The expected life of the ring slideway has decreased due to the lack of oil being present in the felt wipers which are in contact with the ring.

Technical Bulletin

| TB Number: | 0075 |

| Originator: | Jem |

| Machine: | All rotary Head machines |

| Date: | 10/05/07 |

| Circulate to: | Service |

| Title: | Oil pots for Hepco ring lubrication |

Problem

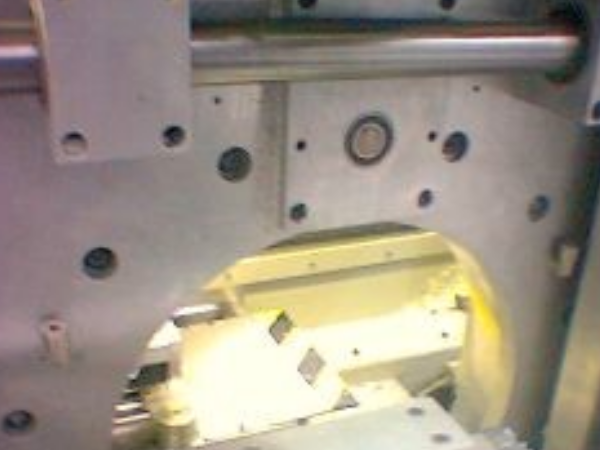

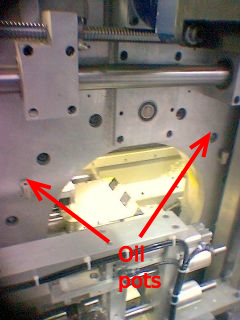

The expected life of the ring slideway has decreased due to the lack of oil being present in the felt wipers which are in contact with the ring.

Solution

After working out cycle times on our application with supplier it has been determined that the oil remains with in the wiper felts for a minimum of 3 months so oil pots have been introduced which can be topped up every 2 months to ensure lubrication is present on the ring at all times .

By drilling through into the rear of the top 2 wipers an oil way can be created allowing an oil pot to act as a reservoir.

A simple piece of marking out can be used to put the hole in the correct place and as long as care is taken to remove swarf from drilling there should be no or very little contamination of aluminium swarf.

Everybody will be issued with drills, taps and drill jigs very soon so that this can be done when a machine service is undertaken and the aim is to get all variants of flowlines along with Ecolines upgraded as soon as possible.

Method

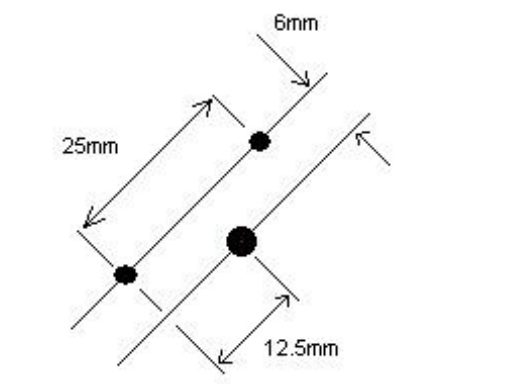

The depth of hole to be drilled has to be done to a depth of 36mm; the main aly backplate is 25mm the spacer block underneath the wiper is 5mm and the distance from base of plastic wiper to felt is 6mm.

| 1 | Mark the position of hole for each oil pot using the existing M4 wiper holes which are at 25mm centres and then drill to a depth of 30mm. (note that hole to be drilled has a 6mm bias and this is set towards the centre of the ring) | |

| 2 | Open up 4mm hole with 11.5 mm drill to a depth of 20 mm and then tap ¼ bsp full depth of hole. | |

| 3 | Blow out all swarf from hole | |

| 4 | Set drill 4mm drill depth to minimum of 36mm maximum of 38mm and drill out final 6mm into plastic wiper you should be able to feel the sponginess of felt when through to the chamber containing the felt. | |

| 5 | Screw in 90 degree elbows so that they point upwards , These will force round and lock into position . | |

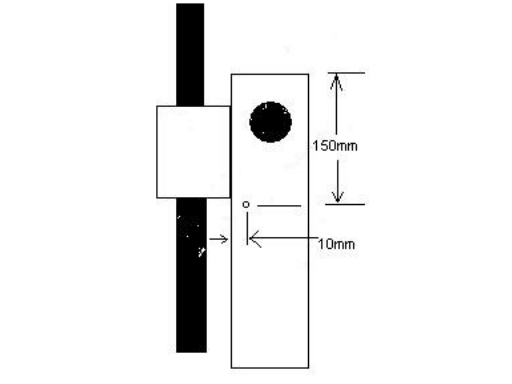

| 6 | When fitting to a Mk3 flowline a stop must be fitted to the rear of the machine to ensure that the oil pot does not collide with main aluminium upright bearer. | |

| 7 | A M6 screw with a lock nut can then be set at 15mm and drilled in the below position |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português