Instructions to correctly set drive pinions into positions on shafts

Introduction

Tools Required

Standard Hex key set

Parts Required

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all fasteners to show finalised

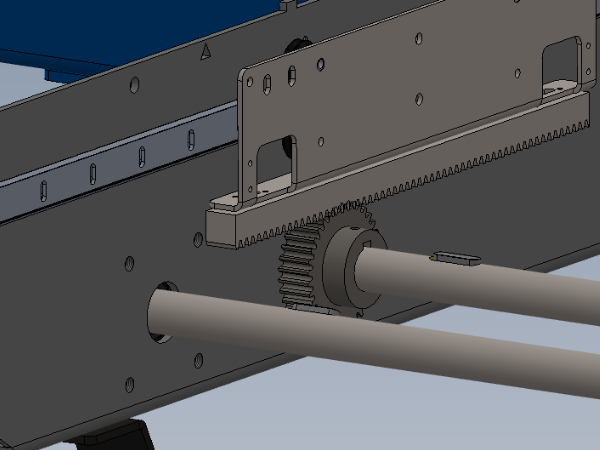

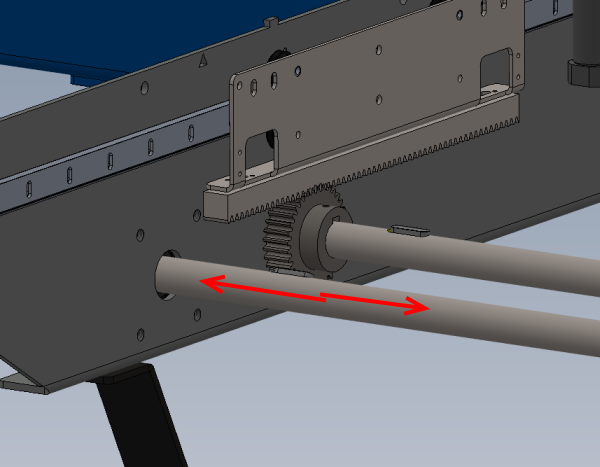

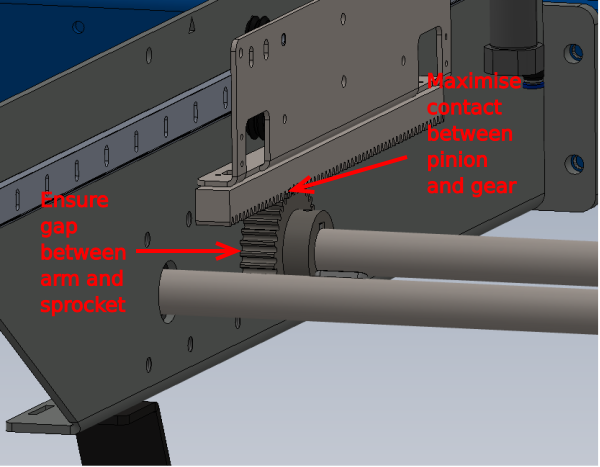

Étape 2 - Set shaft position

- Each pair of shafts that are joined together can be moved in the directions show to give the optimal contact on keys and drive pinions

- Take all 9 arm positions into consideration and position each shaft accordingly to achieve the best overall position to suit all arms

- Pinion lock points should always be above keyways

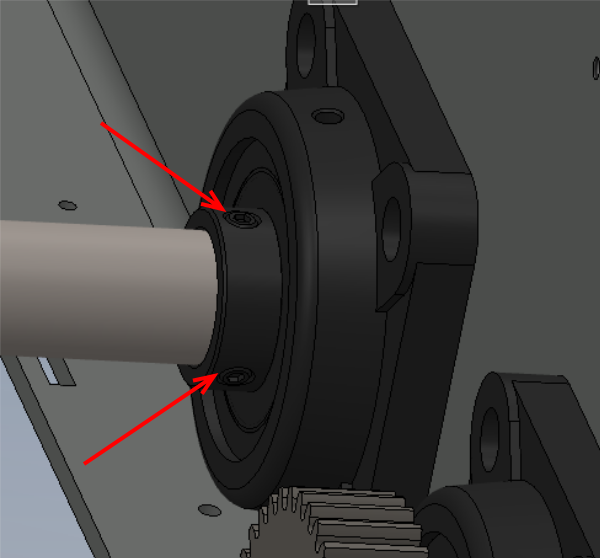

Étape 3 - Lock shaft position

Individually remove and apply Loctite 243 to all grubscrews on spherical bearings.

2 off grubscrew per bearing

18 off bearing

36 off grubscrew in total

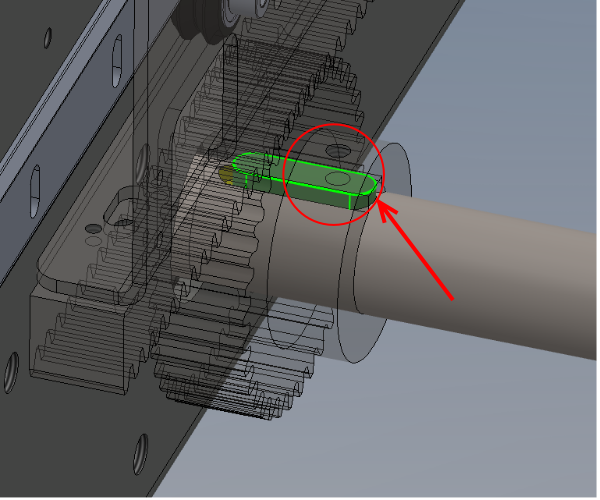

Étape 4 - Set pinion position

9 off pinions can now be set in position and finalised

Set position of pinion to achieve as much contact as possible with drive rail, without contacting side of support arm

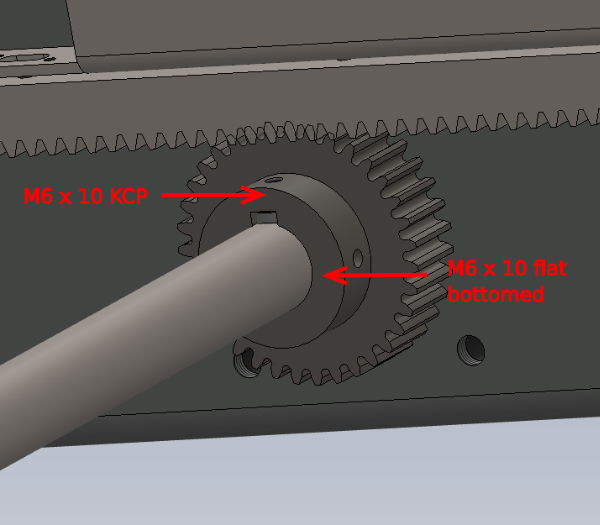

Étape 5 - Lock Pinion

lock each pinion in position as follows.

M6 x 10 kcp Grubscrew in hole that contacts key on shaft

M6 x 10 flat bottomed grubscrew on fixing hole that contacts directly onto shaft

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português