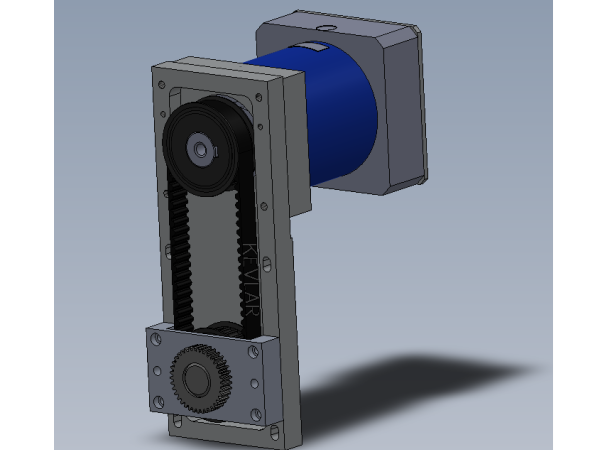

Assembly instructions for R axis gearbox

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Assemble drive spigot

- 4 Étape 3 - fit key and pulley

- 5 Étape 4 - Attach to gearbox plate

- 6 Étape 5 - Gear box bung supplied with gearbox C0001211

- 7 Étape 6 - Check pulley fitment

- 8 Étape 7 - Fit Servo gearbox cap

- 9 Étape 8 - Couple and align gearbox and pinion assembly

- 10 Étape 9 - Align pulleys

- 11 Étape 10 - Remove pulley assembly

- 12 Étape 11 - Tension belt

- 13 Étape 12 - finalise position

- 14 Étape 13 - Quality check

- 15 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Tensioning jig

Standard HSS drill set

300mm rule

Parts Required

B0000062 Circlip 20mm External x 2

B0000092 Belt: Toothed 640-8MGT 20 (R Axis) (KEVLAR) x 1

B0000095 Bearing NR6004 2RS with snap ring (NSK) x 2

C0001211 Gearbox NP035s 5:1 x 1

D0000268 Rotary Drive Tooth Pulley x 1

D0001286B-2MOD Welded Ring Pinion Gear 2MOD (for 8mm key) x 1

D0006058 Gearbox Plate x 1

D0006060 Spigot Cap x 1

D0007849 Servo gearbox cap x 1

D0008585B Rotary Ring Drive Pulley (for 8mm key) x 1

D0015801 Feather Key 8mm x 8mm x 22mm x 1

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

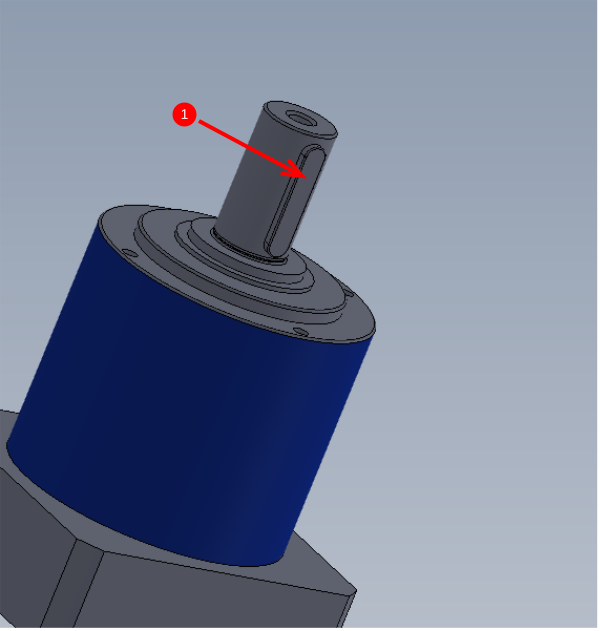

Étape 2 - Assemble drive spigot

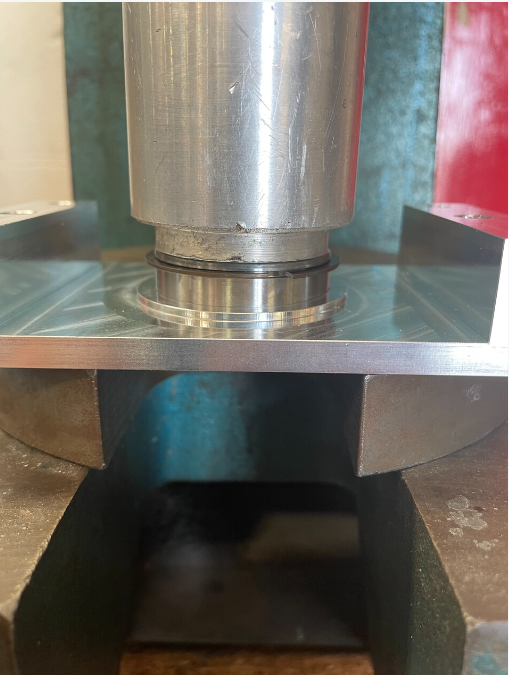

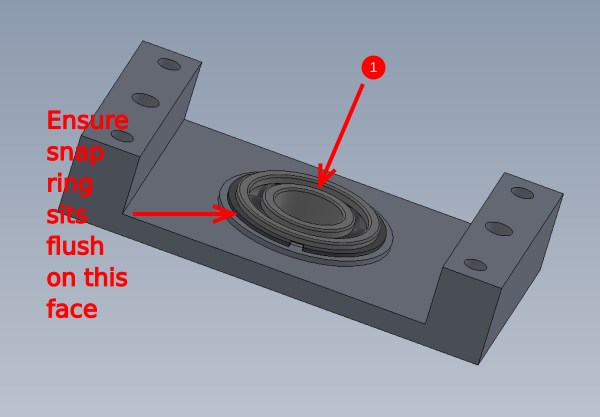

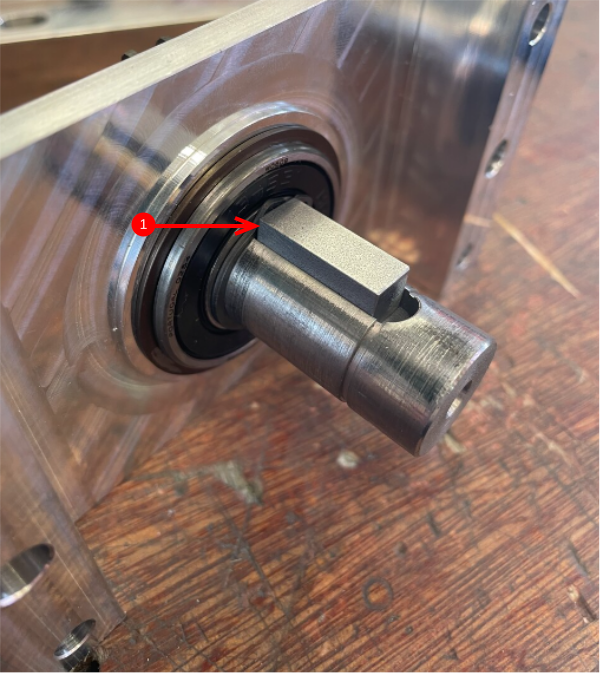

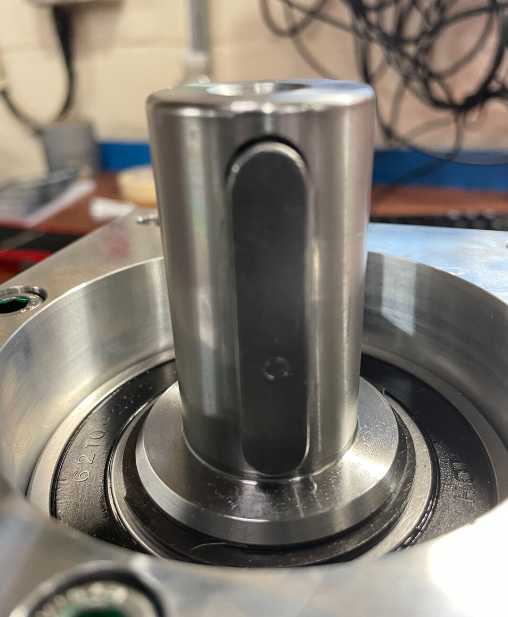

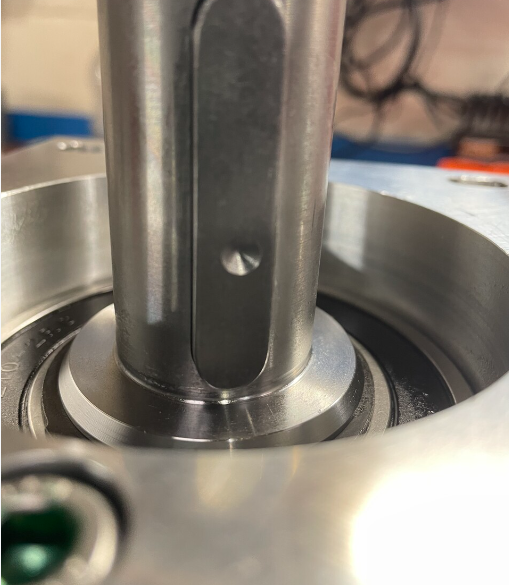

1 Press B0000095 Bearing into D0006060 Spigot Cap so snap ring sits flush

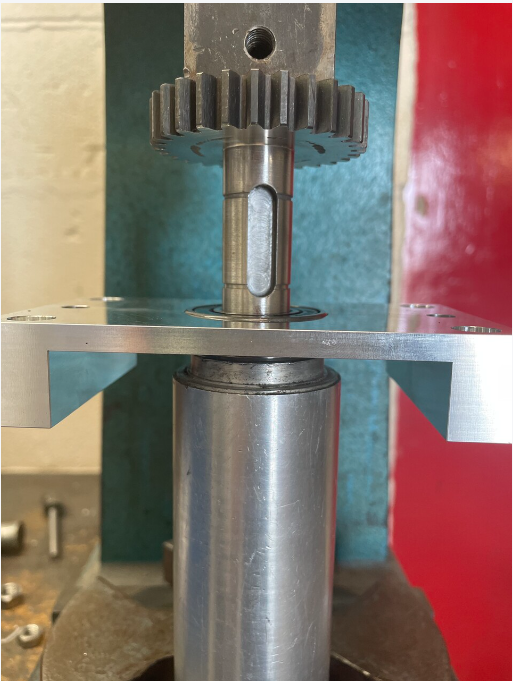

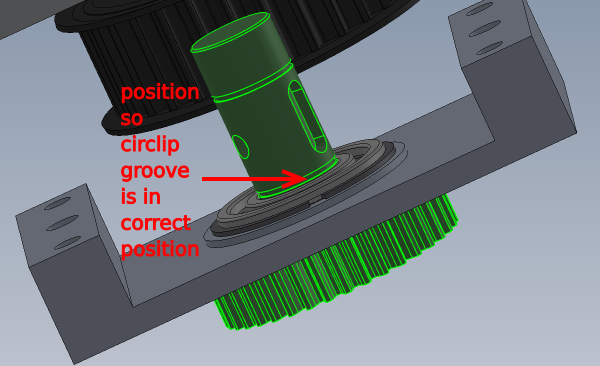

2 Fit D0001286B-2MOD Welded Ring Pinion Gear 2MOD as shown Use jig to ensure bearing is not moved from location. Push through until circlip groove is in correct place

Étape 3 - fit key and pulley

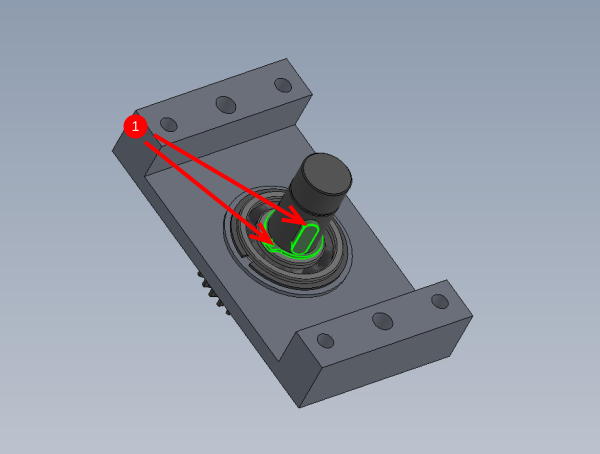

1 Fit Circlip 20mm and D0015801 Feather Key 8mm x 8mm x 22mm as shown

2 Fit D0008585B Rotary Ring Drive Pulley as shown . Only press down until circlip groove is present

3 Fit 20mm external circlip

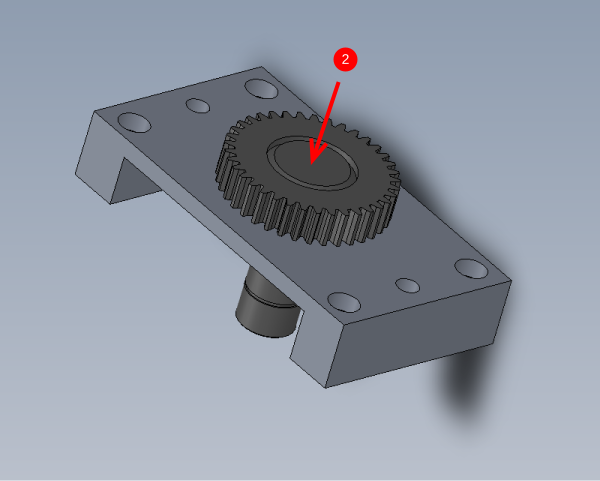

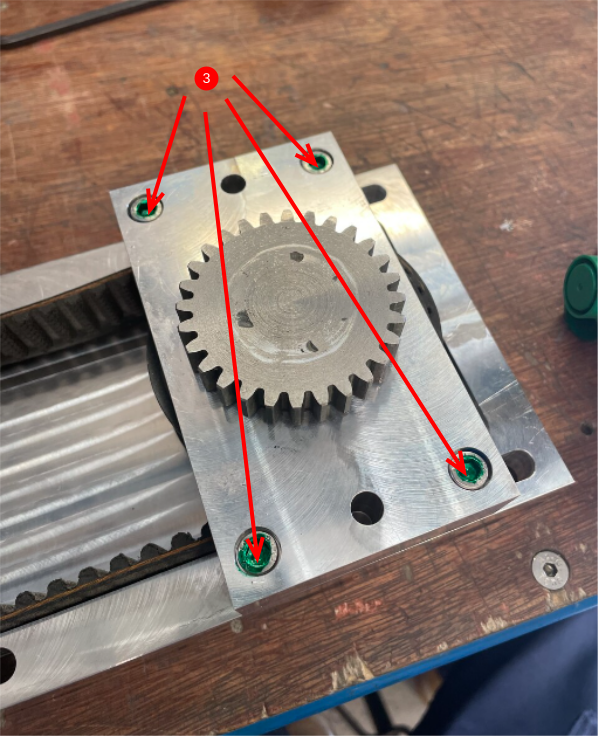

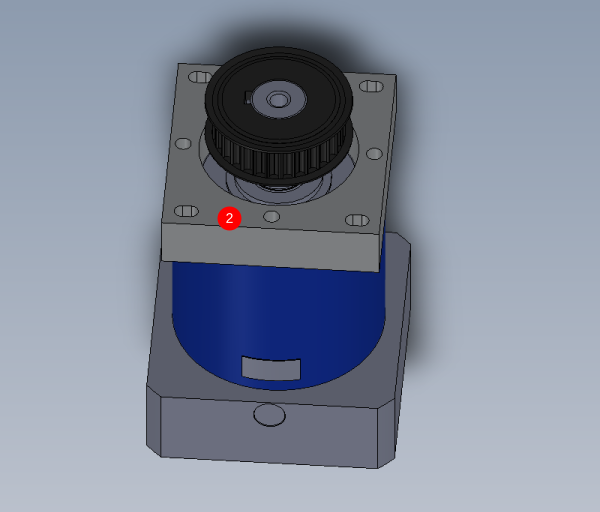

Étape 4 - Attach to gearbox plate

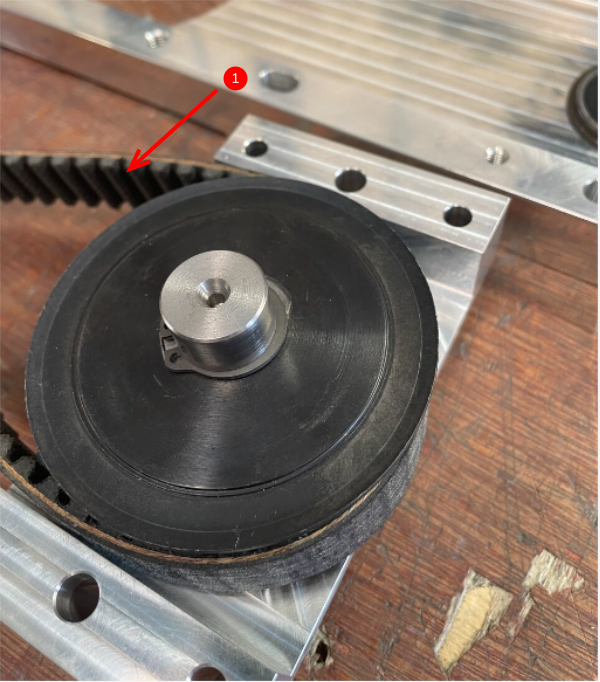

1 Attach B0000092 Belt: Toothed 640-8MGT 20 as shown

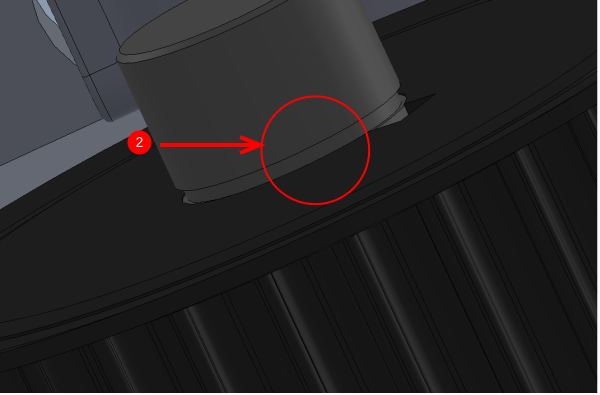

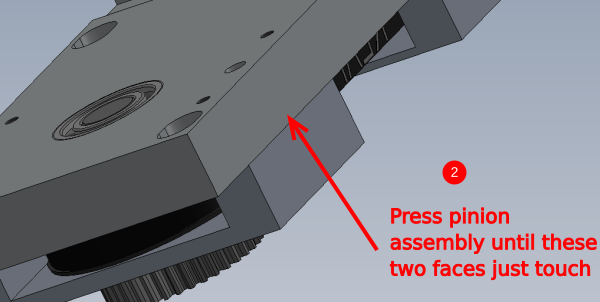

2 Press pinion assembly onto gearbox plate

3 Secure lightly with 4 off M6 x 35 socket caps

4 Add 2 off 8mm x 50mm dowels into indicated holes . Ream if holes are tight

5 Finalise 4 off M6 socket caps

Étape 5 - Gear box bung supplied with gearbox C0001211

Étape 6 - Check pulley fitment

Check D0000268 Rotary Drive Tooth Pulley fits onto C0001211 Gearbox

If pulley fits move to step 6, if it does not fit follow these steps

1 Remove key from gearbox shaft

2 Test pulley again for fitment.

- If the pulley still does not fit, polish inner face of pulley until fitment is achieved

- if the pulley does fit when the key is removed , move to next step

3 Refit key

4 Test pulley , if the pulley still doesn't fit correctly dress keyway slot gently until fit is achieved

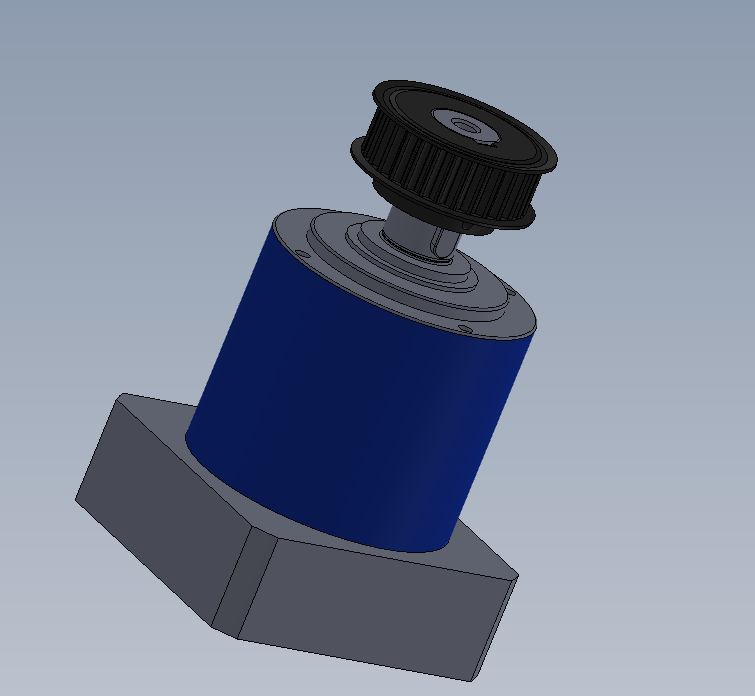

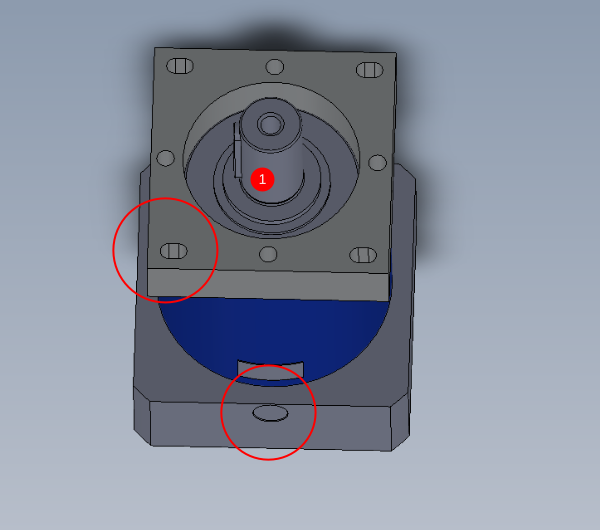

Étape 7 - Fit Servo gearbox cap

1 Fit D0007849 Servo gearbox cap as shown. No adhesive on the 4 off M8 x 35 socket caps

Orientate as shown

2 Fit D0000268 pulley

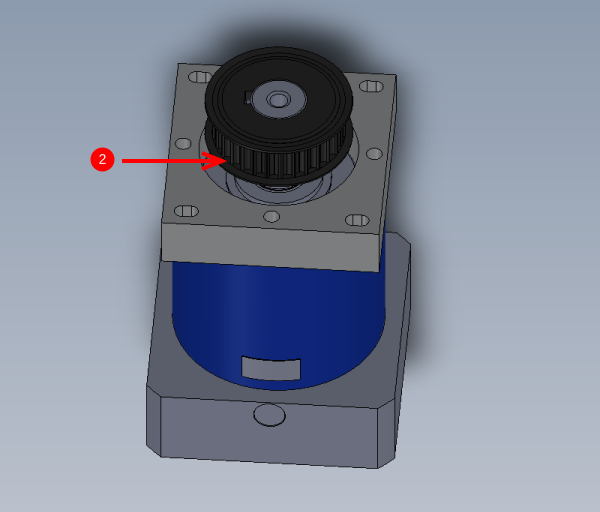

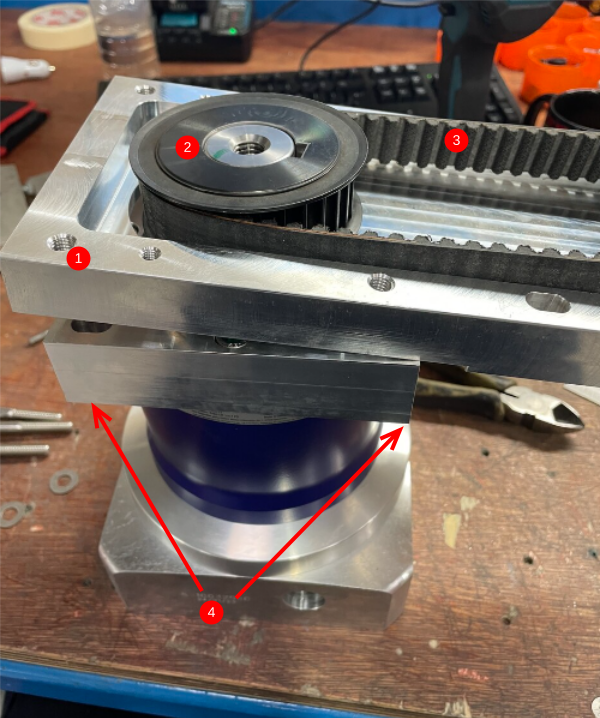

Étape 8 - Couple and align gearbox and pinion assembly

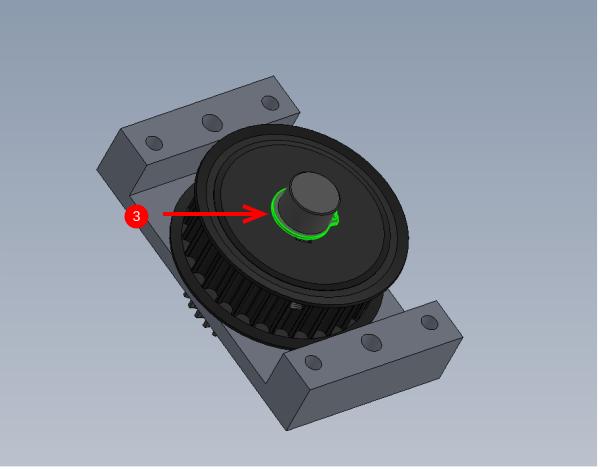

Insert part1 through part 2

Hook over belt (3)

insert 4 off m8 x 50 with a form washers a pull to face lightly

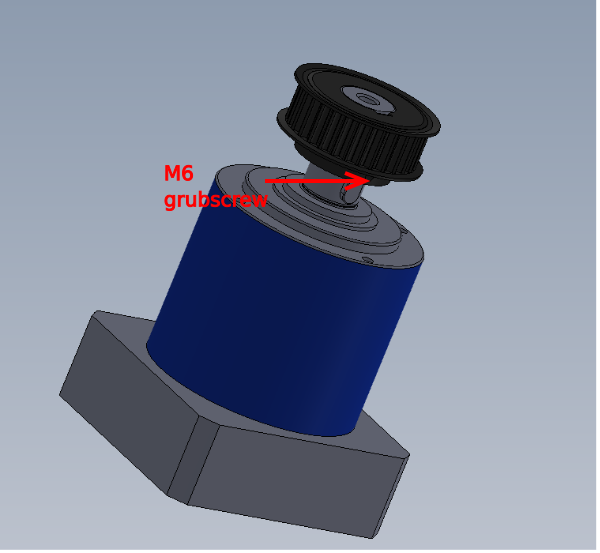

Étape 10 - Remove pulley assembly

Reverse steps to remove assembly 1

Remove part 2

Tighten grubscrew to leave witness mark , Remove pulley and drill 5mm dimple at indicated point

Use M6 x 10 kcp grubscrew to lock pulley in final position

Rebuild parts to get to 3

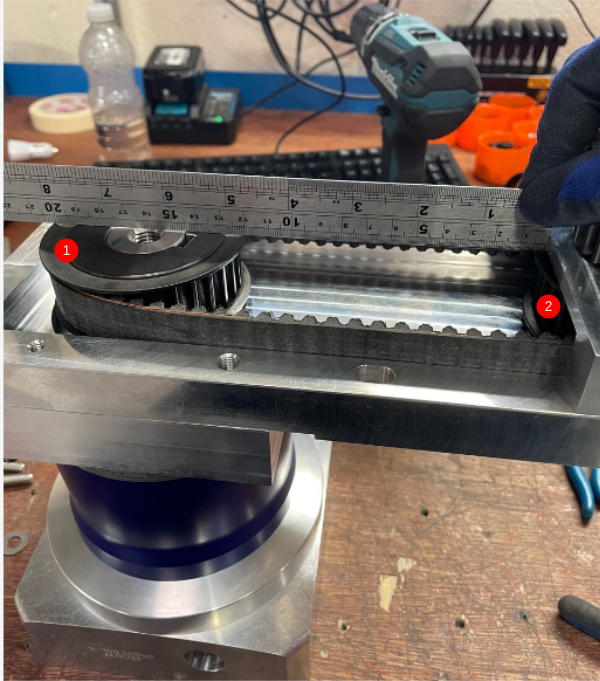

Étape 11 - Tension belt

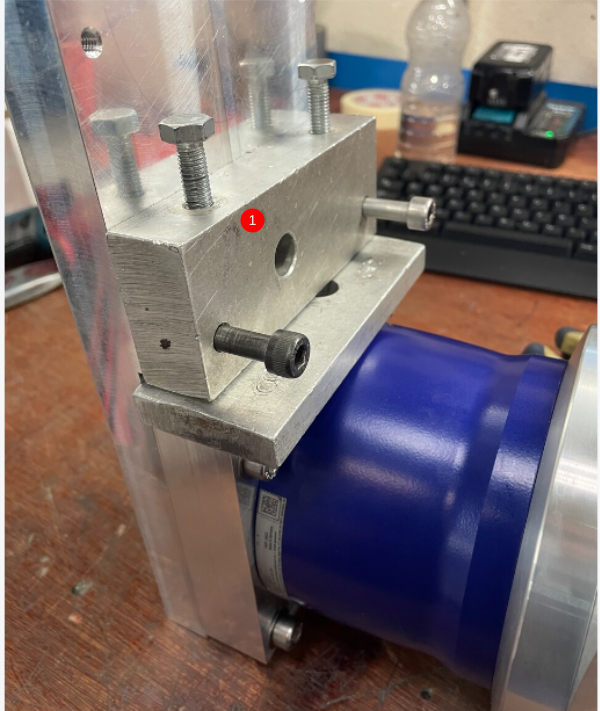

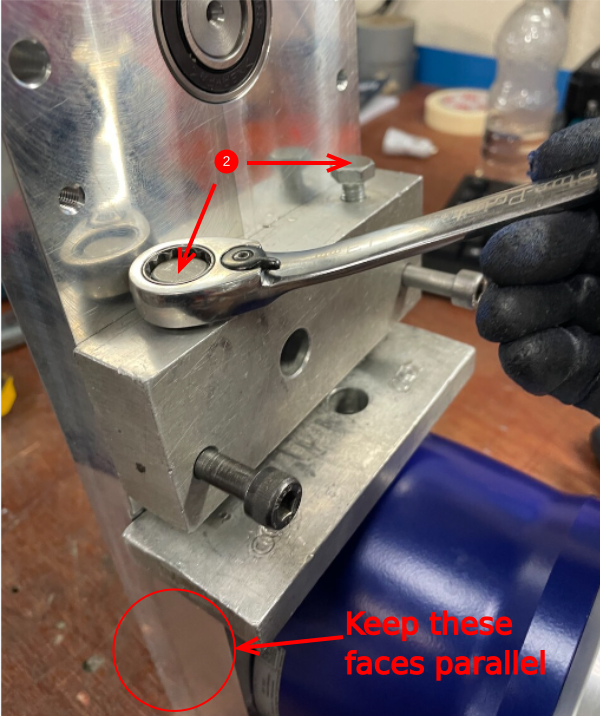

1 Attach tensioning jig as shown

2 Apply tension to belt , spreading tension over two bolts indicated . Maintain parallel on these faces as adjusting

Set belt tension to 5mm deflection (Drum Tight )

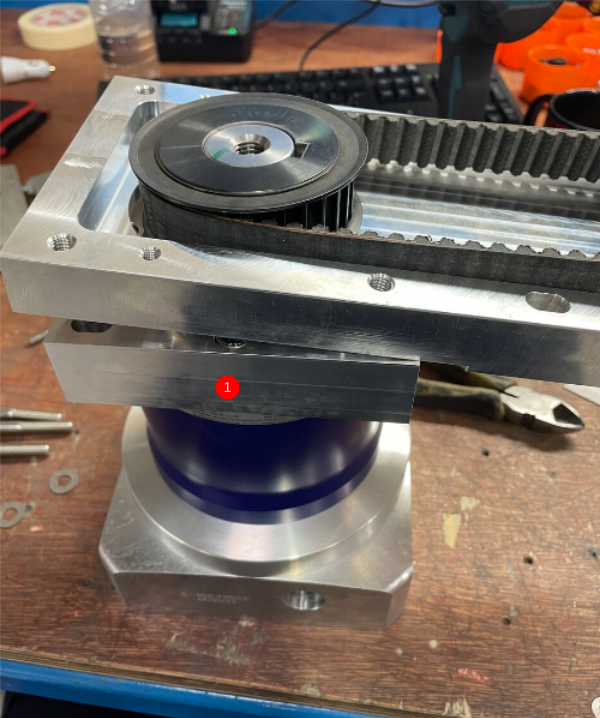

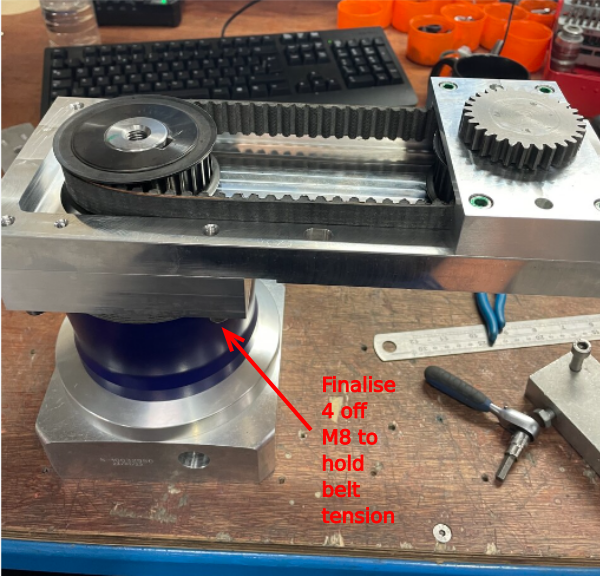

Étape 12 - finalise position

finalise 4 off m8 socket caps to hold tension

Remove setting jig plates

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português