Bench assembly of Material Gripper

Sommaire

- 1 Introduction

- 2 Introduction

- 3 Étape 1 - Unless otherwise stated

- 4 Étape 2 - Fit bushes and bearings

- 5 Étape 3 - check fitment of D0015084 shafts

- 6 Étape 4 - Assemble load switch plate

- 7 Étape 5 - Assemble cylinder P0001120

- 8 Étape 6 - Assemble grip pin assembly

- 9 Étape 7 - Mount grip pin assembly to grip slide

- 10 Étape 8 - Assemble main frame of gripper assembly

- 11 Étape 9 - Fit link bars to assembly

- 12 Étape 10 - Fit Cylinder assembly

- 13 Étape 11 - Add mounting brackets

- 14 Commentaires

Introduction

Introduction

Tools Required

External circlip pliers

Standard Hex key set

Standard spanner set

Reed switch setting box

Hammer

Standard screwdriver set

Rule

Parts Required

B0001106 x 20

D0015095 x 8

D0015096 x 2

D0015086 x 1

B0000034 x 2

D0015084 x 2

D0015083 x 1

D0015082 x 1

E0000366L x 1

B0001182 x 2

M0001182 x 2

D0015756 x 1

P0001047 x 1

P0001041 x 1

P0001128 x 1

P0001198 x 2

P0001120 x 1

D0015431 x 1

B0000437 x 1

D0015430 x 1

D0015090 x 2

D0015085 x 1

D0015102 x 2

D0015103 x 2

D0015104 x 2

D0015170 x 2

P0000049 x 1

D0015097 x 2

D0015101 x 2

D0015292 x 1

E0000336 x 1Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Pen mark all bolts once finalised

Étape 2 - Fit bushes and bearings

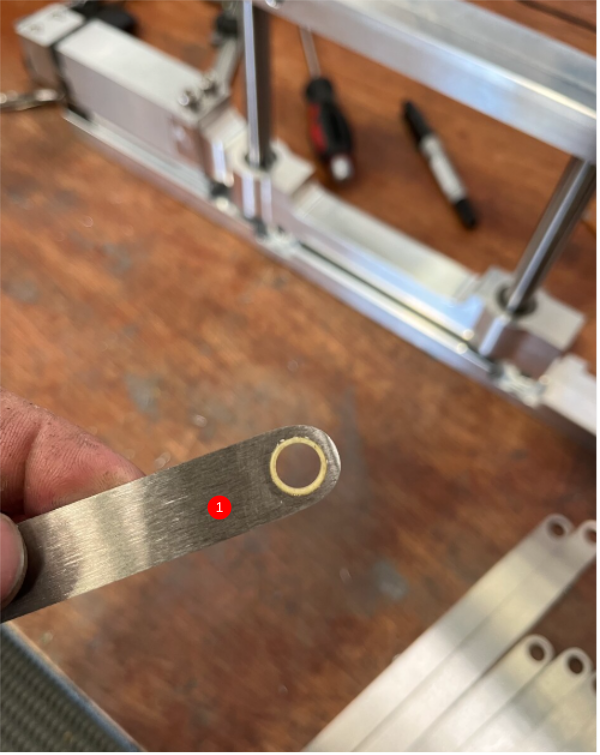

1 Fit bushes B0001106 (20 off) to

8 off D0015095 link bars

2 off D0015096 link bars

2 Fit bearings B0000034 x 2 into D00015086 grip slide body. Use grease to lubricate bearing before assembly

Étape 3 - check fitment of D0015084 shafts

check shafts fit correctly into bores of D0015082 gripper bottom bar and D0015083 gripper upper bar

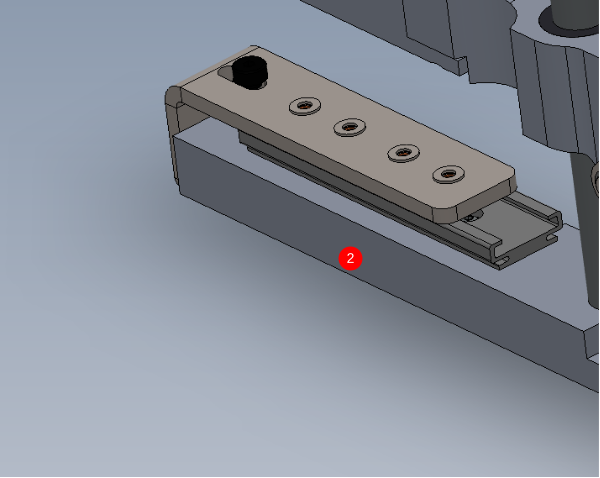

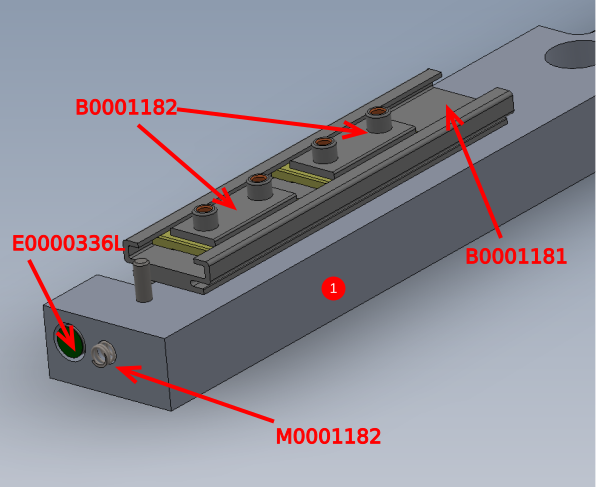

Étape 4 - Assemble load switch plate

1 Use M4 x 6 panhead to attach B0001181 rail to gripper base

Fit E0000336L sensor and M0001182 spring to main base

2 Use M5x 6 x 16 shoulder bolt and M4 x 6 pan heads to attach D0015756 lever to assembly

Étape 5 - Assemble cylinder P0001120

Fit air fitting P0001198 to cylinder

Remove 32mm nut from cylinder and discardd

Mount reed switch and band (P0001041 x 1 P0001047 x 1 P0001128 x 1) to cylinder in piston retracted position , mark as X291

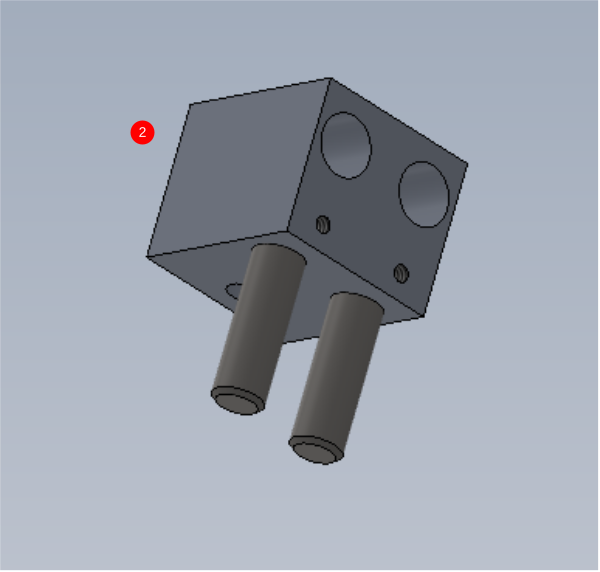

Étape 6 - Assemble grip pin assembly

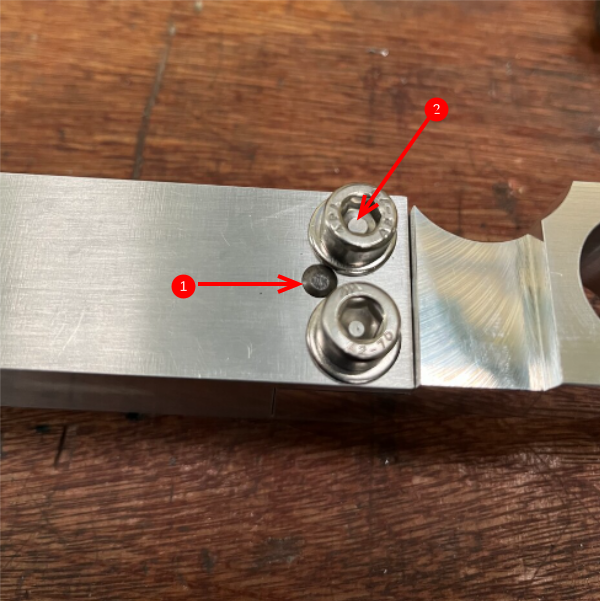

1 Fit bushes B0000437 x2 to body D0015431

2 Use 2 off 10mm x 40mm dowel. Ensure dowels fit correctly in nose D0015430. Check dowels have pushed all the way to the bottom of the bore . Secure with 2 off M4 x 8 grubscrew

3 Fit D0015090 Grip pin x 2 and secure with M5x 16 socket cap

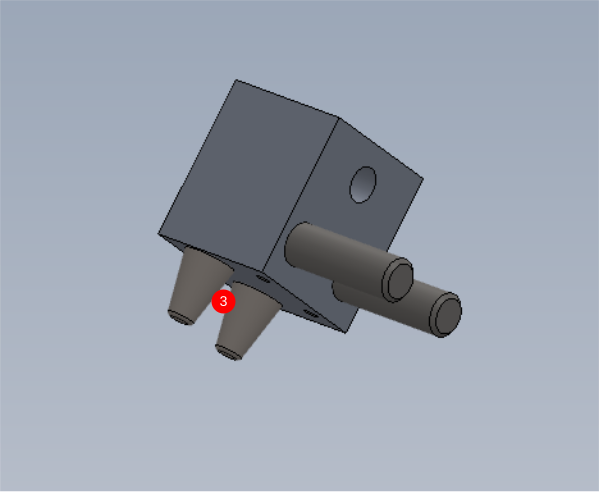

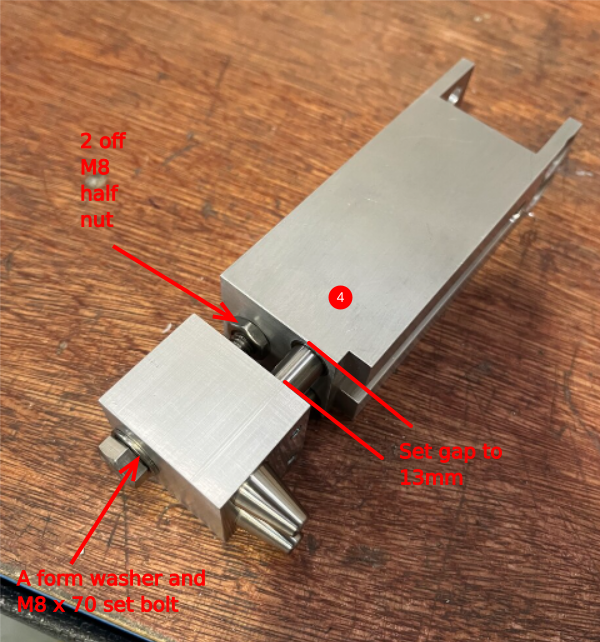

4 Combine together and use m8 x 70 set bolt, a form washer and 2 x m8 half nuts to secure. Set gap to 13mm and lock all fasteners

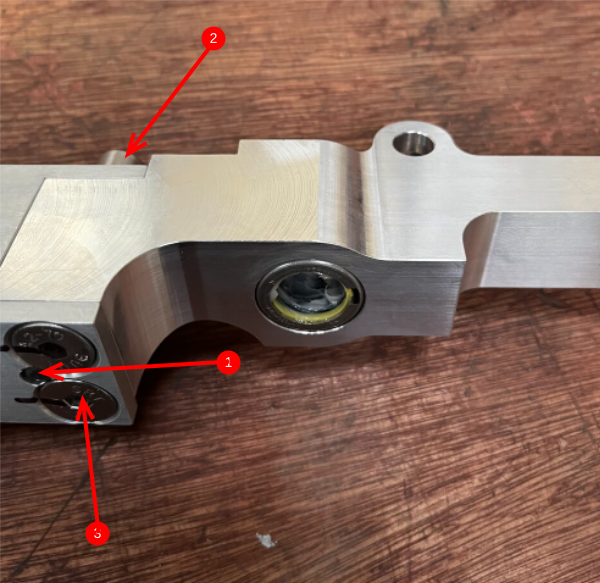

Étape 7 - Mount grip pin assembly to grip slide

Combine parts

1 Use 2 off 6mm x 16mm dowels to align ( 1 top and 1 bottom)

2 M8 x 16 socket cap and A form washer

3 M8 x 20 countersink

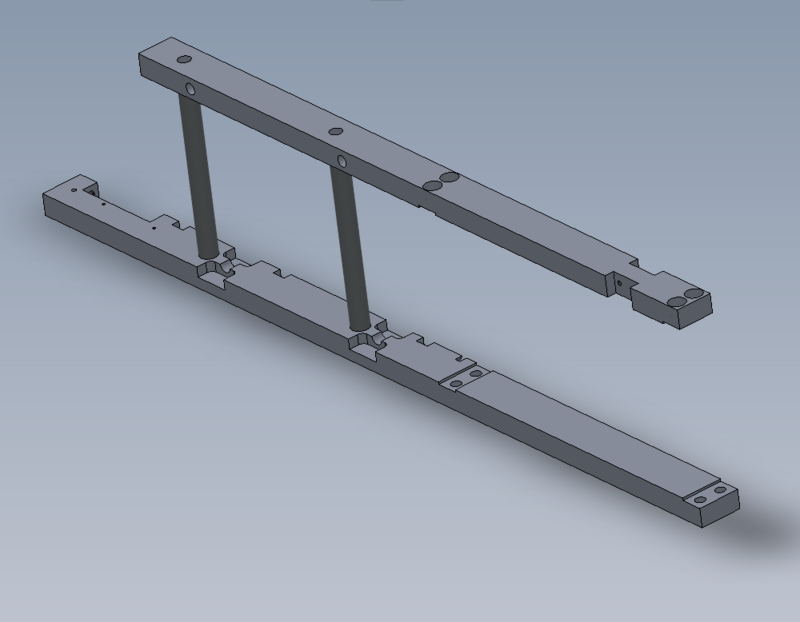

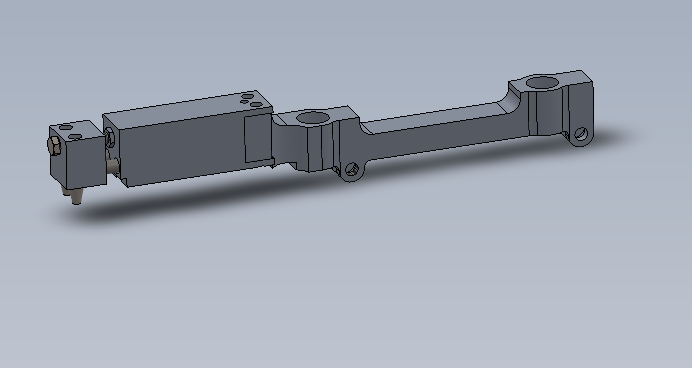

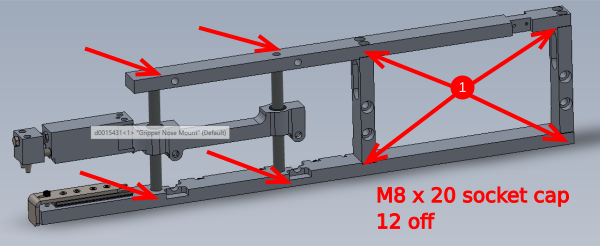

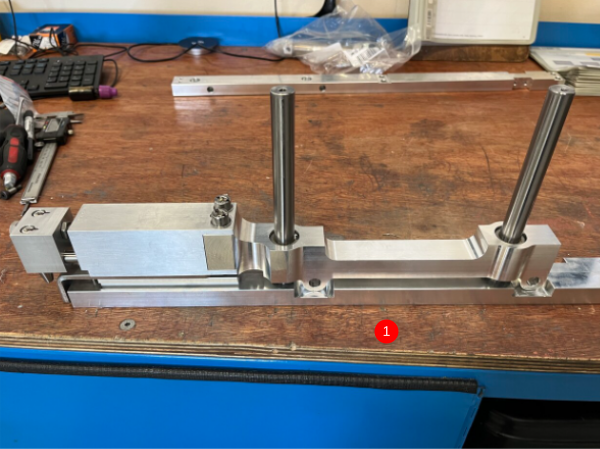

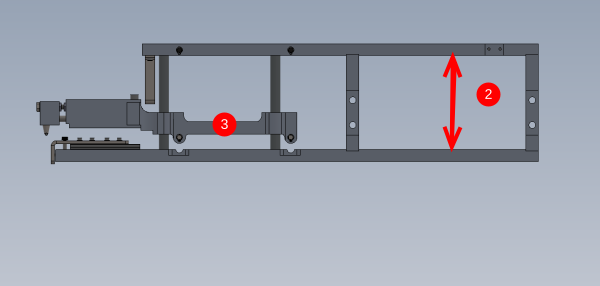

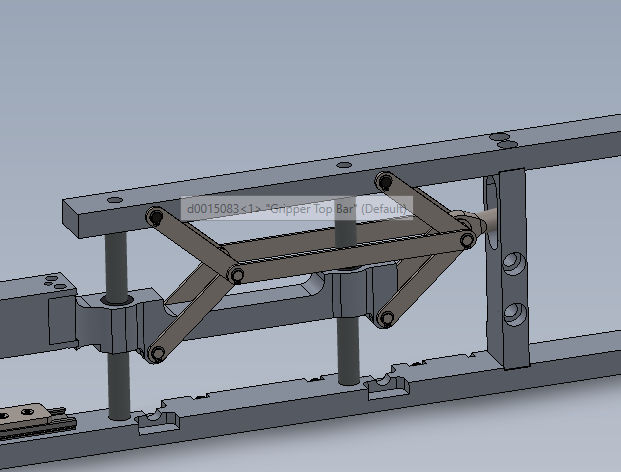

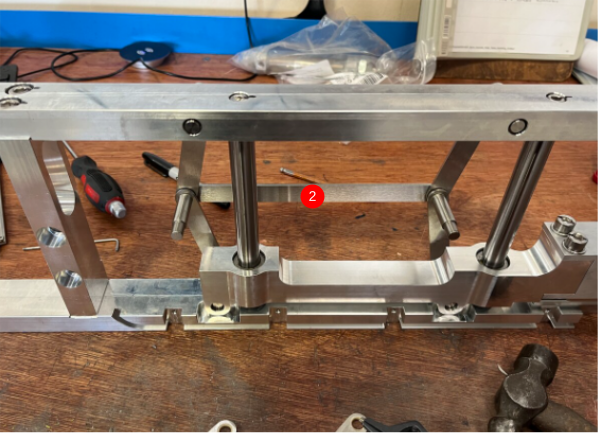

Étape 8 - Assemble main frame of gripper assembly

Use 2 off D0015085

1 Assemble as shown using 12 off M8 x 20 socket caps

2 Check top and bottom bars are parallel

3 Check grip slide moves freely up and down

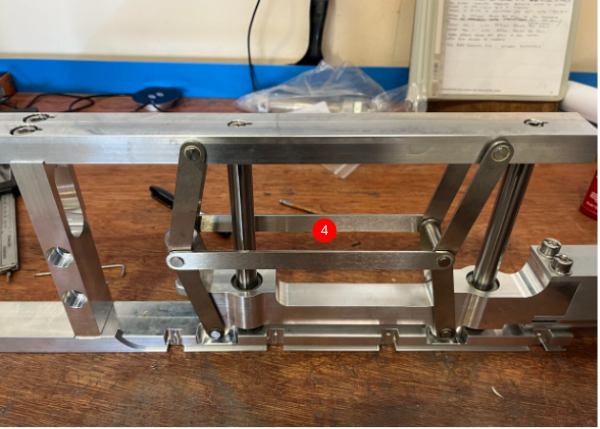

Étape 9 - Fit link bars to assembly

1 Use 2 off D0015103 and 8mm external circlips (B0000200) and assemble two off as shown

2 Use 2 off D0015102, 2 off D0015104 and assemble as shown with 8mm circlips

3 Use 2 off D0015170 gripper spacers and P0000049 spherical end and add as shown

4 Add remaining link shafts and circlips

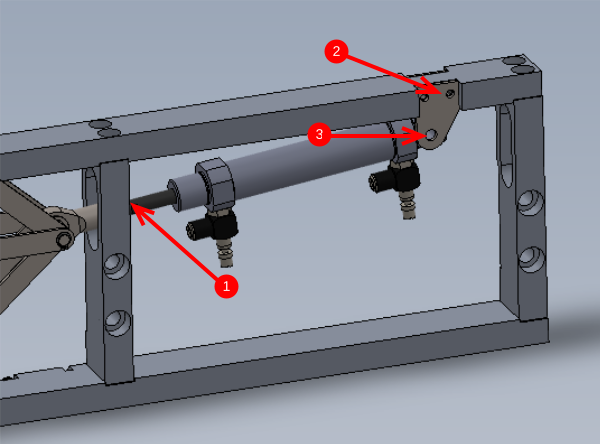

Étape 10 - Fit Cylinder assembly

Fit assembled cylinder unit to gripper frame

1 Wind cylinder thread into spherical bearing lock cylinder nut off with 1 thread of cylinder piston exposed behind lock nut

2 Use M5 x 10 with a form washer to secure D0015097 2 off mounting plates

3 Use M8 x 30 with M8 nyloc nut to secure cylinder to brackets

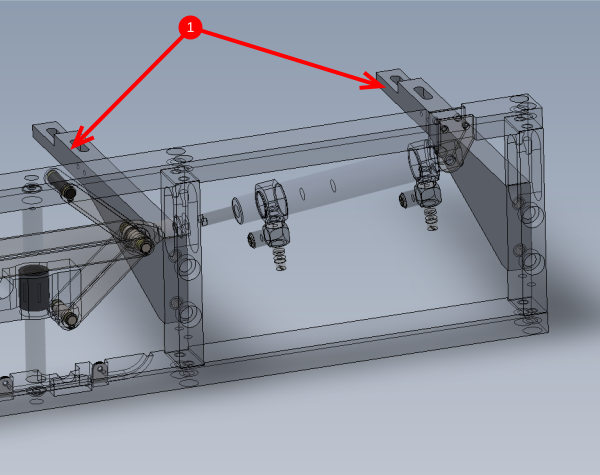

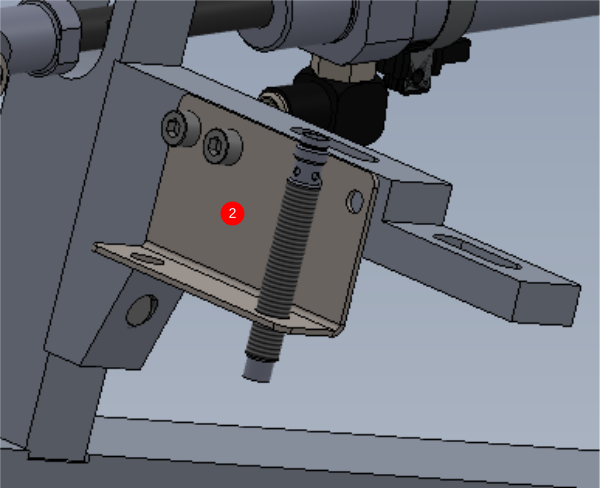

Étape 11 - Add mounting brackets

1 Fix as shown 2 off D0015101 brackets with 4 off M10 x 40 socket caps

2 Mount Sensor bracket D0015292 with 2 off M5 x 30 socket caps, A form washers and M5 Nyloc nuts. Mount E0000336 as shown using both lock nuts and shake proof washers provided with sensor

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português