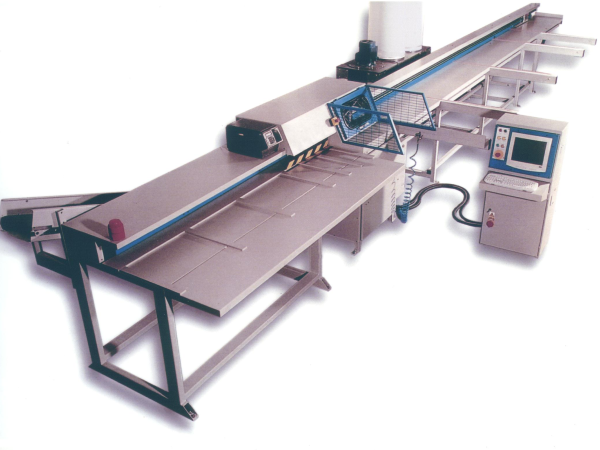

Details on the Beckhoff upgrade available to Stuga Autocut saws

Details

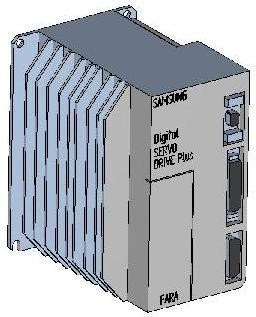

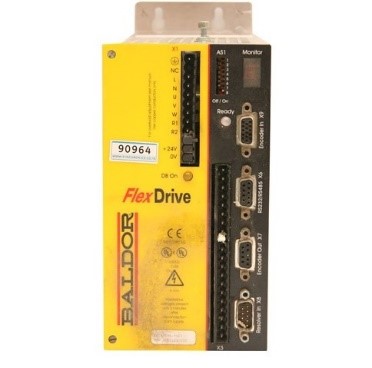

Your Stuga machine has a control system in it with various components that are now obsolete . This technology has been used in the Stuga machines for over 20 years. The motion control was developed by a UK company based in Bristol in the early 1990’s, the company was very successful and was purchased by an American company “Baldor” around 2004.

The Baldor group was bought by the giant electronics company “ABB” in 2015. There was an assurance at this time that the Nextmove platform would be fully supported by ABB and be used as a new base for their motion control department.

ABB have now withdrawn the supply of all Nextmove products as they do not wish to pursue this product going forwards. They have not offered any kind of alternative and they are shutting down the production facility which will make repair impossible.

- The Nextmove product is obsolete.

- Stuga have secured a last supply of Nextmove products to cover future spares / warranty issues, but this supply is finite

- On older saws, the main PC is an "ACEpc" which is also obsolete

| ACEpc | Samsung Servo Drive | Baldor Flexdrive |

|---|---|---|

Beckhoff Upgrade

Since 2010, Stuga has been working with another drives and controls manufacturer – Beckhoff – who are widely regarded as the No1 supplier of control systems into the Window Industry thanks to their very close ties with Schirmer.

We have developed a full control system upgrade using Beckhoff components which covers the full system from motion control PC through to drives and motors. This has been fitted to all new machines since 2016.

This system has now been fully tested for release as an on-site upgrade to remove all obsolete parts on any Autocut Standalone Saw. The kit comprises these brand-new components, which is effectively a replacement of the entire control system

- Version 6 control software

- Windows 10 PC

- Flat panel / touchscreen displays

- Beckhoff PLC (Main control system)

- Beckhoff Input and Output interfaces

- Beckhoff AM5000 Servo Drive

- Beckhoff Servo Motor – latest models with “One Cable Technology”

- Beckhoff Servo motor cable

- Reprogramming of all profile and operation data to new system

- On site fitting and full testing

- Operator Training

The Beckhoff system is cutting edge and far more dynamic than all previous systems, thanks to the sheer power of the computing systems now available. This allows an immediate improvement on acceleration and deceleration times, thus improving the cycle times.

The “one cable technology” of the motors cuts down the amount of individual motor wires and connections from 20 on each axis to just 7. This has proven to be much more reliable. The drive technology also allows greater precision in the “servo loop” which improves accuracy.

In Summary – The entire electronic control system is replaced. This is necessary because all old components are incompatible with the Beckhoff system. They are also completely obsolete and unsupported by the original manufacturers.

Other Benefits

· Teamviewer iTbrain backup. Automated backup of profile / operation data to the cloud every 2 hours

· Animated bar display. Shows operator the profiles and operations on the bars in real-time

· Batch timing calculations. Based on continuous measurement of individual operation timings, gives an indication of how long a batch will take to complete (at 100% efficiency)

· Bar foil colour indicator. Helps operator determine the correct orientation of foiled bars

· Auto email of production reports. Software can be set up to email a daily production report to any email address

The Version 6 control software is the platform that all future software improvements will be based on, this upgrade unlocks the ability for your machine to be further improved in the future.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português