How to quickly repair a loose datum pin

Introduction

The datum pin on the old ZX4 at Sidey was recommended to be changed at my last service visit. Unfortunately there are quite a few different datum spindle plates and we were having problems tracking down the correct one so it was decided that I would be sent out the new replaceable datum pin carrier as Sidey have a small machine shop I could use to modify the existing plate to make it fit. Unfortunately the mounting holes of the new carrier interfered with the mounting holes of the pneumatic cylinder so it couldn't be used.

After taking dimensions of the existing plate for identification I realised there was actually a very small and quick repair that could be carried out until the correct parts were identified.

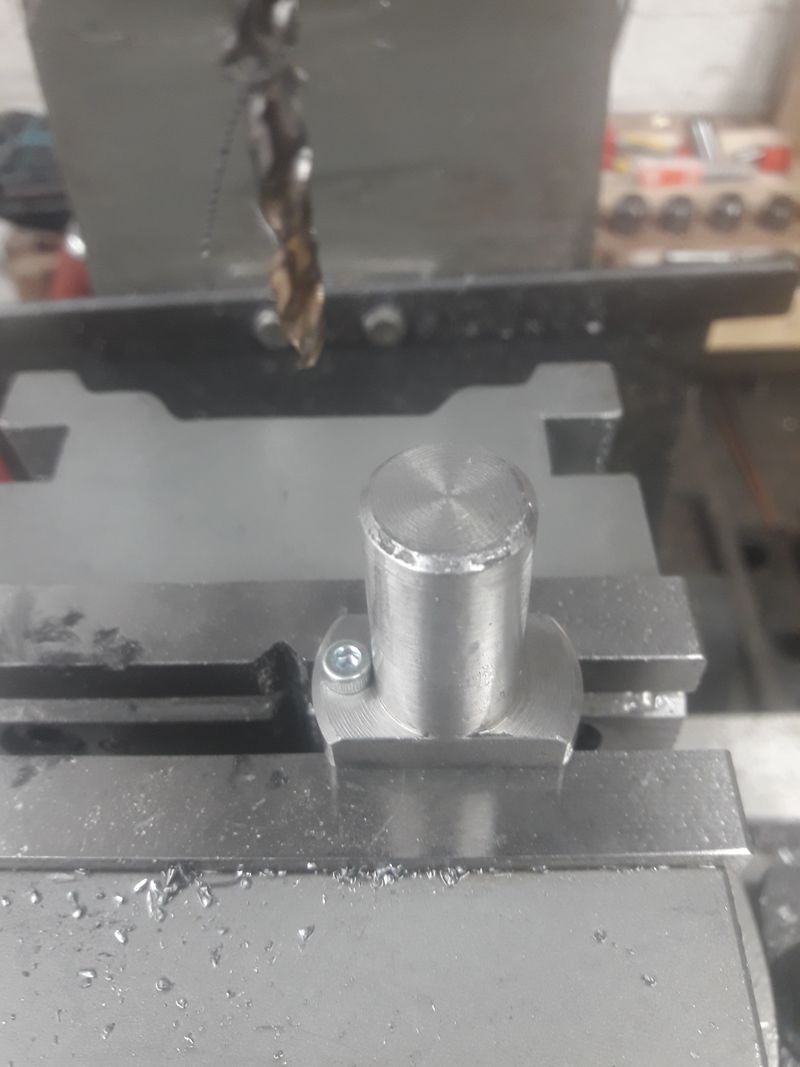

All you need is a cordless drill, a 2.5 and a 3.1mm drill, M3 tap and an M3 x 15mm cap head screw.Étape 1 - Drill 2.5mm hole

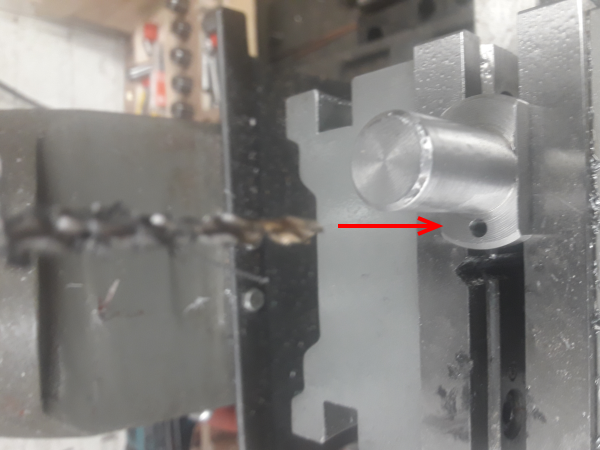

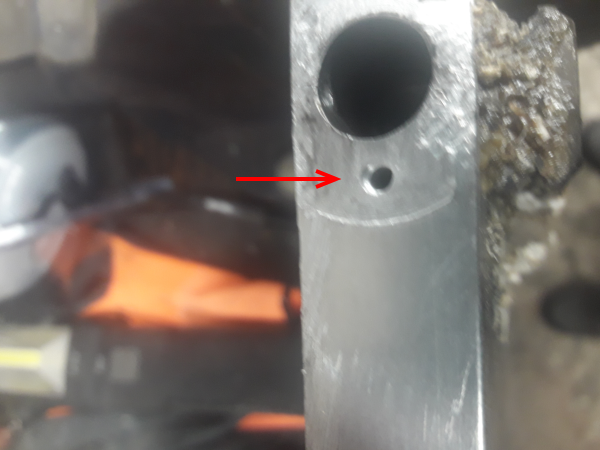

Drill a 2.5mm hole in the datum pin shoulder. Refit to datum plate and use the drilled hole as a guide to drill the aluminium spindle plate. Remove datum pin and tap the hole in the plate using the M3 tap.

Étape 3 - Fit datum pin to plate

Fit datum pin to plate using a low strength threadlock and reinsert roll pin.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português