles that use this set VsTilt parameter

- useAngleNotCharacter=true (6.4.98.2 onwards, this is a profile parameter)

See video

https://vimeo.com/694147297/55dc5eab6d

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português