instructions to check parts and prepare for fitting

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

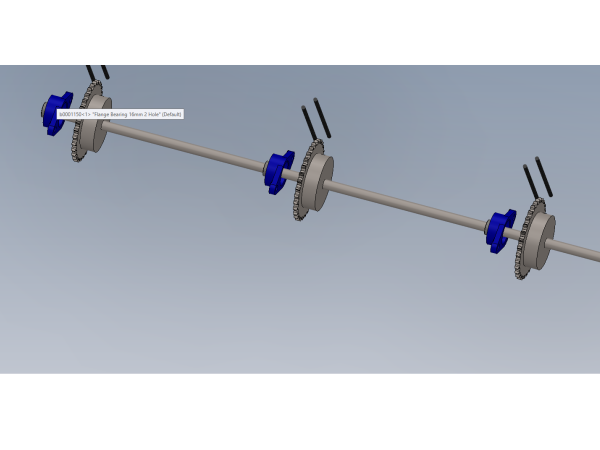

- 3 Étape 2 - Prepare shafts

- 4 Étape 3 - Prepare bearings

- 5 Étape 4 - Prepare Drive sprockets

- 6 Étape 5 - Check fit of bearings on shafts

- 7 Étape 6 - Check fit of sprockets on shafts

- 8 Étape 7 - Grease bearings

- 9 Étape 8 - Store prepared parts

- 10 Commentaires

Introduction

Tools Required

Emery tape 180 grit

FE10 solvent

Compressed air line

Cleaning cloth

Grease application gun

Parts Required

D0015459B x 1

D0015458B x 1

B0001150 x 9

B0001145 x 9Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

Étape 2 - Prepare shafts

Check for any burrs or damage . If present remove with emery tape

Clean shafts D0015459B and D0015458B with fe10 solvent and compressed air to remove any debris or contamination

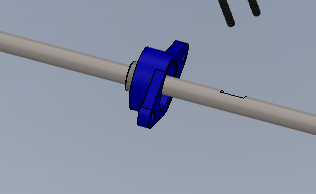

Étape 3 - Prepare bearings

Check for any internal burrs around tapped holes . If present remove with emery tape

Clean 9 off bearings B0001150 with fe10 solvent and compressed air to remove any debris or contamination

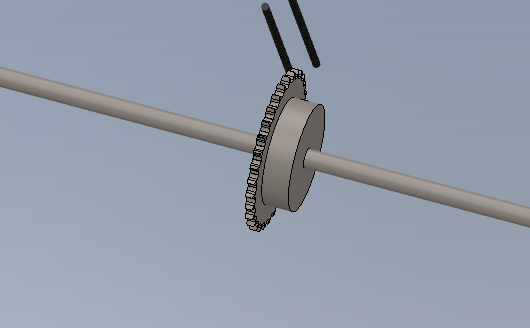

Étape 4 - Prepare Drive sprockets

Check for any internal burrs around tapped holes . If present remove with emery tape

Clean 9 off sprockets B0001145 with fe10 solvent and compressed air to remove any debris or contamination

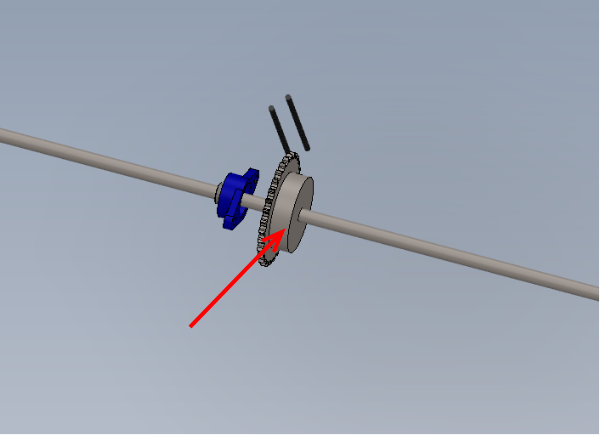

Étape 5 - Check fit of bearings on shafts

Check that all bearings slide easily along the entire length of both shafts .

Any tight spots should be dressed down with emery tape, cleaned and retried.

Repeat until all bearings pass freely along both shafts

Étape 6 - Check fit of sprockets on shafts

Check that all sprockets slide easily along the entire length of both shafts .

Any tight spots should be dressed down with emery tape, cleaned and retried.

Repeat until all sprockets pass freely along both shafts

Étape 7 - Grease bearings

Spherical bearings should be greased with grease gun prior to fitting to ease spherical movement and aid installation

Étape 8 - Store prepared parts

Store prepared shafts, sprockets and bearings ready for next stage

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português