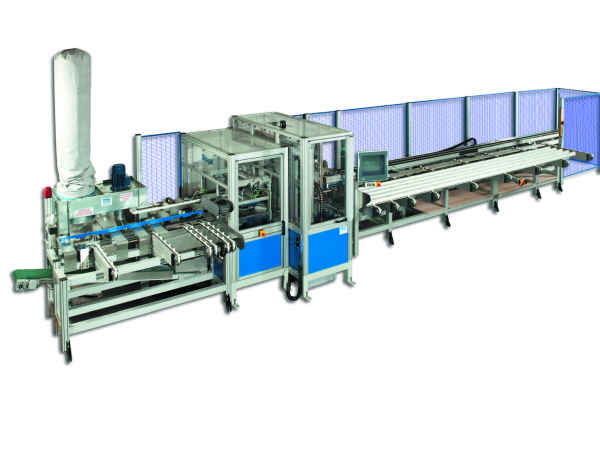

Report of a near miss on an Autoflow machine when servicing

Details

Close call to report from A2018 Autoflow machine during a routine service. The Z axis/ring abruptly dropped from its max position without warning. An engineer was inside the machine at the time, and the potential risk was crushing under the weight of the ring leading to a major accident

The emergency stop / guard circuit was overridden at the time, as the engineer had placed an override key in the door interlock mechanism, as is standard practice during servicing. The machine was in SETUP mode, which meant that the low air warning was not displayed

The Z axis was enabled and at its maximum height.

The customer turned off the mains air compressor, leading to a gradual loss of the support pressure for the Z axis assembly. In this instance, the weight of the Z axis assembly gradually increased until it overcame the holding torque of the Z axis motor.

This resulted in a sudden and immediate drop of the axis and the engineer was able to get out of the way

Immediate Procedural Changes

Until a permanent fix is applied, the following procedural changes should be noted when dealing with any Z axis supported by air:

Further Changes

A pilot operated valve will be fitted to all machines as soon as is practically possible. This will block the possibility of air escape if the mains pressure is removed.

The situation is more sudden on an Autoflow as there is less friction in the single, large pitch leadscrew. on all other Stuga machines, the Z axis runs through a dual, higher pitch leadscrew connected with a chain drive that increases friction.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português