Instructions to pneumatically test build module

Sommaire

- 1 Introduction

- 2 Étape 1 - Health and Safety

- 3 Étape 2 - Check all connections are made

- 4 Étape 3 - Connect air feed

- 5 Étape 4 - check for air leaks

- 6 Étape 5 - Check home positions

- 7 Étape 6 - Test valve bank outputs

- 8 Étape 7 -

- 9 Étape 8 -

- 10 Étape 9 -

- 11 Étape 10 -

- 12 Étape 11 -

- 13 Étape 12 -

- 14 Commentaires

Introduction

Tools required

Pcl air line -12mm connector

Parts Required

Étape 1 - Health and Safety

In this process pneumatic outputs will be tested in a non emergency stop environment

Ensure safe working practice is followed

- Ensure Machine test area is clear from personnel and all staff are aware of testing procedure commencing

- Ensure all Air connection lines are connected

- Ensure all walkways are not impeded by trailing pipes/leads

- Ensure all mechanical assemblies are at a sufficient stage for testing

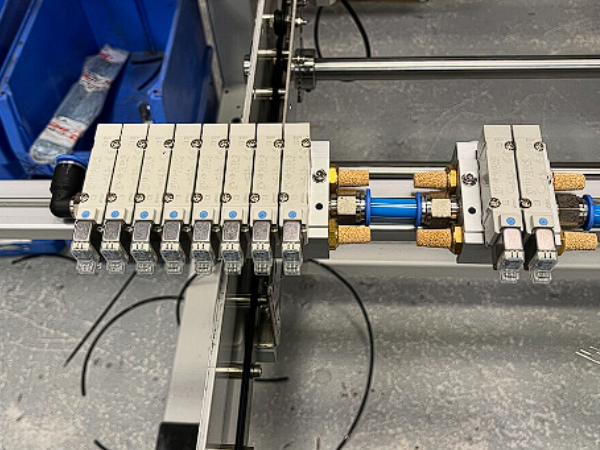

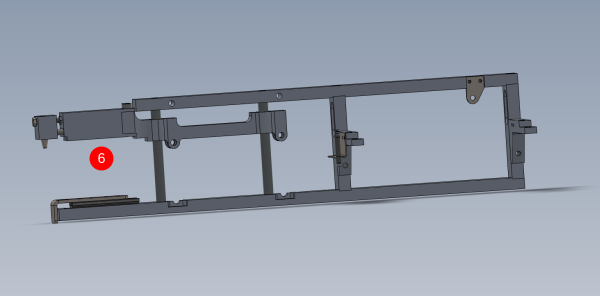

Étape 2 - Check all connections are made

- Check all valve bank ports are either connected or blanked off

- Check all mains feed pipes are connected or isolated

- Check all regulators are regulated to minimum setting

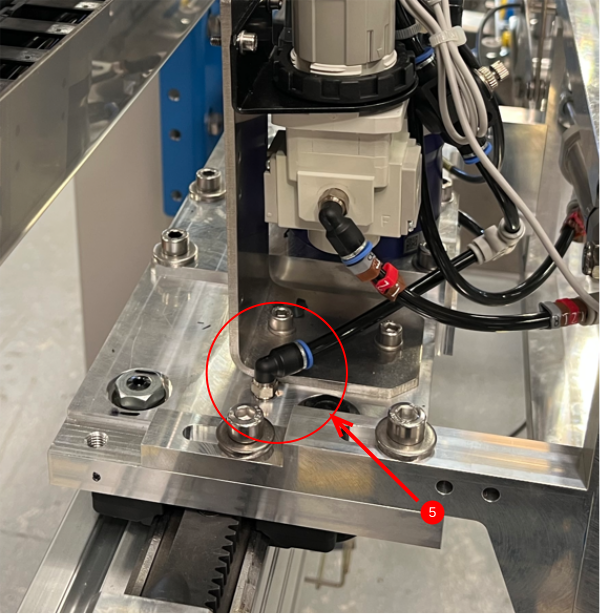

- Check all air flow control valves on cylinders and blow lines are set to mid range adjustment

Étape 3 - Connect air feed

Connect air feed to mains 12mm feed pipe using pcl coupling and 12mmm push fit adapter

Étape 4 - check for air leaks

Investigate any air leaks and resolve

Étape 5 - Check home positions

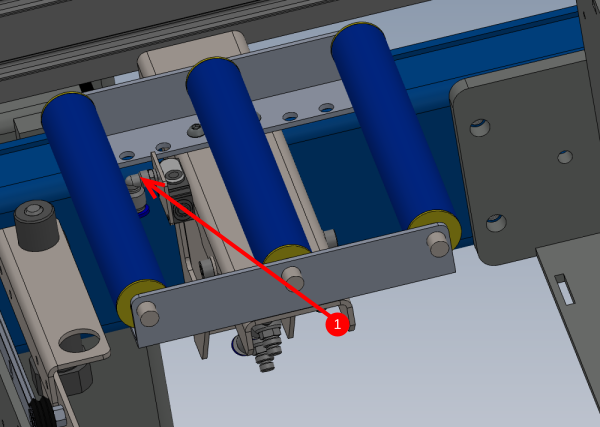

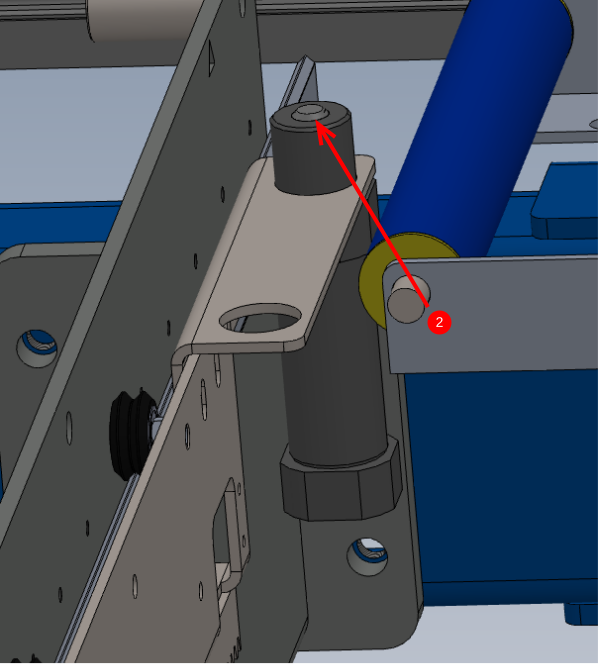

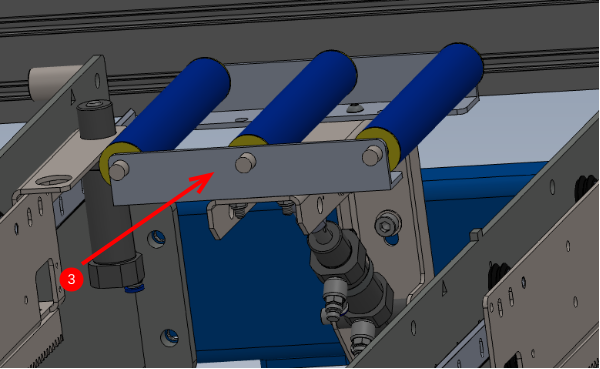

With no valves active ( no over rides pressed ) the following home positions of pneumatic assemblies should be

1 Y244 material load sensor blowers should be switched OFF

2 Y125 Pop up C should be retracted

3 Y124 Roller beds should be lifted

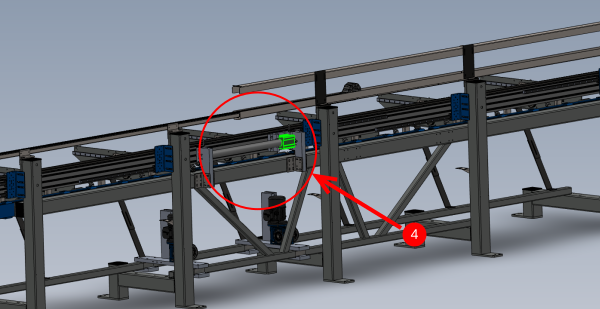

4 Y126/Y127 Beam position should be closest to extraction end

5 Y122 Rack blower ashould be switched OFF

6 Y121 Gripper height should be raised up

Any discrepancies on these should be investigated to correct

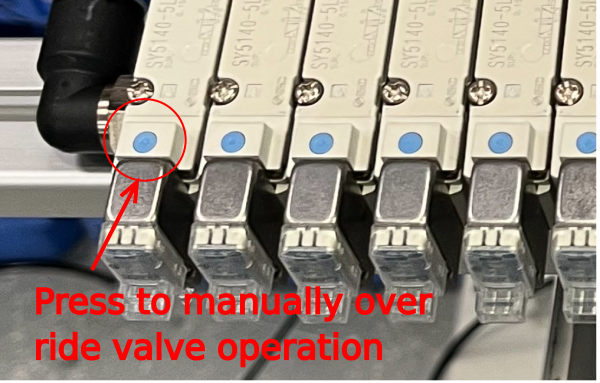

Étape 6 - Test valve bank outputs

Each valve on the Valve bank can be manually overridden to activate the output.

Étape 7 -

Étape 8 -

Étape 9 -

Étape 10 -

Étape 11 -

Étape 12 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português