Instructions to mount pre built assemblies to main frame

Sommaire

- 1 Introduction

- 2 Étape 1 - Mount pre built R0015007 Bench Assemble Roller Tables

- 3 Étape 2 - Mount pre built R0015004 Bench Assemble Gripper

- 4 Étape 3 - Mount Energy chain angle brackets Lower

- 5 Étape 4 - Mount upper chain angle brackets

- 6 Étape 5 - Mount short upper chain angle brackets

- 7 Étape 6 - Fit lower chain trays

- 8 Étape 7 - Mount upper chain guides

- 9 Étape 8 - Fit Carriage bracket

- 10 Étape 9 - Attach pre built R0015251 energy chain

- 11 Étape 10 - Adjust lower trays to suit energy chain

- 12 Étape 11 - Adjust lower tray height

- 13 Étape 12 - Adjust Top chain guides

- 14 Étape 13 - Quality check

- 15 Étape 14 - Finalise fixings

- 16 Étape 15 - Mount Datum flag

- 17 Étape 16 - Mount R0015096 Bench Assemble Transfer Drive Assembly

- 18 Étape 17 - Add drive chain.

- 19 Commentaires

Introduction

Tools Required

Standard Hex key set

Standard spanner set

300 mm rule

1000mm rule

Parts Required

D0015291 Datum Flag x 1

D0015717 Energy Chain Angle Bracket Lower x 5

D0015718 Energy Chain Angle Bracket Upper x 2

D0015718B Energy Chain Angle Bracket Double Deck x 3

D0015720 Carriage Bracket x 1

D0015721 Energy Chain Tray Deep Longx 3

D0015722 Energy Chain Tray Shallow Long x 1

D0015861 Energy Chain Cable Support x 1

D0015862 Energy Chain Tray Deep Long x 1

R0015007 Bench Assemble Roller Tables

R0015096 Bench Assemble Transfer Drive Assembly

R0015251 Bench Assemble X axis components and energy chain

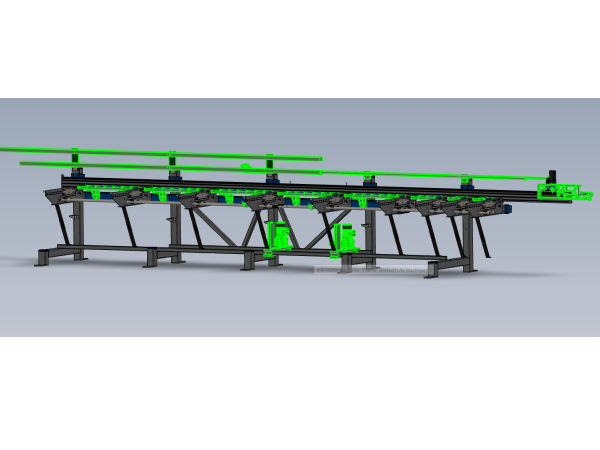

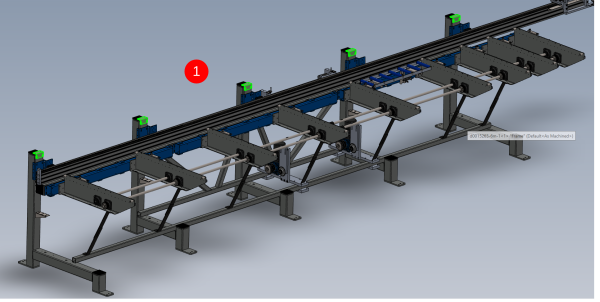

R0015004 Bench Assemble GripperÉtape 1 - Mount pre built R0015007 Bench Assemble Roller Tables

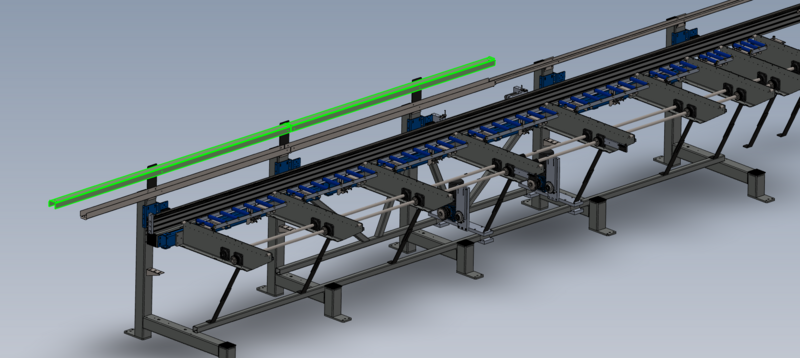

Mount roller beds as indicated , using M8 x 30 socket caps and heavy M8 washers.

Do not apply adhesive to fasteners and only apply holding tension to fasteners

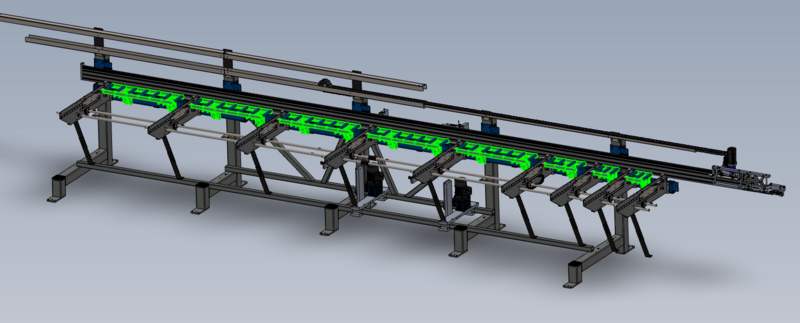

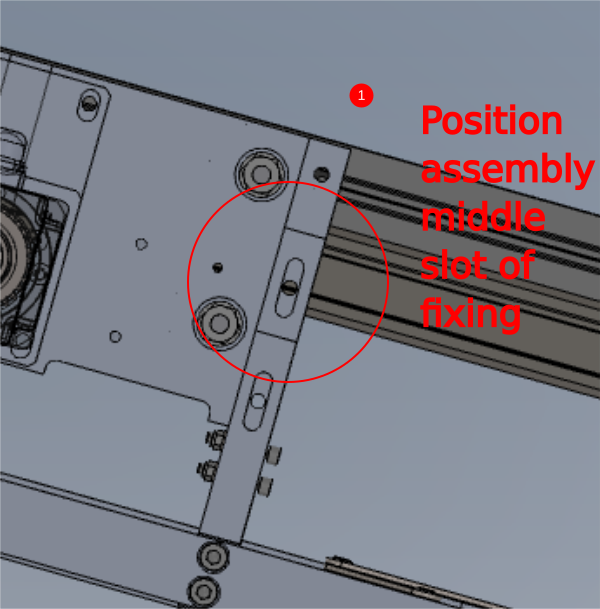

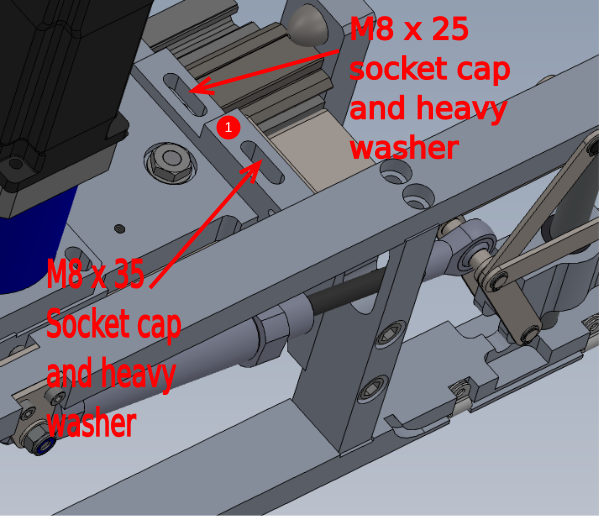

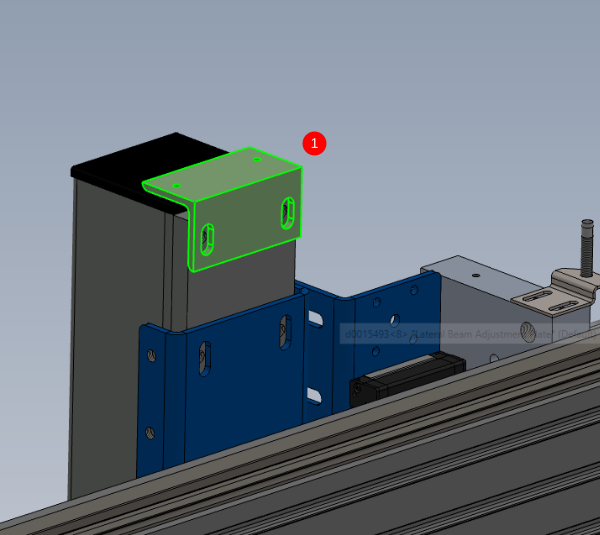

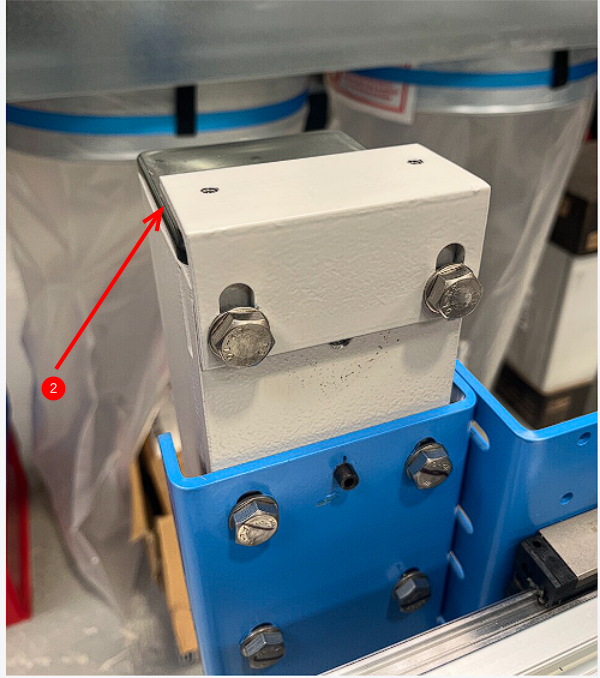

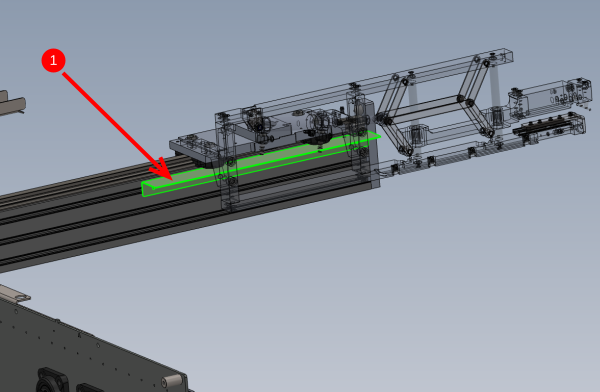

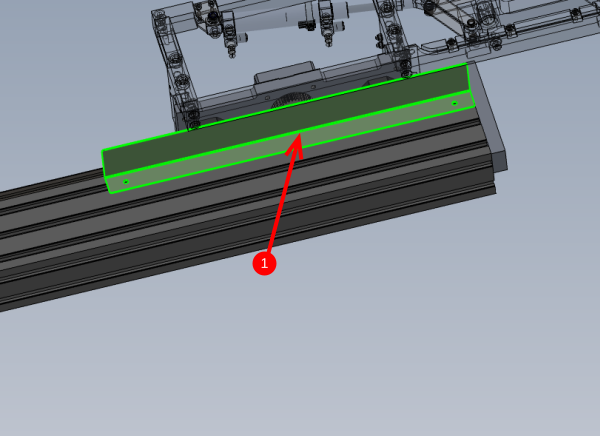

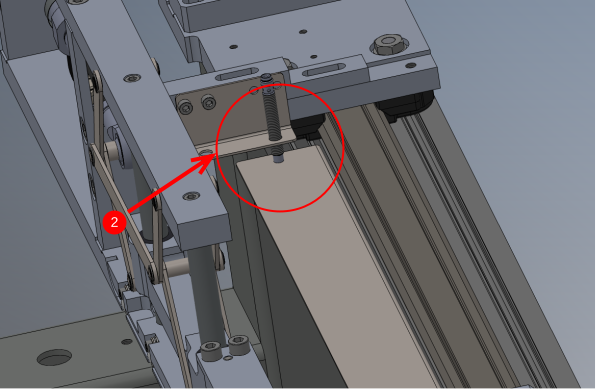

Étape 2 - Mount pre built R0015004 Bench Assemble Gripper

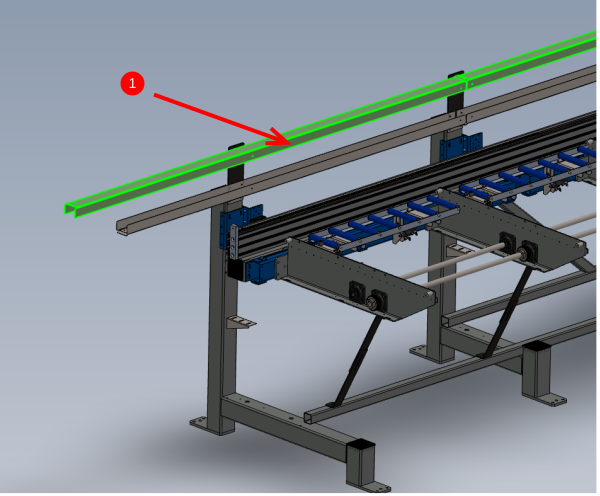

1 Mount Gripper assembly to carriage using 2 off M8 x 35 socket caps 2 off Mi8 x 25 socket caps and heavy M8 washers

2 Check and adjust parallel to ensure gripper is true to hepco beam both indicated measurements should be identical

Étape 3 - Mount Energy chain angle brackets Lower

1 Mount 5 off D0015717 Lower mounting angle with 2 off M10 x 25 set bolts and A form washers per bracket . Do not apply adhesive at this point

2 Set height to just clear plastic frame cap and set bracket level

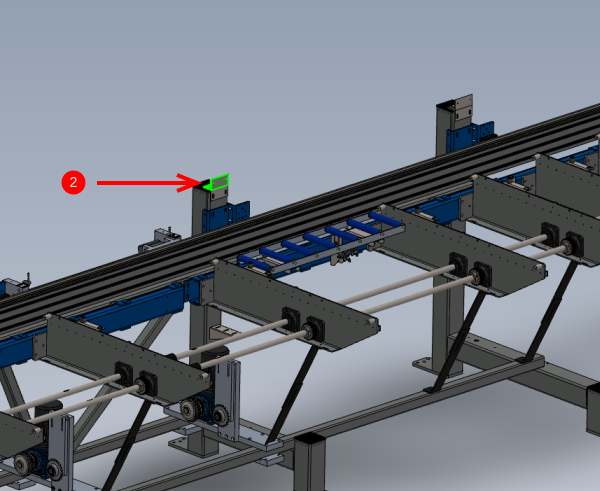

Étape 4 - Mount upper chain angle brackets

1 Mount 2 off D0015718B to positions shown using M6 x 16 socket caps and heavy M6 washers .

2 Mount 1 off D0015718B to position indicated with M6 x 20 Socket capsand heavy M6 washers. Do Not apply adhesive yet to this brackets fasteners

3 Set slot position to be flush with lower bracket

Étape 5 - Mount short upper chain angle brackets

1 Mount 1 off D0015718 to indicated point using M6 x 16 socket caps and heavy M6 washers . Set faces flush as with previous step

2 Position 1 off D0015718 at indicated point and use M6 x 20 socket caps and heavy washer to fix in position combining part D0015861 as shown

3 Use previous fitted fasteners to mount other end of D0015861 onto previous fitted bracket , and finalise bolts

Étape 6 - Fit lower chain trays

Lightly fix these parts, as adjustment will be required later

1 Fit D0015721 at indicated position . Use M5 x 16 button hex bolt, M5 penny washer and M5 nyloc nut .

2 Fit D0015721 to indicate point with same fixings as above

3 Fit D0015722 to indicate point with same fixings as above

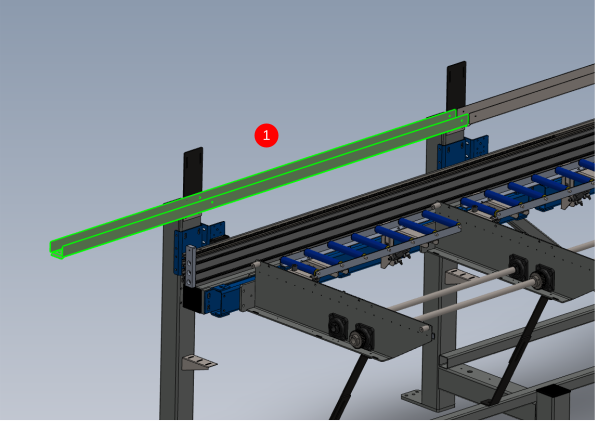

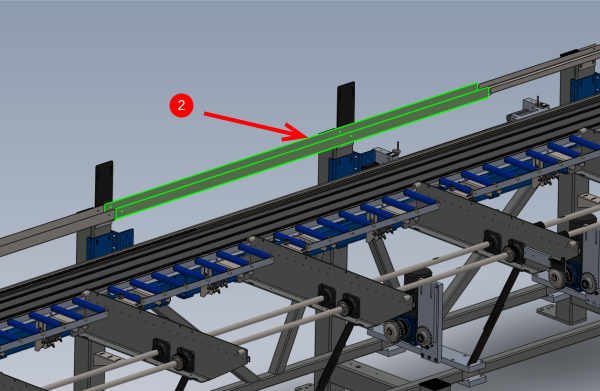

Étape 7 - Mount upper chain guides

Use same method as step 6 to mount indicated upper chain guides 2 off

1 D0015862 upper chain guide

2 D0015721 upper chain guide

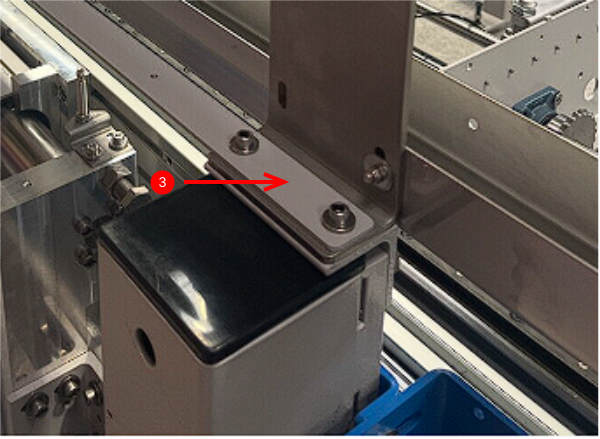

Étape 8 - Fit Carriage bracket

Fit D0015720 carriage bracket as shown using M6 x 16 socket caps and A form washers

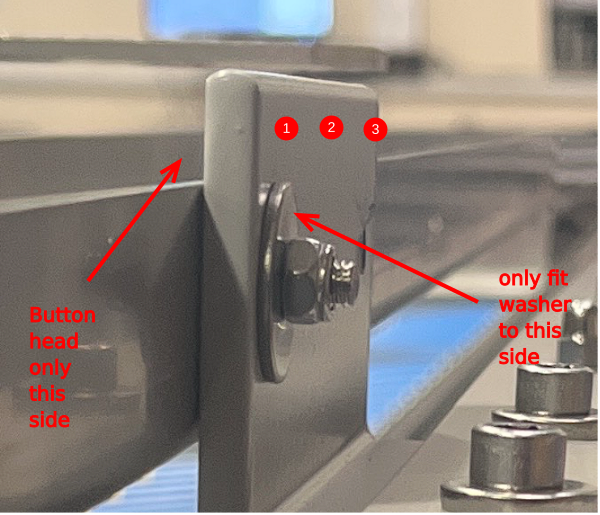

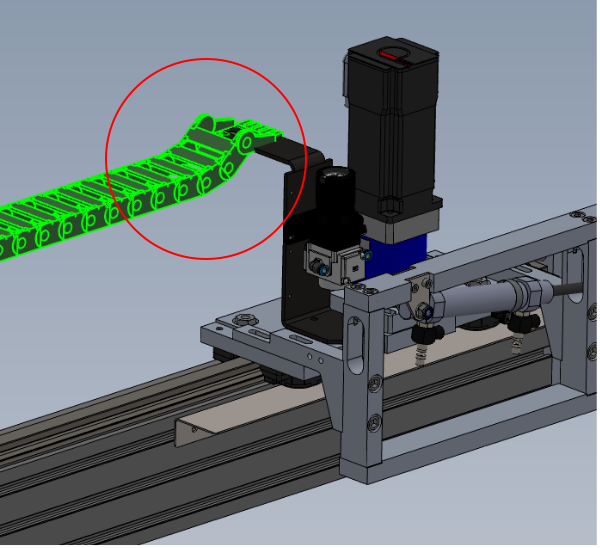

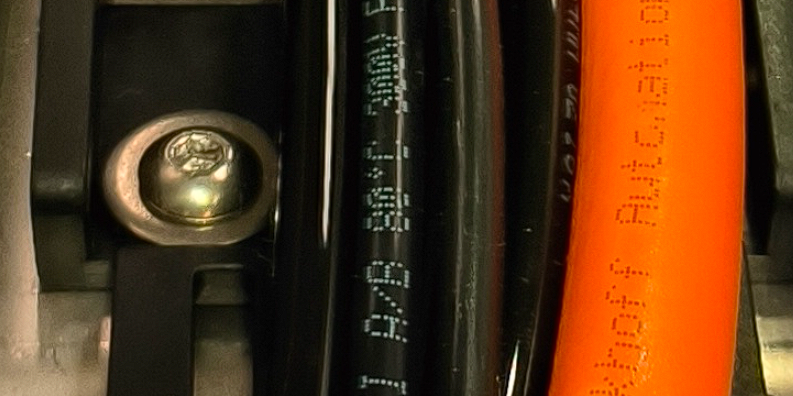

Étape 9 - Attach pre built R0015251 energy chain

Fit pre built energy chain from assembly R0015251 and attach using M5 x 16 button heads, medium washers and M5 nyloc nuts as shown

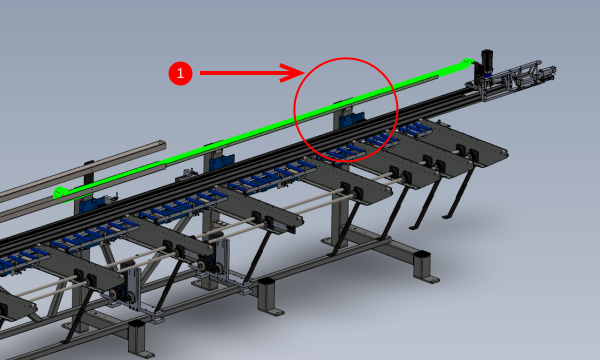

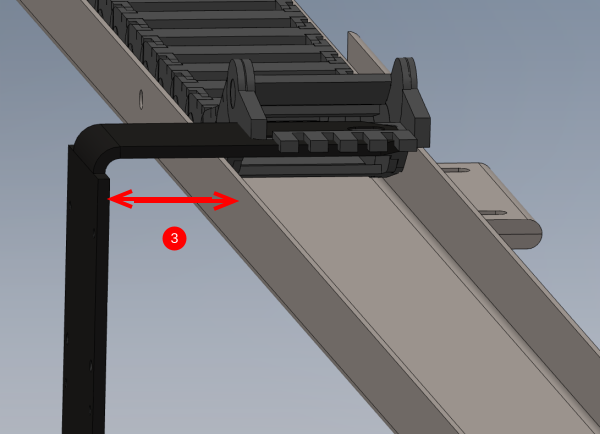

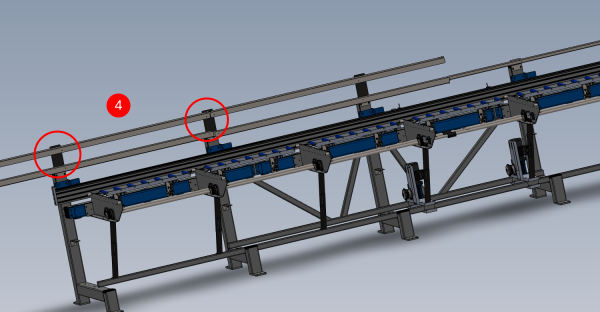

Étape 10 - Adjust lower trays to suit energy chain

1 Move gripper with energy chain attached to point indicated

2 Adjust bracket in indicated direction so that energy chain sits central in the tray

3 Measure indicated distance S

4 Set the next 4 lower tray mounting points to replicate this measurement using the same method of adjustment with the angled bracket

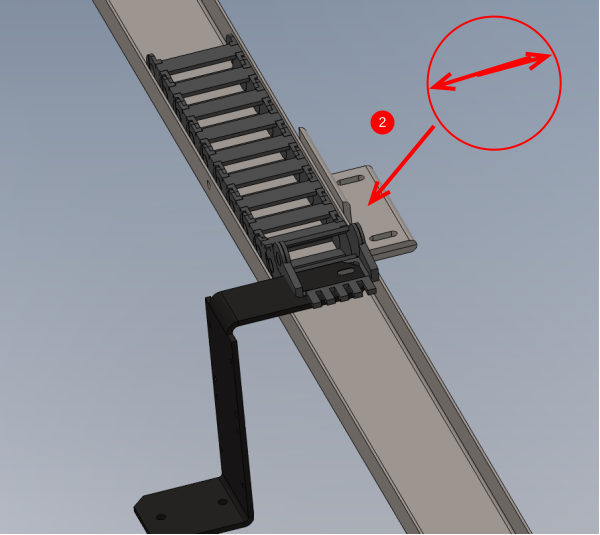

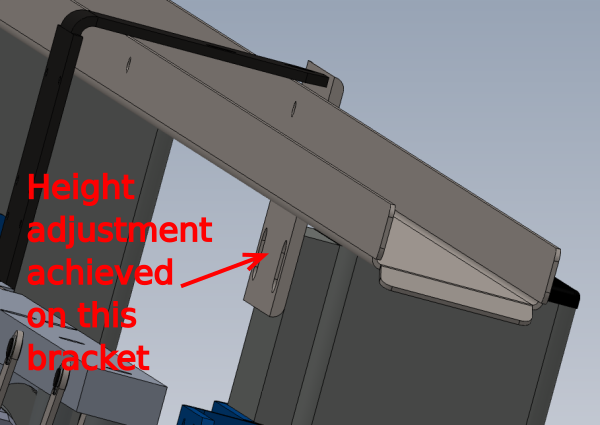

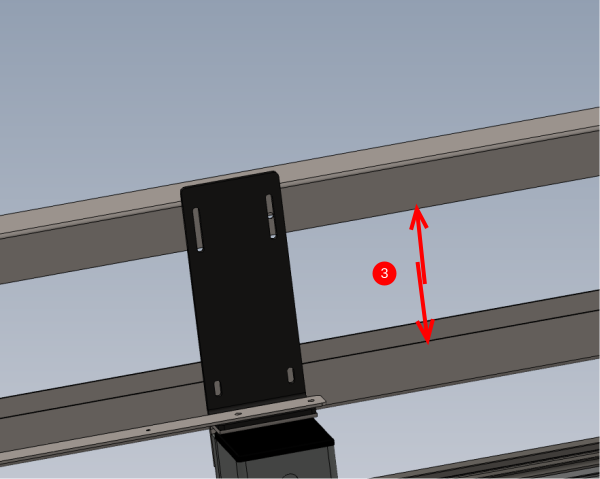

Étape 11 - Adjust lower tray height

Using the first point used to set the brackets , measure the gap indicated and replicate this measurement on the other 4 points . This is adjusted by moving the indicated bracket up or down .

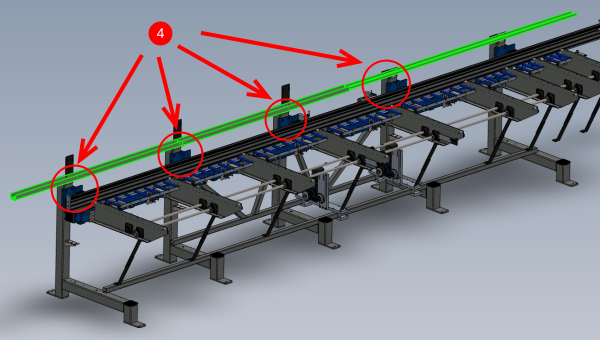

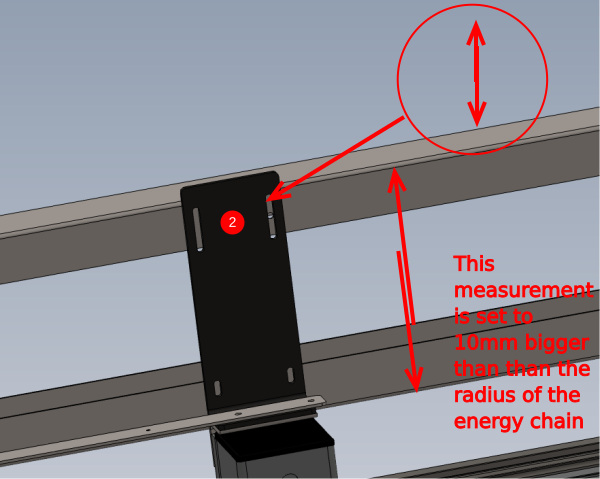

Étape 12 - Adjust Top chain guides

1 Move large radius of energy chain to the indicated point

2 Adjust height of top tray so internal gap is 10mm bigger than the height of the bend of the energy chain

3 Measure indicated gap

4 Set 2 remaining points indicated to step 3 measurement

Étape 13 - Quality check

Move Gripper carriage along the complete length of the hepco beam , and monitor the energy chain .

Check that there is no sideways pressure on the chain from misalignment

Check that no snags occur on fixings when energy chain is travelling

Étape 14 - Finalise fixings

Now aligned , ensure all fixings used to assemble the energy trays and brackets have adhesive apllied and final tension added to fasteners and pen marked

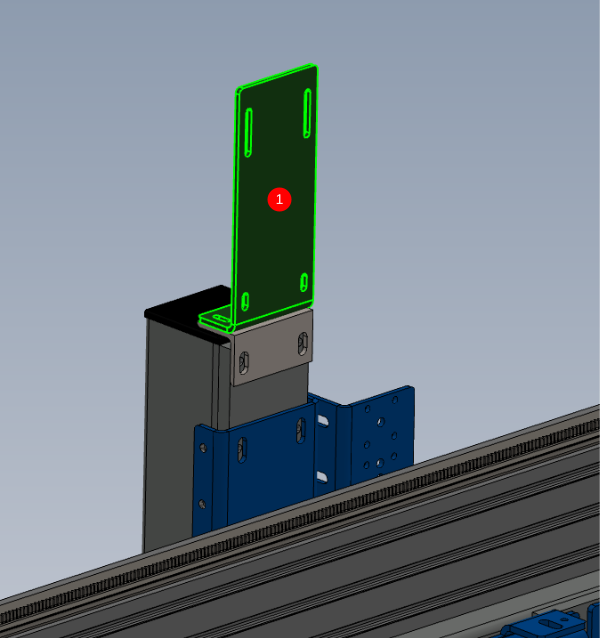

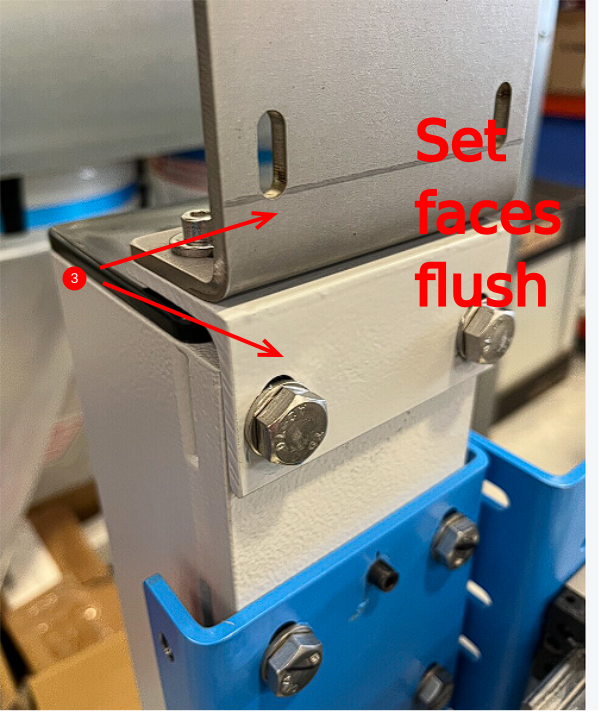

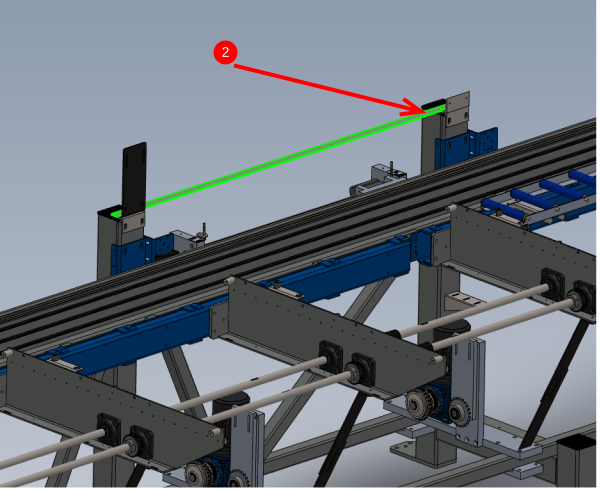

Étape 15 - Mount Datum flag

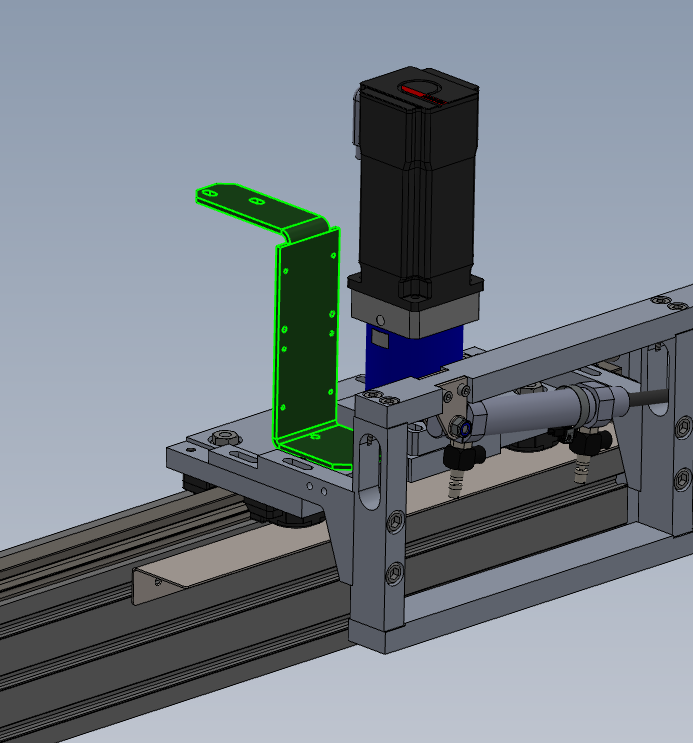

1 Mount D0015291 Datum Flag to hepco beam in position shown using M6 x 12 socket caps , A form washers and D nuts ( size type required )

2 Adjust Datum sensor at point indicated to be less than 1mm above datum flag face . Use thread and nuts on sensor to adjust height

3 Move gripper to indicated point and adjust datum flag up or down to replicate gap set on previous side

4 Move gripper back to previous point and check sensor gap is still acceptable

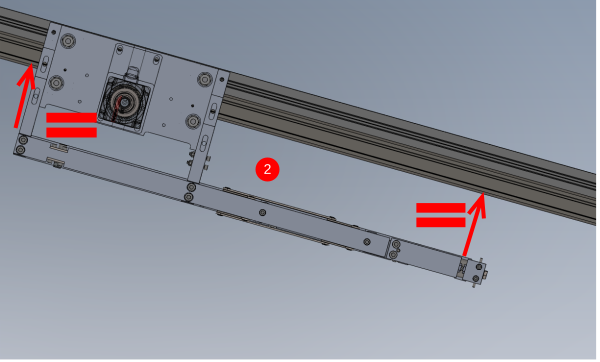

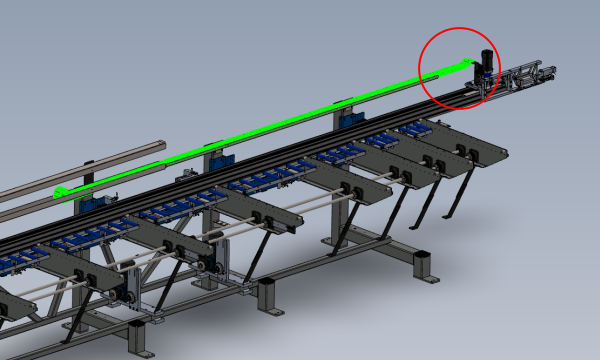

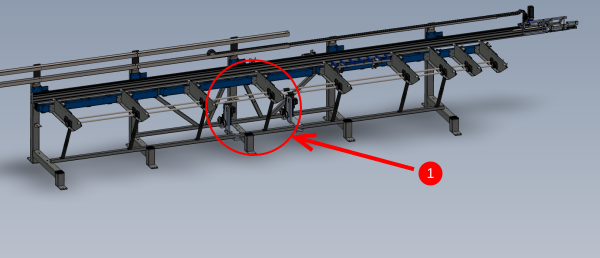

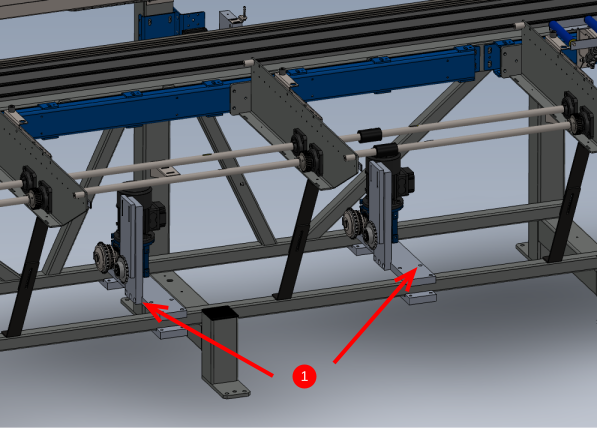

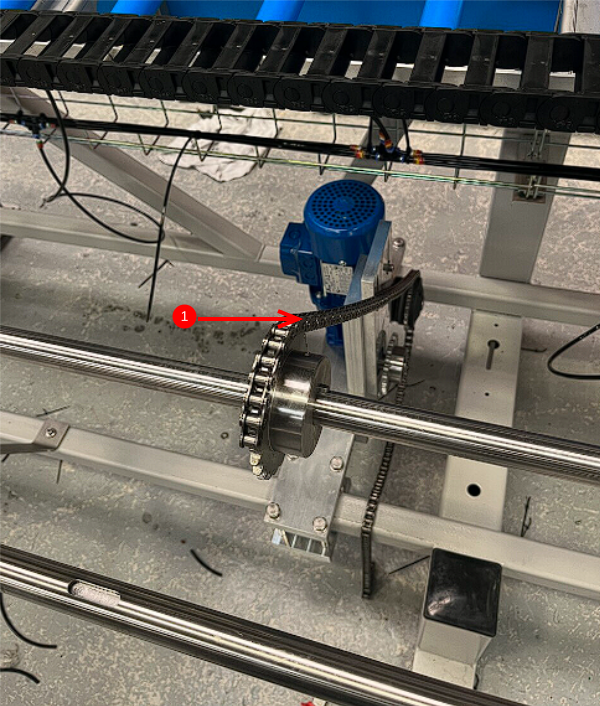

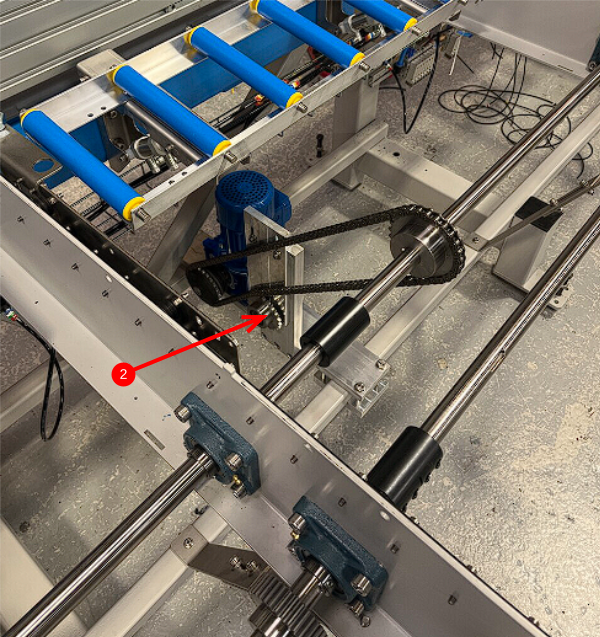

Étape 16 - Mount R0015096 Bench Assemble Transfer Drive Assembly

1 Position 2 off drive assemblies in the positions indicated

2 Use a 1000mm steel rule to align indicated sprocket with drive sprocket on drive shaft indicated

Repeat for both motor assemblies

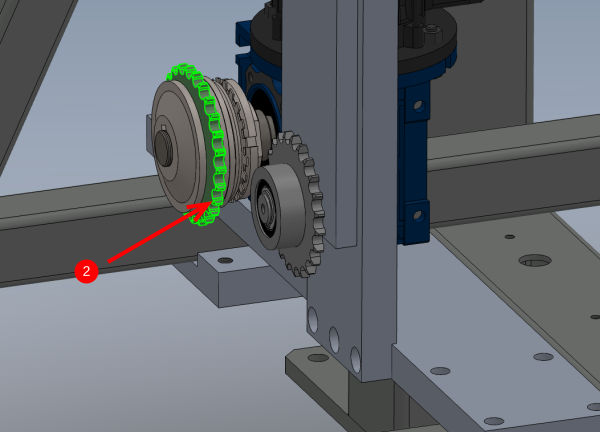

Étape 17 - Add drive chain.

1 Fit drive chain to shaft sprocket and motor assembly.

2 Adjust tensioner to apply tension to chain

Repeat for both motor assemblies

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português