Instructions to correctly align and mount hepco drive beam

Difficulté

Difficile

Durée

8 heure(s)

Introduction

Tools Required

Engineers level

Étape 1 - Unless otherwise stated

Always Use Loctite 243 on all fasteners

Always use Loctite 570 on all threaded pneumatic connections

Pen mark all fasteners to show finalised

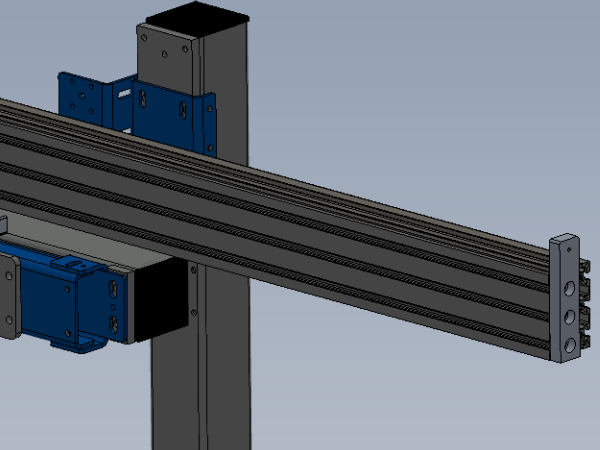

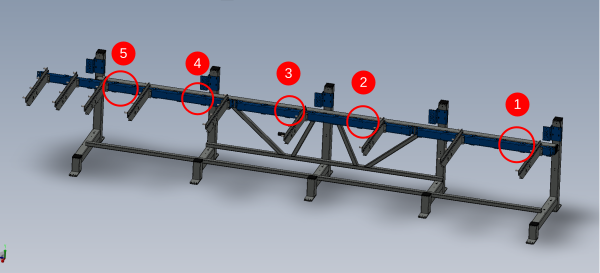

Étape 2 - Attach Setting jigs

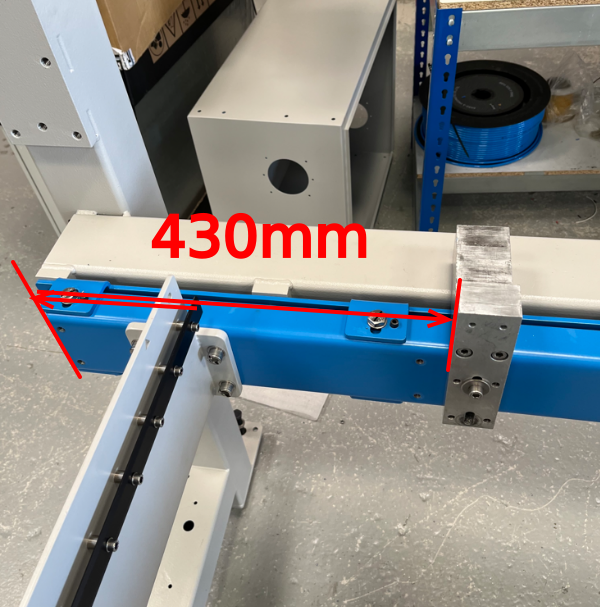

Mount setting jigs to channel section in positions shown using M8 cap head bolts and heavy washers

Position one shown will require fixing points drilling to channel section . Drill M8 and position to measurement shown of 430mm

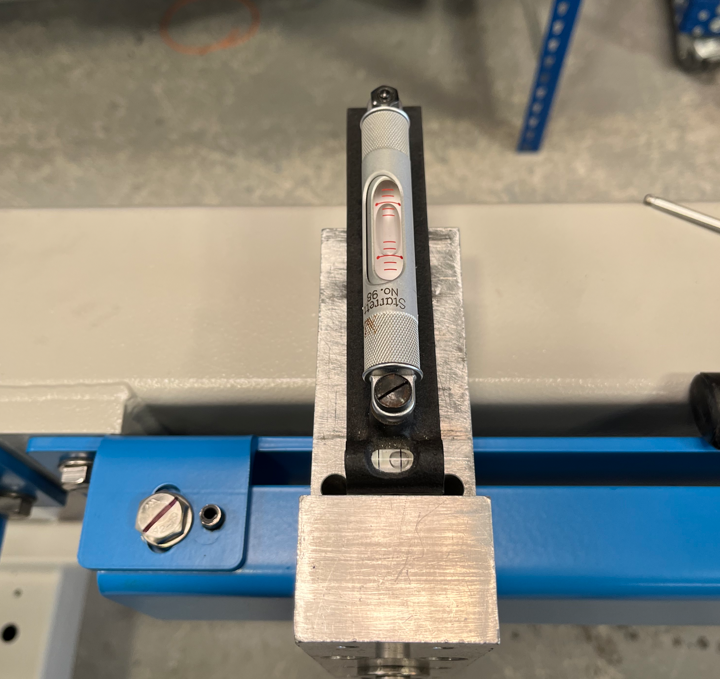

Étape 3 - Level Setting Jigs

Use an engineers level to individually adjust each jig to be level on both axis

Étape 4 - Level x axis between jigs

Using a 2 meter straight edge , the jigs should be levelled to each other as shown

Étape 5 -

Étape 6 -

Étape 7 -

Étape 8 -

Étape 9 -

Étape 10 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português